My 320ise S62.

Moderator: martauto

- GermanGorilla

- E30 Zone Regular

- Posts: 528

- Joined: Mon Feb 07, 2005 11:00 pm

Hi,

The ''Luk'' pattern 850 Manual Clutch

use to be available via GSF at approx

225/250 at Trade.

As its thew same Clutch in the 850 Csi

then it will hold all you require and the

sprung disc will assist with Gearbox Chatter.

BMW S62 Shells are approx 90/95.00 from

the dealer and much the same from the

Factors.

But be careful as there are ''Blue'' and ''Red''

versions.

The last set i purchased were all blue, yet some

maintain that its Blue for the lower and Red upper.

Others attain that its Red for Warmer climates and

Blue for colder.

Bit of a strange one.

std S62 Bearings will go very quickly once you start

regualy creeping past 7250 rpm and extended

periods or prolonged stints at 7500 rpm

they can be gone very quickly indeed.

Even the coated Race versions are prone to wear

rapidly when 7500 is used as the Rev cut.

Have you tried moving the car in revearse and

then with car costing rearwards select first and

let out clutch, if its a Big end you will hear it then

ok.

If its Shells are you going ''engine'' out or attempt

while engine in ?

Persoanlly I would have the engine out and

clean eveything as if the shells are gone then

you will have oil contamination which is very

hard to clean properly in situ.

Its all the oil lines, cooler, oit filtre housing that

will have dopsits of the ''white metal filings''

which require proper cleaning.

On the positive side better now like this, than at full

chat on some Track !!!!

Regards,

The Gorilla

The ''Luk'' pattern 850 Manual Clutch

use to be available via GSF at approx

225/250 at Trade.

As its thew same Clutch in the 850 Csi

then it will hold all you require and the

sprung disc will assist with Gearbox Chatter.

BMW S62 Shells are approx 90/95.00 from

the dealer and much the same from the

Factors.

But be careful as there are ''Blue'' and ''Red''

versions.

The last set i purchased were all blue, yet some

maintain that its Blue for the lower and Red upper.

Others attain that its Red for Warmer climates and

Blue for colder.

Bit of a strange one.

std S62 Bearings will go very quickly once you start

regualy creeping past 7250 rpm and extended

periods or prolonged stints at 7500 rpm

they can be gone very quickly indeed.

Even the coated Race versions are prone to wear

rapidly when 7500 is used as the Rev cut.

Have you tried moving the car in revearse and

then with car costing rearwards select first and

let out clutch, if its a Big end you will hear it then

ok.

If its Shells are you going ''engine'' out or attempt

while engine in ?

Persoanlly I would have the engine out and

clean eveything as if the shells are gone then

you will have oil contamination which is very

hard to clean properly in situ.

Its all the oil lines, cooler, oit filtre housing that

will have dopsits of the ''white metal filings''

which require proper cleaning.

On the positive side better now like this, than at full

chat on some Track !!!!

Regards,

The Gorilla

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Thanks Gorilla. I reckon I'm pretty set on a Luk 850 clutch with suitable custom single mass flywheel.

Retail, shells come out at £19.10 each, rod bolts are £8.35 a piece. With sump gaskets, oil filter etc the parts bill is £500 and a bit, plus oil. I've read lower = blue shells, upper = red. Interesting though! I'll look into that further.

I reckon now would be a good (if a little frustrating) time to do the shells even if they're not shot. I could see the job being put off until the end of summer if the car's up and running, which could potentially be a crankshaft too far into the future!

As you say, better to be replacing shells than an engine! I'll crack on and get them done in the next couple of weeks, then they'll be done.

As you say, better to be replacing shells than an engine! I'll crack on and get them done in the next couple of weeks, then they'll be done.  I'm not convinced there'll be enough clearance to hear the end knock with your reverse-1st gear trick TBH, but I'll give it a try!

I'm not convinced there'll be enough clearance to hear the end knock with your reverse-1st gear trick TBH, but I'll give it a try!  I read a thread on one of the M5 forums the other day with pretty much identical symptoms (the owner was also convinced it was det). It was big ends.

I read a thread on one of the M5 forums the other day with pretty much identical symptoms (the owner was also convinced it was det). It was big ends.

I was set on doing the job without having the engine out again TBH. I'm short of garage space at the moment, and would prefer to use an engine stand, which I've not got. If the shells (I'll have a quid on it just being one which is a problem) are missing a lot of material, I'll not have a lot of choice but to take it out and give it a thorough clean. I *think* I'll suck it and see.

Cheers! Dave.

Retail, shells come out at £19.10 each, rod bolts are £8.35 a piece. With sump gaskets, oil filter etc the parts bill is £500 and a bit, plus oil. I've read lower = blue shells, upper = red. Interesting though! I'll look into that further.

I reckon now would be a good (if a little frustrating) time to do the shells even if they're not shot. I could see the job being put off until the end of summer if the car's up and running, which could potentially be a crankshaft too far into the future!

I was set on doing the job without having the engine out again TBH. I'm short of garage space at the moment, and would prefer to use an engine stand, which I've not got. If the shells (I'll have a quid on it just being one which is a problem) are missing a lot of material, I'll not have a lot of choice but to take it out and give it a thorough clean. I *think* I'll suck it and see.

Cheers! Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

So, a quick up-date..

The sump is off, and the big ends have been examined.

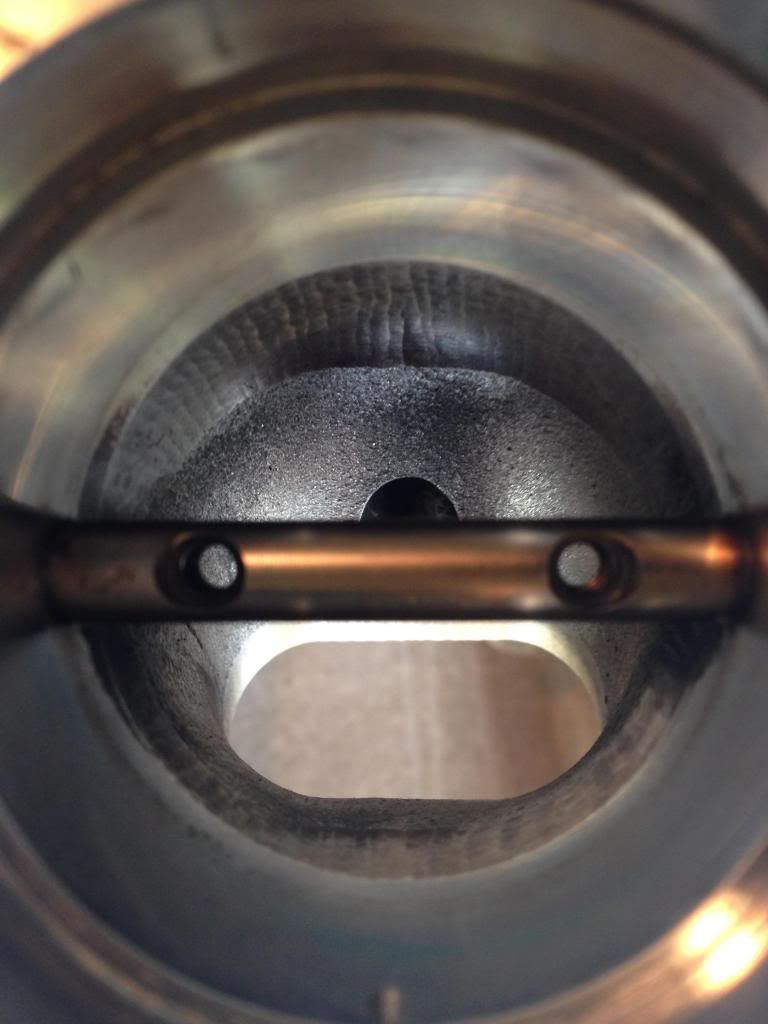

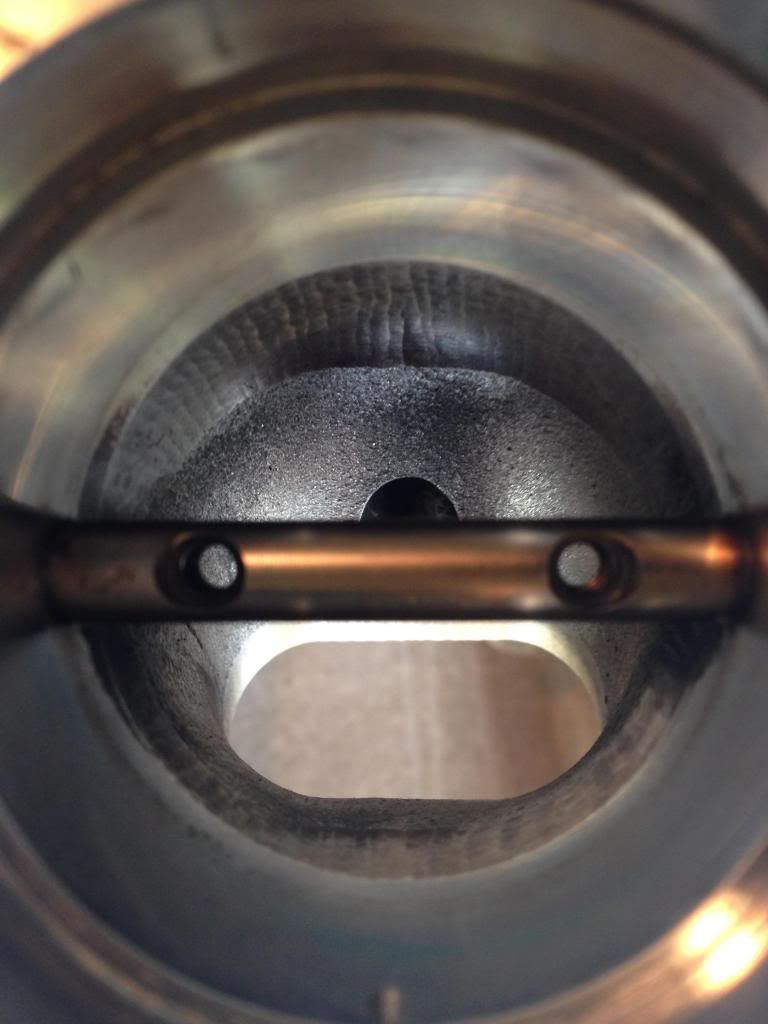

I've found where the noise was coming from. It's a bit of a weird one. All the bearing surfaces are in pretty decent condition, and the crank journals are completely unmarked. Here's one of the worst:

It's a bit of a weird one. All the bearing surfaces are in pretty decent condition, and the crank journals are completely unmarked. Here's one of the worst:

Strangely, although the bearing surface of the shells are in good condition, three have spun properly. One has spun around 4mm. This is what I was greeted with when I removed number 7 end cap (this is the outside of the spun bearing):

And number 7 cap:

Number 3 cap and shell:

It seems a bit odd that there are no signs of friction on the bearings to explain them spinning.

More later. I need a beer!

Cheers. Dave.

The sump is off, and the big ends have been examined.

I've found where the noise was coming from.

Strangely, although the bearing surface of the shells are in good condition, three have spun properly. One has spun around 4mm. This is what I was greeted with when I removed number 7 end cap (this is the outside of the spun bearing):

And number 7 cap:

Number 3 cap and shell:

It seems a bit odd that there are no signs of friction on the bearings to explain them spinning.

More later. I need a beer!

Cheers. Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Well well... In preperation for bolting it all back together with the new big end shells, O-rings and wot not which I ordered, I had a dull day yesterday cleaning stuff.

Sump:

scavenge pipes (which the solenoid valves in the sides of the sump control) re-installed:

Baffle plates re-installed:

There's a couple of oil pipes which protrude upwards from the sump into the block, the smaller of which (as it says in BMW's literature) is easily bent as the sump's removed (pictured on the left below). There was always going to be one part which had to come from Germany. This was it. Luckily, it straightened pretty easily.

So a box of parts arrived this morning including two bags of shells. I went with the blue/red combination which is listed on real OEM and TIS in the end. At a glance, the only difference between the two is that the part numbers are on opposite ends of the shells. The size listing appears to be the same.

Unfortunately, whoever packed the two bags appears to have a problem with counting beyond five, as there are only 6 shells in one of the bags. Luckily, I can get one shell for tomorrow morning. Not so luckily, the remaining shell won't get with me 'till Tuesday. Which is total arse.

Luckily, I can get one shell for tomorrow morning. Not so luckily, the remaining shell won't get with me 'till Tuesday. Which is total arse.

On the up-side, I've got a mate's 40th to go and get smashed at tomorrow, so I can happily write off Sunday watching World Superbikes with an enormous hangover.

Cheers. Dave.

Sump:

scavenge pipes (which the solenoid valves in the sides of the sump control) re-installed:

Baffle plates re-installed:

There's a couple of oil pipes which protrude upwards from the sump into the block, the smaller of which (as it says in BMW's literature) is easily bent as the sump's removed (pictured on the left below). There was always going to be one part which had to come from Germany. This was it. Luckily, it straightened pretty easily.

So a box of parts arrived this morning including two bags of shells. I went with the blue/red combination which is listed on real OEM and TIS in the end. At a glance, the only difference between the two is that the part numbers are on opposite ends of the shells. The size listing appears to be the same.

Unfortunately, whoever packed the two bags appears to have a problem with counting beyond five, as there are only 6 shells in one of the bags.

On the up-side, I've got a mate's 40th to go and get smashed at tomorrow, so I can happily write off Sunday watching World Superbikes with an enormous hangover.

Cheers. Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers flashBE!

Well well. This is what's in the boot of my car.

A box full of this:

And these empty boxes and gaskets:

If I'm honest, I couldn't be arsed to take pictures of the big ends going in, but they're in, along with various O-rings and a new oil pump drive tensioner.

So, has the knock gone? Has it f**k.

On the upside..... Nothing.

(Although the shells had spun, so as said, it could well have gone very pear shaped at some point.)

I guess I'll be having a proper look at the vanos next.

Can anyone reccommend a cheap boroscope which'll fit down my plug holes?

Cheers. D.

Well well. This is what's in the boot of my car.

A box full of this:

And these empty boxes and gaskets:

If I'm honest, I couldn't be arsed to take pictures of the big ends going in, but they're in, along with various O-rings and a new oil pump drive tensioner.

So, has the knock gone? Has it f**k.

On the upside..... Nothing.

(Although the shells had spun, so as said, it could well have gone very pear shaped at some point.)

I guess I'll be having a proper look at the vanos next.

Can anyone reccommend a cheap boroscope which'll fit down my plug holes?

Cheers. D.

Dave a cheap borescope will be no good, if you want to get a proper look inside your engine a karlsrorz scope with light source will do the trick iv'e used one with a 6mm camera ( they do come smaller too)straight down a spark plug hole, 360 deg control really good light and a medical quality picture. Google Inlec hire,they cost £250 per week but they will do a 3 day hire for £150, they courier to your door and collect after. Its not cheap but your hiring a 6k bit of kit. If your interested i have some video clips of a chp engine i look after ( we had to video inside the engine and send the vid clips abroad) using a karlstorz scope, let us know. Cheers

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers Ajay. I was looking at the cheap boroscopes thinking that they wouldn't be much cop. I'll have a think about hiring one versus the price of parts I'd need to tear the engine down if it comes to it.

It feels like my car's slowly reaming my anus at the moment. If it gets much worse I'll probably be finding the need for a second use for it!

Cheers.

It feels like my car's slowly reaming my anus at the moment. If it gets much worse I'll probably be finding the need for a second use for it!

Cheers.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

I've got to say, it's not exactly what I'd hoped for Rav!

-

DanThe

- E30 Zone Team Member

- Posts: 28641

- Joined: Sat Sep 10, 2005 11:00 pm

- Location: Staffs

- Contact:

Where was the microphone? Sounds more like a loose engine mount than anything to do with the crankdavethegoat wrote:I got a (not especially good) recording of the noise today.

Any informed suggestions welcomed! :

I had suggested it sounded like the self adjusting clutch springs clicking about when I first heard it. But as it only happens under light throttle.

Do u have a mic you can position in the engine bay? Also, might be worth chatting to you local rolling road guys to see if they'll let you run the car gently on the rollers while you have a good ol listen!

Do u have a mic you can position in the engine bay? Also, might be worth chatting to you local rolling road guys to see if they'll let you run the car gently on the rollers while you have a good ol listen!

S54, S62, S65 & S85 Plug & Play loom/Ecu Kits

Sump Baffles

Engine Conversion Kits/Parts

TrackDays

Sump Baffles

Engine Conversion Kits/Parts

TrackDays

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Hi Dan,

I checked the engine mounts, bell hosing bolts etc today, hoping I'd left something/something had become loose. No dice. That would have been brilliant though!

That would have been brilliant though!  The mike (iPhone) was taped to the ash tray lid in front of the gear stick in the first clip.

The mike (iPhone) was taped to the ash tray lid in front of the gear stick in the first clip.

I then taped the "mike" in the engine bay, on the nearside inner arch. There wasn't a ton of difference, but if anything the noise was a touch quieter, though perhaps being masked by more engine noise.

Then, I taped it at the rear of the engine bay where the battery used to live, at the rear of the engine bay. As I reversed down my driveway, I heard a bit of noise as I slipped the clutch, so I took the drive train slack out a few times (at around 46 seconds on the following clip). I did the same when I did a three point turn (at around 1 minute 40).

As well as the noise sounding familiar, it was also louder with the mike in this position:

So, now I have the gearbox sitting on my workbench. The Dual mass flywheel has somewhere around 10mm of free play ("measured" at the outermost part of the flywheel). I believe this is about right? It also takes almost no effort to move through that 10mm though, and makes a metallic noise at the end of its travel, which I believe to be less right??! (I have litterally zero expierience with dual mass flywheels!)

As I said, the gearbox is sitting on my workbench. I drained the oil from it, which with the exception of maybe a dozen tiny (I'm talking half a mm or less) metal fragments, seemed fine, though thin and smelly!

I guess while the 'box is out, I might as well have a peek inside to check that nothing's amiss. What do you reckon?!

Cheers Turk. I thought about a dyno, but didn't really want to drive it too far. I also thought about getting someone at the controls trying to replicate the noise by giving it some brake pressure with the car running on axle stands. Unfortunately the gearbox was half way out by then!

Cheers! Dave.

I checked the engine mounts, bell hosing bolts etc today, hoping I'd left something/something had become loose. No dice.

I then taped the "mike" in the engine bay, on the nearside inner arch. There wasn't a ton of difference, but if anything the noise was a touch quieter, though perhaps being masked by more engine noise.

Then, I taped it at the rear of the engine bay where the battery used to live, at the rear of the engine bay. As I reversed down my driveway, I heard a bit of noise as I slipped the clutch, so I took the drive train slack out a few times (at around 46 seconds on the following clip). I did the same when I did a three point turn (at around 1 minute 40).

As well as the noise sounding familiar, it was also louder with the mike in this position:

So, now I have the gearbox sitting on my workbench. The Dual mass flywheel has somewhere around 10mm of free play ("measured" at the outermost part of the flywheel). I believe this is about right? It also takes almost no effort to move through that 10mm though, and makes a metallic noise at the end of its travel, which I believe to be less right??! (I have litterally zero expierience with dual mass flywheels!)

As I said, the gearbox is sitting on my workbench. I drained the oil from it, which with the exception of maybe a dozen tiny (I'm talking half a mm or less) metal fragments, seemed fine, though thin and smelly!

I guess while the 'box is out, I might as well have a peek inside to check that nothing's amiss. What do you reckon?!

Cheers Turk. I thought about a dyno, but didn't really want to drive it too far. I also thought about getting someone at the controls trying to replicate the noise by giving it some brake pressure with the car running on axle stands. Unfortunately the gearbox was half way out by then!

Cheers! Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

So, after looking at clutch/flywheel options for ages I decided to take the (so I thought) easy/quickest option of a standard sized clutch and "off the shelf" single mass flywheel. The flywheel I ordered was in stock, so would be with me within a week. A Helix sprung hub clutch would have taken a few weeks to get manufactured, so I ordered a Clutchmasters FX250 clutch from the U.S, a bad review of which I'm yet to come accross.

http://clutchmasters.com/shop/?page=sho ... AppID=1816

So that was that sorted. Except it wasn't. I was informed near the end of the week that the flywheel was in fact not in stock, and would take around 3 weeks to be made. FFS! Give me a break!

I've got a few other boring bits and pieces to get on with in the mean time at least.

Cheers. Dave.

http://clutchmasters.com/shop/?page=sho ... AppID=1816

So that was that sorted. Except it wasn't. I was informed near the end of the week that the flywheel was in fact not in stock, and would take around 3 weeks to be made. FFS! Give me a break!

I've got a few other boring bits and pieces to get on with in the mean time at least.

Cheers. Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Well well. It turned out that the flywheel was in stock after all!  It's made by TTV, came via Co-Ordsport (who have been really good to deal with) and is nice!:

It's made by TTV, came via Co-Ordsport (who have been really good to deal with) and is nice!:

Here's the back side of it. It weighs 7kg, compared to the stock dual mass' 15kg:

Also, this arrived:

Here's another backside shot. :

:

It's a bit of a funny old design, but they apparently give good modulation, last well and don't slip. Ding dong.

Here's the pressure plate:

I got hold of these too. They're hanging out with a clutch aligning tool which came along for the ride with the clutch from the States. There was also a clutch release bearing which evidently, was camera shy:

Seeing as I'd drained the gearbox oil, I got some of this (not awefully cheap) Royal Purple Synchromax. It's meant to be the dog's doo dahs.

I grabbed enough time today to get the gearbox bolted up. It might even be running again somewhere into the weekend.

Cheers. Dave.

Here's the back side of it. It weighs 7kg, compared to the stock dual mass' 15kg:

Also, this arrived:

Here's another backside shot.

It's a bit of a funny old design, but they apparently give good modulation, last well and don't slip. Ding dong.

Here's the pressure plate:

I got hold of these too. They're hanging out with a clutch aligning tool which came along for the ride with the clutch from the States. There was also a clutch release bearing which evidently, was camera shy:

Seeing as I'd drained the gearbox oil, I got some of this (not awefully cheap) Royal Purple Synchromax. It's meant to be the dog's doo dahs.

I grabbed enough time today to get the gearbox bolted up. It might even be running again somewhere into the weekend.

Cheers. Dave.

Last edited by davethegoat on Thu Jul 11, 2013 10:09 pm, edited 1 time in total.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Ha! I thought I'd put them in there. Duh. It must be the heat!  I'll pop them in above in a tick..

I'll pop them in above in a tick..

I didn't get any pics of the pressure plate face, but there's nothing particularly trick looking in there.

I didn't get any pics of the pressure plate face, but there's nothing particularly trick looking in there.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Seeing as it's been ages since I updated this, I thought I would, erm, update.

Rav, yep, the TTV flywheels are nice! It's worth shopping around for them though. I could have paid an extra £120 at least for mine. So, where was I... Ah yes. I fitted the flywheel and clutch, re-fitted the 'box, fired it up, drove it up the road, and......... you'll never guess! Yeah baby! Noise still there!

I posted on one of the M5 forums and got a few helpful suggestions, checked a few things, then (as a couple of peeps had suggested it could be a gearbox bearing), whipped the 'box out again and made it look like this:

There was nothing obviously wrong, so after getting a gearbox specialist to have a look "Uh, yeah, maybe, dunno", I popped it back together. It was all pretty straightforward, though there are a couple of bits and pieces to watch out for which I'll go into later if anyone's interested.

I'd noticed a touch of wear on the input shaft before, but have seen worse running with no ill effects. Anyway, I decided to space the pilot bearing back onto a fresh bit of shaft ( ) as I thought there was a (tiny) chance the free play could be setting off some sort of resonance and cause this to happen (but a bit faster, obviously!):

) as I thought there was a (tiny) chance the free play could be setting off some sort of resonance and cause this to happen (but a bit faster, obviously!):

so I made this, which goes in the 'ole before the bearing:

Anyway, in the 'box went in again. And. The. Noise. Was. Still. There. Not a big surprise, as I'd not really found much.

Anywho, the way I've been describing the noise is that if it was in ye olden days on a straightforwarde engine, I would have been sure it was det, so I did what I should have done in the first place, pulled a coil plug off and drove it. When number 5 is pulled, there's no rattle. I swapped number 5 coil, plug and injector and the rattle was still on number 5. So, I have a problem with number 5 cylinder!

I've read a couple of proper horror stories as far as piston/cylinder wall damage, but I'm rather hoping the block's not goosed. Having run it with the breather pipes straight to atmosphere, it doesn't appear to be a heavy breather at least. I did find a loose throttle body nut when swapping injectors and wot not the other day. Some monkey's been there before, but it would appear to have been a good while ago.

I'll update this when I know more, but in the mean time, I have a box in the boot which looks like this:

and an engine which looks like this:

Cheers. D.

Rav, yep, the TTV flywheels are nice! It's worth shopping around for them though. I could have paid an extra £120 at least for mine. So, where was I... Ah yes. I fitted the flywheel and clutch, re-fitted the 'box, fired it up, drove it up the road, and......... you'll never guess! Yeah baby! Noise still there!

I posted on one of the M5 forums and got a few helpful suggestions, checked a few things, then (as a couple of peeps had suggested it could be a gearbox bearing), whipped the 'box out again and made it look like this:

There was nothing obviously wrong, so after getting a gearbox specialist to have a look "Uh, yeah, maybe, dunno", I popped it back together. It was all pretty straightforward, though there are a couple of bits and pieces to watch out for which I'll go into later if anyone's interested.

I'd noticed a touch of wear on the input shaft before, but have seen worse running with no ill effects. Anyway, I decided to space the pilot bearing back onto a fresh bit of shaft (

so I made this, which goes in the 'ole before the bearing:

Anyway, in the 'box went in again. And. The. Noise. Was. Still. There. Not a big surprise, as I'd not really found much.

Anywho, the way I've been describing the noise is that if it was in ye olden days on a straightforwarde engine, I would have been sure it was det, so I did what I should have done in the first place, pulled a coil plug off and drove it. When number 5 is pulled, there's no rattle. I swapped number 5 coil, plug and injector and the rattle was still on number 5. So, I have a problem with number 5 cylinder!

I've read a couple of proper horror stories as far as piston/cylinder wall damage, but I'm rather hoping the block's not goosed. Having run it with the breather pipes straight to atmosphere, it doesn't appear to be a heavy breather at least. I did find a loose throttle body nut when swapping injectors and wot not the other day. Some monkey's been there before, but it would appear to have been a good while ago.

I'll update this when I know more, but in the mean time, I have a box in the boot which looks like this:

and an engine which looks like this:

Cheers. D.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers Will. I elected to steam in there and remove the head.

For a minute, it looked like this:

As I said, I've read a few horror stories of epic disaster, and was fearing the worst. Was this the kind of thing you were thinking of Will?:

Quite handily, although that's an S62 piston, it isn't from my engine!

What I found was a little bit.. ok, a whole lot less dramatic.

Here ya go:

Yipee!

The head gasket has failed between cylinders 5 & 6, and has just started to fail between 6 & 7. The head is very slightly marked, so I'll get that lapped. The block is thankfully, as near as fu*k is to swearing, perfect. Bloody phew!

Seeing as the other head has done a very similar amount of work, I popped that off too. The gasket had just started to fail between cylinders 2 & 3. There's a small mark on the block, which I'll spend around four seconds on with some scotchbrite and it'll be sorted:

I suspect this engine's had the inlets walnut blasted at some point:

Now my boot looks like this (I've got some parts cleaning to do)

Here's where the rear seat should be:

And here's my work bench:

So that's where I'm at! A lot happier than I thought I'd be!

Cheers! Dave.

For a minute, it looked like this:

As I said, I've read a few horror stories of epic disaster, and was fearing the worst. Was this the kind of thing you were thinking of Will?:

Quite handily, although that's an S62 piston, it isn't from my engine!

What I found was a little bit.. ok, a whole lot less dramatic.

Here ya go:

Yipee!

The head gasket has failed between cylinders 5 & 6, and has just started to fail between 6 & 7. The head is very slightly marked, so I'll get that lapped. The block is thankfully, as near as fu*k is to swearing, perfect. Bloody phew!

Seeing as the other head has done a very similar amount of work, I popped that off too. The gasket had just started to fail between cylinders 2 & 3. There's a small mark on the block, which I'll spend around four seconds on with some scotchbrite and it'll be sorted:

I suspect this engine's had the inlets walnut blasted at some point:

Now my boot looks like this (I've got some parts cleaning to do)

Here's where the rear seat should be:

And here's my work bench:

So that's where I'm at! A lot happier than I thought I'd be!

Cheers! Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

That's the low compression model then Will?

When I was a diesel fitter, one of our tippers came in with a misfire. No rattles, just misfiring on number 6 (on a straight 6). After a bit of investigation I had the heads off and noticed that number 6 piston was in the wrong place. Turned out that the crank had broken, turned a bit, and locked on the break! New crank, job done!

Here are some more bits:

I've spent a (fair) bit of time making some bits of a big piece of aluminium into a lot of small pieces:

I'll put some more pics up when my "DTG" heads are finished.

Cheers! Dave.

When I was a diesel fitter, one of our tippers came in with a misfire. No rattles, just misfiring on number 6 (on a straight 6). After a bit of investigation I had the heads off and noticed that number 6 piston was in the wrong place. Turned out that the crank had broken, turned a bit, and locked on the break! New crank, job done!

Here are some more bits:

I've spent a (fair) bit of time making some bits of a big piece of aluminium into a lot of small pieces:

I'll put some more pics up when my "DTG" heads are finished.

Cheers! Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

It's been a while. Again!

I finished cleaning up the ports a bit ago. If the engine was going to have forced induction, (or if I was doing them for someone else) I would have done more to the exhaust ports. Being coated in carbon, I wasn't able to get a decent "before" pic, but I was a little surprised at how ugly they come out of the factory. Anyway, after:

I also cleaned these:

Got the head faces lapped:

Ordered some stuff (some of which wasn't here for a photo as it was busy emigrating from Germany):

I also ground the valves in, and now one of the heads is now back together. Woohoo!:

It'll be good to get the buggers bolted back on!

Cheers. Dave.

I finished cleaning up the ports a bit ago. If the engine was going to have forced induction, (or if I was doing them for someone else) I would have done more to the exhaust ports. Being coated in carbon, I wasn't able to get a decent "before" pic, but I was a little surprised at how ugly they come out of the factory. Anyway, after:

I also cleaned these:

Got the head faces lapped:

Ordered some stuff (some of which wasn't here for a photo as it was busy emigrating from Germany):

I also ground the valves in, and now one of the heads is now back together. Woohoo!:

It'll be good to get the buggers bolted back on!

Cheers. Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers Turk.

I got the second head finished today. It looks pretty similar to the other head, so I didn't bother taking a photo.

It looks pretty similar to the other head, so I didn't bother taking a photo.

I also popped the oil pump apart. I like the elegantly simple design of oil pumps. They're cool. I'd just started putting it back together and realised that I hadn't taken a pic, so I took an especially cr@p one!

I'd just started putting it back together and realised that I hadn't taken a pic, so I took an especially cr@p one!  :

:

It's back together now. Cheers.

I got the second head finished today.

I also popped the oil pump apart. I like the elegantly simple design of oil pumps. They're cool.

It's back together now. Cheers.

I have a spare pump if u need any 'spares' for any reason. look quite tidy tho  Hows the shaft? they're know to shear.

Hows the shaft? they're know to shear.

S54, S62, S65 & S85 Plug & Play loom/Ecu Kits

Sump Baffles

Engine Conversion Kits/Parts

TrackDays

Sump Baffles

Engine Conversion Kits/Parts

TrackDays

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

It all looks fine in there matey. I'm guessing the shafts break just behind the drive sprocket retaining nut. There's a decent stress raiser there for overtightened nuts/siezed pumps! Mine, right now, is unbroken....

Cheers.

Cheers.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Well then. I've got a bit more done.

I did a bit of this:

Then I had a bit of a think and sorted the cam timing. BMW's instructions make it seem like building a space ship and flying to Jupiter would be an easier option, but in fact, it's really not as complex as it first appears. (I'm saying this before I've fired it up.... Duh!! )

)

So, TDC on number one cylinder. Cams locked (with the stainless cap screws poking out of the front cam caps). Turn vanos wheels clockwise. Pop vanos cover on. Tighten vanos wheel bolts. That's it! timed up! (Ok, I've simplified it a little. ):

):

More soon! Cheers!

I did a bit of this:

Then I had a bit of a think and sorted the cam timing. BMW's instructions make it seem like building a space ship and flying to Jupiter would be an easier option, but in fact, it's really not as complex as it first appears. (I'm saying this before I've fired it up.... Duh!!

So, TDC on number one cylinder. Cams locked (with the stainless cap screws poking out of the front cam caps). Turn vanos wheels clockwise. Pop vanos cover on. Tighten vanos wheel bolts. That's it! timed up! (Ok, I've simplified it a little.

More soon! Cheers!

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

It's getting closer to fire it up time! I seem to be doing my best to hold things up though.  I cleaned the throttle bodies ready to fit and found that they looked like this (the photo of which I've had a couple of different go's at rotating and given up):

I cleaned the throttle bodies ready to fit and found that they looked like this (the photo of which I've had a couple of different go's at rotating and given up):

In similar style to the inlet ports, they've had some attention in the most important places, but as you can see, there's a pretty substantial ridge where the machining stops and the plain casting starts, as well as a couple of smaller ridges.

I planned to pop the butterflies out (which were minging), give them and the bodies a clean, and bolt them on. After an argument with myself though, a bit more than cleaning happened. Now they look like this:

Now they're back together, nice and clean.

The bottom of the engine's back together, I played swordfights with the headers and re-fitted them, fitted the steering shaft (managing to get my hand fairly firmly stuck between two headers) and the crossmember/steering rack and control arms are back where they should be. Smart!

Cheers. D.

In similar style to the inlet ports, they've had some attention in the most important places, but as you can see, there's a pretty substantial ridge where the machining stops and the plain casting starts, as well as a couple of smaller ridges.

I planned to pop the butterflies out (which were minging), give them and the bodies a clean, and bolt them on. After an argument with myself though, a bit more than cleaning happened. Now they look like this:

Now they're back together, nice and clean.

The bottom of the engine's back together, I played swordfights with the headers and re-fitted them, fitted the steering shaft (managing to get my hand fairly firmly stuck between two headers) and the crossmember/steering rack and control arms are back where they should be. Smart!

Cheers. D.