Martin's rally car build - update 8/2/16

Moderator: martauto

On a rally car I'd have thought it was worth retaining the drum-handbrake gubbins for hairpins etc?

Drums are normally more effective than a disc handbrake (even an OEM one), I suppose there's a slight weight penalty to retaining the shoes though.

Drums are normally more effective than a disc handbrake (even an OEM one), I suppose there's a slight weight penalty to retaining the shoes though.

WMS E30 brake kits! (4-pot 280mm & 300mm front / 2-pot 290mm rear)

www.wms-brakes.co.uk / http://www.e30zone.net/modules.php?name ... c&t=209737

www.wms-brakes.co.uk / http://www.e30zone.net/modules.php?name ... c&t=209737

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

You are correct, the drum brake tends to be snappier than a disc activated handbrake, however I and many others have had problems with the mechanical systems disintegarating after constant use whilst i motion, they're just not designed for it. It would be annoying not to ginish an event due to something silly like a handrbake mechanism seizing your wheel.

Ah! Fair enough.

WMS E30 brake kits! (4-pot 280mm & 300mm front / 2-pot 290mm rear)

www.wms-brakes.co.uk / http://www.e30zone.net/modules.php?name ... c&t=209737

www.wms-brakes.co.uk / http://www.e30zone.net/modules.php?name ... c&t=209737

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

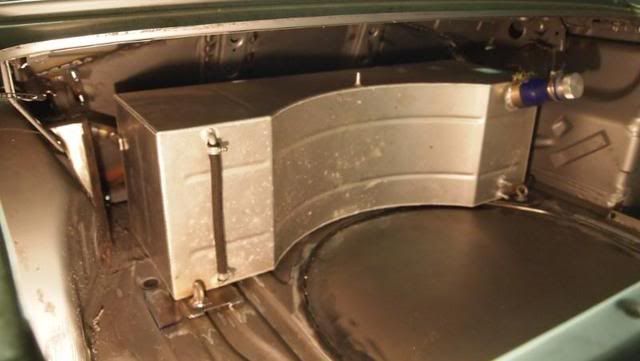

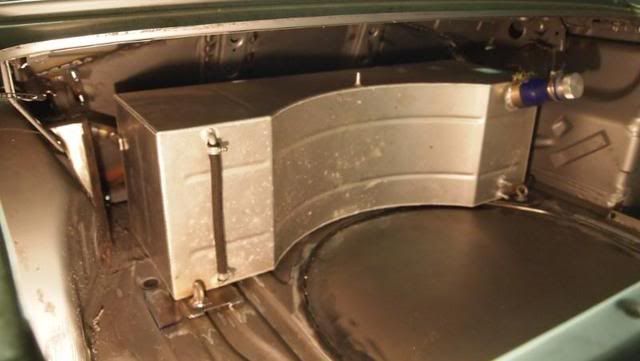

Got the rear seat area and the chassis members notched for the beam and rear arm reinforcing tubes - amazing how many issues moving the beam 40mm causes!

Also started planning how im going to tie the diff to the chassis, going to use use this alloy spacer between the beam and boot floor and weld a tube between the turrets going down to a reinforcement on the boot floor.

Its all going very slowly at the moment -these jobs seem to take forever!

Also started planning how im going to tie the diff to the chassis, going to use use this alloy spacer between the beam and boot floor and weld a tube between the turrets going down to a reinforcement on the boot floor.

Its all going very slowly at the moment -these jobs seem to take forever!

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

Those welds are so clean!

2nded!

WMS E30 brake kits! (4-pot 280mm & 300mm front / 2-pot 290mm rear)

www.wms-brakes.co.uk / http://www.e30zone.net/modules.php?name ... c&t=209737

www.wms-brakes.co.uk / http://www.e30zone.net/modules.php?name ... c&t=209737

Nice work Martin! Very impressive.

Can I ask what 16" wheels you have to clear the E36 M3 brakes? I've done a similar thing using Koni coilovers and stock E36 M3 Evo control arms. How did you do the camber shims on the king pin? Did you have to use longer bolts for the strut-kingpin?

Also, how much clearance do you have between the tyre and spring platform on the coilover? I find with 7J ET41 wheels with 205 tyres (just the cheap 16" wheels I have for rolling the shell on) JUST foul the spring platform on the coilover. An 8J ET25 wheel should give me 3mm extra clearance but using the kingpin to change the camber angle would reduce this again right? I guess a 225 tyre on an 8J ET25 rim would also give a little extra clearance...

Can I ask what 16" wheels you have to clear the E36 M3 brakes? I've done a similar thing using Koni coilovers and stock E36 M3 Evo control arms. How did you do the camber shims on the king pin? Did you have to use longer bolts for the strut-kingpin?

Also, how much clearance do you have between the tyre and spring platform on the coilover? I find with 7J ET41 wheels with 205 tyres (just the cheap 16" wheels I have for rolling the shell on) JUST foul the spring platform on the coilover. An 8J ET25 wheel should give me 3mm extra clearance but using the kingpin to change the camber angle would reduce this again right? I guess a 225 tyre on an 8J ET25 rim would also give a little extra clearance...

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

I will take some photos for you next time I have the front suspension all built up.

Progress report for the last week - cut the backstays out of the cage, they were heavy as fook, mounted on the arch tubs which have the structural integrity of plastic and the harness bars were in such a shite position that the harnesses would have pointed downwards towards the seat - big order of tubing on its way from custom cages. Also bought a tube notcher from demon tweeks - best hundred quid I ever spent!

Drawing some inspiration from the more upmarket safety devices cage I decided to make the backstays mount on the turrets but in a slightly neater fashion than chopping 2 big holes in the rear bulkhead so this is what I came up with, pictures speak for them themselves, you can also see the rear strut brace which ties to the boot floor and provides the diff mountings

All on captive nuts for easy fitting and should be as strong as an ox. Just need the tubing to arrive

Progress report for the last week - cut the backstays out of the cage, they were heavy as fook, mounted on the arch tubs which have the structural integrity of plastic and the harness bars were in such a shite position that the harnesses would have pointed downwards towards the seat - big order of tubing on its way from custom cages. Also bought a tube notcher from demon tweeks - best hundred quid I ever spent!

Drawing some inspiration from the more upmarket safety devices cage I decided to make the backstays mount on the turrets but in a slightly neater fashion than chopping 2 big holes in the rear bulkhead so this is what I came up with, pictures speak for them themselves, you can also see the rear strut brace which ties to the boot floor and provides the diff mountings

All on captive nuts for easy fitting and should be as strong as an ox. Just need the tubing to arrive

-

Rallyprep_UK

- formerly Driftnething

- Posts: 832

- Joined: Thu May 08, 2008 11:00 pm

- Location: Cornwall

- Contact:

awesome

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

Some more progress....

Diff mounts done

front strut brace

cage and bulkhead

brackets and anchor points for the fuel tank, wheel well also plugged

Diff mounts done

front strut brace

cage and bulkhead

brackets and anchor points for the fuel tank, wheel well also plugged

- Kos

- E30 Zone Team Member

- Posts: 15546

- Joined: Tue Jul 12, 2005 11:00 pm

- Location: London / Cyprus

- Contact:

Fab Fab

PUKAR DESIGNS - Reproduction BMW Decals Labels Sticker & Number Plates

www.pukardesigns.com

www.facebook.com/pukar.designs/

IG Pukar.Designs

www.pukardesigns.com

www.facebook.com/pukar.designs/

IG Pukar.Designs

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

long overdue update at last!

there has been progress - although not a massive amount on the shell itself - sneak peak at the new rear axle which is in hiding under the old shell - i would have taken a proper one but couldn't be bothered to pull the thing out. Its an e30 one with a custom blade type arb mounted under it, e30 arms with e34 inner and outer flanges, e46 300mm rear discs with and powerlite 4pot calipers with an internal handbrake mechanism

new diff to go in the axle - this was a bit of a nightmare - its an e28 m5 diff with an e46 m3 3.62 CW&P e28 LSD unit which I though would be easy to 4 plate - unfortunately the large case diffs don't have space to fit 4 plates in by simply machining 50 though off the end plate and omitting the spacer - this needed 3.5mm taken off the end plate and the inside of the basket - this meant that the oil channels needed machining back in too. The holes for the crown wheel bolts also needed taking out to 14mm for the m3 ring gear. all new bearings and seals, a lick of paint and a breather welded into the back plate and I should have a theoretically bullet proof diff. Got 4 porsche 930

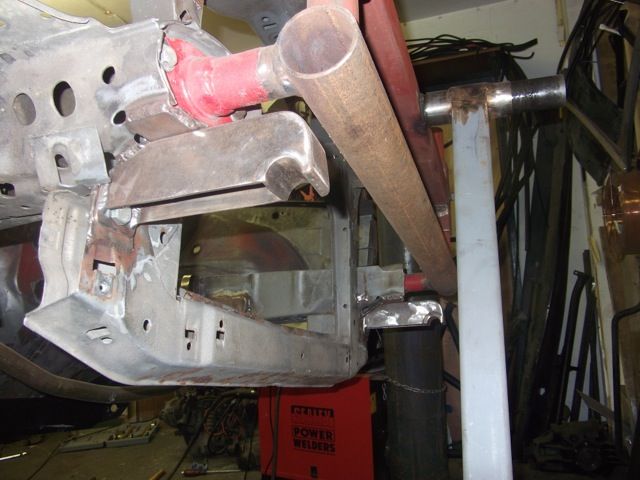

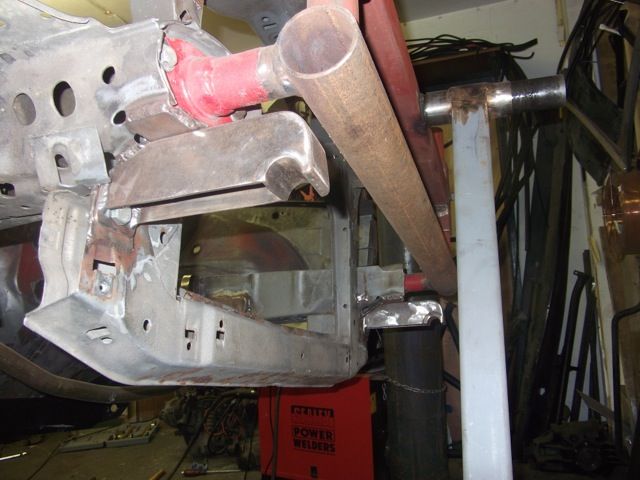

I also needed to put a dome in the boot floor as the combination of raising the beam and the large diff meant there was a lot of interference - the brackets at the end of the diff bolt to the tubes through the boot floor to support the heavy bugger. I tied the front chassis mounts for the diff into a plate with a captive nut on the rear seat area where the brackets for the seat belts used to be.

Then added a bar into the cage which pics up on these - should stop he whole thing ripping the floor to pieces in the (hopefully) unlikely event of a diff failure

made a rather unconventional handbrake

Strengthened the front end a bit

bent up the anti roll bar and welded some brackets to hole the thing on

made the removeable front jacking points up

got hole of a rod of polyurethane - after much cursing managed to turn the thing into something resembling some engine mounts. These are to replace the the mk2 escort type ones I used previously. These are wider and harder so should cope with the weight of the s50 better. Now I need to make up some new plates for the motor and dummy fit it for welding together.

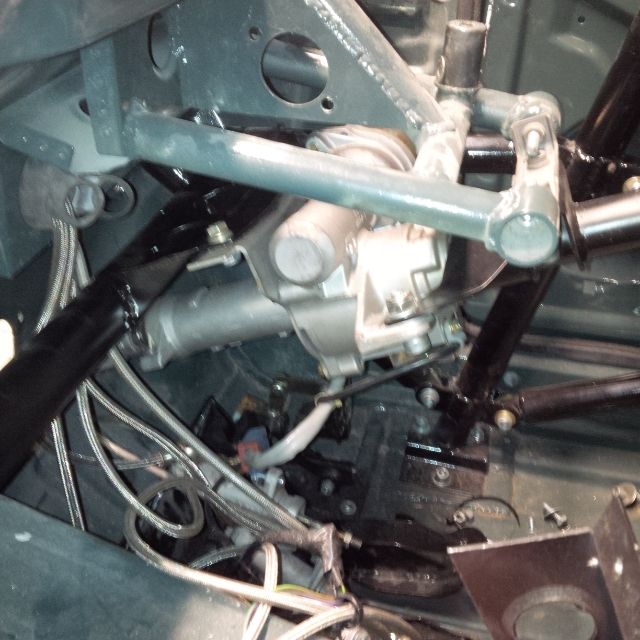

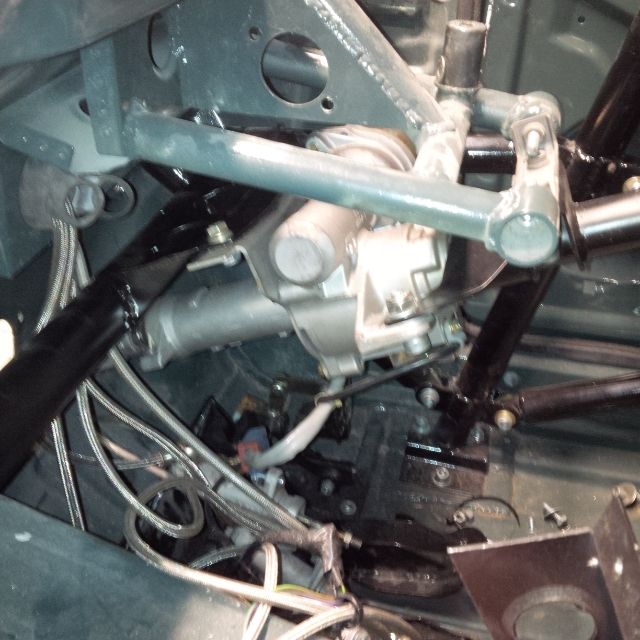

Pedal box now assembled - I had the front and rear suspension powdercoated and this was done at the same time.

Welded up the copious amounts of wholes in the rear firewall too

Thats it for now - going to be taking a week off in February hopefully to get it all in paint - then it should fly!

there has been progress - although not a massive amount on the shell itself - sneak peak at the new rear axle which is in hiding under the old shell - i would have taken a proper one but couldn't be bothered to pull the thing out. Its an e30 one with a custom blade type arb mounted under it, e30 arms with e34 inner and outer flanges, e46 300mm rear discs with and powerlite 4pot calipers with an internal handbrake mechanism

new diff to go in the axle - this was a bit of a nightmare - its an e28 m5 diff with an e46 m3 3.62 CW&P e28 LSD unit which I though would be easy to 4 plate - unfortunately the large case diffs don't have space to fit 4 plates in by simply machining 50 though off the end plate and omitting the spacer - this needed 3.5mm taken off the end plate and the inside of the basket - this meant that the oil channels needed machining back in too. The holes for the crown wheel bolts also needed taking out to 14mm for the m3 ring gear. all new bearings and seals, a lick of paint and a breather welded into the back plate and I should have a theoretically bullet proof diff. Got 4 porsche 930

I also needed to put a dome in the boot floor as the combination of raising the beam and the large diff meant there was a lot of interference - the brackets at the end of the diff bolt to the tubes through the boot floor to support the heavy bugger. I tied the front chassis mounts for the diff into a plate with a captive nut on the rear seat area where the brackets for the seat belts used to be.

Then added a bar into the cage which pics up on these - should stop he whole thing ripping the floor to pieces in the (hopefully) unlikely event of a diff failure

made a rather unconventional handbrake

Strengthened the front end a bit

bent up the anti roll bar and welded some brackets to hole the thing on

made the removeable front jacking points up

got hole of a rod of polyurethane - after much cursing managed to turn the thing into something resembling some engine mounts. These are to replace the the mk2 escort type ones I used previously. These are wider and harder so should cope with the weight of the s50 better. Now I need to make up some new plates for the motor and dummy fit it for welding together.

Pedal box now assembled - I had the front and rear suspension powdercoated and this was done at the same time.

Welded up the copious amounts of wholes in the rear firewall too

Thats it for now - going to be taking a week off in February hopefully to get it all in paint - then it should fly!

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

Nice wand!

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Blimey!

Pretty bespoke looks interesting

Pretty bespoke looks interesting

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

Topic moved in here

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

Update time

Have got the car painted underneath and inside. Fuel system is finished and the suspension is in. Narrow rear 2 way shocks to clear the big CV joints from AVO have arrived but not yet fitted as they forgot to include the upper spring seats. Have bolted on all the bits to get it rolling and made the brackets for the brake calipers front and rear.

Currently prepping the bodywork for paint. Hoping to get the main body done next weekend so that I can basically get the car built minus the exterior panels and move enough parts out of the way to allow me to prep the things like wings bonnet, boot and doors.

Have got the car painted underneath and inside. Fuel system is finished and the suspension is in. Narrow rear 2 way shocks to clear the big CV joints from AVO have arrived but not yet fitted as they forgot to include the upper spring seats. Have bolted on all the bits to get it rolling and made the brackets for the brake calipers front and rear.

Currently prepping the bodywork for paint. Hoping to get the main body done next weekend so that I can basically get the car built minus the exterior panels and move enough parts out of the way to allow me to prep the things like wings bonnet, boot and doors.

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

Got use of the bodyshop Last night so wheeled the car in after some last minute flatting down - by 2 AM the body was in paint. Priming the panels tomorrow and hoping to get the rest painted next weekend.

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

Happy and sad past week. Happy as the car was finished last minute Thursday - logbooked at 7pm and scrutineered successfully for a rally I had entered on Saturday. All going well for 3 quarters through the first stage. Then after a long straight coming into a chicane the power steering died and left me wrestling to get the car through the damn thing. After limping to service and expecting to be greeted by a red engine bay covered in pas fluid I was surprised to see nothing wrong and the reservoir full. On closer inspection in turned out that the shaft in the PAS pump had sheered and come out about half an inch, taking the serpentine belt with it onto the last 2 grooves. After running round service and to the cafe trying to unsuccessfully find a tray to bleed the system into in the hope we could continue with it dry, we decided it would be safer to call it a day in case the pump broke up further and left us stranded.

On the plus side the car felt like it had a lot of potential, handled very predictably, brakes were awesome and the box transforms the experience completely when flat out.

entry will be going in for a single venue event on 13th July. have ordered an Merc A class power steering pump so will change the mechanical out for that and hopefully that will enable us to finish an event second time lucky!

Some pictures from Saturday

On the plus side the car felt like it had a lot of potential, handled very predictably, brakes were awesome and the box transforms the experience completely when flat out.

entry will be going in for a single venue event on 13th July. have ordered an Merc A class power steering pump so will change the mechanical out for that and hopefully that will enable us to finish an event second time lucky!

Some pictures from Saturday

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Good stuff

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

We took part in the Jersey rally last week. Was a rush to get the car sorted we didn't do a recce which quite frankly scared the crap out of me. The event was spread over 2 days starting friday afternoon and running into the night, then running all day Saturday. 30 stages sown tight lanes all on close plublic roads. the cars still hadnt had a proper shakedown so I was very apprehensive. 73 cars started on Friday and right from the outset a lot of people were crashing, it rained most of Friday and the roads were greasy, by the time we got to the night stages it was pouring it down.

We made it through daylight but had various issues with the car. First problem was driveshafts coming loose which we had to tighten at every service, this was a recurring problem which had to be addressed every service, the brakes werent great to begin with, they had never worked particulary well and i ordered new pads as I felt this was the problem. These were fitted the day before the event and as a result we never had a chance to bed them in, eventually they settled, however the balance bar bearing then decided to move out of the pedal constantly, this meant it didnt really balance anything and we were stuck with the front doing all the work. Suppose thats better than just the rears.

The most frustrating problem was that when revving over 5k the clutch pedal would get lost and I would have to pump it to get it to disengage. not too much of an issue on long straights where I had the chance to think about it, however in short bursts i struggled changing down the gears.

By the time it got to night time I was much more at home in the car, howeverwhilst in the queue for stage stage when it was pouring with rain, the wiper linkage decided it would pop off the arm on the motor, i managed to put it back on and we started the stage, but by the first corner it popped of again and we had to continue with zero visibility. we still managed to catch a car on stage so didnt effect the satge times too horrifically! On the final evening stage (the longest of them all) we came through an artificially tightened hairpin down a narrow hill which had 3 1 ton bags of gravel on the outside. as it was the thrird time through i got cocky and went it too fast and jabbed the handbrake. we were greeted by a large thud when one of the gravel bags hit the rear quarter. Another thing to add to the list of things to do. we finished friday lying in 37th place (would have been 35th but we had a minute penalty for arriving early in service.

We started early saturday morning on and opted to stay on the hankook wets for the first couple of stages as they were still very slippy , half way through the day the rears were going off badly as it had dried up more or less completely. we changed to mediums on the rear and kept the wets on the front, this helped a lot.

by this point i was driving round the clutch and brake issues. the rest of the day was more or less uneventful , we kept it steady a tightened the shafts each service. on long right handers the car was filling with smoke as the rear arch rubbed the tyre so had to take it easy to avoid a blowout.

we finished the event at 6pm saturday 26th overall. Much to our surprise only 36 cars finished!

Overall very happy. considering the lack of testing and the fact this isnt an easy event at all we were over the moon.

plenty I want to change on the car over the winter but nothing fundamental. first thing will be having the rear wing repaired and a nice rest from working on the car for a couple of months!

We made it through daylight but had various issues with the car. First problem was driveshafts coming loose which we had to tighten at every service, this was a recurring problem which had to be addressed every service, the brakes werent great to begin with, they had never worked particulary well and i ordered new pads as I felt this was the problem. These were fitted the day before the event and as a result we never had a chance to bed them in, eventually they settled, however the balance bar bearing then decided to move out of the pedal constantly, this meant it didnt really balance anything and we were stuck with the front doing all the work. Suppose thats better than just the rears.

The most frustrating problem was that when revving over 5k the clutch pedal would get lost and I would have to pump it to get it to disengage. not too much of an issue on long straights where I had the chance to think about it, however in short bursts i struggled changing down the gears.

By the time it got to night time I was much more at home in the car, howeverwhilst in the queue for stage stage when it was pouring with rain, the wiper linkage decided it would pop off the arm on the motor, i managed to put it back on and we started the stage, but by the first corner it popped of again and we had to continue with zero visibility. we still managed to catch a car on stage so didnt effect the satge times too horrifically! On the final evening stage (the longest of them all) we came through an artificially tightened hairpin down a narrow hill which had 3 1 ton bags of gravel on the outside. as it was the thrird time through i got cocky and went it too fast and jabbed the handbrake. we were greeted by a large thud when one of the gravel bags hit the rear quarter. Another thing to add to the list of things to do. we finished friday lying in 37th place (would have been 35th but we had a minute penalty for arriving early in service.

We started early saturday morning on and opted to stay on the hankook wets for the first couple of stages as they were still very slippy , half way through the day the rears were going off badly as it had dried up more or less completely. we changed to mediums on the rear and kept the wets on the front, this helped a lot.

by this point i was driving round the clutch and brake issues. the rest of the day was more or less uneventful , we kept it steady a tightened the shafts each service. on long right handers the car was filling with smoke as the rear arch rubbed the tyre so had to take it easy to avoid a blowout.

we finished the event at 6pm saturday 26th overall. Much to our surprise only 36 cars finished!

Overall very happy. considering the lack of testing and the fact this isnt an easy event at all we were over the moon.

plenty I want to change on the car over the winter but nothing fundamental. first thing will be having the rear wing repaired and a nice rest from working on the car for a couple of months!

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

-

rix313

- E30 Zone Team Member

- Posts: 4947

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

It's a hell of an event the Jersey Rally! I'm a bit disappointed I didn't get to go last year. I worked for a team who ran one of the Aston Vantage Rally GT cars a couple of years ago and were there last year with a Mk2 Escort that was Focus RS Green. It was a bit '  ' but it was cool.

' but it was cool.

' but it was cool.

' but it was cool.- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

Been a while side I updated this - didn't do anything with the car after the Jersey rally, I knew there was a list of things that really needed sorting so sort of buried my ahead in the sand for a bit. Couple of weeks ago decided it was time to crack on with it.

First thing was to pull the motor out. stripped off the heavy wiring loom as will be going standalone at last.

The motor has done 100k and was used for track days including nurburgring trips originally, so knew it was time for a freshen up. Whipped off the rod caps, nothing too nasty but the shells are all worn. Have ordered a set of fresh ACL bearings and got some arp rod bolts to go in. Interstigly enough these look to be a much darker colour then all the shells I've seen before?

Decided to sack off the heavy crossmember which allows the use of a rear loading sump. This meant i had to make up another crossmember.

After the mechanical steering pump failed i fitted a Merc A- class electrohydraulic pump. it was fine at normal speeds but struggled through and with fast movements of the wheel chicanes. did some research and its due to BMW's running lower flow an higher pressure than most cars. Apparently new mini pumps have an adjuster so that you can turn the pressure up, after consideration i decided it was time to ditch it all and fit some vauxhaul tat

With this there was no need for the z3 rack, so that was sold and replaced with a z4 rack, which is light because its manual, cheap and also 2.7 turns lock to lock.

Fitted in the car - the z4 steering shaft is good because its telescopic and fits straight onto the bottom of the corsa column. I also noticed after id pulled the motor out that the engine mount tabs had pulled and deformed where they were mounted to the front chassis rails. they had moved so much so that the engine was rubbing on the bulkhead. I think this came about from a combination of running very hard bushes on the gearbox and engine mounts, swell as the short tabs simply not being strong enough to hold the heavy engine!

made up some new ones - if these move then i won't be happy! will have to make some brackets for the front arb now that in needs to be at the back of the crossmember.

Also had some rings machined so that I can run a top bolting top mount, this should help with remote canister inserts and easy changing of springs. it also give more travel.

i had issues with the front discs getting very hot, the standard 3.0 m3 discs weigh a ton too. I ordered some universal bells and had them machined to suit the hubs. the new set up is much lighter and apse 32mm wide - i had to take the callipers apart, make a 4mm spacer swell as a new crossover pipe.

Thats it for now - also fitting a skeleton flywheel and a twin plate clutch to help it rev and relieve some of the stress on the box. I knew the prop doughnut had died during the jersey rally but also found that the prop centre bearing carrier has fallen apart too, will have to make something beefier I think.

First thing was to pull the motor out. stripped off the heavy wiring loom as will be going standalone at last.

The motor has done 100k and was used for track days including nurburgring trips originally, so knew it was time for a freshen up. Whipped off the rod caps, nothing too nasty but the shells are all worn. Have ordered a set of fresh ACL bearings and got some arp rod bolts to go in. Interstigly enough these look to be a much darker colour then all the shells I've seen before?

Decided to sack off the heavy crossmember which allows the use of a rear loading sump. This meant i had to make up another crossmember.

After the mechanical steering pump failed i fitted a Merc A- class electrohydraulic pump. it was fine at normal speeds but struggled through and with fast movements of the wheel chicanes. did some research and its due to BMW's running lower flow an higher pressure than most cars. Apparently new mini pumps have an adjuster so that you can turn the pressure up, after consideration i decided it was time to ditch it all and fit some vauxhaul tat

With this there was no need for the z3 rack, so that was sold and replaced with a z4 rack, which is light because its manual, cheap and also 2.7 turns lock to lock.

Fitted in the car - the z4 steering shaft is good because its telescopic and fits straight onto the bottom of the corsa column. I also noticed after id pulled the motor out that the engine mount tabs had pulled and deformed where they were mounted to the front chassis rails. they had moved so much so that the engine was rubbing on the bulkhead. I think this came about from a combination of running very hard bushes on the gearbox and engine mounts, swell as the short tabs simply not being strong enough to hold the heavy engine!

made up some new ones - if these move then i won't be happy! will have to make some brackets for the front arb now that in needs to be at the back of the crossmember.

Also had some rings machined so that I can run a top bolting top mount, this should help with remote canister inserts and easy changing of springs. it also give more travel.

i had issues with the front discs getting very hot, the standard 3.0 m3 discs weigh a ton too. I ordered some universal bells and had them machined to suit the hubs. the new set up is much lighter and apse 32mm wide - i had to take the callipers apart, make a 4mm spacer swell as a new crossover pipe.

Thats it for now - also fitting a skeleton flywheel and a twin plate clutch to help it rev and relieve some of the stress on the box. I knew the prop doughnut had died during the jersey rally but also found that the prop centre bearing carrier has fallen apart too, will have to make something beefier I think.