M5x

The BMW M5x range of engines are a line of 6-cylinder engines, fitted to BMW models between 1991 and 2001. The range is comprised of two main units; the M50 and the M52. All M5x engines are fundamentally based on the M20 engine that powered the E30 320i, 323i and 325i, and are therefore a very popular engine swap.

Contents

Versions

M50

The M50 engine first saw action under the bonnet of the E34 ad E36 as the humble 2.0 variant before being enlarged to 2.5 in 1993. Being little more than an M20 engine with a 24V head, these engines are great upgrades for those who have tired of the M20 donk. Considering there is no difference when installing, there is little or no point fitting the weaker 2.0 version of the M50.

M50 engines weigh 138kg

| Engine | Displacement | Power | Torque | Redline | Bore | Stroke | Year |

|---|---|---|---|---|---|---|---|

| M50B20 | 2.0 L (1990 cc/121 in³) | 110 kW (150 hp) @ 6000 | 190 N·m (140 ft·lbf) @ 4700 | 6750 | 80mm | 66mm | 1991 |

| M50B25 | 2.5 L (2494 cc/152 in³) | 141 kW (192 hp) @ 6000 | 245 N·m (181 ft·lbf) @ 4700 | 6500 | 84mm | 75mm | 1991 |

M50TU

After letting the M50 prove itself, BMW released a Technical Update for the engine in September 1992, announcing the new engine as the M50TU. These units featured an even more complex head design incorporating VANOS technology; a variable-valve timing system that modifies the position of the intake camshaft. This has no effect on the overall power of the engine, but does improve torque at lower revs.

Because of this increased complexity, VANOS engines are best avoided for first-time engine swappers.

| Engine | Displacement | Power | Torque | Redline | Bore | Stroke | Year |

|---|---|---|---|---|---|---|---|

| M50TUB20 | 2.0 L (1990 cc/121 in³) | 110 kW (150 hp) @ 5900 | 190 N·m (140 ft·lbf) @ 4700 | 6750 | 80mm | 66mm | 1993 |

| M50TUB25 | 2.5 L (2494 cc/152 in³) | 141 kW (192 hp) @ 5900 | 250 N·m (184 ft·lbf) @ 4200 | 6500 | 84mm | 75mm | 1993 |

M52

Despite being heavily based on the M50, the M52 was a whole new engine, and it feels it. 20kg slimmer and a lot more responsive at the pedal, these engines are the most desirable of the M5x swaps.

M52 engines weigh 118kg

| Engine | Displacement | Power | Torque | Redline | Bore | Stroke | Year |

|---|---|---|---|---|---|---|---|

| M52B20 | 2.0 L (1990 cc/121 in³) | 110 kW (148 hp) @ 5900 | 190 N·m (140 ft·lbf) @ 4700 | 6500 | 80mm | 66mm | 1994 |

| M52B25 | 2.5 L (2494 cc/152 in³) | 123 kW (170 hp) @ 5500 | 245 N·m (181 ft·lbf) @ 3950 | 6500 | 84mm | 75mm | 1995 |

| M52B28 | 2.8 L (2793 cc/170 in³) | 142 kW (193 hp) @ 5300 | 280 N·m (207 ft·lbf) @ 3950 | 6500 | 84mm | 84mm | 1995 |

M52TU

Another Technical Update came in 1998, affecting all the M52 engines with a system called Double-VANOS, which applied the existing VANOS technology to the exhaust camshaft as well. Alongside that, the Block of the engine was changed from cast iron to aluminium, and the engine management system was upgraded. Unfortunately, all this complexity somehow robbed the M52 of its charm, and these Double-VANOS units are best avoided.

| Engine | Displacement | Power | Torque | Redline | Bore | Stroke | Year |

|---|---|---|---|---|---|---|---|

| M52TUB20 | 2.0 L (1990 cc/121 in³) | 110 kW (148 hp) @ 5900 | 190 N·m (140 ft·lbf) @ 3500 | 6500 | 80mm | 66mm | 1998 |

| M52TUB25 | 2.5 L (2494 cc/152 in³) | 123 kW (170 hp) @ 5500 | 245 N·m (181 ft·lbf) @ 3500 | 6500 | 84mm | 75mm | 1998 |

| M52TUB28 | 2.8 L (2793 cc/170 in³) | 142 kW (193 hp) @ 5500 | 280 N·m (207 ft·lbf) @ 3500 | 6500 | 84mm | 84mm | 1998 |

Components

Sump

Just like any other engine, the sump is an oil bath to soak the bottom end of the engine, and to capture all the precious Oil that filters back down from the top of the engine.

The sump is one of the most important aspects when fitting an M5x engine to your E30, since its size will have an impact on which engine mounts you use and how the engine is positioned on top of the crossmember. The E34 sump will have the main body at the front of the engine, while the E36 sump is at the back. It is imperative that you fit the E34 sump.

While all sumps are interchangeable, there are some subtle differences between them. The M50B20 sump fitted to the E34 have a blanking plate where the oil level sensor should be; this can be unscrewed and a standard M50 oil sensor put in.

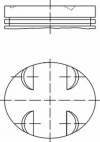

To fit the E34 sump to an M52 engine, you will need to remove the internal baffle plate (see pic). The plate unbolts, but it is also necessary to drill or grind down the mounting columns so that the bottom of the dish is flat.

Oil Pump

The M50 and M52 pumps are both fitted at the front of the engine, and are both driven from a chain drive from the crankshaft (visible when the sump is removed). However, there are key differences between the two, and an M52 pump cannot be fitted to an M50 engine, due to different layouts of the oil pickup.

If you are fitting an M5x engine to your E30, you will need the oil pickup from an E34.

Block

The block is one of the most contentious elements when it comes to M5x engines. While internal structure of M50 and M52 blocks are different in a large number of ways, they are similar enough to allow the internal components to be interchangeable.

The real issue is the construction material. While the M50 engines relied on cast iron to provide a steady heat source and a solid body, the M52 engines were built from aluminium to decrease weight.

Unfortunately, aluminium's malleability make it unsuitable for cylinders, and therefore the cylinder bores were coated with a second metal to protect against bore wear. The disastrous choice of material would become a byword for modern BMW engines, and is something that still haunts the company's reputation today. That material was Nikasil.

The Bavarian boffins had looked at the effect of sulphur on Nikasil, and were aware of the damaging affects. For that purpose, they fitted all US engines with cast iron blocks, but pumped out the Nikasil version to the rest of the world. Unfortunately for BMW, British suppliers started buying American fuel, which was far richer in sulphur than the Ultra-Low Sulphur petrol available in mainland Europe at the time. Within just a few years, M52 engines were suffering from catastrophic engine wear, causing huge financial and technical headaches for BMW, and a dark cloud was to hang over engines tainted with the Nikasil reputation.

Years later, it's not easy to find a Nikasil block; most were converted to steel liners or scrapped. But the M52 reputation was already tarred. While some owners reported "moving liners" causing engine damage, others found hot-running engines not only buckled their heads but also stripped the threads from the blocks, ruining the engine beyond repair. In this way, the M52 developed a perhaps undeserved reputation for unreliability, which is why the M50 iron block is preferred despite its extra weight.

Anyone considering a turbo conversion on their M5x engine is advised to stay well away from the M52 block.

Crankshaft

While the block determines the maximum capacity for the engine, the crankshaft determines the stroke of the engine, and therefore the actual displacement. Mounted to the bottom of the block, the crank holds the bottom of the piston rods and converts their up/down motion into rotary force known as torque. It does this by holding the rods on a series of lobes or 'throws' which extend away from the centre of the crank by a certain distance.

It is this distance, known as the Stroke, that differentiates each of the crankshafts fitted to M5x engines. Stroke sizes are shown in the Pistons table.

In terms of construction, M50 non-Vanos cranks are cast, while M52 cranks are forged. Aside from that, M5x cranks are fully interchangeable between engines, since the bearing design is identical to engines all the way back to the first M20.

The main shaft of the crank is held in place with 'caps', inside which are simple bearings called 'shells', made of steel-backed white metal. The caps and shells fit around the shaft at fixed points called 'journals'. From the journals, arms known as 'webs' extend outwards to hold the 'throws', while the throws themselves connect to the piston rod or con rod.

Both ends of the crank shaft protrude through the block. The front end carries a number of pulleys to control engine timing and to power engine ancillaries, while the rear holds a wheel to bolt to the flywheel.

M5x cranks have seven main bearings and six piston rod bearings. The main bearing bolts can be re-used, but the piston rod bolts ('big end' bolts) are stretch bolts and must be replaced. M50 main bearing caps should be torqued to 20Nm, and then a torque angle of 50 degrees.

Before fitting a used crank shaft, check it for cracks. This can be done by lifting the crank off the ground and striking each one of the 12 counter weights with a large wrench (19 mm or larger). It should ring like a bell. If it doesn’t - check the rod journal nearest the dead counter weight and look for a crack. A dead ring indicates a junk crankshaft.

Piston Rods

Piston rods, or con rods, connect the pistons to the crank. At the top or 'small end', the piston is held in place with a gudgeon pin, while at the bottom or 'big end', rod caps bolt around the cap.

The rod lengths for M5x engines are shown in the Pistons table.

Pistons

Crank Pulley

Head

Just like the blocks, the Heads fitted to M5x engines are fundamentally the same lumps of metal; so similar that they all share the same head gasket. The same casting number is used as well; 400, although heads were available in both iron (M50) and aluminium (M52).

Essentially, this means that all heads are the same, but experience tells us there are actually three heads in use; non-VANOS, VANOS and Double-VANOS. Learn more about VANOS.

The non-VANOS head, as fitted to the first M50 engines, is a twin-cam unit based around an 'interference' design with valves that protrude into the cylinder, resulting in a relatively high compression ratio. These heads use double valve springs as standard, and a high valve duration of 240 degrees.

The first VANOS heads were introduced in 1992, and offered variable-valve timing to the inlet cam. This allowed for a smoother, more efficient idle without compromising mid-range torque. No extra power was offered, but emissions and fuel economy were improved. These early VANOS systems were primitive, and only offered variable timing at two points of the rev range.

For the Double-VANOS, more valve changes were made. The same cam timing was kept, but valves were upgraded to a conical design compared to the earlier double-spring technology. More significantly, VANOS technology was applied to the exhaust cam, allowing for a much more comprehensive adjustment of the valve timing; over 40 degrees of crankshaft sweep for the intake cam, and 25 degrees for the exhaust, which basically means much better emissions and much smoother torque delivery.

Rocker Cover

Rocker covers were available in plastic or aluminium.

Physically, the covers on these engines are interchangeable, but the cover on top is specific to M50 and M52 engines for a number of reasons.

Primary of these is the engine diagnostics plug. The M50 engine used the first generation diagnostic system known as OBD I, while the M52 used the industry-standard OBD II. The spark plug coils used in the engine are specific to these systems, so something as simple as a cover necessitates a whole changeover of ignition components, which just isn't worth it.

Secondly, plumbing for the crankcase breather hose is different between the engines, so re-working some pipes would be needed.

Finally, Double-VANOS covers are specific to those engines.

Inlet Cam

Because of the complexities of the VANOS system, there are clear differences in the camshafts of these engines.

M50 non-Vanos shafts are 240 degrees with a valve lift of 9.7 mm M50 and M52 VANOS shafts are 228 degrees with a lift of 9mm lift

Exhaust Cam

Unlike the inlet, the exhaust cams are almost identical, with a minor difference in lobe height between VANOS and non-Vanos engines.

M50 non-Vanos shafts are 228 degrees with 8.8mm lift M50 and M52 VANOS shafts are 228 defrees with 9mm lift

Valves

Non-Vanos valves, such as those fitted to the M50B20 and B25, are double-sprung. Their valve stems are also thicker than their VANOS counterparts, being 7mm rather than 6mm, making them better able to tolerate increases in power and torque.

Lifters

To make the valves work, the M5x engines use hydraulic lifters for the cam to operate the valves. Because of this, there is no need to set valve clearances, unlike earlier BMW engines like the M20.

VANOS

Main article: VANOS

VANOS is a variable-valve timing system that determines how long each valve stays open for. Before VANOS, each camshaft was locked into a fixed rotation based on the crank; as the crank turned, so would the cam shafts.

VANOS changed all this by introducing a gearing system which could slow down or speed up exactly when the valves opened, depending on crankshaft position. By installing this gearing mechanism at the front of the camshaft, the opening of the valves could be better co-ordinated to the engine speed, so that a faster-spinning engine can suck in air earlier on each stroke. The time between the intake closing and the exhaust opening is known as Cam-Phasing.

On early VANOS engines, this phasing was a basic switch, giving an ON-OFF characteristic. The engine was either on its idle timing, or its power timing, and the gear system would turn on or off depending on the ECU.

With Double-VANOS, this gearing system was applied to the exhaust cam too, allowing all sorts of clever overlaps regarding when the intake closed and the exhaust opened. The more the overlap, the more efficient the engine.

The actual gearing is a mixture of electric solenoids and hydraulic pressure, and the oil seals in these hydraulic systems are a known issue. If you ask BMW to repair it, they will replace the entire system, but oil seals are available separately and can be fitted with the right tools.

Head Gasket

The biggest indication of how similar the two heads are is the identical head gasket.

Inlet

Main article: M5x Inlet

One of the most noticeable features of the M5x engines, in comparison to standard E30 lumps, is the big plastic Inlet manifold as opposed to the cast aluminium.

These plastic inlets vary across engines, and create wildly varying performance characteristics depending on which one is fitted. The M50B25 manifold offers a much greater air volume to flow into the engine, and is considered one of the best modifications to make to an M52 engine. Performance gains of 15bhp are not unheard of.

However, be aware that the M50B20 inlet manifold is smaller than the B25, and there have been cases of sellers, knowingly or otherwise, offering B25 manifolds that are in fact the smaller B20 article.

To distinguish the difference between the two - notice the 'ribs' on the sides of the 2 middle inlet runners on both the B20 and B25 manifolds. The B25 manifold ribs are much thinner because the inlet runner is larger whereas the B20 one is larger because the inlet runners are smaller.

The main difference between the 325 and 328 inlet is the plastic manifold and the size of the ports in it. This manifold is 10mm greater (width) in port size over the standard 328. The 325 has 55x25mm port's and the 328 has 45x25mm port size. This equates to a much bigger flow rate; the 325 inlet will flow 50% more than the 328.

Connected to the Inlet is the Throttle body; the mechanism through which the driver controls the engine. Again, these differ between M50 and M52, but can be made to fit either engine with the appropriate modifications. Learn more about the M5x throttle bodies.

Wiring

Loom

Main article: M5x Looms

The M5x series of engines differ substantially from their M20 predecessors in the labyrinth of wires that wind their way around the engine bay. Fortunately, BMW designed them to be detachable, and therefore the primary engine loom is a one-piece component terminating in a plug called the X20. This plug is the counterpart of the C101 plug on the M20 loom, although the pin layout differs substantially. For a pin-to-pin comparison, check out our loom tables.

ECU

M50 engines come with a red label 413 ECU or a silver label 413 ECU. The silver labeled ECU uses EWS

EWS

Main article: EWS

EWS is the immobiliser system fitted to BMW models with M50 and M52 engines from 1994 onwards. Its basic function was to check that the doors were unlocked correctly and that the correctly-coded ignition key is being used. If it fails to detect the right signal, it will disable the ignition circuit, the injectors and the starter motor, which is a right pain if you're trying to do an M50 or M52 engine swap.

If you are trying to chip-tune your M5x engine, you will need to disable the EWS to do so. Learn more about disabling the EWS.

Temp Sensor

If you are running the E30 cluster, make sure you put in an E30 temp sender, as the E36 one will not operate the gauge properly. It is difficult to get to when the engine is in the car. Don't remove the existing one, as it also sends to the ecu; you will need to add the E30 one. If you are lucky there will be a blanked off spot to mount it in.

Servicing

Main article: Basic M5x Servicing

Common Problems

Not Turning Over

This is a common problem for those engines fitted with the M20 flywheel. The back of the flywheel will either be catching on the block where the long rear sump bolts come home, or the bolts that hold the flywheel onto the crank will be too long.

The solution to this is either to grind away a small section of the sump (not recommended), or have the flywheel lightened by removing part of the back. Either way, the engine and gearbox will have to come out of the engine to cure the problem.

Not Starting

If NOTHING happens when you turn the key, then you have an issue with the red wire that feeds the ignition switch from the fuse box.

If nothing engine-related happens when you turn the key, then the issue is with the plain green wires that drive the ignition. These wires are found behind the glovebox, where you will probably find a pair not connected to anything; these need to be joined together.

In the same area as these green wires, you should find two single plug and sockets, each joining a black/yellow wire to another wire (plain black, usually). Disconnect both of these and plug the two halves with black/yellow wires together.

This bypasses the auto inhibitor switch, and arranges the wiring just as it would be from the factory on a manual car. Follow the two left over wires to a relay, remove the relay base, the wires, and the other wires to the relay, which you will find a lead to the area under the front console where your gear lever will be. You need to find the reverse light loom and gear lever grommet from a manual E30, which will connect between the reverse light switch on the gearbox and the plug you have found.

Overheating

The aluminium blocks used in the M52 are a lot more sensitive to overheating than the cast-iron M50. For this reason, serious overheating has been known to completely kill an M52 engine beyond economical repair.

VANOS Chatter

A problem with the sprocket on early VANOS engines caused a problem with chattering. Although it doesn't highlight any mechanical failings or loss of performance, the noise can be downright annoying.

In 1995 BMW released an updated sprocket designed to deal with this problem. A repair guide is available here.