Problem is that after a few miles all brakes gradually lock on until they seize.

See my video and pic of when it very first happened to me:

YouTube video http://www.youtube.com/watch?v=Ru4C5TH5o3A

Anyway, I've tried various items and even replaced the master cylinder, servo, diagonal routing of pipes (and parallel), adjustments on the inside servo pivot bracket, thread transfer bar.

Then the problem hit me;

When installing the master cylinder, you really have to push very hard to get it into the servo (sometime enough that a second person could be helping hold the master cylinder in place whilst you fit the nuts).

As I was pushing the master cylinder into the servo, brake fluid suddenly squirted out of the master cylinder ports. Strange I thought...... went and checked and E30 master cylinder and servo setup and it fits with no pressure needed at all.

E30 cylinder on the left and Audi cylinder on the right:

Depth difference:

So basically what's happening is that the piston in the master cylinder is having to be depressed when fitting just to fit it into the servo, which means the brakes are slightly 'on' even before its been bled, which is strange as the car is very free moving for the first 5 mins / 2miles driving until it starts to seize on and within 2 mins - your going no-where!

Anyway, I must have either the wrong servo or the wrong master cylinder. Here's some more pictures of the Golf servo and the Audi master cylinder:

Servo:

Servo pushrod flush with the servo opening for the master cylinder:

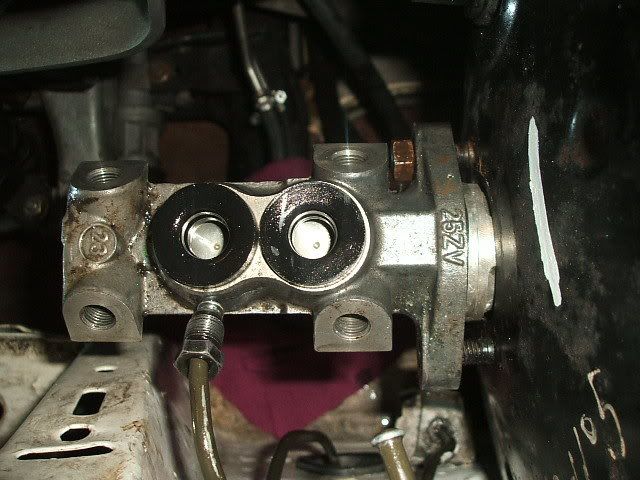

Audi master cylinder '25ZV' which i think is the correct one. This picture shows it in its position before pushing into the servo (its just located itself on the 2x servo studs) at this point it is about to need force to get it any further in:

On with 1 nut. Now the master cylinder piston has already been depressed to get it in this far. So its under tension and 'sprung' already:

Both nuts on and more pressure needed to get the master cylinder into the servo, whereas i think it should be able to be 'placed' in without any pressure needed from your hands.

Can anybody confirm this please?

Does it look like i have a wrong master cylinder or servo, or both?

Quick fixes (if even possible) seem to be cut/shorten the servo pushrod, or drill deeper into the master cylinder.

Only problem is that it's currently Thursday morning and tomorrow afternoon (Friday) i'm meant to be leaving Bristol to a trackday at Snetterton on Saturday.

So as you can imagine i'm in a rush and pulling my hair out as i'm running out of idea's.

Your thoughts please.....

Cheers

James