316 e30 track build. 7 years and counting.

Moderator: martauto

- jonknee1234

- E30 Zone Newbie

- Posts: 39

- Joined: Thu Dec 06, 2007 11:00 pm

BMW N45b20 out of a 2006 320si. Z4 gearbox and m3 itb’s + link fury ecu.

-

DanThe

- E30 Zone Team Member

- Posts: 28641

- Joined: Sat Sep 10, 2005 11:00 pm

- Location: Staffs

- Contact:

Looking forward to itjonknee1234 wrote: ↑Thu Apr 09, 2020 1:58 pmHey. Yep it runs but needs tuning as fuel and ignition map all over the place but idles ok. Will upload a vid shortly. Cost a few quid to get to this stage. Engine block was new from BMW about £1600 + god knows how much in bits and bobs as the project ran. Will do a proper update soon with more info.

- jonknee1234

- E30 Zone Newbie

- Posts: 39

- Joined: Thu Dec 06, 2007 11:00 pm

Standard trim in the 320si was about 180 BHP but it was restricted as at the time could not infringe on the 325i engine power numbers. With ITBs and a proper tune hoping for anything that starts with a 2xx.

I finally found your build thread!

First of all congrats on this awesome awesome engine swap - looks amazing. You inspired me going the same route on my facelift 316i sedan which is already converted to 6 speed using the gs6-17 GB mated to the almighty m40b16. I kept postponing the engine swap on it since I really like the feel of a light engine in this car. Now that you managed to complete your swap last year I got enough courage and pulled the trigger on a complete 320si that is on it's way to me atm. So I am going all in and looking at the engine peripherals these days - that's gone be a hard one.

It will be awesome if you will be willing to show a bit more on the swap - what I haven't been able to see myself from the pics and vids is what mods you've done to the subframe and/or oil pan as well as the way you've done the mounts.

I see that the antiroll bar is moved upfront and I only imagine that the subframe has been also modified to allow space for the oil pan, but I highly hope there is enough clearance to put the engine further back and hop over the subframe before it hits the firewall. On the m40 this seems not possible..

Let us know what power figure you have been able to pull out as well and how does it feel.

First of all congrats on this awesome awesome engine swap - looks amazing. You inspired me going the same route on my facelift 316i sedan which is already converted to 6 speed using the gs6-17 GB mated to the almighty m40b16. I kept postponing the engine swap on it since I really like the feel of a light engine in this car. Now that you managed to complete your swap last year I got enough courage and pulled the trigger on a complete 320si that is on it's way to me atm. So I am going all in and looking at the engine peripherals these days - that's gone be a hard one.

It will be awesome if you will be willing to show a bit more on the swap - what I haven't been able to see myself from the pics and vids is what mods you've done to the subframe and/or oil pan as well as the way you've done the mounts.

I see that the antiroll bar is moved upfront and I only imagine that the subframe has been also modified to allow space for the oil pan, but I highly hope there is enough clearance to put the engine further back and hop over the subframe before it hits the firewall. On the m40 this seems not possible..

Let us know what power figure you have been able to pull out as well and how does it feel.

- jonknee1234

- E30 Zone Newbie

- Posts: 39

- Joined: Thu Dec 06, 2007 11:00 pm

Been a while but have a little bit of time to do an update. Car fully done and running the N45b20 on ITB’s with Z4 6 speed. It runs a link Fury ECU and last Dyno made just under 180 BHP. More important than that it revs like a motorbike and tops out at 7500rpm. In the following pages will try and share whatever pics I have a stages of the engine install

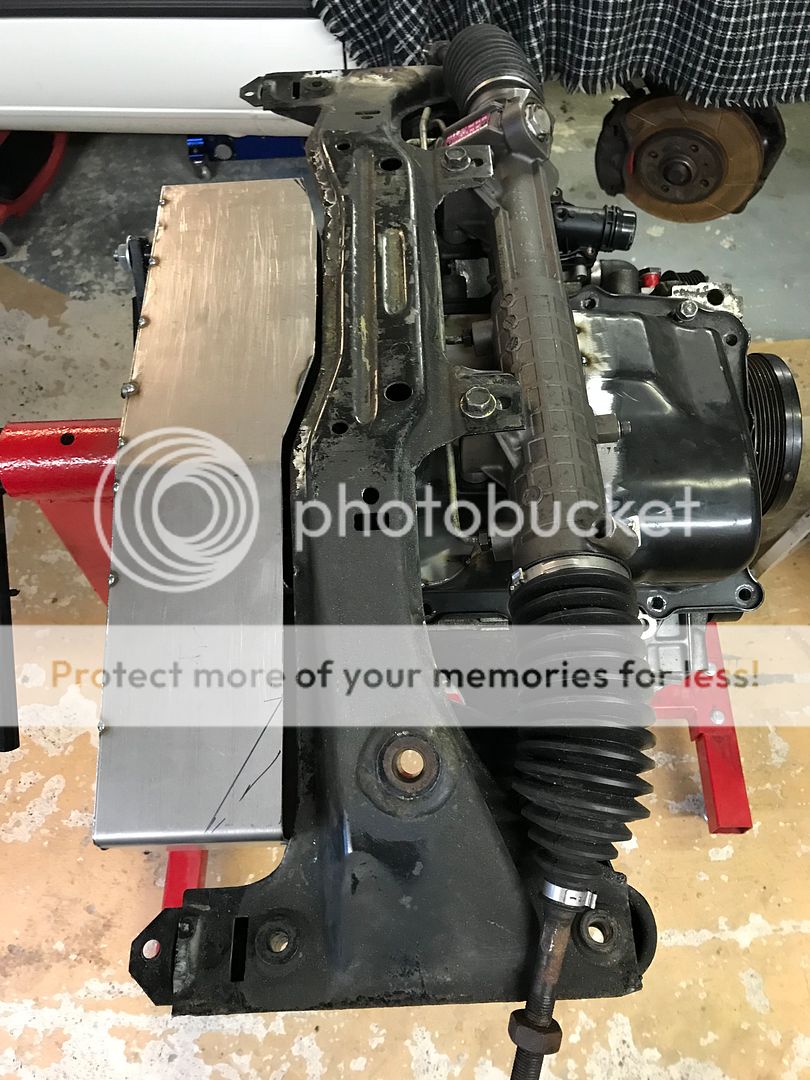

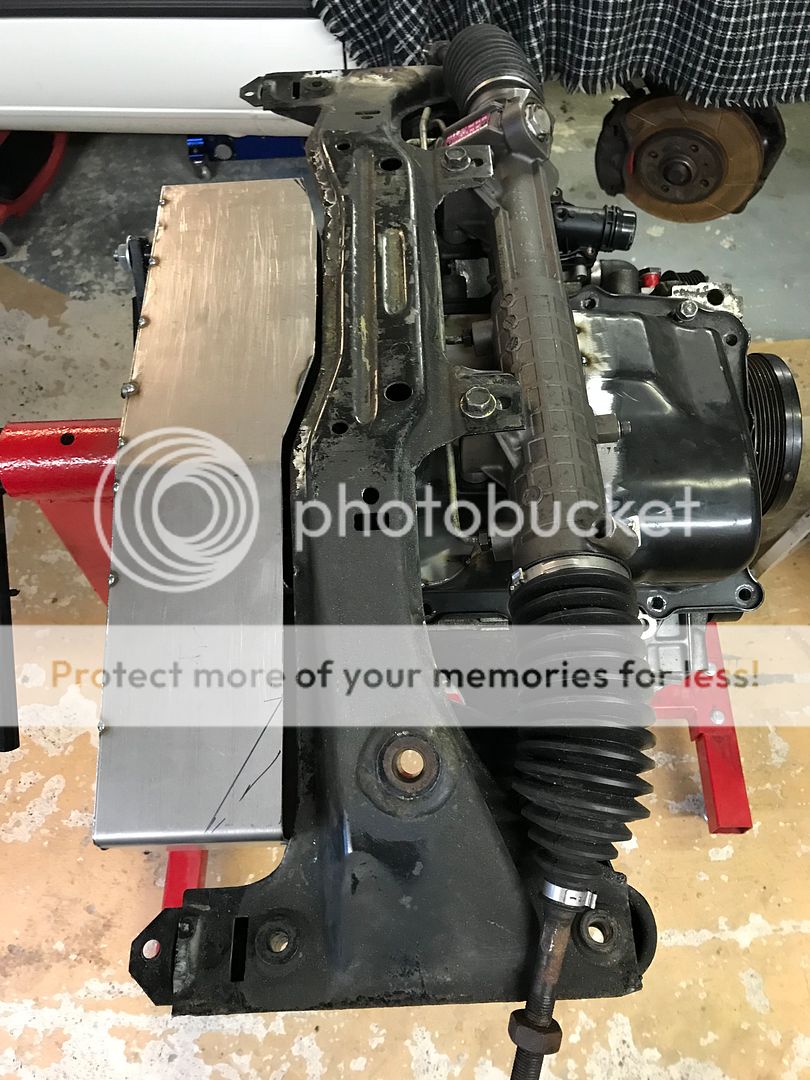

First up - making the engine mounts. I have used BMW M1 rubber mounts and home made arms that I built myself with 1/4 inch steel plate, a vice and me welding.. turned out ok. I hung the engine in place with the engine crane and got the position correct - as far back as possible with height set so I can just about close the bonnet. As for the engine I had to remove the balancer shafts, modify the oil pump so it could run without balancer shafts. Also had to remove the sump for pre install as the shape was all wrong and hit on the cross member.

When the engine was in place temp welded some bracing in so I could remove the whole thing ( engine and front brace ) to work on it out of the vehicle.

Next up - redesign of the sump, used the old one but cut off most of it so it did not hit the front cross member, used the old outline and grafted a new skin over the top making a oil swirl pot for the pick up to sit in. Modified oil pump pick up taken from a BMW e60 M57TU ( eBay ) bent to fit and made a new oil pump connection ring in place of the old plastic one from the original engine. Also had a go at making a baffle plate to stop the oil moving around.

In order to get the engine to fit in position, even with balencer shafts removed and new oil pan - I had to rotate the anti roll bar 180 degrees and make new supports. Quite straight forward just time consuming - had the front beam ballasted and then powder coated afterwards

Now for the engine build - new block and pistons ( OEM ) measured all the clearances and fitted brand new shells ( main ). Stripped rods, new big end bearings. balenced all pistons with rods and adjusted to within .02 of a gram. New king pins. New rings.

New lightened flywheel ( single piece ) from TVV.

M3 e36 throttle bodies / removed the back 2 and modified the shaft assemble

Made a aluminium adaptor plate from head to throttles and ported the holes + throttles and head ( mock up in Wood first )

Used the correct throttle intakes from a e36 M3 - but added a carbon Bespoke air box

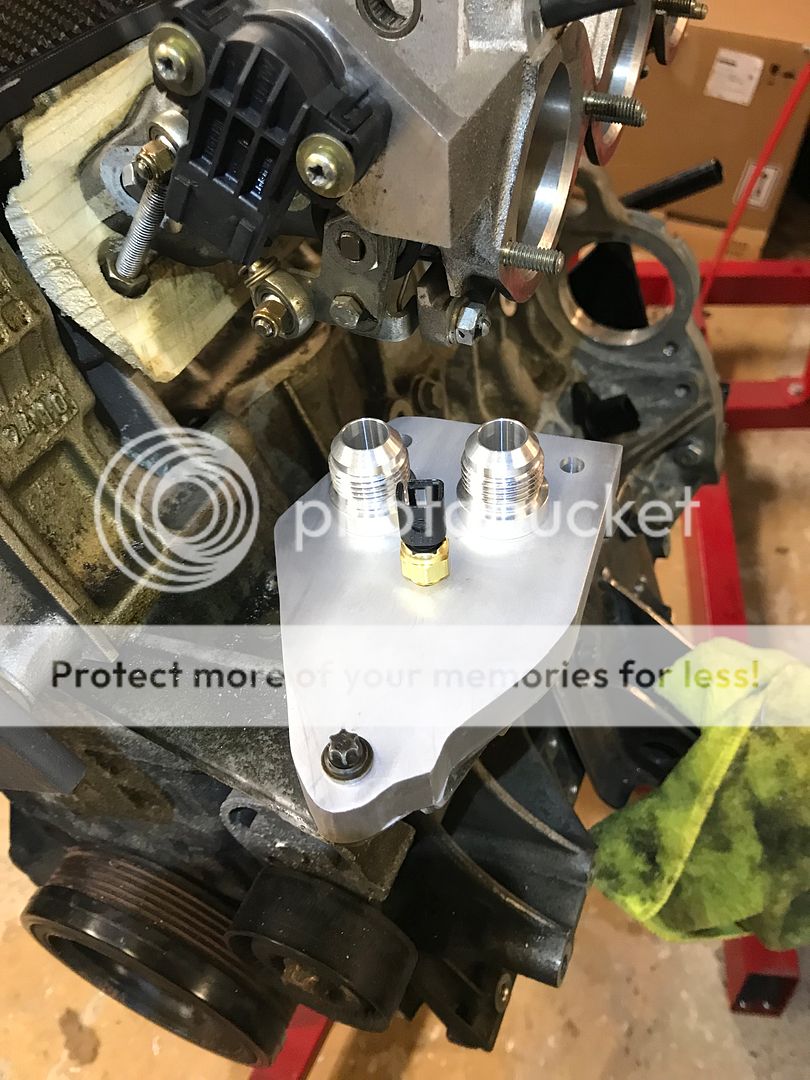

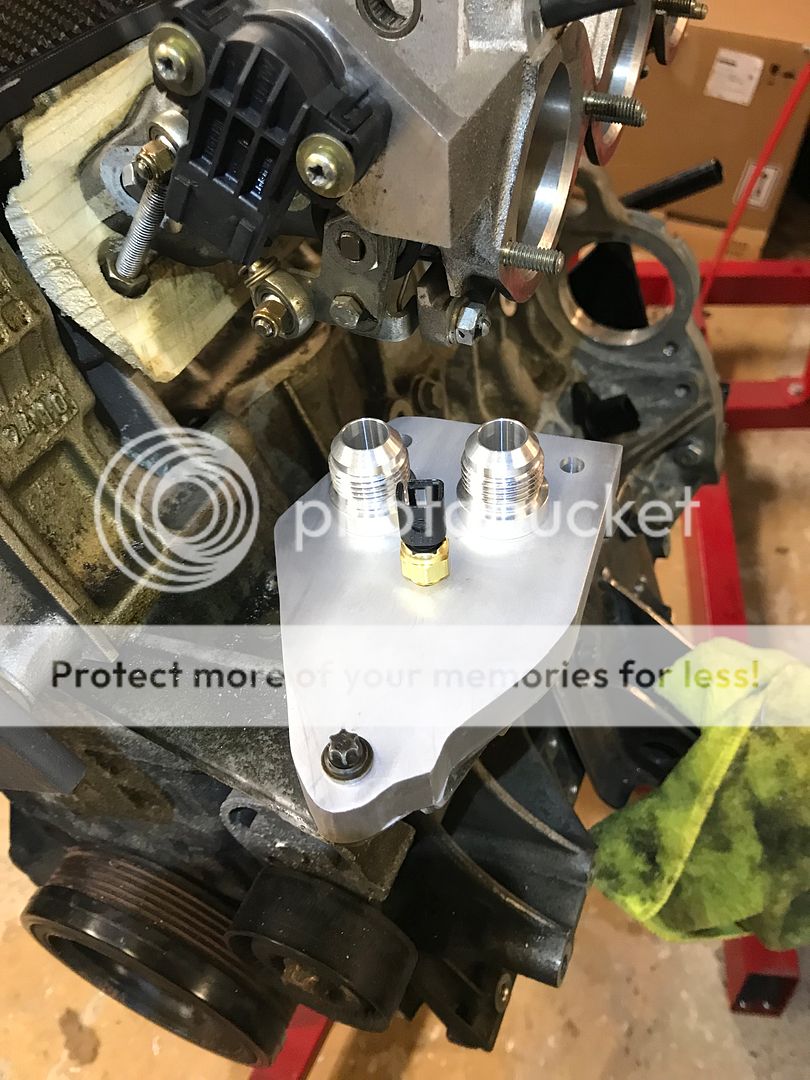

Also made Bespoke oil pick me as needed to remove the old oil filter as would not fit due to throttle bodies + needed to get the oil off to the coolers - mounted in the front bumper

At this point got distracted by fitting all new front GAZ coil overs and new Mazda RX7 callipers and performance pads

Made a new - in wing - washer bottle as old new now had no room in the engine bay

Made fuel system for the boot - return less with swirl pot and lift pump under the vehicle

Then 100’s of hours of boring bits, including wiring, cooling system, oil coolers, fitting the Link ECU, gauges - fuel, oil pressure, water temp, Lambda, getting the bloody thing running - x2 dyno sessions and loads of other stuff I have forgotten.

End result - first track day at Brands as a shake down - went really well with no great issues, rev’ed its nuts off all day and did not miss a beat. Only issue was PAS oil over heated .. which I can and have now added a cooler for.

Hope you enjoyed the update....

Brands vid link below ( watch to the end ) nearly crashed....

First up - making the engine mounts. I have used BMW M1 rubber mounts and home made arms that I built myself with 1/4 inch steel plate, a vice and me welding.. turned out ok. I hung the engine in place with the engine crane and got the position correct - as far back as possible with height set so I can just about close the bonnet. As for the engine I had to remove the balancer shafts, modify the oil pump so it could run without balancer shafts. Also had to remove the sump for pre install as the shape was all wrong and hit on the cross member.

When the engine was in place temp welded some bracing in so I could remove the whole thing ( engine and front brace ) to work on it out of the vehicle.

Next up - redesign of the sump, used the old one but cut off most of it so it did not hit the front cross member, used the old outline and grafted a new skin over the top making a oil swirl pot for the pick up to sit in. Modified oil pump pick up taken from a BMW e60 M57TU ( eBay ) bent to fit and made a new oil pump connection ring in place of the old plastic one from the original engine. Also had a go at making a baffle plate to stop the oil moving around.

In order to get the engine to fit in position, even with balencer shafts removed and new oil pan - I had to rotate the anti roll bar 180 degrees and make new supports. Quite straight forward just time consuming - had the front beam ballasted and then powder coated afterwards

Now for the engine build - new block and pistons ( OEM ) measured all the clearances and fitted brand new shells ( main ). Stripped rods, new big end bearings. balenced all pistons with rods and adjusted to within .02 of a gram. New king pins. New rings.

New lightened flywheel ( single piece ) from TVV.

M3 e36 throttle bodies / removed the back 2 and modified the shaft assemble

Made a aluminium adaptor plate from head to throttles and ported the holes + throttles and head ( mock up in Wood first )

Used the correct throttle intakes from a e36 M3 - but added a carbon Bespoke air box

Also made Bespoke oil pick me as needed to remove the old oil filter as would not fit due to throttle bodies + needed to get the oil off to the coolers - mounted in the front bumper

At this point got distracted by fitting all new front GAZ coil overs and new Mazda RX7 callipers and performance pads

Made a new - in wing - washer bottle as old new now had no room in the engine bay

Made fuel system for the boot - return less with swirl pot and lift pump under the vehicle

Then 100’s of hours of boring bits, including wiring, cooling system, oil coolers, fitting the Link ECU, gauges - fuel, oil pressure, water temp, Lambda, getting the bloody thing running - x2 dyno sessions and loads of other stuff I have forgotten.

End result - first track day at Brands as a shake down - went really well with no great issues, rev’ed its nuts off all day and did not miss a beat. Only issue was PAS oil over heated .. which I can and have now added a cooler for.

Hope you enjoyed the update....

Brands vid link below ( watch to the end ) nearly crashed....

Looks like an awesome level of work, love it - Brands is a great track, pace looks good. Nice tank slapper! Glad it worked out well. Tyre pressure issue?

When people question what the zone is about or if it is relavent these days in the light of "social media" then check this thread out !!!!!!!

One of many utterly brilliant threads which need to be seen to be believed , I dont know about alot of what has happened here, but there is fantastic engineering going on here.

Well done mate !!!!!

Mart.

One of many utterly brilliant threads which need to be seen to be believed , I dont know about alot of what has happened here, but there is fantastic engineering going on here.

Well done mate !!!!!

Mart.

Only the E46 cab left now.

Just got too old.

Just got too old.

-

steve_k

- E30 Zone Team Member

- Posts: 8044

- Joined: Fri May 23, 2008 11:00 pm

- Location: in the vale of mansfield

- Contact:

no that is impressive

it's threads like this that keep me coming back,

keep up the good (fantastic) work.

it's threads like this that keep me coming back,

keep up the good (fantastic) work.

if it's got t*ts or wheels it's bound to be trouble...............prove me wrong.

getting oral sex off an ugly person is like rock climbing.....don't look down ;)

getting oral sex off an ugly person is like rock climbing.....don't look down ;)

Amazing work!

This is where I am atm and your updates come at such a right time I was surprised to see your subframe basically untouched. I though you have moded it heavily similar BMP's s54 subframes,

I was surprised to see your subframe basically untouched. I though you have moded it heavily similar BMP's s54 subframes,

It looks possible to go for a front oil sump an perhaps enlarge it further upfront - that is what I am thinking currently to do and it will be great to hear your opinion. I can imagine front oil sump brings risk of starvation under acceleration, but looking at the deign of yours might be better in the corners.

This is where I am atm and your updates come at such a right time

It looks possible to go for a front oil sump an perhaps enlarge it further upfront - that is what I am thinking currently to do and it will be great to hear your opinion. I can imagine front oil sump brings risk of starvation under acceleration, but looking at the deign of yours might be better in the corners.

- jonknee1234

- E30 Zone Newbie

- Posts: 39

- Joined: Thu Dec 06, 2007 11:00 pm

steffgang wrote: ↑Thu Feb 11, 2021 5:37 amAmazing work!

This is where I am atm and your updates come at such a right time

146686377_238928561046939_2987148462801576820_n.jpg

148397772_839662013549800_8174676727868675964_n[1].jpg

I was surprised to see your subframe basically untouched. I though you have moded it heavily similar BMP's s54 subframes,

It looks possible to go for a front oil sump an perhaps enlarge it further upfront - that is what I am thinking currently to do and it will be great to hear your opinion. I can imagine front oil sump brings risk of starvation under acceleration, but looking at the deign of yours might be better in the corners.

Hey, Great to see your E30 project / history - very good work.

In answer to your question about the sump. My first plan was to go with modifying the front of the oil pan but the problem is that the anti roll bar (in standard position) hits the N45 sump (when you go to try and fit the engine), so you can either move the anti roll bar ( flip it 180 deg ) or remove a large proportion of the rear sump - to get the engine to fit. If you choose rear sump removal / modification and add volume to the front of the oil pan you will find it very difficult to get the volume of oil in the pan that you need to keep it working and cool. Unless you go this route and opt for a dry sump solution- which I decided against as was to expensive. So the logical route is to flip the roll bar (to give you the space you need at the rear) but that means you don’t have the correct clearance at the front for sump modification - the other problem is the oil pick up coming out of the pump - you would have to turn it through 90 degrees (down) and its too tight against the roll bar. So I ended up mod’ing the rear. Oil volume in total is 4.5l in the sump (just about enough, would have liked more but not possible) but with a oil cooler in the front it works fine and temp is constant at about 75 to 90 degrees when driving super hard ( track day conditions )

- jonknee1234

- E30 Zone Newbie

- Posts: 39

- Joined: Thu Dec 06, 2007 11:00 pm

Also - to help, added some more sump pics - should help explain what the text above try to say.

Do you remember what thickness of sheet metal you used for your mounts and also if they feel strong enough or unneededly too strong?

Got my latest update in my thread - see where I am

viewtopic.php?f=112&t=281615&p=2980252#p2980252

Got my latest update in my thread - see where I am

viewtopic.php?f=112&t=281615&p=2980252#p2980252

- jonknee1234

- E30 Zone Newbie

- Posts: 39

- Joined: Thu Dec 06, 2007 11:00 pm

Hey Steffgang.

Engine mounts are probably a little over engineered in terms of material thickness, the plate I used was 4 mm, you should consider 3 mm or a tube based setup would be lighter I would think.

Engine mounts are probably a little over engineered in terms of material thickness, the plate I used was 4 mm, you should consider 3 mm or a tube based setup would be lighter I would think.

[/img]

[/img]