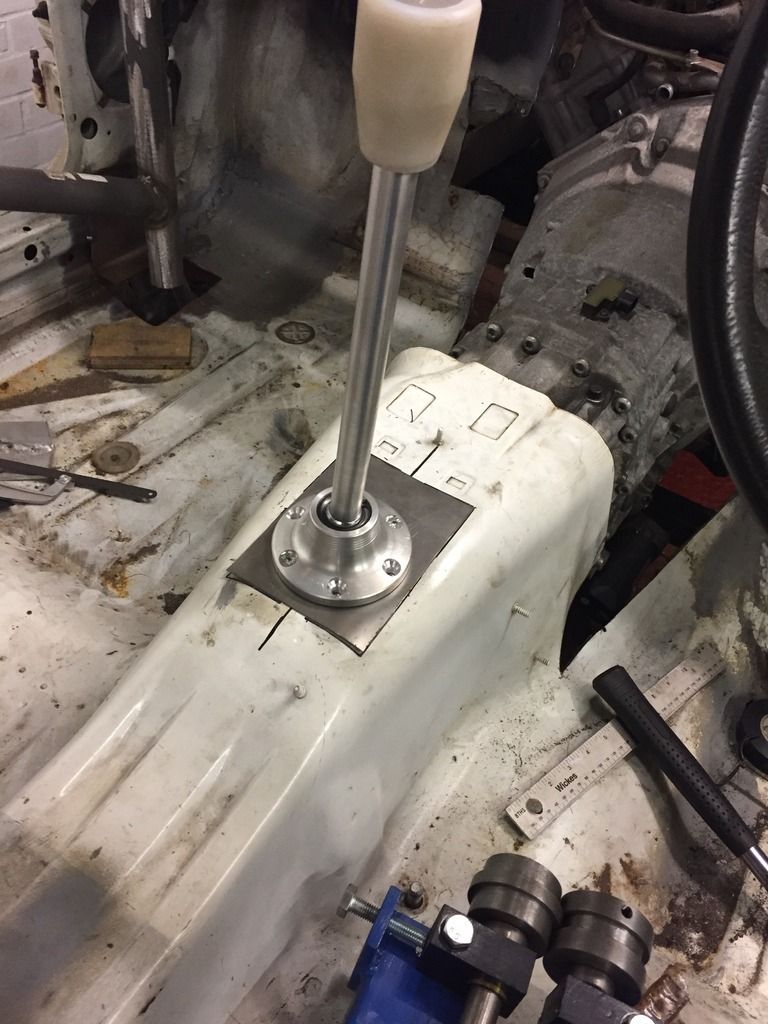

Have managed to fit the bonnet on just at this height.

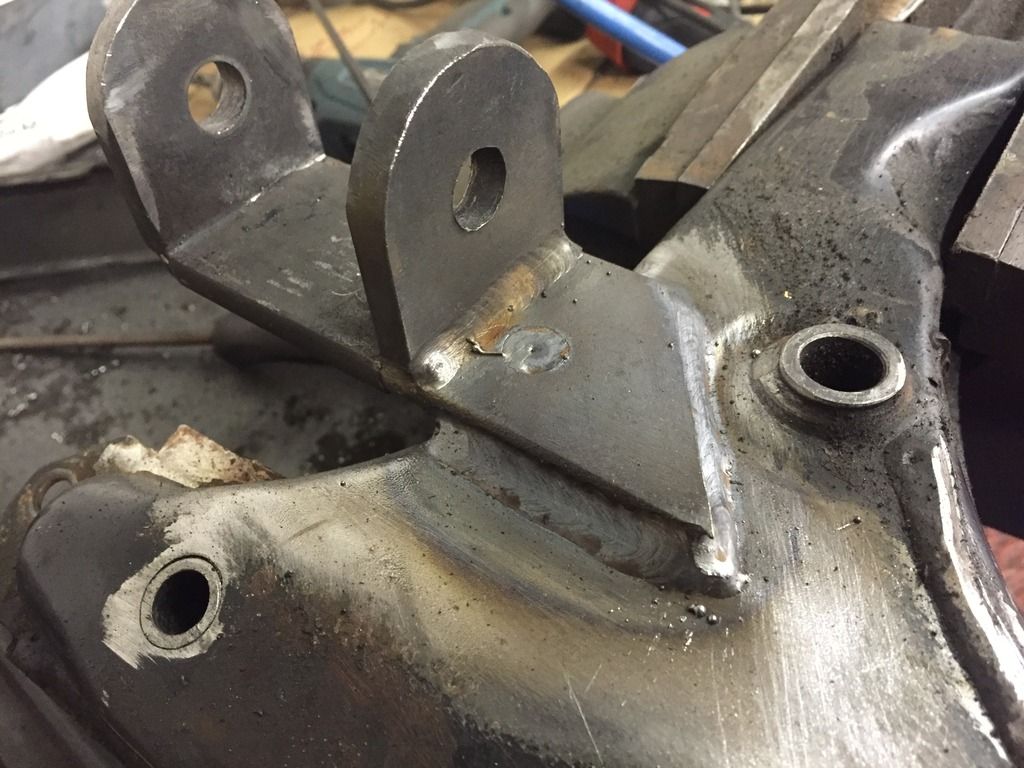

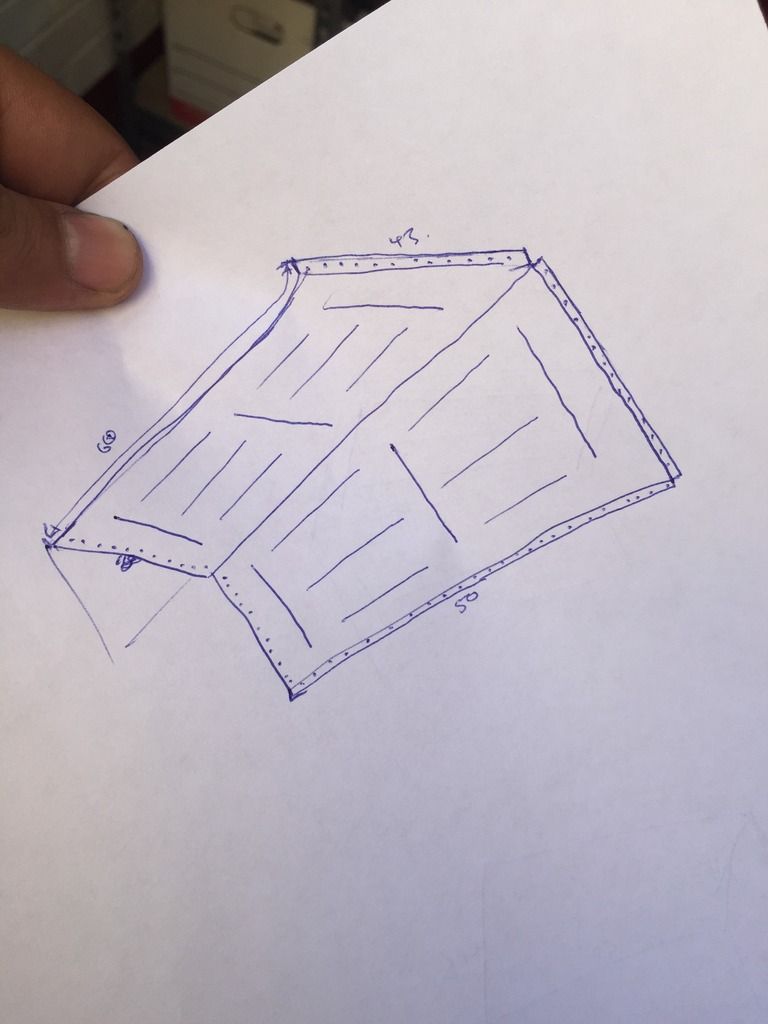

Was very time consuming to make sure everything Bob on and to allow clearance for steering rack pinion

More pics updates tmro eve hopefully with mounts completed!

Moderator: martauto

Thanks I was using 1mm filler 316l for the pipejimmyspeed wrote:good work, i was gonna moan at you for the lack of preparation (cleaning) on your ali welding but saw it was only a jig !

but i reckon the neatness of your stainless weld would benefit from larger rods. I'm not saying there gonna brake, they're pretty good. Though there is some undercutting and close stacking (top photo left hand size) where you can see lots off feeding.

i don't know the size of the weld so its hard to tell what your using but if your using 1m maybe try a 1.2 or if using a 1.2 try a 1.6

the 1.6 takes a bit of get used too, as you need to keep it close and warm so it melts freely but it makes for a less frantic feed and bigger fuller ripples

an if you didn't know stainless warps like a mofo so try and heat sink or clamp the face to a block where possible. We often airline sheet panels and spray with water to try keep flattish