it last time out on the road was when i last posted this ! the car had a few issues that came to light so i just threw it in the garage and didn't really do much

three issues needed attending

1- brakes still binding

2- low oil pressure on idle when warm

3- overcooling when cruising down the motorway, and getting warm in traffic

the brakes was narrowed down to 2 things, either sticking linkage to sticking master cylinder. everything else had been changed

it only tended to happen when the stuck in traffic, hot engine bay, stop start all the time. maybe they are interlinked ??

low oil pressure, well i changed the oil press switch for an OEM one so this meant taking the sump off to investigate

overcooling/overheating - well water flow was good, the rad is good so lets consider the thermostat and viscous

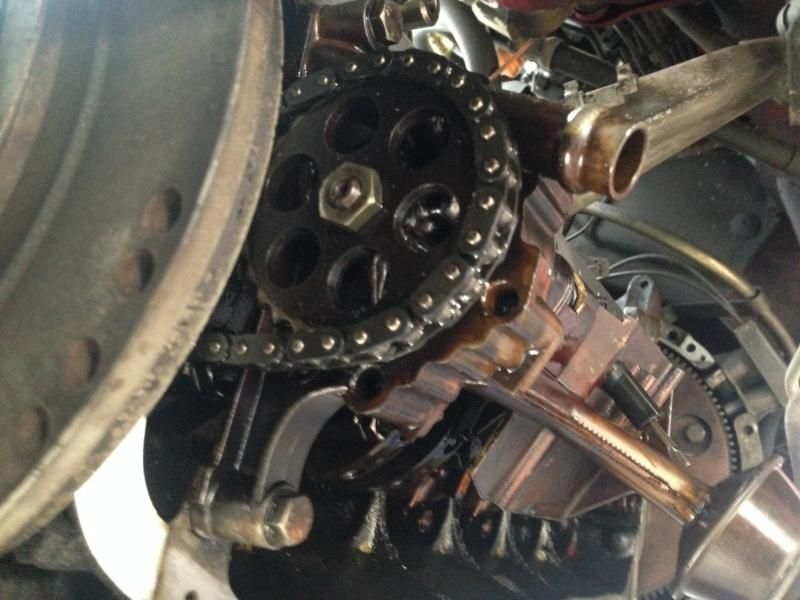

first was to pull the sump off and change the oil pump. new one ordered from the dealers and while it was off i decided to change the big end shells. It was a no brainer to do this as its sad job getting the sump off.

At the same time i had the front crossmember blasted, the steering box mounting bracket reinforced and powder coated in the original satin black finish. Also while working on the front end i changed the NS arch liner (its metal one). I had anew one which i purchased a couple of years ago but it was in grey powered coat so again i did it in black. no rattle can jobs here !

so, heres some photos go what we were looking at....

shells out and now time to match them up

not to much wear really

the crossmember

new oil pump (dealer only) £350

shells were matched up and supplied by middlesex rebore for OEM ones but substantially less

new ATE master cylinder from ECP

new brake fluid reservoir from the dealers which came in the old style packaging which was nice to see

i also got my self a new header tank and screen wash reservoir wight he correct OEM white cap, not the new style ones. i bought the last 4 in stock, sole one on ebay for £55 but I'm keeping the other 3

but then we noticed this

drip drip drip

we have a head gasket breach

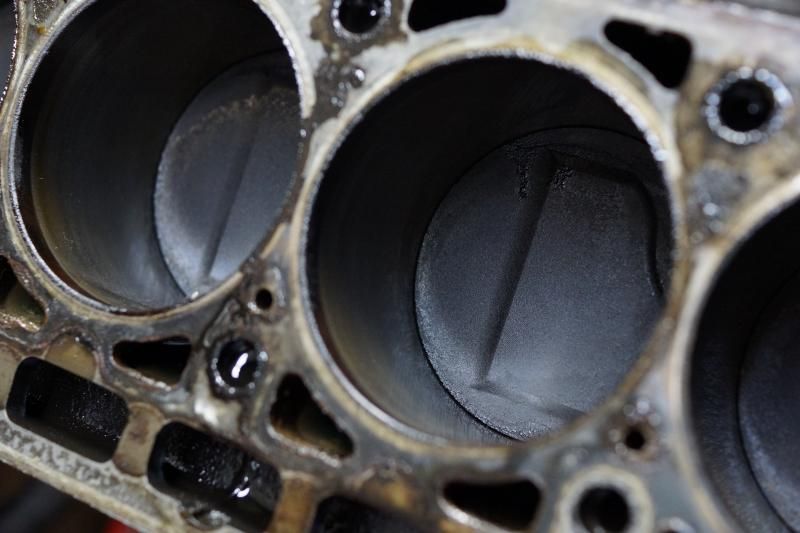

head off and can you spot where the breach is

the rest were fine but the head has some serious corrosion going on.

water pipe off the back of the head

the cylinder bores were good though. prior tot he head coming off we ran a compression check and all was good bar cylinder 6.

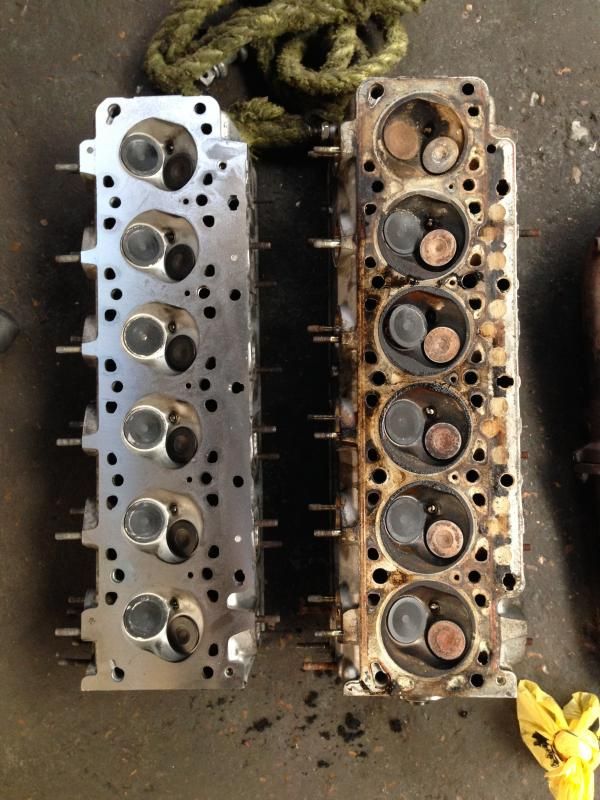

corrosion was bad, but it can be repaired but at a price. then i had a call from pacer who let me know that Mr everett had a good m30 head, no corrosion and with a good cam and rockers. there was nothing wrong with my cam and rockers but it makes sense to have good spares. he wanted £150 which was going to be cheaper than welding up my one

head turned up and it had the exhaust manifold attached which was handy as mine had a small crack. i could have just refaced the head but i decided as i was this far in to send it to middlesex rebore and get it overhauled. 12 new valve guides, valved lapped in and refaced along with a pressure test

this is how it came back

this is the same section of the old head

side by side

cam gear was re fitted using the best of the parts in the original head and used head. there was no wear on any them to be fair and now i have good OEM spares

so, we are almost ready to reassemble it now but nor before more peado action

everything that needed blasting or powder coating was sent away to have the work done. i did consider having he exhaust manifold sent away for creamic coating but at over £300 they can fuck off. i had it blasted an a phosphor coating applied. it should be alright for a few years as long as i maintain it.

the inlet managed to develop a crack as well where it mounts to the head. alloy became pours and a leaky injector fucked it but the looks of it. Pacer came to the rescue with another inlet for me and injectors were sent away for overhauling

heres the bits i took away for blasting and powder coating. the inlet and some other parts were vapour blasted

and heres how they came back and compare to the originals

zinc plated PAS reservoir lid

water pipe off the back of the head and timing case cover

love a bit of vapour blasting

[URL=http://s20.photobucket.com/user/kosbm/m ... 3.jpg.html]

[/URL]

[/URL]airbox, fuel rail, main pulley AFM bracket and a few other assorted parts

some i had spares of so i had them done in OEM silver and others in black, i'll try them both and see which i prefer

random parts from the dealer

so, its all went back together add a new water pump, viscous, thermostat (along with blasting the housing) various new sensors, new plugs and all the fluids and filters have been changed and we fired her up. she fired up on the button

its been at my fried work shop since early may and it was nice to hear her fire up. this was early last week. everything was check, looked for any leaks etc and we took her for a gentle run. once up to temp she held temp fine and we got her back tot he work shop to adjust the tappets. when we got back, the PAS started to grumble. we bled it again and it cleared up. good. come thursday morning it was going to go for alignment and the PAS grumble came back !

no one had a PAS pump bar KMS and they had to get it in from germany and it would arrive after gaydon ! i was all set to have her ready for gaydon and this happened. i was a touch pissed off but these things happen. i could have got o e from the dealers but at over £300 i wasn't going to, not for the sake of one day and one show.

so, thats were we are.

once the pumps on, its off for alignment and and then i'll get some more photos up of the peado'd engine bay