So as I said in the above post, I was lucky enough to finish work a bit earlier today so as the missus was also still at work decided to have a look at how to tackle the roof skin swop.

First of all after looking at the 4 roofs I have one on the car, one touring, one non sunroof and one IS there is two different styles of fitting the skin to the frame, three are the same but on the IS one the join in the gutter trim area is spot welded were as on the others it is different, think x-works called it roll welded but i could be making that up.

Hard to see but it looks like lots of spot welds but over lapped.

My car, the non sunroof skin and the touring skin are the same as the above but the IS one I have is spot welded at 1”a or so spacing.

Either way that still means both of the ones I would be working with are ”aroll welded”a so I attacked the skin as though it was the real thing.

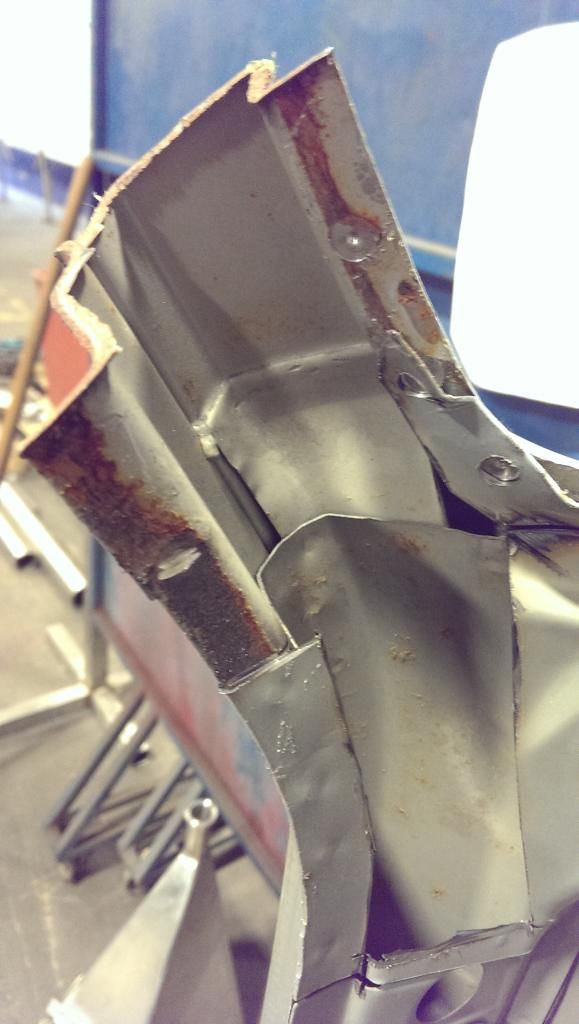

First thing was to cut a section out to play with.

Can you guess were my plates for the rest of the car came from?

Section cut out and this is what you get.

With colours to show the sections.

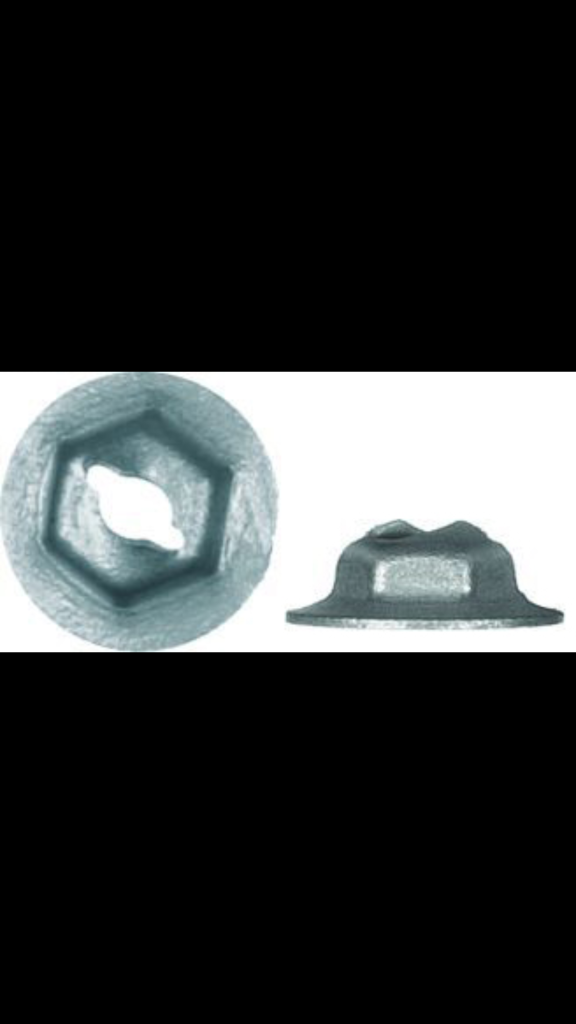

Green is to show the position of the spot/roll welds

Purple is to show the angle of grinding to remove the roof skin from the frame.

The frame once I’ve cut off the old skin and flatted down the gutter lip.

The bit of roof skin I saved without damaging it.

Polished back

And an old and new bit clamped together, as you can see there is a little bigger gap between the roof frame and the skin this was how it was originally it’s just that this time you are looking down the panel rather than up it if that make sense.

So basically I'm happy that I can do it and that its not to bigger job just time consuming, could have polished down the frame lip a bit more but the grinder flap disc I had was well worn down and for a trail it wasn't important, for the real job I have some sanding discs for a grinder backing plate which will get right in the corner and sand down the old lip.

There was also some odd stuff in the join between the spot welds sort of a bluey/ green colour of old copper with the constancy of wax, any ideas??

Also toying with the idea of making a gig to hold the skin while I work on it, something like a ply wood sheet with a big bag on then fill it with expanding foam to make a solid but softish support for it.

Again any input or idea welcomed