Top work mate, keep it up.

Production BMW Build 320 - RACING!

Moderator: martauto

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Thanks MH!

Now to the front struts:

Now the fronts are a nightmare and straight away the reason why is because of the ball joints at the bottom of the struts. I went to Halfords for a fork type splitter, and wish I'd researched this art a bit more, of which there's plenty of generic ball joint splitting advice on t'nterweb. Mind you everyone seems to know what the best method is and they are often different!

What's certainly true is fork type splitters are good at knackering your ball joint rubber and seals. This side is bad enough but the passenger side ended up utterly mulered, and probably not a lot of grease is left in the wishbone joint...So I'll be getting new tie rod ends and control arms at some stage, and having seeen what they do I'd like the peace of mind anyway.

Got the strut off, old vs new. At the time of writing the passenger side simply will not come off, and the driver's side was very stubborn. So I'm drafting in outside assistance for this!

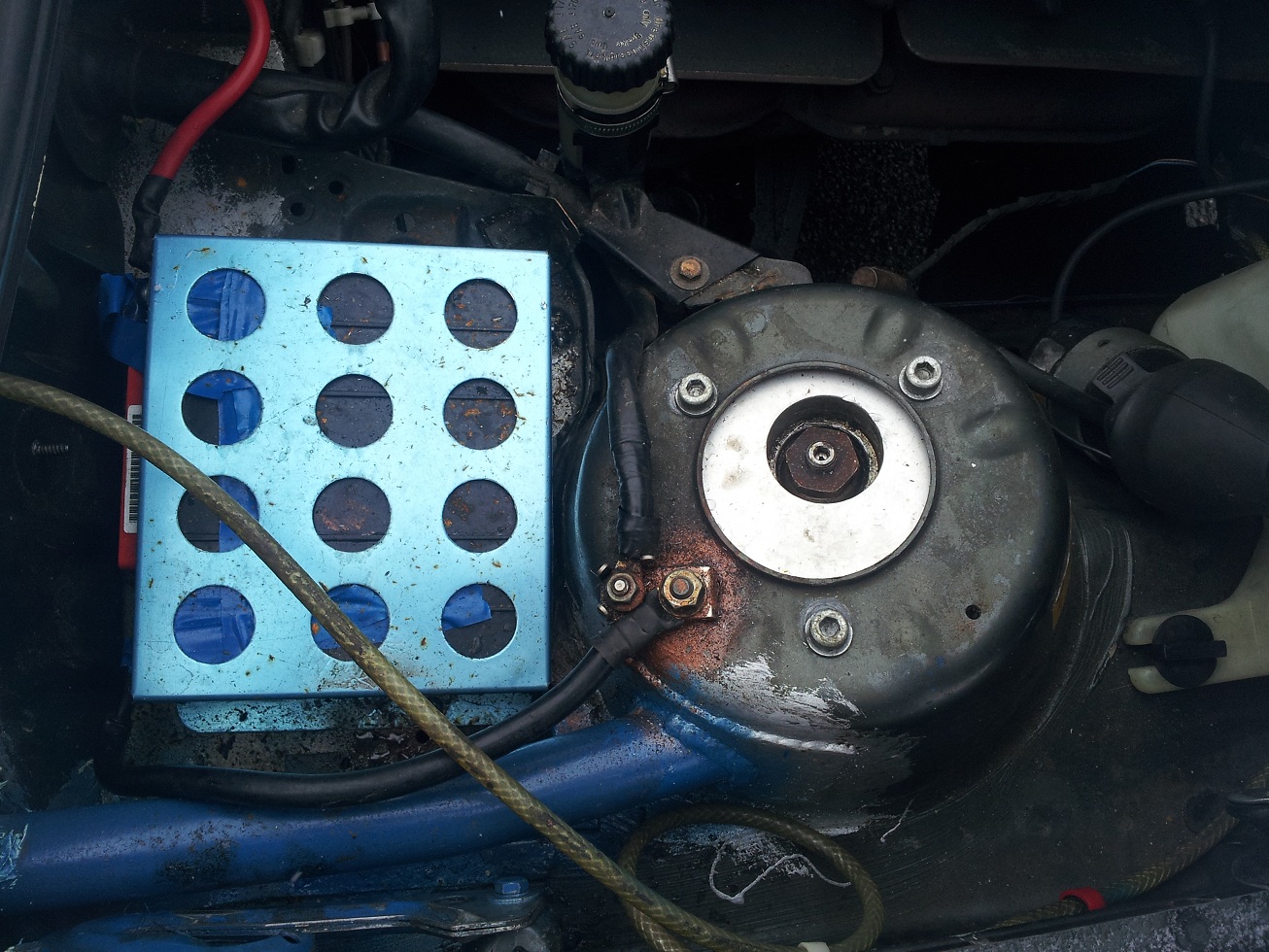

This was how it was shaping up, nicely. I also have another issue that the front strut top mount nut cannot be tightend easily as it spins the strut shaft. So hopefully I'll get some assistance with that too.

Now to the front struts:

Now the fronts are a nightmare and straight away the reason why is because of the ball joints at the bottom of the struts. I went to Halfords for a fork type splitter, and wish I'd researched this art a bit more, of which there's plenty of generic ball joint splitting advice on t'nterweb. Mind you everyone seems to know what the best method is and they are often different!

What's certainly true is fork type splitters are good at knackering your ball joint rubber and seals. This side is bad enough but the passenger side ended up utterly mulered, and probably not a lot of grease is left in the wishbone joint...So I'll be getting new tie rod ends and control arms at some stage, and having seeen what they do I'd like the peace of mind anyway.

Got the strut off, old vs new. At the time of writing the passenger side simply will not come off, and the driver's side was very stubborn. So I'm drafting in outside assistance for this!

This was how it was shaping up, nicely. I also have another issue that the front strut top mount nut cannot be tightend easily as it spins the strut shaft. So hopefully I'll get some assistance with that too.

Last edited by milescook on Sun Mar 22, 2015 6:13 pm, edited 1 time in total.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

Ah, Koni's have a little hex nib on the strut shaft that you can hold with a spanner while you torque up the top nut. Do the Gaz have similar?

Been lucky enough not to have to split a ball joint with a splitter yet - some pressure on the ball joint from below with a bottle jack and the nuts undo/tighten nicely. Maybe that's just because everything is new - I dropped the entire front end when I removed the old stuff. Lollipops, top-mount bolts, subframe bolts and steering linkage undone, it just drops off and slides out as one unit

Been lucky enough not to have to split a ball joint with a splitter yet - some pressure on the ball joint from below with a bottle jack and the nuts undo/tighten nicely. Maybe that's just because everything is new - I dropped the entire front end when I removed the old stuff. Lollipops, top-mount bolts, subframe bolts and steering linkage undone, it just drops off and slides out as one unit

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

No such luck for me sadly. There are Allen key hex sockets on in the stud but i haven't got a socket combination to allow both to work at the same time.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

I have and the strut shafts still turn.a 1 inch socket fits so i just need to use a ring spanner and Allen key. annoyingly all i really need is a 25 mil ring spanner that is offset so can drop in the mount.halfords and screwfix don't do that sodding size!

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

I orded one cheers, then tried to cancel my order as I discovered with some help (Cheers Andrew!) the reason why they would never have gone in - the circular part of the nut was grinding against the spherical bearing. Anyway, a new snippet of the build blog:

--

On the other side I spent a lot of time trying to get the control arm joint of the strut and like I said, destroyed my rubbers in the process. Enlightenment came when my neighbour Will turned up with a scissor type seperator. You keep turning a bolt and it pushes the ball joint bolt down levering against the bottom of the arm. The seperation took seconds, and marked it's fanfare with a very satisfying metalic bang. So my advice in the sea of ball joint advice is very simple: you need one of these tools in your life!

The next problem was the top mount nuts:

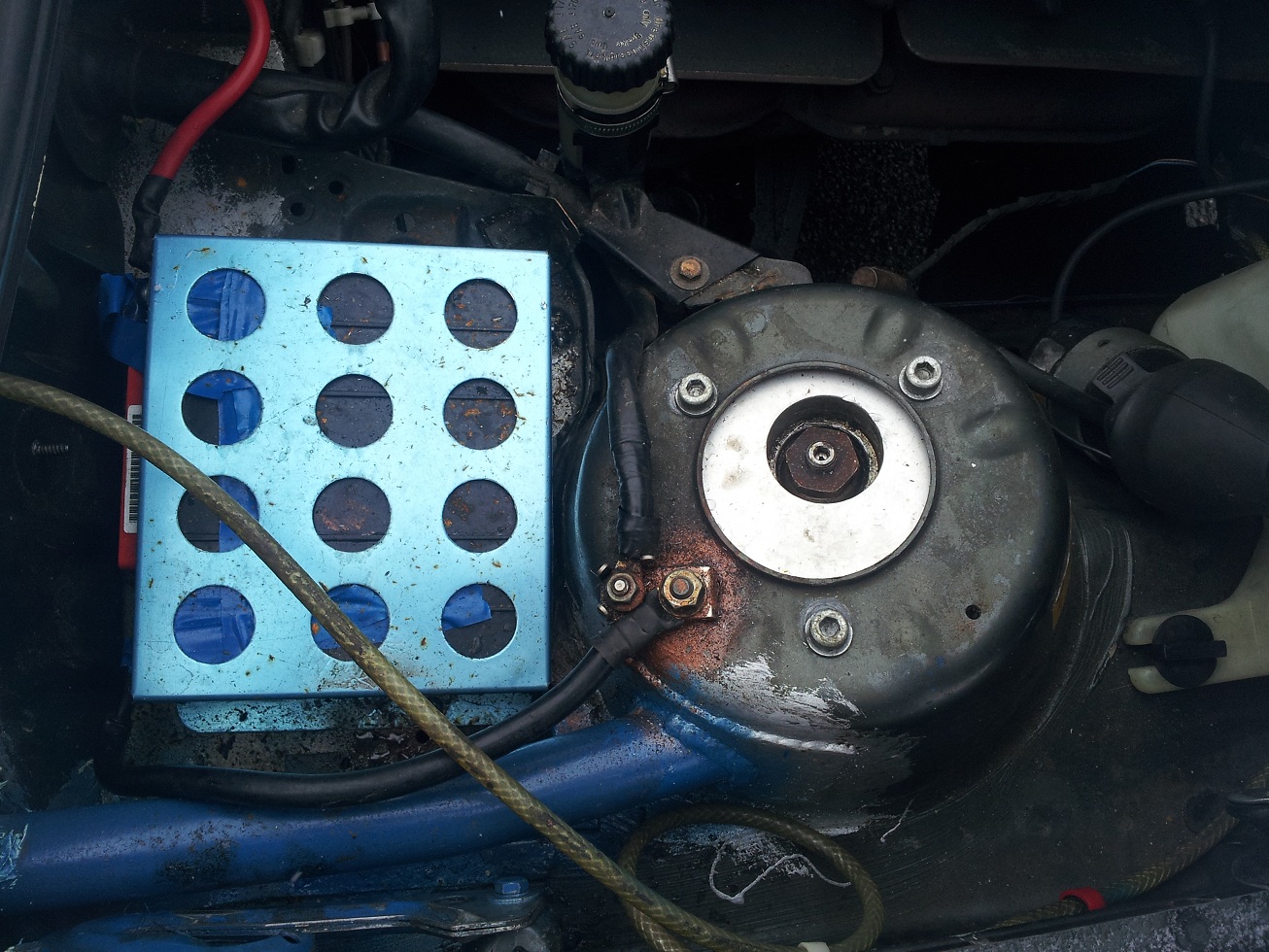

I've just noticed how messy the bay is and my cheap electrical tape does not cover the battery terminals - something to do with me needing to take them off to give the car a jump start! I'm already wondering if I can fashion some sort of easy access positive terminal in my B&Q junction box behind it's screwed in waterproof cover. But anyway, I digest.... (FG)

Firstly I slightly reamed out the three mouting holes as the top mount wouldn't line up. I probably should have gone for a bit more inward negative camber here but I measured the reaming out to the top mount holes that looked like they'd been used by the previous E30 race car. I'll probably adjust and on the next available fitting holes the mount will bring the top more rear giving a bit more castor. But that wasn't my biggest worry. As I've seen on various searches, many people have issues tightening the top mount main nut on coilovers, and I was no exception.

After realising that I could keep the strut from turning with an allen key, and turn the nut with a 25 mil ring swan necked spanner (which I couldn't find locally for love nor money!), another E30 zone member popped up with a better solution - an impact driver. I'd already tightened as much as possible using mole grips on the top part of the shaft which wouldn't travel past the damper seals, but the passenger side could not be tightened very well. Unsuprisingly, on the test drive I'd get a knock noise rom that strut going over bumps, reminding me of my early days in my MK3 Golf. When we tried the impact driver method it became apparent that the circular shoulder of the nut was grinding in the spherical bearing stopping it from easily going in. A bit of "surgery" on the nut, and she was in tightly - huge relief. However, I didn't even get chance to start my drive slowly on the back roads back, because it was instantly obvious the front was now ready to play ball. And that's the first time it really hit me how much of an improvement all 4 corners were - even on my badly set up "stilts" suspension setting and slightly wonky tracking!

Fun doesn't even come close to describing the car now after all this messing with rear beams bushes, a dog's dangly bits roll cage stiffening the car, powerflex control arm bushes and finally Gaz coilovers. It's instant connection with the road - even a snowy / wet pot holed ridden one! I utterly loved the drive back, and can't wait to round off the edges of my bodged set up to a decent aligned lowered spec.

--

On the other side I spent a lot of time trying to get the control arm joint of the strut and like I said, destroyed my rubbers in the process. Enlightenment came when my neighbour Will turned up with a scissor type seperator. You keep turning a bolt and it pushes the ball joint bolt down levering against the bottom of the arm. The seperation took seconds, and marked it's fanfare with a very satisfying metalic bang. So my advice in the sea of ball joint advice is very simple: you need one of these tools in your life!

The next problem was the top mount nuts:

I've just noticed how messy the bay is and my cheap electrical tape does not cover the battery terminals - something to do with me needing to take them off to give the car a jump start! I'm already wondering if I can fashion some sort of easy access positive terminal in my B&Q junction box behind it's screwed in waterproof cover. But anyway, I digest.... (FG)

Firstly I slightly reamed out the three mouting holes as the top mount wouldn't line up. I probably should have gone for a bit more inward negative camber here but I measured the reaming out to the top mount holes that looked like they'd been used by the previous E30 race car. I'll probably adjust and on the next available fitting holes the mount will bring the top more rear giving a bit more castor. But that wasn't my biggest worry. As I've seen on various searches, many people have issues tightening the top mount main nut on coilovers, and I was no exception.

After realising that I could keep the strut from turning with an allen key, and turn the nut with a 25 mil ring swan necked spanner (which I couldn't find locally for love nor money!), another E30 zone member popped up with a better solution - an impact driver. I'd already tightened as much as possible using mole grips on the top part of the shaft which wouldn't travel past the damper seals, but the passenger side could not be tightened very well. Unsuprisingly, on the test drive I'd get a knock noise rom that strut going over bumps, reminding me of my early days in my MK3 Golf. When we tried the impact driver method it became apparent that the circular shoulder of the nut was grinding in the spherical bearing stopping it from easily going in. A bit of "surgery" on the nut, and she was in tightly - huge relief. However, I didn't even get chance to start my drive slowly on the back roads back, because it was instantly obvious the front was now ready to play ball. And that's the first time it really hit me how much of an improvement all 4 corners were - even on my badly set up "stilts" suspension setting and slightly wonky tracking!

Fun doesn't even come close to describing the car now after all this messing with rear beams bushes, a dog's dangly bits roll cage stiffening the car, powerflex control arm bushes and finally Gaz coilovers. It's instant connection with the road - even a snowy / wet pot holed ridden one! I utterly loved the drive back, and can't wait to round off the edges of my bodged set up to a decent aligned lowered spec.

Last edited by milescook on Sun Aug 07, 2016 9:09 pm, edited 1 time in total.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Next mini drama then - fuel pump! Driving back on my rationed 1 trip to work a week she just cut out. I had an 8th of a tank left but assumed the guage may have been fibbing. A work colleague picked me up, we got a can of petrol and dropped me back off. Good job I didn't walk the trip in the freezing cold as it would have been bitterly dissapointing, as fuel quantity wasn't the issue. Would not start and the race battery was now dying (after a lot of turning over to be fair).

RAC chap rocked up, couldn't find the fuel pump, couldn't work out how to resurect the battery initially (as it's my B&Q and FIA approved setup), was dismayed to see a tow rope instead of towing eye, and almost couldn't get the car on the towing ramp for clearance! So I'll be getting my towing eye back in the toolkit, and a c spanner for the coilovers soon. Handy breakdown kit for a track car, on the road.

Got it home, tried the starting troubleshooting advice so checking for spark, un-plugged the fuel filter checked for fuel being pumped out on cranking, checked for some power to the pump with an indicator bulb (for which I was chuffed with my soldering and electrical tape efforts with, and decided it would be a handy diagnostic tool. Unil I dropped a hammer on it as soon as I'd finished with it...). All pointed to a dead pump.

Much drama again from ECP sadly, but despite their website telling me lies on what was an in-tank pump, I finally got the right one. Only after visits to their Coventry and Swansea branches. And it isn't funny playing with the fuel tank, it smells bad and I was pretty nervous throughout. My on board Fire Extinguisher probably wouldn't have been much help! But good news - I "found" my missing jubilee clip when I was finished. It had dropped in the tank... I'm at a complete loss how even I could be so retarded. But it turns out you can very carefuly rescue it with a magentic screw driver - as long as you don't make any sudden sparks. I fortunately didn't, and that's why Im still here...

Anyway, car works again!

RAC chap rocked up, couldn't find the fuel pump, couldn't work out how to resurect the battery initially (as it's my B&Q and FIA approved setup), was dismayed to see a tow rope instead of towing eye, and almost couldn't get the car on the towing ramp for clearance! So I'll be getting my towing eye back in the toolkit, and a c spanner for the coilovers soon. Handy breakdown kit for a track car, on the road.

Got it home, tried the starting troubleshooting advice so checking for spark, un-plugged the fuel filter checked for fuel being pumped out on cranking, checked for some power to the pump with an indicator bulb (for which I was chuffed with my soldering and electrical tape efforts with, and decided it would be a handy diagnostic tool. Unil I dropped a hammer on it as soon as I'd finished with it...). All pointed to a dead pump.

Much drama again from ECP sadly, but despite their website telling me lies on what was an in-tank pump, I finally got the right one. Only after visits to their Coventry and Swansea branches. And it isn't funny playing with the fuel tank, it smells bad and I was pretty nervous throughout. My on board Fire Extinguisher probably wouldn't have been much help! But good news - I "found" my missing jubilee clip when I was finished. It had dropped in the tank... I'm at a complete loss how even I could be so retarded. But it turns out you can very carefuly rescue it with a magentic screw driver - as long as you don't make any sudden sparks. I fortunately didn't, and that's why Im still here...

Anyway, car works again!

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

This is good tape for almost everything: http://www.ebay.co.uk/itm/300631772100? ... 1439.l2649

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Awesome - as you saw my loom is a bit err, pikey!  So I'll tidy that up. Which leads me to my next point...

So I'll tidy that up. Which leads me to my next point...

I'm kind of out of things to do, so suggestions o a massive postcard please guys I need to replace the control arms for peace of mind and I butchered the rubber joints, and the tie rod ends. Then I reckon I'll change the timing belt and water pump as per wiki - very scared about this, and I'm now in South Wales so will have to recruit new helpers who use beer as currency

I need to replace the control arms for peace of mind and I butchered the rubber joints, and the tie rod ends. Then I reckon I'll change the timing belt and water pump as per wiki - very scared about this, and I'm now in South Wales so will have to recruit new helpers who use beer as currency

For the series I need 4 control tyres, a second set of wheels, finish my extinguisher plumbing, set the suspension and tracking properly and a cisrcuit shakedown. Bit scared now! Any suggestions to put off having to actually go racing?

I'm kind of out of things to do, so suggestions o a massive postcard please guys

For the series I need 4 control tyres, a second set of wheels, finish my extinguisher plumbing, set the suspension and tracking properly and a cisrcuit shakedown. Bit scared now! Any suggestions to put off having to actually go racing?

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Good point, I'll keep putting it off whilst saving up race fees and fuel money

I wonder what more to do with the car that I haven't already done, that really ought to be done rather than a nice to have. A reinforced sump guard could be one...

I wonder what more to do with the car that I haven't already done, that really ought to be done rather than a nice to have. A reinforced sump guard could be one...

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

Rallyprep_UK

- formerly Driftnething

- Posts: 832

- Joined: Thu May 08, 2008 11:00 pm

- Location: Cornwall

- Contact:

nearly there

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Next step now is to fetch the car down. I moved a few weeks back now and it's been sat on a neghbour's drive. I have a garage I'm checking tonight, all is well I'll get a lift up later in the week and drive it the 250 odd miels  I think I'll need some headphones and paracetemol

I think I'll need some headphones and paracetemol

Just bought some of that tape so can tidy up the electrics and keep them reliable. I'll also be ordering a new timing belt kit and water pump, so I'll be doign a coolant flush at last. Scary!

Then, 4 tyres and possibly spare wheels, and some track time at Pembrey

Just bought some of that tape so can tidy up the electrics and keep them reliable. I'll also be ordering a new timing belt kit and water pump, so I'll be doign a coolant flush at last. Scary!

Then, 4 tyres and possibly spare wheels, and some track time at Pembrey

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Brought the car down the 250 mile journey. Apart from the tyres initially rubbing on the front spring, caused by being a bit flat so I pumped them up, absolutely no problems in the baking heat! Fair play for a 25 year old car.  I do think my blower is stuck on hot though, so an open window down the motorway was a nice source of cool air. I'll look into that at some point.

I do think my blower is stuck on hot though, so an open window down the motorway was a nice source of cool air. I'll look into that at some point.

Tracking is obviously way out, I need it set up properly since I changed the suspension, so it wanders to the left unless you hold the wheel. Plus the tyres are knackered and wheels badly out of balance, so bad wobbles weren't great. But for the 4 hour engine drone, (very noisey in the cockpit with no insulation and headlining!), I almost managed to drown it out with headphones and radio from my phone.

Sourced some wheels and track tyres, so that's positive news (reminds me I need to pay the chap a deposit!). Also been up working on the car a little today for the first time in 3 months, now I finally have it back. After Andrew's suggestion of loom tape, I got stuck in to tidying up the battery terminals and internal wiring. Looks a hell of a lot neater and surely more reliable!

There's still (despite some trimming) loads of excessive / un-required wiring in the glovebox area, I'll only take bits out piece by piece that obviously don't need to be there - it used to be a massive birds nest of wire. Unless someone comes and points what wires to cut.

Also noticed something odd, it's cut out twice stalling trying to drive over a small ramp into the garage it' parked at. No problem. But starting up again is tricky, it seems to not quite get enough momentum to fire properly. I need to look at the fuel filter - it's not obvious to me which pipes go to the engine and which to the pump, but I think it's the wrong way round. Hopefully that's what is causing that hickup.

Tracking is obviously way out, I need it set up properly since I changed the suspension, so it wanders to the left unless you hold the wheel. Plus the tyres are knackered and wheels badly out of balance, so bad wobbles weren't great. But for the 4 hour engine drone, (very noisey in the cockpit with no insulation and headlining!), I almost managed to drown it out with headphones and radio from my phone.

Sourced some wheels and track tyres, so that's positive news (reminds me I need to pay the chap a deposit!). Also been up working on the car a little today for the first time in 3 months, now I finally have it back. After Andrew's suggestion of loom tape, I got stuck in to tidying up the battery terminals and internal wiring. Looks a hell of a lot neater and surely more reliable!

There's still (despite some trimming) loads of excessive / un-required wiring in the glovebox area, I'll only take bits out piece by piece that obviously don't need to be there - it used to be a massive birds nest of wire. Unless someone comes and points what wires to cut.

Also noticed something odd, it's cut out twice stalling trying to drive over a small ramp into the garage it' parked at. No problem. But starting up again is tricky, it seems to not quite get enough momentum to fire properly. I need to look at the fuel filter - it's not obvious to me which pipes go to the engine and which to the pump, but I think it's the wrong way round. Hopefully that's what is causing that hickup.

Last edited by milescook on Sun Aug 07, 2016 9:13 pm, edited 1 time in total.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Just a small note. Went to the car last night armed with coilover spanners from ebay at a tenner for a pair. And a tape measure. Measuring from the bottom of the collar to the end of the shock, I was way way out on all four corners. No wonder it seemed strange to drive

So I set the heights consistently at least on each side. Remarkable difference! Still wanders to the left but only slightly, though my tyres are old and cracked crap so could be this. The steering is uber light now, and I need to have another blast down a windy road to see what's what

So I set the heights consistently at least on each side. Remarkable difference! Still wanders to the left but only slightly, though my tyres are old and cracked crap so could be this. The steering is uber light now, and I need to have another blast down a windy road to see what's what

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

After a fair bit of sleep today this eve I popped up to thr garage with a set of bbs with worn toyos, which will be ideal just to check the car over on circuit. I also wanted to check the rear for squeak clues and look generally.

I think I scraped thr bottom up a hill and sure enough there is a big dent in th fuel tank the squeek comes from the rear offside coilover maybe where its rubbing the filler hose cover. I also noticed when I was trying to set my dampers consistent so turn all the way back then forward half way,the nearside instead of clicking it seemed to unscrew sightly. Maybe related bit its leaked oil

the squeek comes from the rear offside coilover maybe where its rubbing the filler hose cover. I also noticed when I was trying to set my dampers consistent so turn all the way back then forward half way,the nearside instead of clicking it seemed to unscrew sightly. Maybe related bit its leaked oil  any ideas what to do? Might phone gaz and ask.so far I tightened all yhe way up then carefully tried to click back.

any ideas what to do? Might phone gaz and ask.so far I tightened all yhe way up then carefully tried to click back.

I did manage to get out on my favourite bit of public road over the black mountains. Basically its open and windy with large sections of bends you can see nobody else is usin.

Mine gotte....the beamer is superb up there!

Its so damn calm and responsive you have an eternity to set up for a bend, so composed and grippy and fast. I wasnt sure about the toyos i heard they are useless on roads as tjey cant warm up. Well they were baked in todays heat in the back of my car all day so were nice and toasty. Plus I thought they warmed up fine o the road and felt lovely even if they weren't up to correct temps. Circuits are obviously another level where you are being crushed into each side of the seat but still, this is very promising, and huge fun

So my last list before a full blown shakedown at pembrey next month,

Timing belt and water pump precautionary change and coolant

Ramp check, with subframe diff bolts tightened properly not with spanner

Fire ex plumbing completion

Re stick my halfords digital clock

Nearly there!

I think I scraped thr bottom up a hill and sure enough there is a big dent in th fuel tank

I did manage to get out on my favourite bit of public road over the black mountains. Basically its open and windy with large sections of bends you can see nobody else is usin.

Mine gotte....the beamer is superb up there!

Its so damn calm and responsive you have an eternity to set up for a bend, so composed and grippy and fast. I wasnt sure about the toyos i heard they are useless on roads as tjey cant warm up. Well they were baked in todays heat in the back of my car all day so were nice and toasty. Plus I thought they warmed up fine o the road and felt lovely even if they weren't up to correct temps. Circuits are obviously another level where you are being crushed into each side of the seat but still, this is very promising, and huge fun

So my last list before a full blown shakedown at pembrey next month,

Timing belt and water pump precautionary change and coolant

Ramp check, with subframe diff bolts tightened properly not with spanner

Fire ex plumbing completion

Re stick my halfords digital clock

Nearly there!

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Cheers. Phoned Gaz they can reseal a damper for 23 quid while you wait. Shame they are in essex or involve courier charges im quire skint at the mo

Can a non gaz specialist do them closer to home?

Can a non gaz specialist do them closer to home?

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Finished it!*

*Requires rear damper servicing and precautionary timing belt / water pump replacement

*Requires rear damper servicing and precautionary timing belt / water pump replacement

Last edited by milescook on Sun Mar 22, 2015 6:04 pm, edited 1 time in total.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

It was an utter riot on a mountain road the other day. Brakes super responsive and no fade, everything was crsps and sharp - it seemed like you had a week to decide where to put the car on each corner, and could accelerate up to silly speeds at will knowing you could stop... that's my take on it anyway

The leaking damper has now properly shat all its oil out so not very good going right anymore It will have to go to Gaz, and I'm going to keep it off road for a couple of months. To go testing I need a "racing costume" as the OH puts it, which is around 300 quid. It will have to wait.

It will have to go to Gaz, and I'm going to keep it off road for a couple of months. To go testing I need a "racing costume" as the OH puts it, which is around 300 quid. It will have to wait.

But in summary, yeah it's fun!

The leaking damper has now properly shat all its oil out so not very good going right anymore

But in summary, yeah it's fun!

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Yeah it's been fun overall.... however, due to a probable job change in a few months with an overall paycut, plus 'her' maternity running out soon there's no bloody way I'm going to use it next year. So...

http://classifieds.seloc.org/ads/pbmw-r ... r-turrets/

http://classifieds.seloc.org/ads/pbmw-r ... r-turrets/

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

I still think you'd be best off storing it for a year or two bud! Given the amount of time and money you've put into it, if you can't afford to race now...well you're not going to want to do it all again in 2 years right?

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Its been heart wrenching with the work gone in. But im held ransom to it at the moment as my job is disastrous and I really want to move on, which almost certainly means less money as id have an hour minimum commute. Less funds means no racing and 50 odd quid a month garage fees I can save, plus I can pay off some loans I took out for it meaning more in the bank.

Got a guy coming down from Blackburn Monday by train to pick it up for an m3 replica rally conversion, which was a surprise! But the family has to come first...

So when im in better financial shape ill be much better informed, much more experienced and may get a pre prepared car knowing I could take I apart if need be. Weshall seesee.ive lost 2k in total over 3 years, but as a hobby some people pay more for golf!

Still gutted and will be on tears to see it go but glad someone will buildoon my work. Its been emotional...

Got a guy coming down from Blackburn Monday by train to pick it up for an m3 replica rally conversion, which was a surprise! But the family has to come first...

So when im in better financial shape ill be much better informed, much more experienced and may get a pre prepared car knowing I could take I apart if need be. Weshall seesee.ive lost 2k in total over 3 years, but as a hobby some people pay more for golf!

Still gutted and will be on tears to see it go but glad someone will buildoon my work. Its been emotional...

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Well, still up for sale. But in other news, sent off my GAZ rear dampers asthey are leaking and need a service, and can't fault their service. I posted the dampers to them and within a couple of days I had a phonecall to take payment and told they were back in the post. Two working days later and they were back with me. So this will be a job for the weekend, possibly my last job  Considering getting it taxed up and driving down to some industrial estates begging / offering national sponsorship opportunities...

Considering getting it taxed up and driving down to some industrial estates begging / offering national sponsorship opportunities...

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Just a few pics of the rollcage being sprayed. Need another can as you can see, then I'll try to go over the overspray on the glass and inside, with some spirts and some fresh grey paint if need be.

It looks a bit more presentable already, just need another can to finish it off. Also, turns out this may well be my daily driver for a short commute to a new work as she wants the daily car every day

Ah well! At least it gets a bit of use...

It looks a bit more presentable already, just need another can to finish it off. Also, turns out this may well be my daily driver for a short commute to a new work as she wants the daily car every day

Ah well! At least it gets a bit of use...

Last edited by milescook on Sun Mar 22, 2015 6:07 pm, edited 1 time in total.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Something...

got done!

Admittedly the car could still be sold soon but not long ago I bought some parts it would need anyway so complete control arm bushes, tie rod ends and arb links all around 100 quid.

Managed the arb links they are the famous Mondeo ones.

My little commute was actually a 120 mile round trip 3 times a week which the car coped with fine. Not so much my back but dialing back on the dampers helped! Not too much otherwise it bounces down the motorway. Now it just does 6 miles a day.

Also, noticed there is a circuit not too far away and 80 quid gets you open pitlane for a day. Might have to get done before it goes...

got done!

Admittedly the car could still be sold soon but not long ago I bought some parts it would need anyway so complete control arm bushes, tie rod ends and arb links all around 100 quid.

Managed the arb links they are the famous Mondeo ones.

My little commute was actually a 120 mile round trip 3 times a week which the car coped with fine. Not so much my back but dialing back on the dampers helped! Not too much otherwise it bounces down the motorway. Now it just does 6 miles a day.

Also, noticed there is a circuit not too far away and 80 quid gets you open pitlane for a day. Might have to get done before it goes...

Last edited by milescook on Sun Mar 22, 2015 6:07 pm, edited 1 time in total.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

So... at long last, I've booked some circuit time in a couple of weeks. Llandow circuit all day at £80 - its a short circuit but ideal for a shakedown. All being well ill take some vids onboard.

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

Looking good Miles. I must get some of those Mondeo arb links for mine.

I've not been to Llandow for years (possibly 2004!). Do you know how often they run open pit lane days? I wouldn't mind taking mine up there once the engine is in.

I've not been to Llandow for years (possibly 2004!). Do you know how often they run open pit lane days? I wouldn't mind taking mine up there once the engine is in.

James

'91 325i Sport

'93 318i touring 16v

'91 325i Sport

'93 318i touring 16v