The head had been worked on, but the customer wanted a little improvement while it was apart. The course of action was some nice 3 angle valve seats and back cut valves as the stock valve cuts are a little agricultural, then a quick go over with the soda blaster to get rid of the carbon build up.

Chambers as I got them, not bad really.

Valves as I got them, again not bad. They had been ground in the old fashioned way with a stick and paste, never as good as two freshly machined surfaces.

Valves got cleaned up and the angles recut, the seating face at 45* and then a back cut at 30* this improves flow. By the way the machine doing the cutting is made by black and decker, and over 40 years old, a time when we where still making a few things to be proud of

The finished valves, given a bit of an extra polish to prevent carbon build up.

Next new seats, cutter pilot installed.

The first cut at 60* is the bottom cut.

Followed by a 30* top cut, then the seat cut, both are on a double sided cutter. The seat cut is at 46* the two faces will bed in together within the first moments of the engine being started.

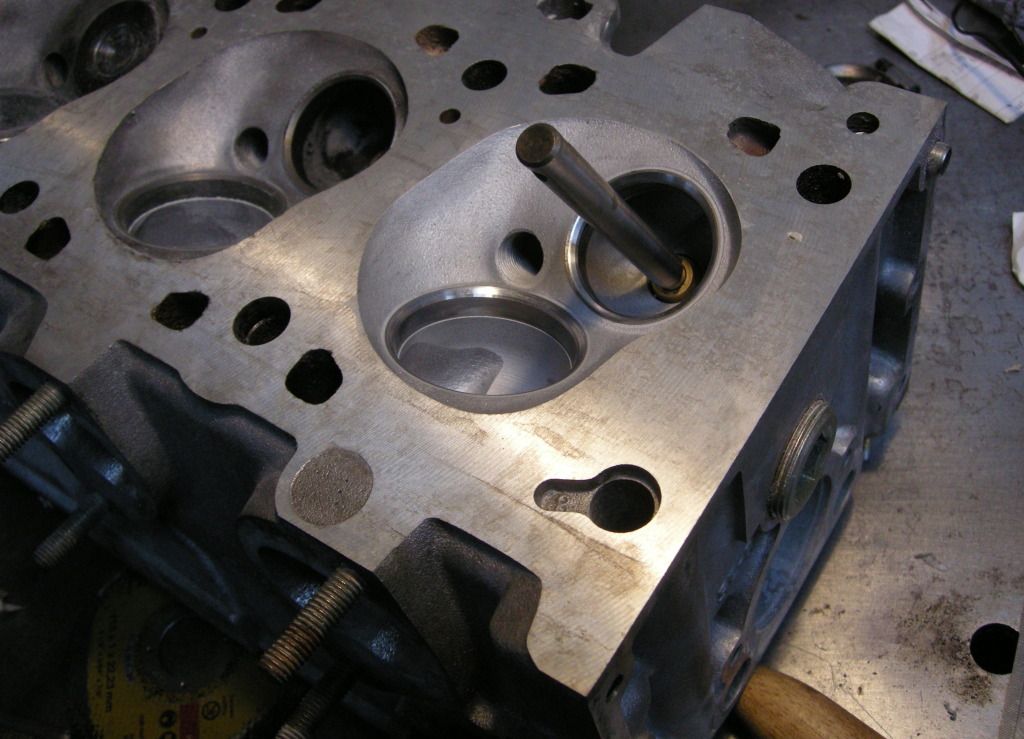

This is what you end up with after it has been soda blasted, and all the cuts finished.

A before and after, not alot of difference really as the head had already been scrubbed, but the soda gives it a nice uniform look and doesn't damage the surface of the alloy.

The real difference will come from the seat, which will no doubt produce an extra 500bhp

There are a few other bits that could have been done to improve flow, but this is the design spec on this one and it will better the head as the seats on the m30 have room for improvment.

I hope you enjoyed you bunch of wrong'uns