Pedal boxes

Moderator: martauto

I'm looking to get an adjustable pedal box for my SR20DET track car and was wondering whether anyone else has done this and might have some useful input on the matter?

I've looked at the two different types of underslung boxes and don't really know which would be the better option - bulkhead fit (cylinders in engine bay) or reverse mount with the cylinders pointing back towards the driver.

I quite like the standard E30 accelerator pedal and was hoping to retain this and just get a brake and clutch pedal box. This is the reverse mount type I was looking at:

http://www.rallydesign.co.uk/popup_imag ... sqd0t1j8e2

This is the bulkhead fit type:

http://www2.obp.uk.net/catalog/images/BCBBCA.gif

http://www.rallydesign.co.uk/images/PEDALC.jpg

I don't mind doing a bit of chopping and fettling with the bulkhead, in reality I just want the easiest option.

I'm also confronted with a choice of pedal ratios, 5:1, 6:1, 6.25:1 and 7:1. I obviously realise that the larger the ratio, the less effort is required, but having never tried any of these ratios I don't know how I'm supposed to make a choice. The Wilwood pedal box is also available with a 5:1 clutch pedal ratio and a 6.25:1 brake ratio. Does anyone know the standard E30 pedal ratio(s)?

Master cylinder sizing. A variety of different size master cylinders are available. This is one of the reasons I quite fancy a pedal box, I've read that the BMW clutch master cylinder couldn't cope with the Nissan conversion so I can spec the clutch master cylinder size to (more or less) the original Nissan size. I also need to decide on the sizing of the two brake master cylinders, presumably you go for a larger front than rear, rather than running equal sizes and then always having the bias bar adjusted to reduce rear braking. What sizes have people used in their track cars? My front brakes are 4 piston jobbies with 35mm (1.38") pistons and the rears are single pot standard E30 M3 calipers which I think are 36mm (1.41") or possibly 40mm (1.57")

Any help on the above would be greatly appreciated.

Theo

I've looked at the two different types of underslung boxes and don't really know which would be the better option - bulkhead fit (cylinders in engine bay) or reverse mount with the cylinders pointing back towards the driver.

I quite like the standard E30 accelerator pedal and was hoping to retain this and just get a brake and clutch pedal box. This is the reverse mount type I was looking at:

http://www.rallydesign.co.uk/popup_imag ... sqd0t1j8e2

This is the bulkhead fit type:

http://www2.obp.uk.net/catalog/images/BCBBCA.gif

http://www.rallydesign.co.uk/images/PEDALC.jpg

I don't mind doing a bit of chopping and fettling with the bulkhead, in reality I just want the easiest option.

I'm also confronted with a choice of pedal ratios, 5:1, 6:1, 6.25:1 and 7:1. I obviously realise that the larger the ratio, the less effort is required, but having never tried any of these ratios I don't know how I'm supposed to make a choice. The Wilwood pedal box is also available with a 5:1 clutch pedal ratio and a 6.25:1 brake ratio. Does anyone know the standard E30 pedal ratio(s)?

Master cylinder sizing. A variety of different size master cylinders are available. This is one of the reasons I quite fancy a pedal box, I've read that the BMW clutch master cylinder couldn't cope with the Nissan conversion so I can spec the clutch master cylinder size to (more or less) the original Nissan size. I also need to decide on the sizing of the two brake master cylinders, presumably you go for a larger front than rear, rather than running equal sizes and then always having the bias bar adjusted to reduce rear braking. What sizes have people used in their track cars? My front brakes are 4 piston jobbies with 35mm (1.38") pistons and the rears are single pot standard E30 M3 calipers which I think are 36mm (1.41") or possibly 40mm (1.57")

Any help on the above would be greatly appreciated.

Theo

Let's give him some helpJhonno wrote:IT IS easy to work out the ratio.. Measure the length from the end of the pedal arm to the pivot and then from the pivot to the end of the lever and there is your ratio..

I am going for 6:1 BTW but all depending on what M/C sizes are going to be used. I made a spread sheet and was working from line pressure backwards to roughly work out what the pedal forces required may be.

Hi TheoTheo325 wrote:I'm looking to get an adjustable pedal box for my SR20DET track car and was wondering whether anyone else has done this and might have some useful input on the matter?

I've looked at the two different types of underslung boxes and don't really know which would be the better option - bulkhead fit (cylinders in engine bay) or reverse mount with the cylinders pointing back towards the driver.

I quite like the standard E30 accelerator pedal and was hoping to retain this and just get a brake and clutch pedal box.

Tilton Engineering (http://www.tiltonracing.com) in the US makes a range of floor mounted, firewall mounted and overhung pedal assemblies. These typically include two brake master cylinders (with balance bar to adjust the front to rear brake bias) and a clutch master cylinder. The pedal ratio is typically 6:1.

The overhung 600 series here is useful if you have limited room inside the engine compartment for the master cylinders, although I suspect that unless the inlet manifold on your SR20DET is in the way you may be able to use the firewall mounted set, see here. I have a firewall mounted set with my 3SGTE engine (similar configuration to SR20) and the master cylinders emerge just below the plenum chamber. The clutch and brake pedal basically straddle the steering column. I would recommend this option to you if you have the room available and can make up some brackets etc to fit the pedal box. Since there is no requirement for a brake servo, finding space for the two brake master cylinders and the clutch cylinder is less of an issue.

BTW, These are both clutch and brake pedal assemblies only, so you get to keep your accelerator pedal as specified.

If, however, your preference is for Wilwood pedals, then of the three you presented above I would recommend this one:

Hope this helps.

Regards

Geoff

I assume your deleting the brake servo? in which case any of the pedal ratios is suitable min you want is 5:1 but agree with above 6:1-6.25:1 is ideal according to your front and rear brake piston sizes using Wilwood's box and keep your E30 go pedal.

Although you can go higher its not just about pedal effort its also about feel too, higher the ratio the longer the pedal travel will feel before you get same amount of braking force and quicker you encounter 'long pedal' situation when the pedal just goes to the floor because you cooked the brake fluid.

With the clutch ratio depends on the cylinders you use with your clutch, high ratio will make a heavy clutch feel lighter and biting point changes with it too more likely to wear out the clutch if biting point to full bite pedal travel is longer than standard. Reduce the ratio it will feel heavier, the biting point higher (more on-off than progressive) but less likely to wear out the clutch as quickly.

I would avoid rear facing cylinders purely because pain to refil and bleed and everything gets slippery right where you don't want it too be slippery. If you boil the brake fluid an it leaks it scoulds quite badly and only situation i would use rear facing ones if forward facing physically will not fit, then in which case i would use remote resoviors in the engine bay.

What brake fluid do you plan to use too?

Note there is no real right or wrong answer its more dependant on personal taste/feel/preference.

Although you can go higher its not just about pedal effort its also about feel too, higher the ratio the longer the pedal travel will feel before you get same amount of braking force and quicker you encounter 'long pedal' situation when the pedal just goes to the floor because you cooked the brake fluid.

With the clutch ratio depends on the cylinders you use with your clutch, high ratio will make a heavy clutch feel lighter and biting point changes with it too more likely to wear out the clutch if biting point to full bite pedal travel is longer than standard. Reduce the ratio it will feel heavier, the biting point higher (more on-off than progressive) but less likely to wear out the clutch as quickly.

I would avoid rear facing cylinders purely because pain to refil and bleed and everything gets slippery right where you don't want it too be slippery. If you boil the brake fluid an it leaks it scoulds quite badly and only situation i would use rear facing ones if forward facing physically will not fit, then in which case i would use remote resoviors in the engine bay.

What brake fluid do you plan to use too?

Note there is no real right or wrong answer its more dependant on personal taste/feel/preference.

Thanks for all the replys, they've certainly clarified matters somewhat.

Geoff, I'm not restricted for space so I think a firewall mounted set is indeed the way forward. I don't have any particular preference on brand, I just found the Wilwood ones after a quick browse and they are fairly inexpensive - £150 + vat. According to Tilton they only have two UK suppliers, I shall contact them and get a price for the pedal box you mentioned.

P.S - your Renault/Toyota/BMW creation is really impressive!

Shakey, I am indeed getting rid of the servo. Previously I'd just moved the servo as far over as possible so as to gain as much clearance as possible from the turbo, this meant I had to use a long linkage rod which would deflect more and increase that nasty feel you get from E30 brakes on a RHD car. It's only recently occured to me that a pedal box would really be a worthwhile addition to the car, and I'm about to strip it to a bare shell to tidy it would make sense to do it now.

I was going to use a decent DOT 4 brake fluid, I was under the influence that a decent DOT 4 regularly changed is good practice.

Thanks again for the posts.

Geoff, I'm not restricted for space so I think a firewall mounted set is indeed the way forward. I don't have any particular preference on brand, I just found the Wilwood ones after a quick browse and they are fairly inexpensive - £150 + vat. According to Tilton they only have two UK suppliers, I shall contact them and get a price for the pedal box you mentioned.

P.S - your Renault/Toyota/BMW creation is really impressive!

Shakey, I am indeed getting rid of the servo. Previously I'd just moved the servo as far over as possible so as to gain as much clearance as possible from the turbo, this meant I had to use a long linkage rod which would deflect more and increase that nasty feel you get from E30 brakes on a RHD car. It's only recently occured to me that a pedal box would really be a worthwhile addition to the car, and I'm about to strip it to a bare shell to tidy it would make sense to do it now.

I was going to use a decent DOT 4 brake fluid, I was under the influence that a decent DOT 4 regularly changed is good practice.

Thanks again for the posts.

Many thanks. You're welcome to some pics of my pedals if they would be of any use to you. Might give you some ideas/tips for your own set - brackets, nuts, bolts etc.Theo325 wrote:P.S - your Renault/Toyota/BMW creation is really impressive!

-

stoneyV6

- E30 Zone Newbie

- Posts: 148

- Joined: Wed May 31, 2006 11:00 pm

- Location: north yorks

- Contact:

Is that right???ShakeyC wrote:Yep Dot4 or Dot4 Plus is the fluid of choice such as ATE Super Blue, Castrol SRF or Motul RBF600. Contrary to common belief Dot5 is actually unsuitable for fast road/racing use.

I have been using AP 5.1

AP Racing Formula DOT 5.1 is non silicone based Suitable for High Performance Road Applications including vehicles fitted with ABS and ESP.

I'd be interested to see some pics if you would be so kind.GeoffBob wrote:Many thanks. You're welcome to some pics of my pedals if they would be of any use to you. Might give you some ideas/tips for your own set - brackets, nuts, bolts etc.Theo325 wrote:P.S - your Renault/Toyota/BMW creation is really impressive!

DOT 5.1 is fine. DOT 5 is crap.stoneyV6 wrote:Is that right???ShakeyC wrote:Yep Dot4 or Dot4 Plus is the fluid of choice such as ATE Super Blue, Castrol SRF or Motul RBF600. Contrary to common belief Dot5 is actually unsuitable for fast road/racing use.

I have been using AP 5.1

AP Racing Formula DOT 5.1 is non silicone based Suitable for High Performance Road Applications including vehicles fitted with ABS and ESP.

AP Dot 5.1 is chemically more similar to Dot4 Plus aka Dot4 Super then Dot5 (note without the .1) The 3 products i listed are the similar chemically so your ok.

AP 5.1, Dot4 Plus or Dot4 Super is fine if you change the fluid on a regular basis 1 yr max intervals, the problem is the chemicals in it degrade very quickly with moisture/water, it drastically lowers its dry and wet boiling points this problem is increased with more pistons in the calipers the more regularly you must change the fluids on a track/fast road car.

Dot5 is seriously bad stuff keep away do not buy!

(picture that bbc advert with kids mixing oil, honey and water together it stays in seperate layers) same thing happens with Dot5 when compressed and heated to 1/4 of the brake fluids boiling point the water violently converts to gas under pressure and hello long brake pedal and armco.

Key is to look for brake fluids dry and wet boiling points even some Dot 3 is way superior than Dot4 Plus or Super. Dry 450 degrees F wet 300 degrees F absolute min boiling points for track car ideally Dry 550 degreesF and Wet 400 degreesF. The Dot rating is based on boiling points and ment to make products, grades and uses clear but it doesnt.

The chemical content is no clear indication on its performance it may say its got glycol ether and borate ester (Dot 4, 4.1, Super, Plus) semi or fully synthetic (Dot5), silcone or not is used as selling points but temperature is much better and easier rating to compare

AP 5.1, Dot4 Plus or Dot4 Super is fine if you change the fluid on a regular basis 1 yr max intervals, the problem is the chemicals in it degrade very quickly with moisture/water, it drastically lowers its dry and wet boiling points this problem is increased with more pistons in the calipers the more regularly you must change the fluids on a track/fast road car.

Dot5 is seriously bad stuff keep away do not buy!

(picture that bbc advert with kids mixing oil, honey and water together it stays in seperate layers) same thing happens with Dot5 when compressed and heated to 1/4 of the brake fluids boiling point the water violently converts to gas under pressure and hello long brake pedal and armco.

Key is to look for brake fluids dry and wet boiling points even some Dot 3 is way superior than Dot4 Plus or Super. Dry 450 degrees F wet 300 degrees F absolute min boiling points for track car ideally Dry 550 degreesF and Wet 400 degreesF. The Dot rating is based on boiling points and ment to make products, grades and uses clear but it doesnt.

The chemical content is no clear indication on its performance it may say its got glycol ether and borate ester (Dot 4, 4.1, Super, Plus) semi or fully synthetic (Dot5), silcone or not is used as selling points but temperature is much better and easier rating to compare

-

stoneyV6

- E30 Zone Newbie

- Posts: 148

- Joined: Wed May 31, 2006 11:00 pm

- Location: north yorks

- Contact:

Thanks for the info chaps,, had me worried for a second there.

I knew to avoid the silicone based fluid so thought the 5.1 a decent option, would be interested to see one of the above pedal boxes fitted as i am thinking of an engine transplant and any extra room would be handy.

plus i could dump the ABS.

I knew to avoid the silicone based fluid so thought the 5.1 a decent option, would be interested to see one of the above pedal boxes fitted as i am thinking of an engine transplant and any extra room would be handy.

plus i could dump the ABS.

Hi Theo,

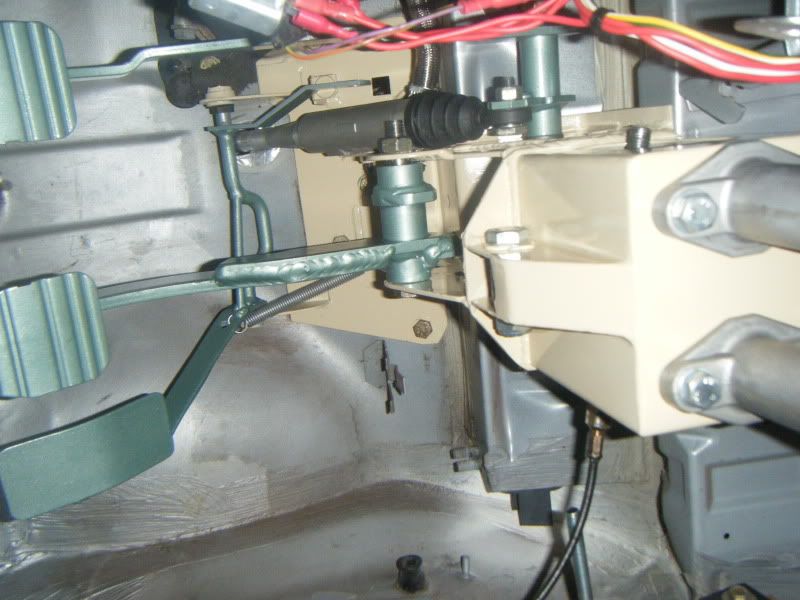

Hope these help. Sorry for flooding your thread with pics. Even though we have very different cars I think you may find these helpful since our inlet manifolds are in a similar position. You'll see that I had to angle the frame/body of the pedal set downwards in order that the master cylinders emerge below the plenum. I think what may also make these pics useful to you is that in some of them the firewall is absent, which makes it that much easier to illustrate the position/mounting of the pedals.

Please keep in mind that these pictures were taken in the very early stages of my build, so please excuse all the rust.

To make my life easier I made up my bracket (visible from the top) and fixed everything in place before I then rebuilt the firewall around the pedals.

This picture most clearly shows the bracket I made to which the frame of the pedals bolt.

This was after I started rebuilding the firewall.

You can mount the fluid bottles directly on top of the master cylinders if you have room, but in my case it was easier for me to mount them remotely. Of course its not a good idea to mount the bottles on the cylinders when they are at an angle

My plenum sits comfortably between the clutch fluid bottle and the two brake bottles.

Viewed from the interior.

I tacked a piece of plate across the top of the steering column to which I attached my clutch and brake switches. My accelerator pedal is my own contrived contraption.

I realise that your own setup will be very different from mine, and in particular you'll have to find your own way to mount your bracket (I also expect that you'll have a lot to move around under you dash) but hopefully these will give a few ideas to help get you started.

Regards

Geoff

Hope these help. Sorry for flooding your thread with pics. Even though we have very different cars I think you may find these helpful since our inlet manifolds are in a similar position. You'll see that I had to angle the frame/body of the pedal set downwards in order that the master cylinders emerge below the plenum. I think what may also make these pics useful to you is that in some of them the firewall is absent, which makes it that much easier to illustrate the position/mounting of the pedals.

Please keep in mind that these pictures were taken in the very early stages of my build, so please excuse all the rust.

To make my life easier I made up my bracket (visible from the top) and fixed everything in place before I then rebuilt the firewall around the pedals.

This picture most clearly shows the bracket I made to which the frame of the pedals bolt.

This was after I started rebuilding the firewall.

You can mount the fluid bottles directly on top of the master cylinders if you have room, but in my case it was easier for me to mount them remotely. Of course its not a good idea to mount the bottles on the cylinders when they are at an angle

My plenum sits comfortably between the clutch fluid bottle and the two brake bottles.

Viewed from the interior.

I tacked a piece of plate across the top of the steering column to which I attached my clutch and brake switches. My accelerator pedal is my own contrived contraption.

I realise that your own setup will be very different from mine, and in particular you'll have to find your own way to mount your bracket (I also expect that you'll have a lot to move around under you dash) but hopefully these will give a few ideas to help get you started.

Regards

Geoff

for the show and shine brigade as it's not corrosive when spilt over airbrushed underbody paintwork.... (probably not the real reason but that's what it's very much used for)mt1104 wrote:what was dot 5 invented for if it fails at 1/4 of its boiling point?

Thanks for all the pics Geoff, I think I've got a fair bit more space to play with compared to you, so it shouldn't be too tricky. I think I'll mount the pedal box to a bracket like you did, determine the position I want it mounted and then modify the bulkhead accordingly.

I see that you used a significantly larger master cylinder for the front brakes, how did you decide on sizing? I was thinking .625 for the rear and .700 for the front - but that really is just a guess plucked out of thin air.

I've found out that the standard Nissan clutch master cylinder is .625, so that makes choosing the clutch M/C size nice and easy.

I see that you used a significantly larger master cylinder for the front brakes, how did you decide on sizing? I was thinking .625 for the rear and .700 for the front - but that really is just a guess plucked out of thin air.

I've found out that the standard Nissan clutch master cylinder is .625, so that makes choosing the clutch M/C size nice and easy.

Its very good brake fluid if you change it on regular basis as proper race cars do on per event basis. As soon as any water gets in there from the atmosphere it drastically lowers its boiling point to 100degrees opposed to 400+degrees. As the water isnt fully absorbed by the synthetic chemicals and these large drops of water when heated vapourises at waters boiling point creating gas pockets in the line which leads to long spongey brake pedal very suddenly without warning which is why not recommended for fast road or track cars.mt1104 wrote:what was dot 5 invented for if it fails at 1/4 of its boiling point?

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

What you need is one of these

<a href="http://s84.photobucket.com/albums/k37/w ... CF5387.jpg" target="_blank"><img src="http://i84.photobucket.com/albums/k37/w ... CF5387.jpg" border="0" alt="Photobucket"></a>

<a href="http://s84.photobucket.com/albums/k37/w ... CF5386.jpg" target="_blank"><img src="http://i84.photobucket.com/albums/k37/w ... CF5386.jpg" border="0" alt="Photobucket"></a>

<a href="http://s84.photobucket.com/albums/k37/w ... CF5385.jpg" target="_blank"><img src="http://i84.photobucket.com/albums/k37/w ... CF5385.jpg" border="0" alt="Photobucket"></a>

<a href="http://s84.photobucket.com/albums/k37/w ... CF5387.jpg" target="_blank"><img src="http://i84.photobucket.com/albums/k37/w ... CF5387.jpg" border="0" alt="Photobucket"></a>

<a href="http://s84.photobucket.com/albums/k37/w ... CF5386.jpg" target="_blank"><img src="http://i84.photobucket.com/albums/k37/w ... CF5386.jpg" border="0" alt="Photobucket"></a>

<a href="http://s84.photobucket.com/albums/k37/w ... CF5385.jpg" target="_blank"><img src="http://i84.photobucket.com/albums/k37/w ... CF5385.jpg" border="0" alt="Photobucket"></a>

- martinpallot

- E30 Zone Regular

- Posts: 352

- Joined: Sat Aug 04, 2007 11:00 pm

- Location: Jersey C.I

Yip. Sounds like the way to do it.Theo325 wrote:I think I'll mount the pedal box to a bracket like you did, determine the position I want it mounted and then modify the bulkhead accordingly.

Yeh, that front M/C is a bit biggerTheo325 wrote:I see that you used a significantly larger master cylinder for the front brakes, how did you decide on sizing? I was thinking .625 for the rear and .700 for the front - but that really is just a guess plucked out of thin air.

The increased pedal ratio (compared to standard) will make the stroke of your clutch pedal a bit longer (EDIT, not shorter) than you are probably used to. If you want to reduce it, like I did, you can choose a larger clutch M/C. At the extreme, it may make your pedal slightly heavier, but I personally prefer a clutch pedal with a short stroke. Your personal preference may however be different.Theo325 wrote:I've found out that the standard Nissan clutch master cylinder is .625, so that makes choosing the clutch M/C size nice and easy.

Thanks ShakeyShakeyC wrote:Geoff that looks very tidy and safe exactly how i do it myself

Last edited by GeoffBob on Wed Jun 17, 2009 9:24 am, edited 1 time in total.

Once again, thanks for the input Geoff. I'd be very interested to see how you worked out what sizes to runGeoffBob wrote:Yeh, that front M/C is a bit bigger . Been a while since I fitted them so I'm afraid I can't remember the sizes out of my head, but I'll have a scratch around through my bits of paper and get back to you. The front one is bigger due to the fact that I have four pot calipers on the front with only the standard single pots on the rear, as well as due to the fact that while braking the COG shifts forwards. I have the details of how I worked it all out if you want?

Just found this link which gives a very detailed run down on master cylinder selection.

http://www.stoptech.com/tech_info/Pedal ... -Guide.pdf

http://www.stoptech.com/tech_info/Pedal ... -Guide.pdf

Hi Theo,

Just edited my last post, was having a daft moment late last night. The increased pedal ratio results in increased (not reduced) clutch pedal travel if you use the stock Nissan clutch M/C with the stock clutch S/C, which is of course why I opted to use a larger clutch M/C with my clutch pedal (to reduce the pedal travel). Sorry about that.

I'll download and have a look at the link you posted during the course of today. Thanks for that.

Just edited my last post, was having a daft moment late last night. The increased pedal ratio results in increased (not reduced) clutch pedal travel if you use the stock Nissan clutch M/C with the stock clutch S/C, which is of course why I opted to use a larger clutch M/C with my clutch pedal (to reduce the pedal travel). Sorry about that.

I'll download and have a look at the link you posted during the course of today. Thanks for that.

Thanks Theo, well worth a read IMO. That's pretty much how I worked out my M/C sizes.Theo325 wrote:Just found this link which gives a very detailed run down on master cylinder selection.

http://www.stoptech.com/tech_info/Pedal ... -Guide.pdf

One comment though, it pays to work out whether your tyres can actually handle the assumed number of G's of deceleration, else you could go through the whole process of working out the required M/C size for say 80lbs of pedal force in order to sustain -1.2G deceleration, and then find out the hard way that your tyres let go at only -1.0G. In my case this situation was made slightly more complicated by the fact that my front tyres (in keeping with the R5turbo design) are smaller than my rear tyres.

Also, have a look at the second paragraph after Figure C on page three. That explains (better than I can) why I fitted a larger M/C on my front brakes.

Good point, I don't want a long clutch pedal. I suppose I should try and match the pedal ratio % change with master cylinder surface area % change?GeoffBob wrote:Hi Theo,

Just edited my last post, was having a daft moment late last night. The increased pedal ratio results in increased (not reduced) clutch pedal travel if you use the stock Nissan clutch M/C with the stock clutch S/C, which is of course why I opted to use a larger clutch M/C with my clutch pedal (to reduce the pedal travel). Sorry about that.

I'll download and have a look at the link you posted during the course of today. Thanks for that.

Are there any issues with using a significantly larger master cylinder in conjunction with the standard slave cylinder? Could it put extra stress on the S/C pivot point or (edited to or, not of) the clutch fork. Do I just need to carefully set the pedal stop position?

The workings and figures listed in the stop tech document along with your remark on the braking potential of the tyres (mine are also different sizes front to rear) is making me think I might be going a bit over the top with this, and should just stick a pair of brake master cylinders on, get the car on track and then go from there based on actual findings rather than just theory.

I'm still very interested to learn more, and your expertise is greatly appreciated.

Last edited by Theo on Wed Jun 17, 2009 6:36 pm, edited 1 time in total.

Exactly as you say, increase the area of the clutch M/C in proportion to the increased clutch pedal ratio. I went one step further and made my clutch cylinder still larger, simply because I prefer a short-stroke clutch. It takes a bit of getting used to, occasionally resulting in a stall, but overall I prefer it. As you say, however, you do need to carefully adjust the pedal-stop. With a larger clutch M/C you can push the release bearing too far if you are not careful, or, if the S/C is particularly small, push the slave piston right out of its cylinder.Theo325 wrote:Good point, I don't want a long clutch pedal. I suppose I should try and match the pedal ratio % change with master cylinder surface area % change?

Are there any issues with using a significantly larger master cylinder in conjunction with the standard slave cylinder? Could it put extra stress on the S/C pivot point of the clutch fork. Do I just need to carefully set the pedal stop position?.

No problem Theo, I understand. I think, exactly as that document says, you can't go wrong with a 3/4" (19mm) M/C with four pot calipers on the front of your car to start out with. If you find that its just too easy to lock your front wheels (ie very little pedal force required to lock up) then you can consider increasing its size. This will decrease the pedal stroke, but you will have to push harder to lock the front wheels.Theo325 wrote:The workings and figures listed in the stop tech document along with your remark on the braking potential of the tyres (mine are also different sizes front to rear) is making me think I might be going a bit over the top with this, and should just stick a pair of brake master cylinders on, get the car on track and then go from there based on actual findings rather than just theory.

I'll check my sizes on the car this evening, but I seem to recall I fitted around a 7/8" (22mm) M/C on my front brakes due, in part, to my cars short wheelbase (short wheelbase cars suffer greater weight transfer from back to front during braking than long wheelbase cars).

The great thing about these pedal sets is you can play with one M/C at a time, which is relatively cheap and easy to do.

Theo,

'Did a quick calculation for you. Let me know if any of the assumed values are incorrect and I'll recalculate.

Assuming your car weighs around 1160kg (stripped out and with the SR20 engine fitted) that equates to around 638kg and 522 kg static weight over the front and rear axles respectively. Braking at 1.25G, this results in roughly 920kg and 240kg dynamic weight over the front and rear axles.

Assuming your wheels have a rolling diameter of 0.58m then you will require 1668Nm of front wheel braking torque and 434Nm of rear wheel breaking torque to sustain a -1.25G braking action. Assuming you have 280mm diameter discs on both the front and rear, with 1x36mm M3 calipers on the rear, and 4x35mm calipers on the front, then you will require a front fluid pressure of 8.37Mpa and rear fluid pressure of 3.95Mpa to hold this brake torque.

With the balance bar centered and with 54kg of pedal force applied to a 6.2:1 ratio brake pedal you will apply 1657N of force to each M/C. You will thus require (roughly) a 5/8" (15.875mm) diameter front M/C and a 7/8" (22.22mm) diameter rear M/C. Any discrepancy in the M/C force (due to the fact that the cylinders are only available in certain sizes) is then worked out with the balance bar. To sustain a -1G braking action will require the recommended 36kg (80lb) pedal force.

Note how in your case the rear cylinders are actually larger than the front. This is not uncommon with front engined cars where, while braking, the majority of the weight is shifted over the front axle. This is why mid and rear engined cars are at such an advantage while braking (that is until they break traction on the rear and the car goes into snap oversteer, like so many 911 owners have found out the hard way).

The above values were calculated assuming the same friction coefficient on both the front and rear brake pads, so if you follow these values, then please make sure you have identical compound pads on the front and back, else it will affect your brake bias! Also, please confirm that your rear calipers have 36mm diameter pistons, as this will have a substantial effect upon the calculated rear MC size if this is not the case.

'Did a quick calculation for you. Let me know if any of the assumed values are incorrect and I'll recalculate.

Assuming your car weighs around 1160kg (stripped out and with the SR20 engine fitted) that equates to around 638kg and 522 kg static weight over the front and rear axles respectively. Braking at 1.25G, this results in roughly 920kg and 240kg dynamic weight over the front and rear axles.

Assuming your wheels have a rolling diameter of 0.58m then you will require 1668Nm of front wheel braking torque and 434Nm of rear wheel breaking torque to sustain a -1.25G braking action. Assuming you have 280mm diameter discs on both the front and rear, with 1x36mm M3 calipers on the rear, and 4x35mm calipers on the front, then you will require a front fluid pressure of 8.37Mpa and rear fluid pressure of 3.95Mpa to hold this brake torque.

With the balance bar centered and with 54kg of pedal force applied to a 6.2:1 ratio brake pedal you will apply 1657N of force to each M/C. You will thus require (roughly) a 5/8" (15.875mm) diameter front M/C and a 7/8" (22.22mm) diameter rear M/C. Any discrepancy in the M/C force (due to the fact that the cylinders are only available in certain sizes) is then worked out with the balance bar. To sustain a -1G braking action will require the recommended 36kg (80lb) pedal force.

Note how in your case the rear cylinders are actually larger than the front. This is not uncommon with front engined cars where, while braking, the majority of the weight is shifted over the front axle. This is why mid and rear engined cars are at such an advantage while braking (that is until they break traction on the rear and the car goes into snap oversteer, like so many 911 owners have found out the hard way).

The above values were calculated assuming the same friction coefficient on both the front and rear brake pads, so if you follow these values, then please make sure you have identical compound pads on the front and back, else it will affect your brake bias! Also, please confirm that your rear calipers have 36mm diameter pistons, as this will have a substantial effect upon the calculated rear MC size if this is not the case.

That is a very interesting post Geoff, thanks for taking time to work that out. I'm quite suprised at the conclusion that the rear needs a significantly larger master cylinder, shows that doing the theory can really help. Had you made those calculations I'd probably have done the opposite!

I think a lot of your assumptions are about right. I couldn't really say what the weight of the car with driver and fuel is, I had hoped it would be a touch lighter than 1160kgs but maybe that was wishful thinking. The PBMW race cars are 1145kg with driver and some fuel. There are some bits I have which are lighter (alloy wishbones, single skin GRP bonnet, alloy engine) and some which add weight (bigger diff, engine ancillaries, passenger seat). I will be very interested to see what it weighs when I have it corner weighted.

Tyre diameter may go down to .576m as I can get 195/50 r888s very cheaply.

I've checked and the M3 rear caliper pistons are indeed 36mm.

If I go for the Wilwood pedal box, which is the more likely, the ratio will be 6.25:1

I do have mismatched front to rear pads at present but will get a set of matching rears. If it's any use, the pads have a friction coefficient of 0.6.

but will get a set of matching rears. If it's any use, the pads have a friction coefficient of 0.6.

I think a lot of your assumptions are about right. I couldn't really say what the weight of the car with driver and fuel is, I had hoped it would be a touch lighter than 1160kgs but maybe that was wishful thinking. The PBMW race cars are 1145kg with driver and some fuel. There are some bits I have which are lighter (alloy wishbones, single skin GRP bonnet, alloy engine) and some which add weight (bigger diff, engine ancillaries, passenger seat). I will be very interested to see what it weighs when I have it corner weighted.

Tyre diameter may go down to .576m as I can get 195/50 r888s very cheaply.

I've checked and the M3 rear caliper pistons are indeed 36mm.

If I go for the Wilwood pedal box, which is the more likely, the ratio will be 6.25:1

I do have mismatched front to rear pads at present

You're welcome. I was also quite surprised how it worked out. Intersting thing is, is that with the standard 32mm calipers and 260mm discs on the rear it immediately swings the other way since the rear calipers now require more pressure to achieve the same brake torque. This sort of investigation really highlights just how little brake torque is needed at the rear as a result of the shift in weight to the front.Theo325 wrote:That is a very interesting post Geoff, thanks for taking time to work that out. I'm quite suprised at the conclusion that the rear needs a significantly larger master cylinder, shows that doing the theory can really help. Had you made those calculations I'd probably have done the opposite!

No worries, mine are also mismatched at present. I'm waiting till I can afford a set of Alcon two-pots with Z1 discs to sort it out. In the mean time my front M/C is oversized to stop me from locking my front brakes while pushing hard enough to get the rear to do anything. And that's mostly as a result of a friction coefficient of 0.6 on the front, and 0.4 on the rear! Far from ideal, but in my defence, never as planned or intended.Theo325 wrote:I do have mismatched front to rear pads at presentbut will get a set of matching rears. If it's any use, the pads have a friction coefficient of 0.6.

I should be running a 3/4" MC on the front brakes, and a 7/10" MC on the rear brakes. Instead I have a 7/8" on the front, and a 7/10" on the rear.

- Dreamracer1

- E30 Zone Regular

- Posts: 609

- Joined: Sat Sep 06, 2008 11:00 pm

- Location: Crymych, Pembrokeshire

Hey Theo,

Don't know if it's too late but have you tried these, optimumbalanceproducts? They're on E-bay.

I dont have any experience of them just seen their stuff and wondered if it was of any use to you or anyone else.

Regards

Keith.

Don't know if it's too late but have you tried these, optimumbalanceproducts? They're on E-bay.

I dont have any experience of them just seen their stuff and wondered if it was of any use to you or anyone else.

Regards

Keith.