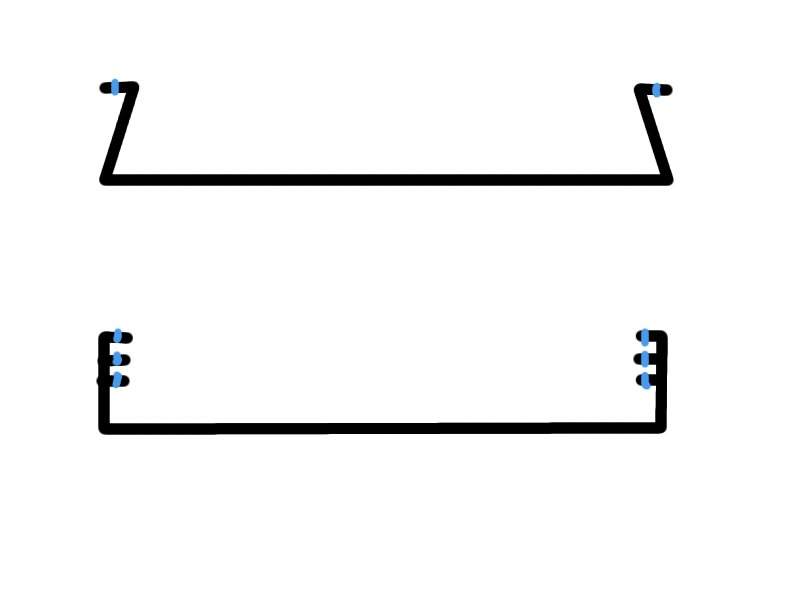

You will need :

a touring/M-Tech front ARB (d'oh!)

a drill (pillar is best, variable speed handheld will do)

a bench grinder or angle grinder

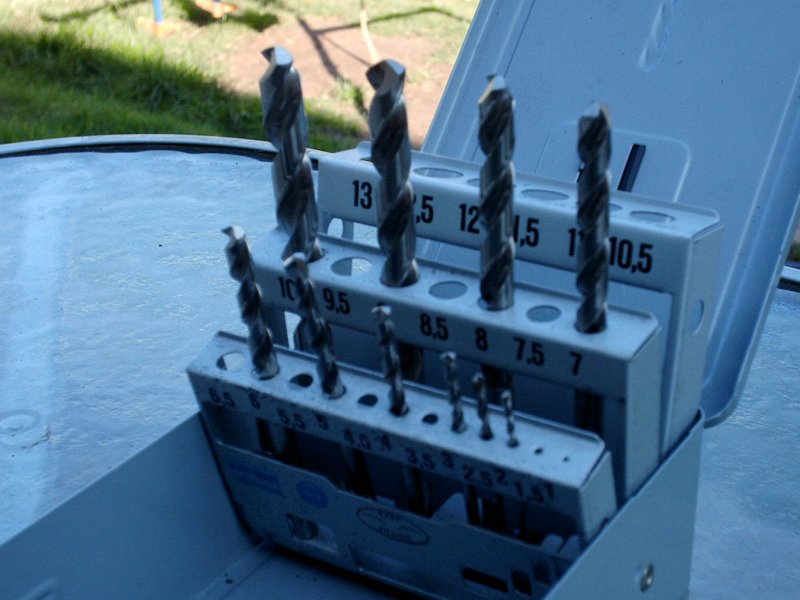

Cobalt steel (HSS-E) drill bits like these :

If all you have is HSS bits, go and buy a set of Cobalts - you will not be able to do this with regular drill bits as they are only slightly harder than the spring steel an ARB is made from. I paid £25 for the box and bits shown above. They're worth having anyway as they go through mild steel like a hot poker through butter - great for drilling out sheared and stuck bolts (front disc allen bolts, anyone?)

Take your ARB and drill a new 10mm mount hole with centre 25mm inward from the original. I drilled a 3mm pilot, then expanded to 6mm before running the 10mm bit through. If you have cutting paste, use it, but as long as you don't force the bit it should be OK.

Remember that large holes should be drilled at low revs - cutting speed for high-carbon steel is 25cm/second which translates to 800 rpm for a 6mm drill and under 500 for the 10mm.

Next, you'll have to grind the bar back a little to provide a flat surface to bolt the droplink onto.

Take off as little as possible and don't leave any sharp corners or steps as these may encourage cracks to start. Be especially careful not to let the bar get too hot - those pretty colours ranging from yellow to violet mean you've re-tempered the bar and it's now softer than it was.

Check for fit by offering up the droplink, remember you'll need a little more room on the back to turn the nut

This is what you should end up with; a new mount point 20% closer to the pivot axis than the original, giving the suspension 20% less leverage over the bar.

Use this guide at your own risk; I'm sure someone will chastise me for my irresponsible and potentially dangerous meddling, but I did over 6,000 road miles and 80+ 'Ring laps with this setup without any trouble