My Track Car Build, Spanning past 3 years

Moderator: martauto

TBH I considered just fitting the M54! But I do kinda want to have the experience building a motor, not something I've done before. And the M52 - ancillaries included - is quite a bit lighter, if manhandling the motors about the garage is anything to go by. I think it will work out cheaper in the long run too if I can pass on the bits I don't need.

The fan - well, it's punted as a pusher/puller depending on polarity. It does seem to do the job, albeit less effectively than the E36 fan. But the E36 fan is at least double the power, I'm sure.

The fan - well, it's punted as a pusher/puller depending on polarity. It does seem to do the job, albeit less effectively than the E36 fan. But the E36 fan is at least double the power, I'm sure.

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

It looks like the veins on the fan are moulded for pull operation, I bet you're loosing quite a bit of efficiency.

I have a thing about power management

I have a thing about power management

Well Blyton went pretty well. Car was reliable again, getting me there and back and taking abuse all day. Changing the oil from 5w40 Castrol Edge to 5w50 Mobil 1definitely helped keep the hot ticking at bay. Despite the S50 rad though, the temp is still rising slowly when it's being given the beans. I need to get to the bottom of that, for piece of mind as much as anything, so any ideas are welcome. It's running an 80 degree stat, Mishimoto S50 ally rad with Mishimoto top/bottom hoses, 50/50 mix of distilled water and Comma xtream g48 antifreeze concentrate, 1.4 bar pressure cap.

I'm not running with the plastic undertray fitted. Could this make a difference? Also, the double skin grp bonnet is definitely a big insulator though. It's cool to the touch on top, even after 15 mins on track!

I'm not running with the plastic undertray fitted. Could this make a difference? Also, the double skin grp bonnet is definitely a big insulator though. It's cool to the touch on top, even after 15 mins on track!

- Mikey_Boy

- E30 Zone Regular

- Posts: 996

- Joined: Sun Mar 16, 2008 11:00 pm

- Location: Cheshire - trying to avoid the bling!

Hello dude - great to see the progress here!  Just a couple of suggestions from me that might help (and no doubt you probably thought of...!):

Just a couple of suggestions from me that might help (and no doubt you probably thought of...!):

You are definitely sure that the fan is pulling air the right way?? Sounds silly but certainly a place to start..

Is the radiator completely sealed around the edges? Any air leakage around the sides of the radiator will reduce its effectiveness massively. I found cutting the OEM cowl to shape (the one that fits behind the kidney trims) and refitting that made a HUGE difference to my S14 conversion. This cowl takes the fast air at the front of the car, slows it down and channels it to the radiator which is a good thing. Air speed through the radiator needs to be pretty slow so that it picks up as much heat as possible as it passes through the rad and also that the air goes through the radiator - air hitting the rad too fast will try and go around the rad doing not very much at all.

I think youve done all the right things with the rad choice, just a matter of ticking off the details and you'll be sweet.

You are definitely sure that the fan is pulling air the right way?? Sounds silly but certainly a place to start..

Is the radiator completely sealed around the edges? Any air leakage around the sides of the radiator will reduce its effectiveness massively. I found cutting the OEM cowl to shape (the one that fits behind the kidney trims) and refitting that made a HUGE difference to my S14 conversion. This cowl takes the fast air at the front of the car, slows it down and channels it to the radiator which is a good thing. Air speed through the radiator needs to be pretty slow so that it picks up as much heat as possible as it passes through the rad and also that the air goes through the radiator - air hitting the rad too fast will try and go around the rad doing not very much at all.

I think youve done all the right things with the rad choice, just a matter of ticking off the details and you'll be sweet.

- Mikey_Boy

- E30 Zone Regular

- Posts: 996

- Joined: Sun Mar 16, 2008 11:00 pm

- Location: Cheshire - trying to avoid the bling!

And yes, the plastic undertray *may* make a small difference to channeling the air out but I wouldn't lose any sleep over that yet - sealing the rad in the aperture will make more difference...

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

Unfortunately, without an oil cooler you will have temp creep, If it was my car, this is what I would be investing in next.Motorhole wrote:Despite the S50 rad though, the temp is still rising slowly when it's being given the beans.

-

DanThe

- E30 Zone Team Member

- Posts: 28641

- Joined: Sat Sep 10, 2005 11:00 pm

- Location: Staffs

- Contact:

There is a good chance those bolt heads are touching the rad and leaving a nice gap for air to pass through, check out how close this E36 style rad is, its more or less touching the front panel http://www.e30zone.net/modules.php?name ... 46#2870946Motorhole wrote:

Some self adhesive foam tape around the edges will help seal things up

Good stuff! Thanks guys. Good point Dan - I'll be checking those bolt heads as soon as I can.

Closing all the gaps around the rad...duh...why didn't I think of that before. Bloody obvious that one! Will get on top of that too.

Andrew - yeah an oil cooler will feature as part of the M52B30 build. I already have some of the bits put to one side for that. So long as I don't do anything too stupid, this engine will hopefully see me through until it's time to drop the new one in. Knowing me, this time next year...at least

Closing all the gaps around the rad...duh...why didn't I think of that before. Bloody obvious that one! Will get on top of that too.

Andrew - yeah an oil cooler will feature as part of the M52B30 build. I already have some of the bits put to one side for that. So long as I don't do anything too stupid, this engine will hopefully see me through until it's time to drop the new one in. Knowing me, this time next year...at least

-

winx

- E30 Zone Camper

- Posts: 1099

- Joined: Wed Jul 30, 2008 11:00 pm

- Location: almost certainly not working on my E30...

I put an oil cooler on my m52b28 for the last track day and it took oil temps down by 22 degrees and water by 12 degrees. Well worth it!

I did also do a little ducting at the sides of the rad but otherwise same setup.

I did also do a little ducting at the sides of the rad but otherwise same setup.

Havn't updated this for a while, but progress has been slow yet omnipresent.

Car hasn't been out since October, for no other reason than I've been a bit busy. Though this week I'm going to change the brake fluid and see what I can do with rad airflow before my next track day on 18th March.

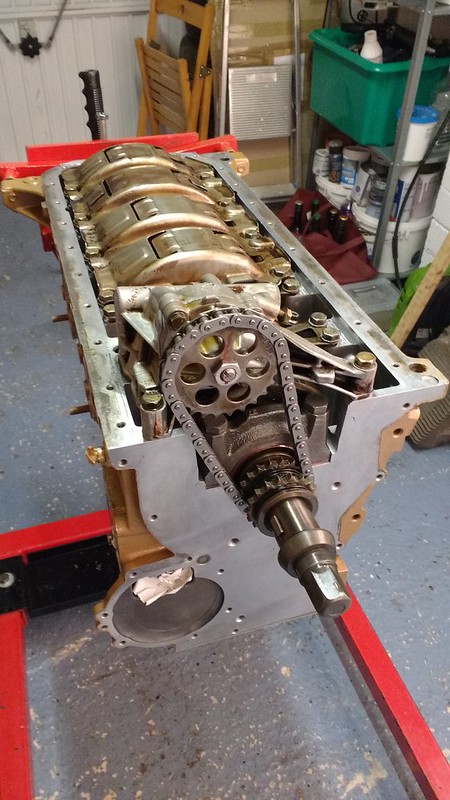

The M52B30 build - well I have some photos of this, though it's more of an M52 stripdown at the moment! I've sold off most of the M54 engine now, so at it stands, the crank, rods, pistons and intake cam have cost me about £30. Still got the block, head and a few other bits - sensors etc - for sale so I will do better than break even eventually.

Then for £200, I bought an M52B25 nikasil lined block and a separate steel-lined block to build it all into.

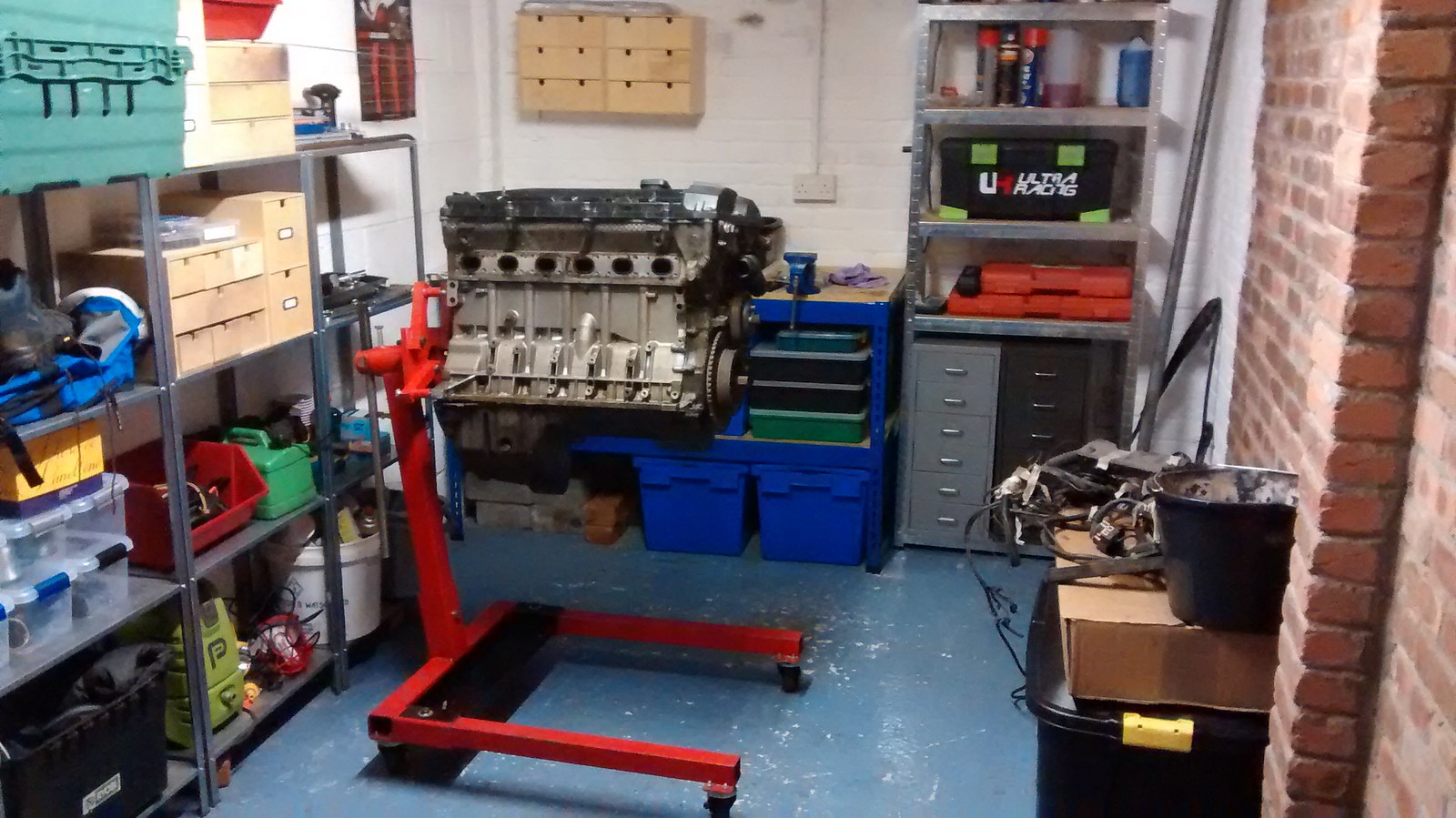

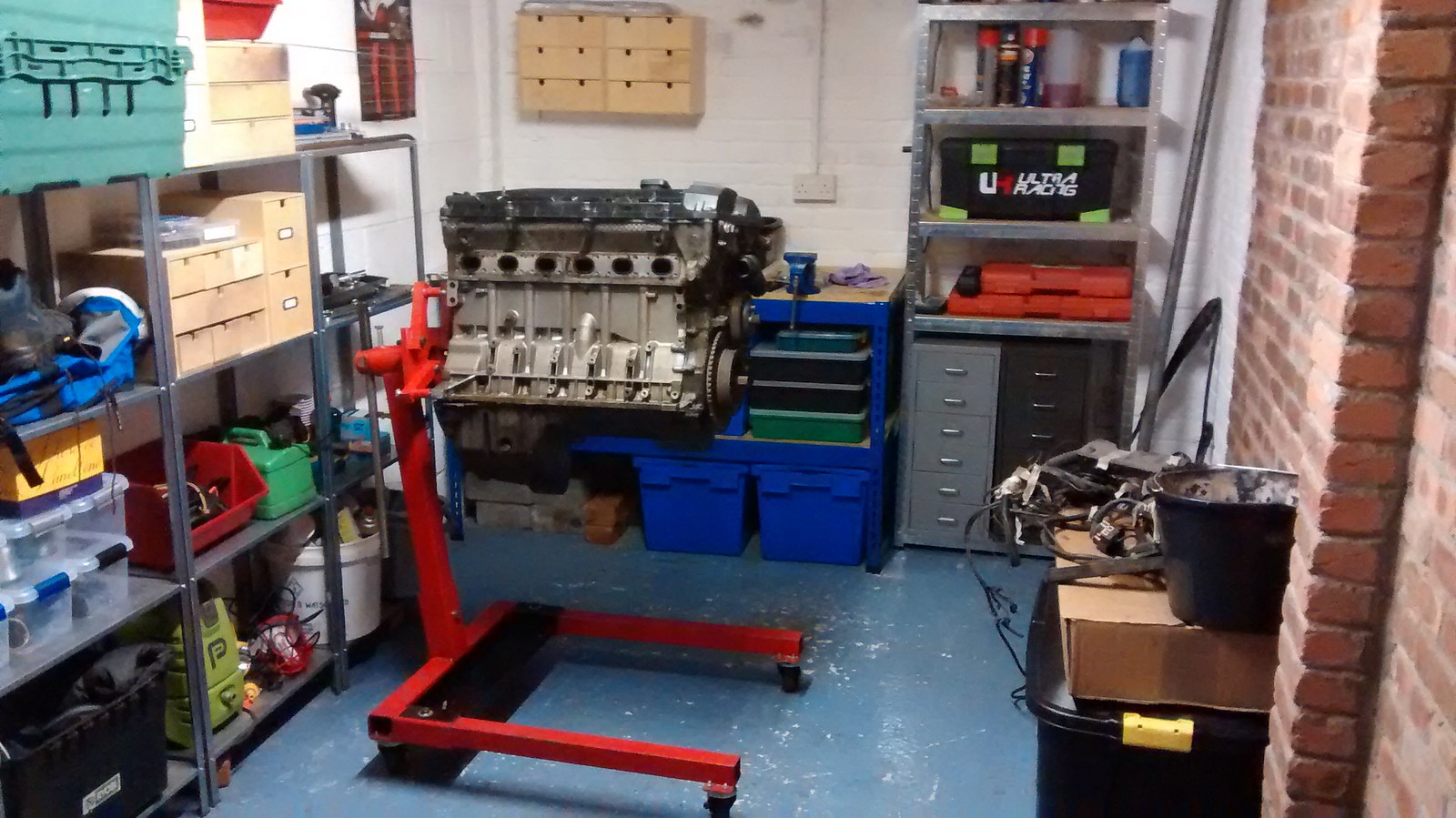

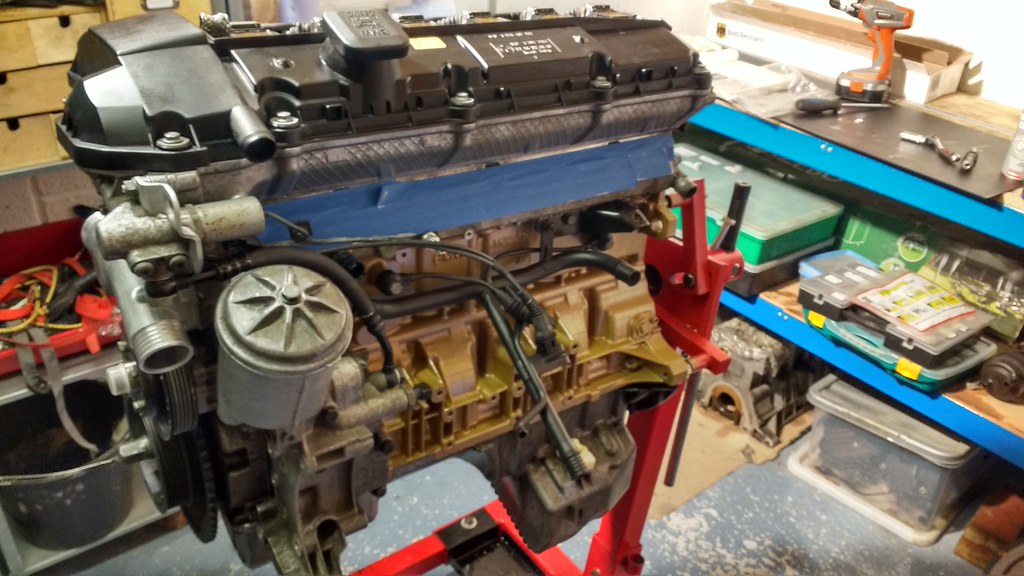

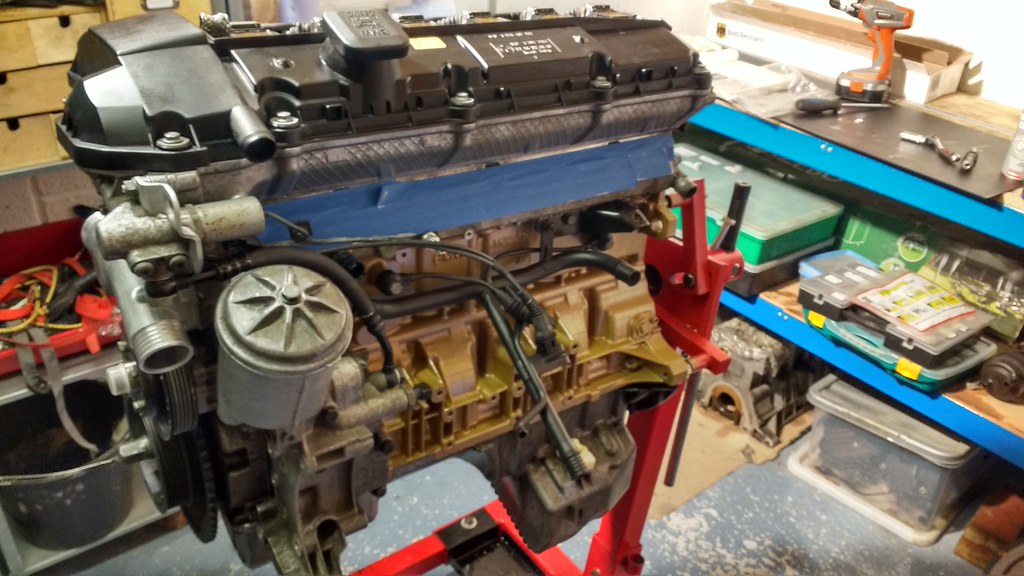

M52 engine on the stand

M52 steel-lined block under the bench

I then set about removing the loom and attached parts then collecting bits and tidying/cleaning the garage for preparation.

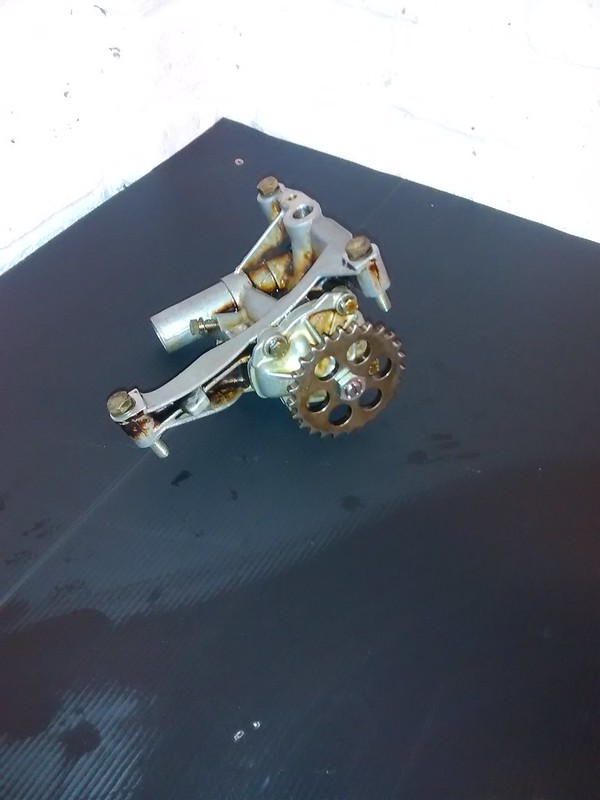

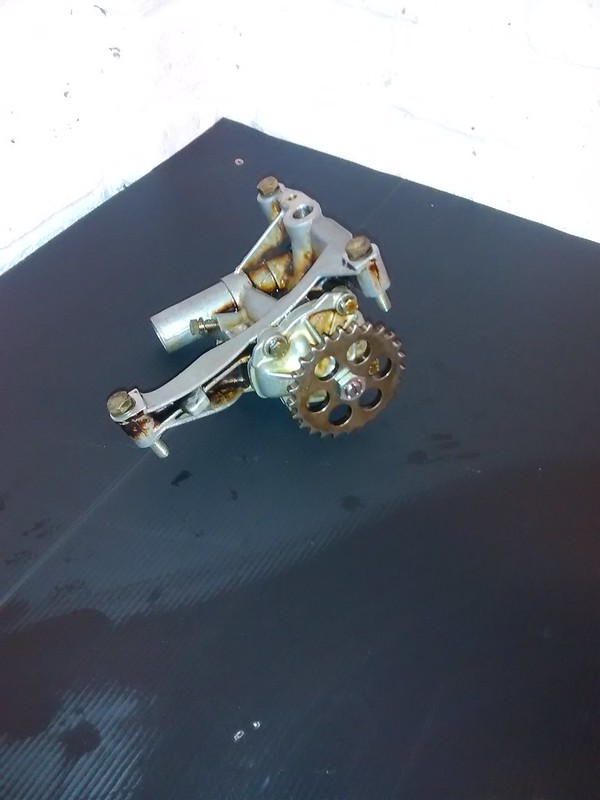

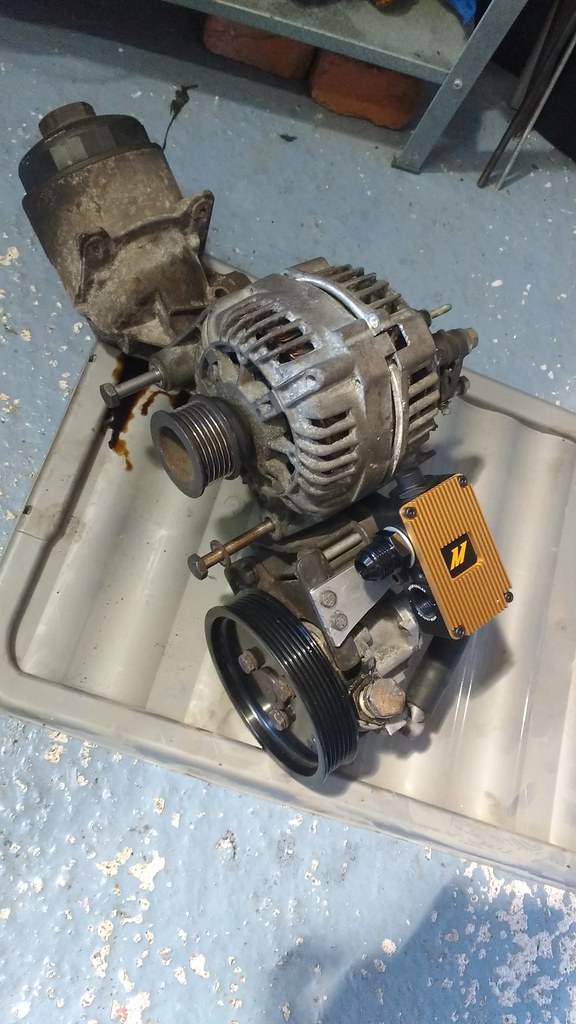

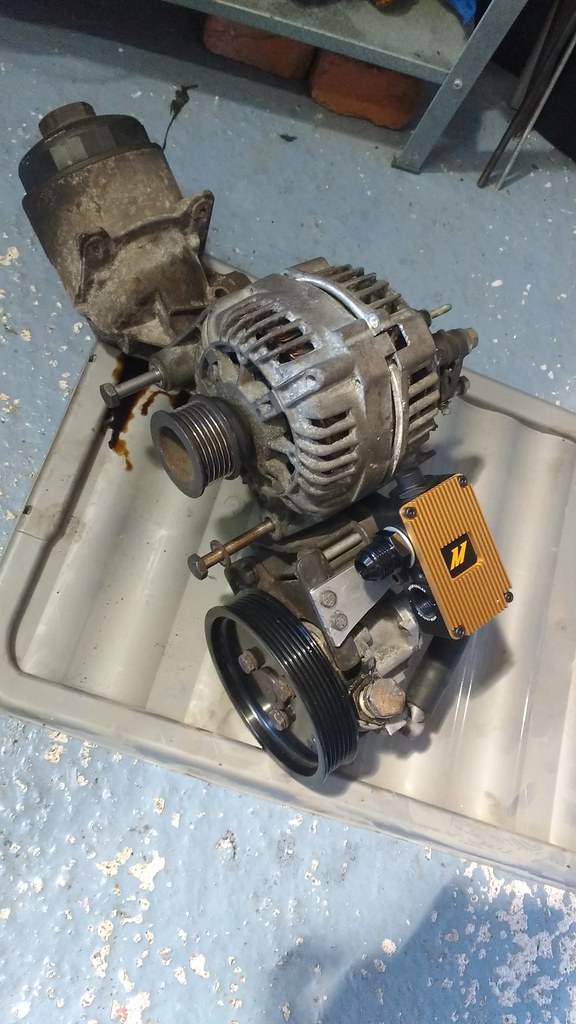

Including this little bad boy so I can fit an oil cooler! I currently have a 16-row cooler and thermostat on the way.

And pretty much since then, I've been dismantling, cleaning and stowing! I figured that if I have all the bits ready to go, the build itself should be fairly hassle free and the 'clean' engine will be open for the minimum amount of time. A 4-day weekend should be enough time for a first time to put an engine together right!?

One question if anyone can help though - basically am I best using assembly grease on cam/crank journals or just using whatever mineral oil I'll be using to break the engine in with? Speaking of which - any recommendations on that front?

So far the M52 cylinder head is pretty much dismantled with everything cleaned up save for the exhaust lifters ( ). All the intake lifters (taken from the M54 to match the cam) have been serviced and cleaned so I'm not looking forward to doing another 12! After that, it should get easier. I also need to drop the block and cylinder head (when it's off) to the machine shop to get everything checked for flatness, squareness, to get the bores honed and to get the M54 cam turned down to fit. Hopefully it'll soon be all ready to put together!

). All the intake lifters (taken from the M54 to match the cam) have been serviced and cleaned so I'm not looking forward to doing another 12! After that, it should get easier. I also need to drop the block and cylinder head (when it's off) to the machine shop to get everything checked for flatness, squareness, to get the bores honed and to get the M54 cam turned down to fit. Hopefully it'll soon be all ready to put together!

Car hasn't been out since October, for no other reason than I've been a bit busy. Though this week I'm going to change the brake fluid and see what I can do with rad airflow before my next track day on 18th March.

The M52B30 build - well I have some photos of this, though it's more of an M52 stripdown at the moment! I've sold off most of the M54 engine now, so at it stands, the crank, rods, pistons and intake cam have cost me about £30. Still got the block, head and a few other bits - sensors etc - for sale so I will do better than break even eventually.

Then for £200, I bought an M52B25 nikasil lined block and a separate steel-lined block to build it all into.

M52 engine on the stand

M52 steel-lined block under the bench

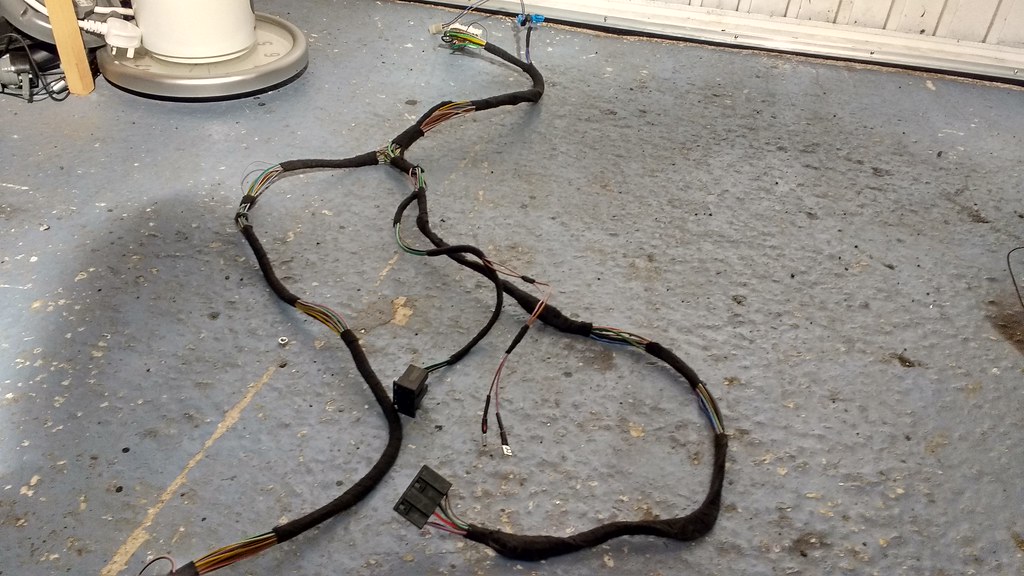

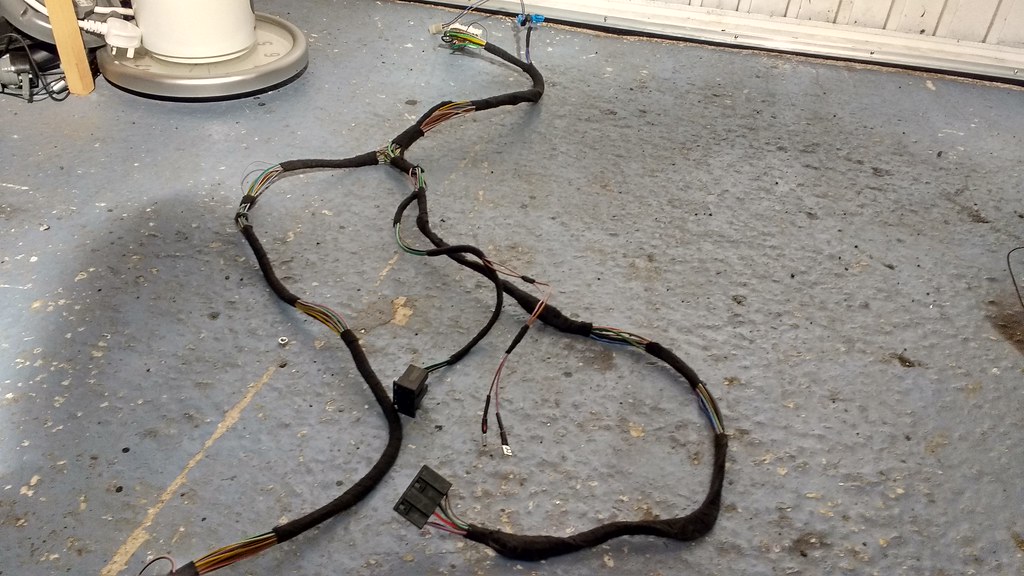

I then set about removing the loom and attached parts then collecting bits and tidying/cleaning the garage for preparation.

Including this little bad boy so I can fit an oil cooler! I currently have a 16-row cooler and thermostat on the way.

And pretty much since then, I've been dismantling, cleaning and stowing! I figured that if I have all the bits ready to go, the build itself should be fairly hassle free and the 'clean' engine will be open for the minimum amount of time. A 4-day weekend should be enough time for a first time to put an engine together right!?

One question if anyone can help though - basically am I best using assembly grease on cam/crank journals or just using whatever mineral oil I'll be using to break the engine in with? Speaking of which - any recommendations on that front?

So far the M52 cylinder head is pretty much dismantled with everything cleaned up save for the exhaust lifters (

- Superleggera

- E30 Zone Newbie

- Posts: 152

- Joined: Wed Nov 05, 2014 11:00 pm

Good work ! Wish I had a little workshop like that at home.

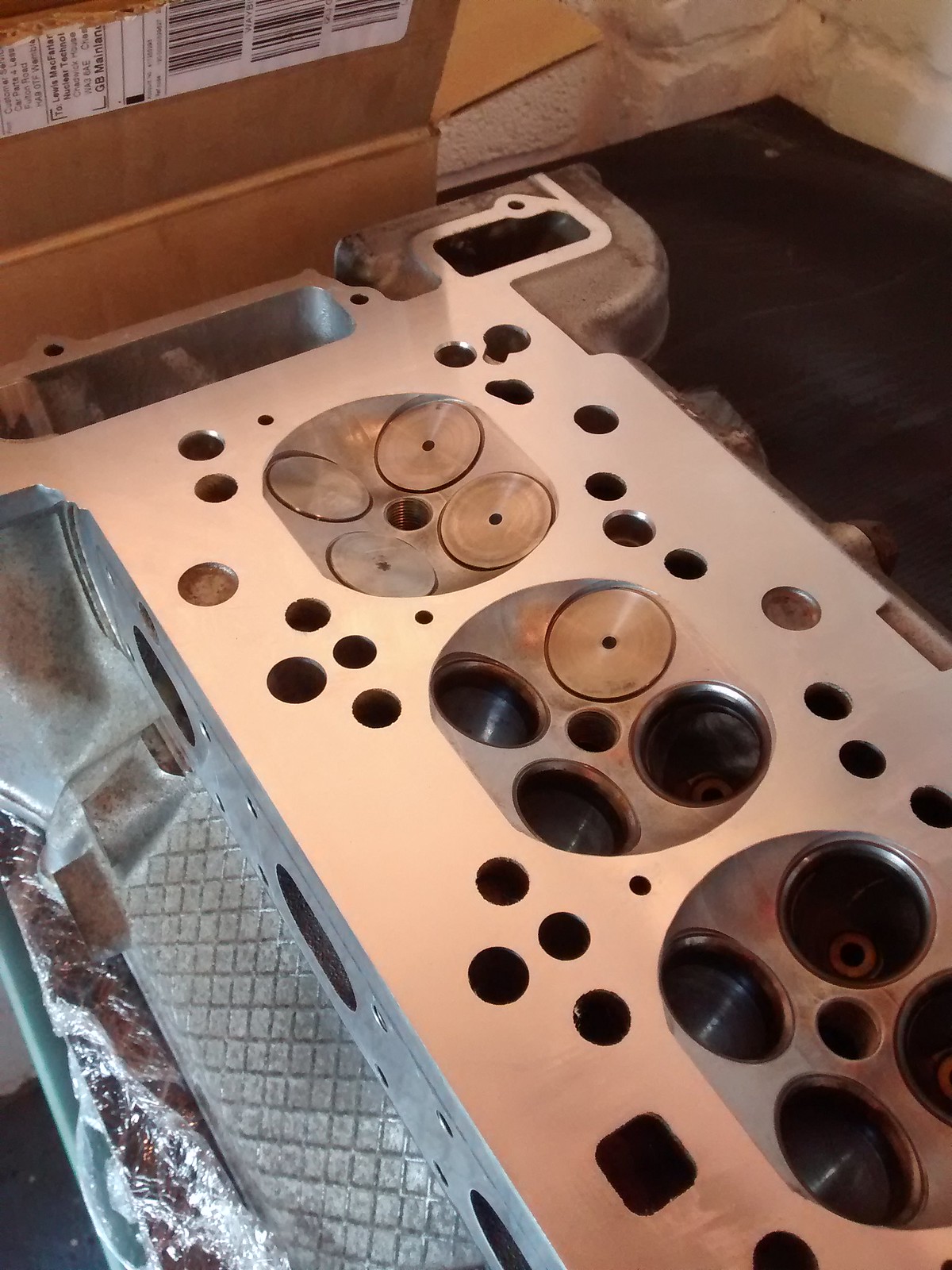

So yesterday I got on with cleaning up the cylinder head. Lots of labour and now I have a stiff right arm from...er...all the reciprocating hand actions. Still...although it's not perfect, I'm fairly happy with the results.

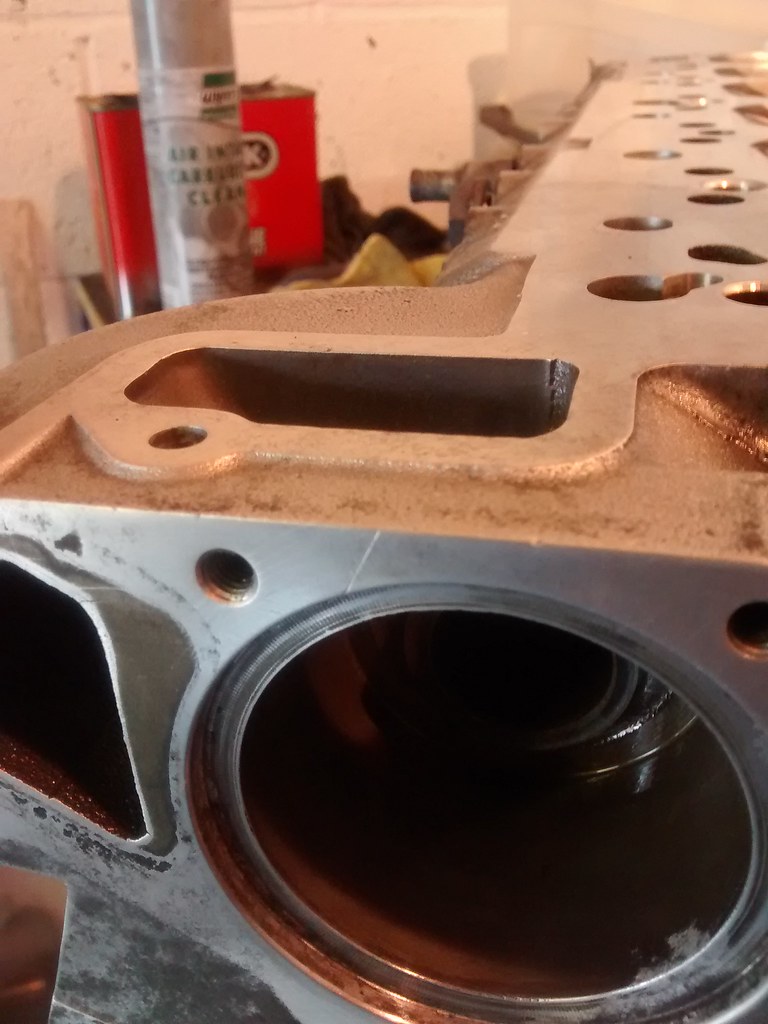

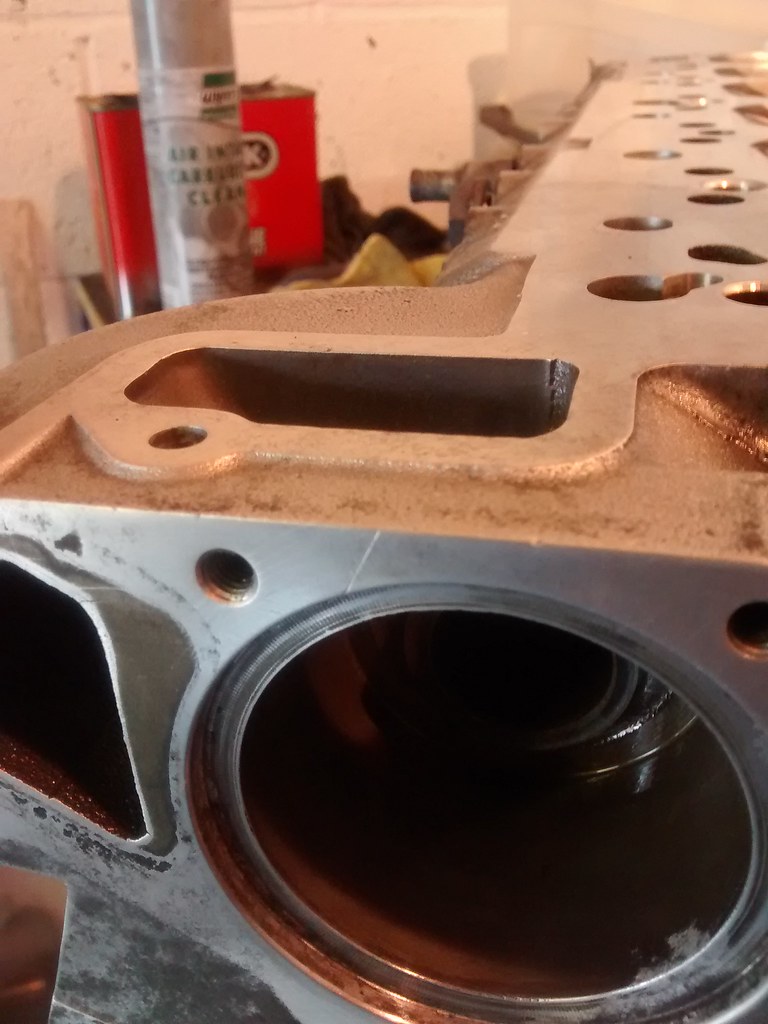

It started looking something like this.

Started with a good soaking in Gunk natural green then a thorough going over with a pressure washer. Then I went to work on the various gasket surfaces, ports etc.

Head gasket surface - began (very, very carefully!) with a sharp Stanley knife blade. Then lots and lots of work with an ultra-fine sanding sponge and wd40 - same in the chambers, taking care to avoid the valve seats. Using a straight edge and feeler gauges, the head comes out nice and flat.

Other gasket surfaces got the same sponge and wd40 treatment. Then to make sure I got all the residual crap out of the head, it got another good soaking in Gunk green and another blast with the pressure washer, taking care to clear out all the galleries and ports. Let it drain, some heat gun action then some oil on parts liable to corrode, job done!

One slight issue - there appears to be a scratch on the gasket surface for the thermostat housing. It's just about deep enough to catch a nail in - is this likely to cause an issue as is? If so, what's the best course of action?

Today, it's back to the car for trackday prep as I'm at Blyton on Friday. After that I need to think about getting all the pistons cleaned up so I can drop them off with the block and M54 intake cam at the machine shop and while all that's being done, I'll get on with putting stem seals, valve, springs etc back into the head

It started looking something like this.

Started with a good soaking in Gunk natural green then a thorough going over with a pressure washer. Then I went to work on the various gasket surfaces, ports etc.

Head gasket surface - began (very, very carefully!) with a sharp Stanley knife blade. Then lots and lots of work with an ultra-fine sanding sponge and wd40 - same in the chambers, taking care to avoid the valve seats. Using a straight edge and feeler gauges, the head comes out nice and flat.

Other gasket surfaces got the same sponge and wd40 treatment. Then to make sure I got all the residual crap out of the head, it got another good soaking in Gunk green and another blast with the pressure washer, taking care to clear out all the galleries and ports. Let it drain, some heat gun action then some oil on parts liable to corrode, job done!

One slight issue - there appears to be a scratch on the gasket surface for the thermostat housing. It's just about deep enough to catch a nail in - is this likely to cause an issue as is? If so, what's the best course of action?

Today, it's back to the car for trackday prep as I'm at Blyton on Friday. After that I need to think about getting all the pistons cleaned up so I can drop them off with the block and M54 intake cam at the machine shop and while all that's being done, I'll get on with putting stem seals, valve, springs etc back into the head

Good day at Blyton park on Friday. Did more track miles in one day than I've done yet - 8 sessions, perhaps 110-120 miles? Plus the 240 miles return trip in the car too with all my cr*p loaded into the boot :p Car didn't miss a beat. I havn't made any progress on sorting earlier minor cooling niggles, but it seemed that with a 6-degree ambient temperature, I had no problems at all. It's proving pretty good on consumables too - still plenty of tread left on the tyres, still plenty of meat left on the pads that have been there since the car first hit the road. The only work I've done on the actual car since October is change the brake fluid.

On the downside - could still be doing with track tyres and it still rolls far too much :p But I knew this already and remedies are waiting in the wings for when the engine build is done and dusted. Had a look at some of my lap times on the videos and the best is about a 1:18 with a passenger - perhaps I went quicker later in the afternoon on my own, on a nearly empty track!? Perhaps not. Ill never know, the GoPro battery had died by then. Still, I'm fairly happy with that sort of pace on Champiro ditchfinders - about 74 mph average on what is a pretty tight track.

Some photos and video from the day Second video - there's a lot of traffic, it's a little less slow from about 12:30 onwards.

Second video - there's a lot of traffic, it's a little less slow from about 12:30 onwards.

On the downside - could still be doing with track tyres and it still rolls far too much :p But I knew this already and remedies are waiting in the wings for when the engine build is done and dusted. Had a look at some of my lap times on the videos and the best is about a 1:18 with a passenger - perhaps I went quicker later in the afternoon on my own, on a nearly empty track!? Perhaps not. Ill never know, the GoPro battery had died by then. Still, I'm fairly happy with that sort of pace on Champiro ditchfinders - about 74 mph average on what is a pretty tight track.

Some photos and video from the day

Yeah I really like Blyton. If it was closer, I'd be there a lot more often! Trackdays there are cheap, it's well managed and it gives you the chance to really find the car's limits with minimal chance of contact with something. And unlike most airfield based circuits, it has proper tarmac and kerbs - against which you can test the abilities of your dampers :prix313 wrote:Looks a good technical little layout that. Although it does look a pain in traffic

I know your engine is heavier but what springs do you have front and rear?

Front spring rates are 450lb Faulkners. Don't know what the standard Koni rates were beforehand but they were definitely some way softer than that. Rears are still the Konis - about about 420lb by my rough estimation when I had them off last.

Reluctant to go higher as would be some way outside of the specs of the damper I'd imagine. Anyway the front coilovers don't allow me to make use of the strut mounted ARB pickup either so I'm looking to flog the lot and upgrade to something more suitable in the future, with appropriate spring rates

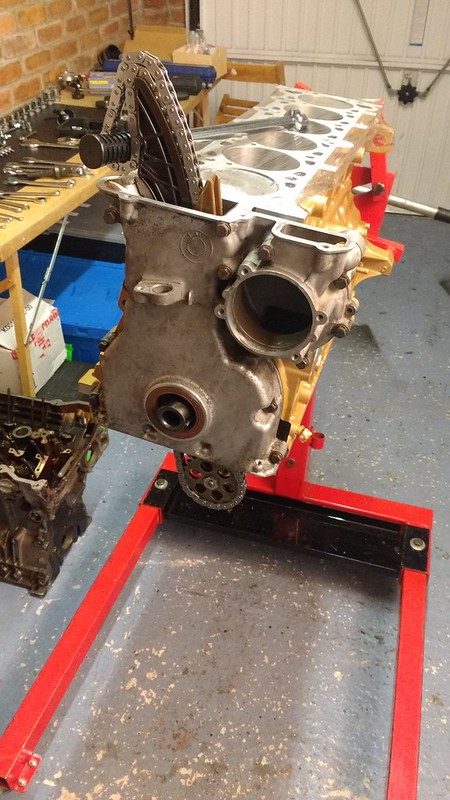

So I guess the engine rebuild has 'formally' begun!

The block, head and intake cam are still at the machine shop, so no progress there. To be honest, I'm still in no particular rush to get them back. I plan to do the bulk of the assembly over a 4-day weekend and I don't have the time to do that for a few weeks at least.

However my box of goodies from BMW arrived this week so I cracked on with rebuilding the oil pump and the VANOS unit. All seemingly basic stuff, so hopefully it'll all function properly when it times come to turn the key!

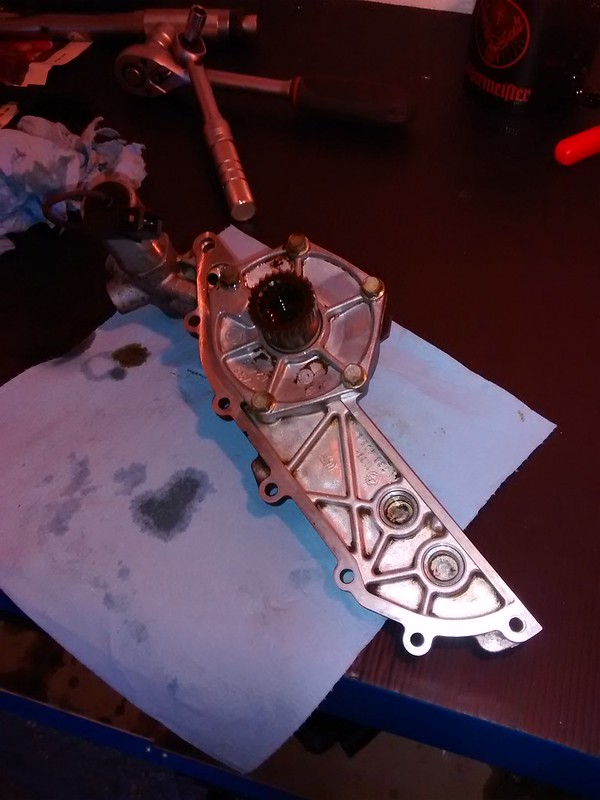

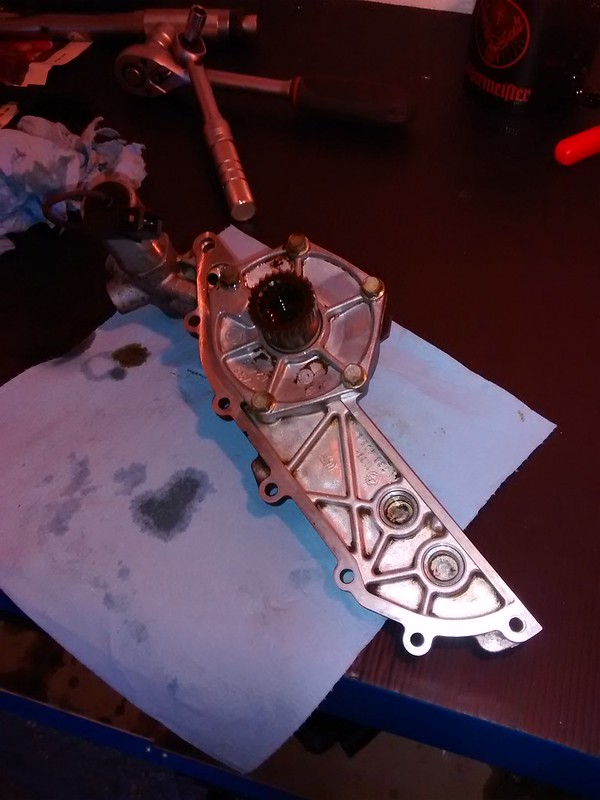

So, some pictures of cleaned/new oil pump bits. The inner/outer rotors, spring, valve and sealing o-ring were all replaced with new.

I'll hopefully be able to get a mate to tack weld the nut on once it's all fitted to the engine with the drive chain.

On the VANOS I replaced the infamous seals and the anti-rattle ring.

Following the rebuild there was no perceivable axial or radial play and a little bit of preload, so it all felt good to me. Hopefully it'll run many thousands of miles with no nasty noises

So far as trackdays are concerned, I'm hoping to do the LMC Aintree day in May as it's pretty local - then I'm at Blyton again on 17th June. That should be the last day out with the old engine...

The block, head and intake cam are still at the machine shop, so no progress there. To be honest, I'm still in no particular rush to get them back. I plan to do the bulk of the assembly over a 4-day weekend and I don't have the time to do that for a few weeks at least.

However my box of goodies from BMW arrived this week so I cracked on with rebuilding the oil pump and the VANOS unit. All seemingly basic stuff, so hopefully it'll all function properly when it times come to turn the key!

So, some pictures of cleaned/new oil pump bits. The inner/outer rotors, spring, valve and sealing o-ring were all replaced with new.

I'll hopefully be able to get a mate to tack weld the nut on once it's all fitted to the engine with the drive chain.

On the VANOS I replaced the infamous seals and the anti-rattle ring.

Following the rebuild there was no perceivable axial or radial play and a little bit of preload, so it all felt good to me. Hopefully it'll run many thousands of miles with no nasty noises

So far as trackdays are concerned, I'm hoping to do the LMC Aintree day in May as it's pretty local - then I'm at Blyton again on 17th June. That should be the last day out with the old engine...

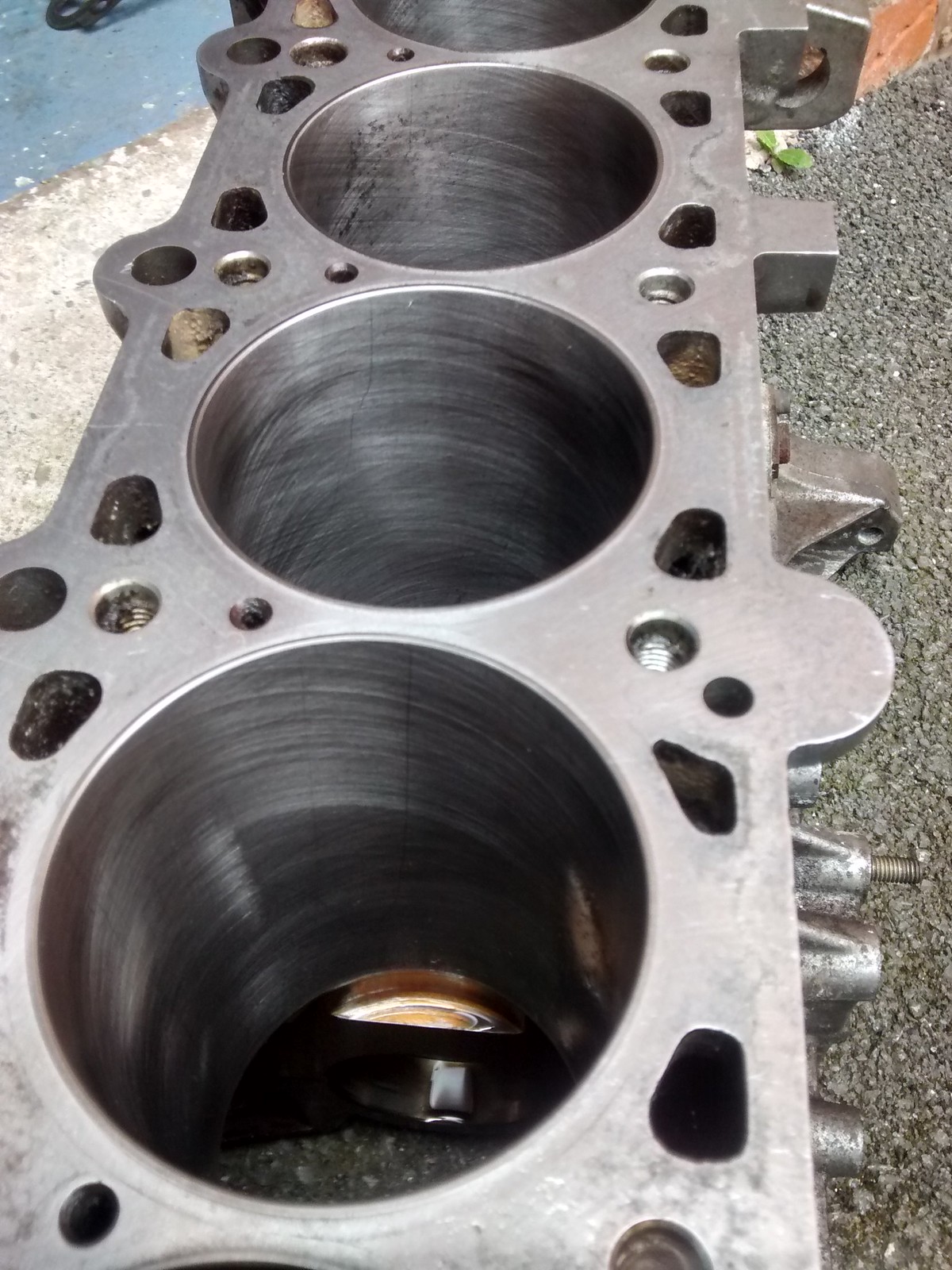

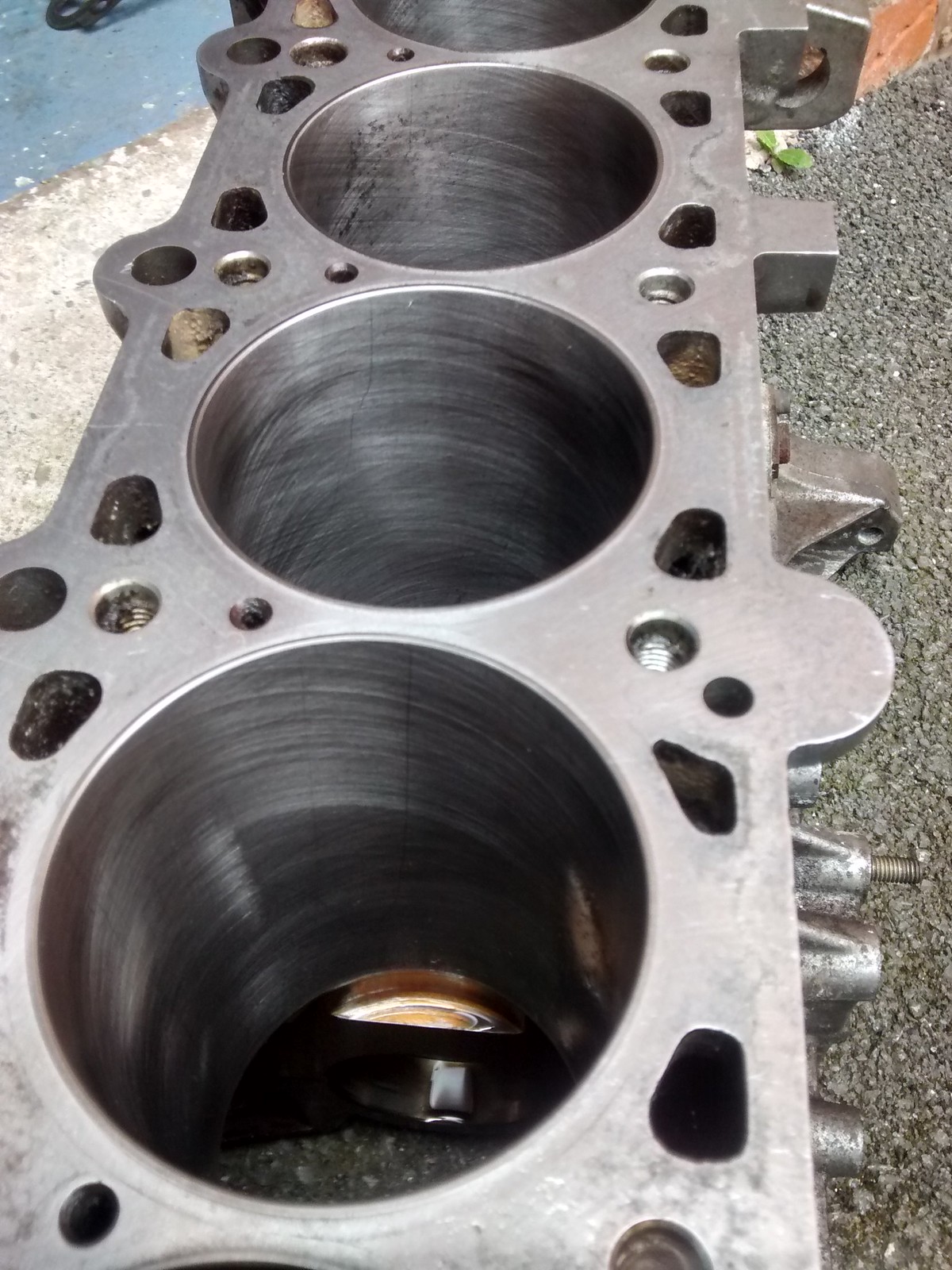

More progress over the weekend, though not as much as I'd originally planned. I hoped to have the block back to do the build this weekend, but that never happened.

The block I'd handed over for machining had excessive wear (0.07 mm - or 3 thou - taper in 5 bores) and water damage in the bores. The only way this block was going to work was with a +0.25 or +0.5 mm overbore. I didn't fancy dropping a grand on oversize pistons, so I sourced another block (thanks to mattxr2 on here) and dropped that off at the shop on Wednesday. I may still go the overbore route if sourcing a good block proves troublesome...but I get the impression from the shear number of people who seem to have done this build, that shouldn't be too hard? We'll see!

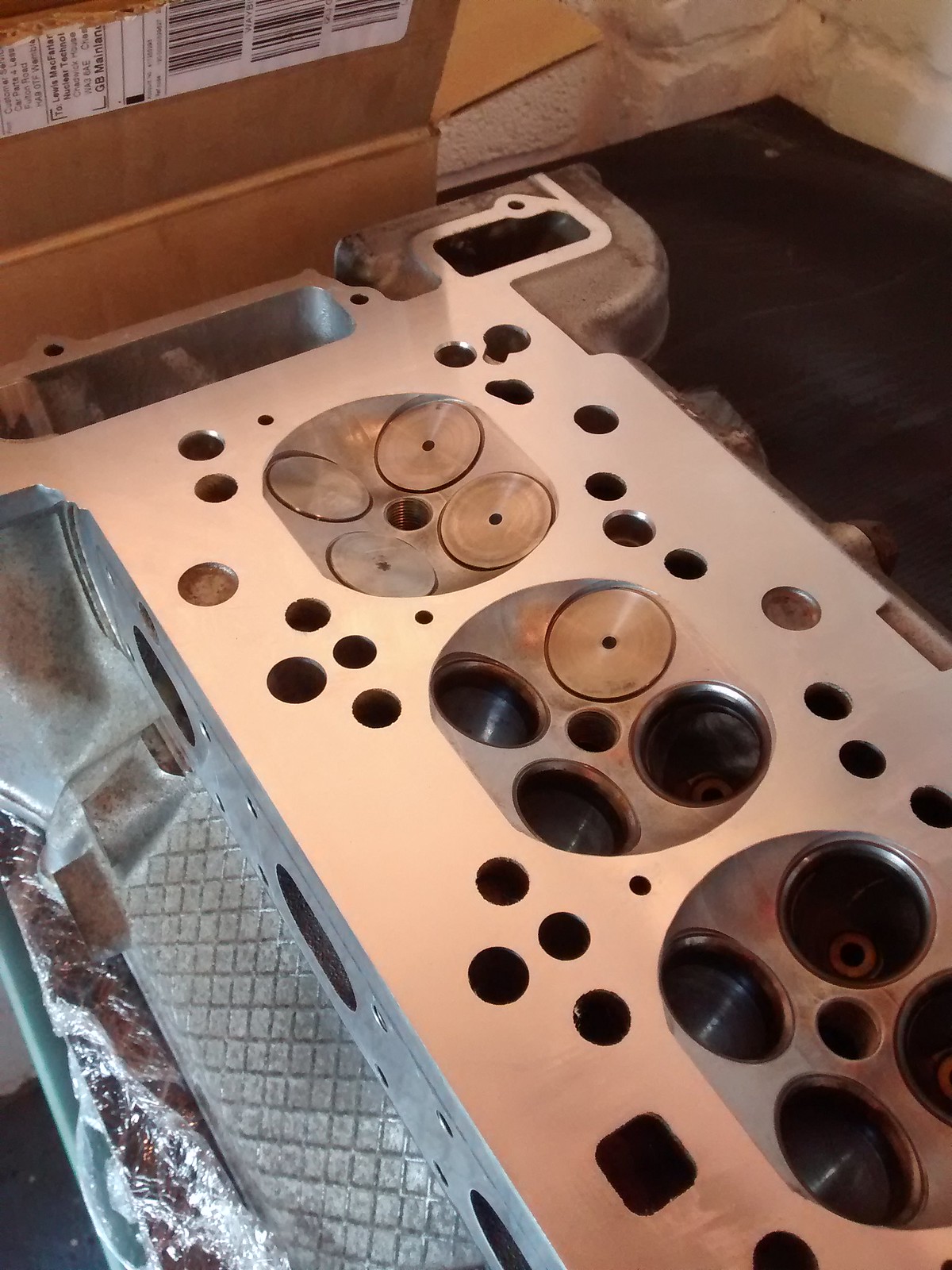

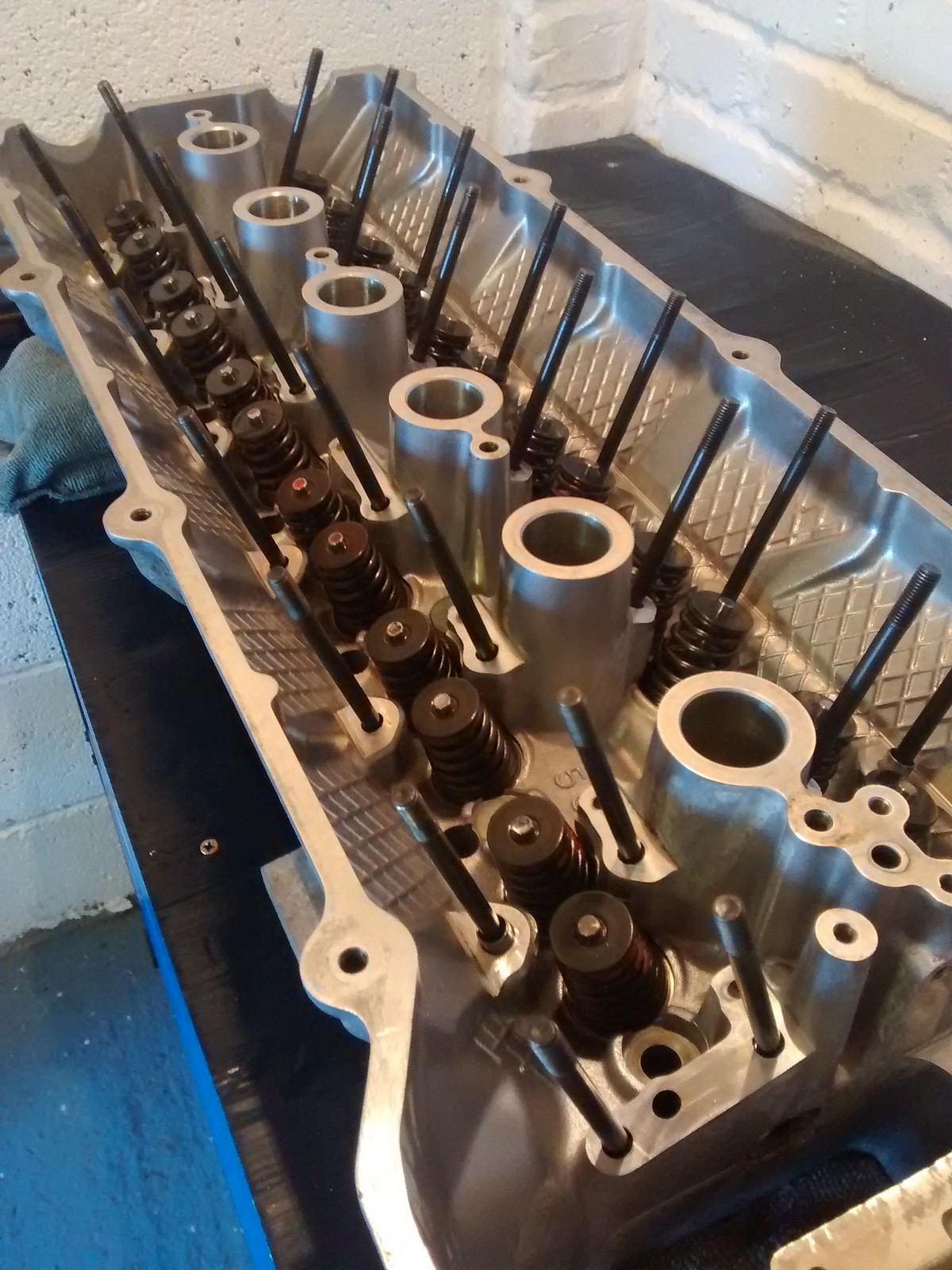

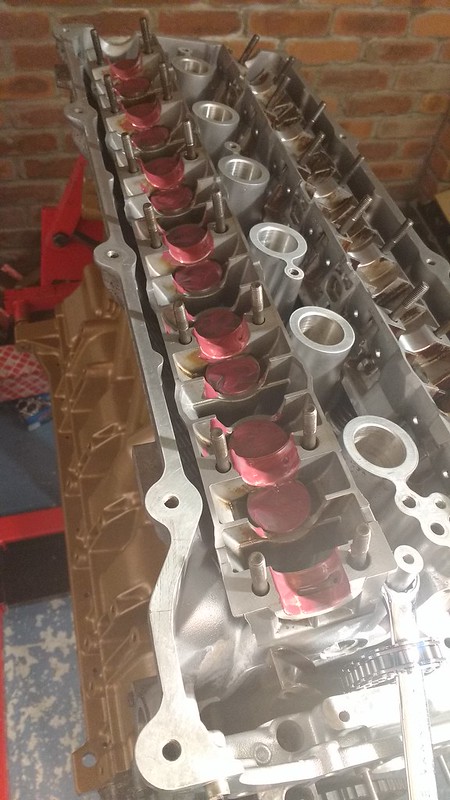

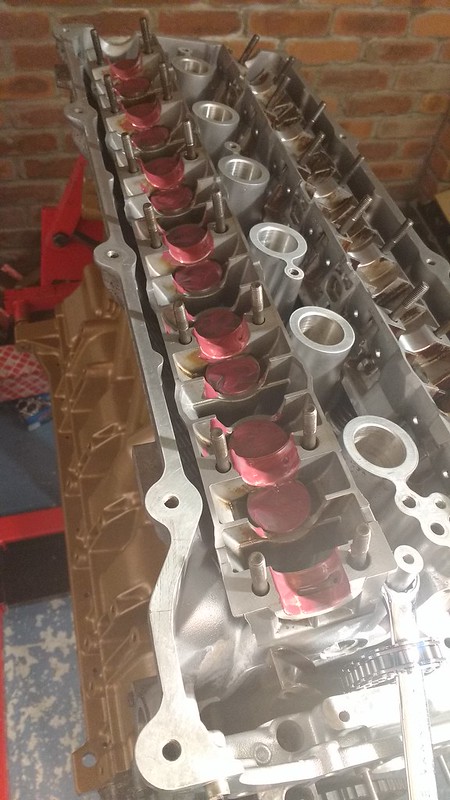

Anyway, I did get my freshly skimmed & tanked cylinder head back at least. So I got on with putting the valves back in that.

I started with some light lapping using a fine paste, checking valve guide clearance as I went. All seemed good and the lapping tidied up the exhaust valve pitting nicely. Didn't need a lot of it mind - and soon I seemed to have a good seal in all 6 chambers. Second photo is lapped vs. unlapped valve seat.

So out came all the valves again, keeping careful note of their original locations. Then I put the jetwash back onto the cylinder head to make sure it was completely clear of machine swarf and abrasives. Then I dried it in the conservatory. My garden is southwest facing and pretty open to the elements! So in this weekend's weather, the conservatory becomes a proverbial oven. Did the job nicely

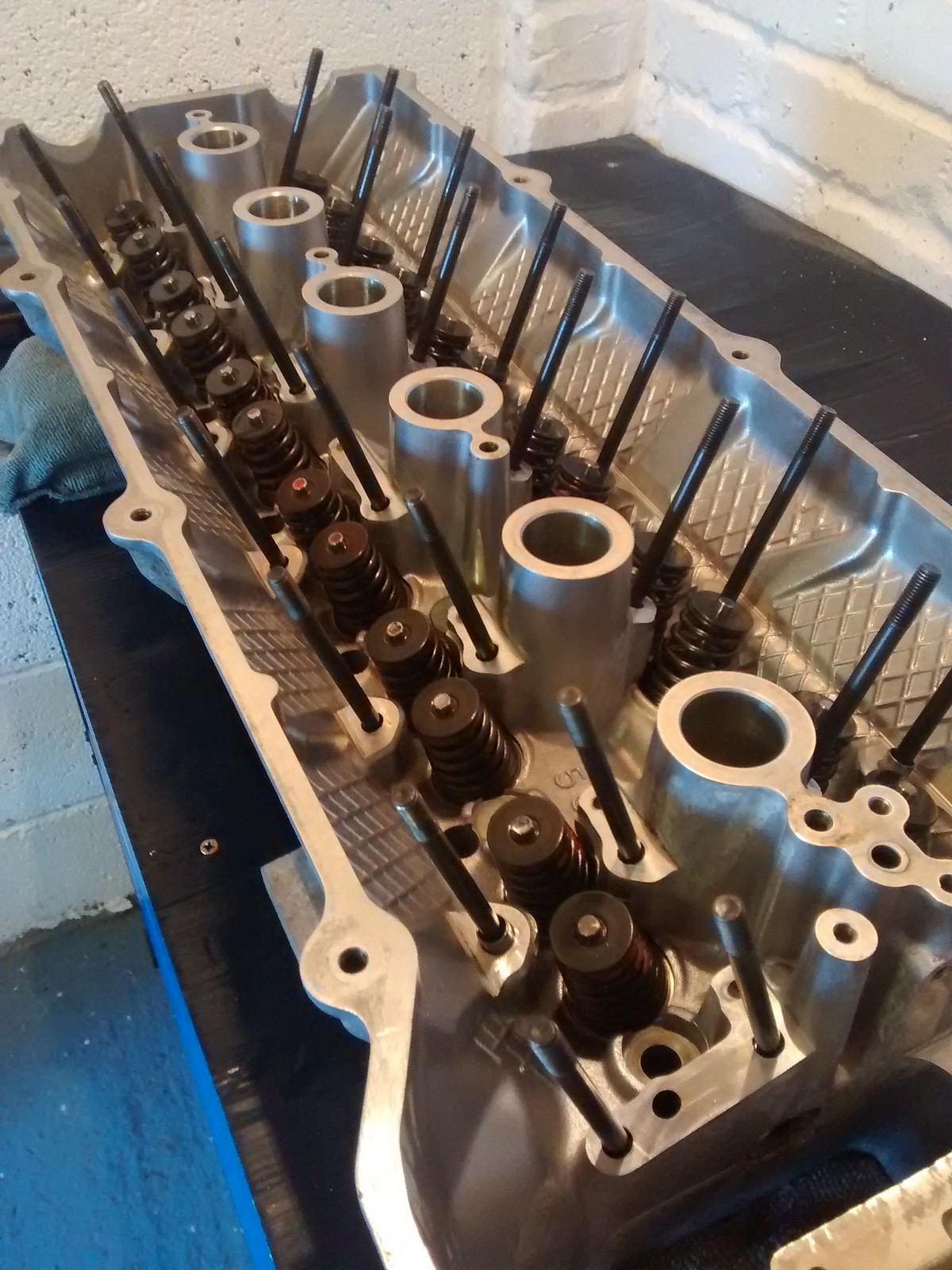

So clean, engine-ruinous-matter free cylinder head was transferred back to the garage for new valve stem seals. Valves popped back into their correct locations. Oil non-return valve and valve spring bottom plates dropped back in. Then to faffing around with springs and collets.

I should add I'm using valve springs from the M54 throughout. The springs are the same part number as M52 valve springs, but after measuring them all up, it seems the M54 ones come in a few mm longer on average. Read - less compression, less wear?

I'd bought a cylinder head servicing toolset before taking the various engines to pieces - that used a lever arm compressor that has a frame that bolts to the head. It also came with a special little collet tool - a magnet for removal at one end (wonderful) and some kind of spring loaded gripper at the other (less so). Faffed around with this thing for a little while only to realise it wasn't going to work with the compressor in situ. So settled for fitting the collets by hand instead. I was worried after a few minutes that this would be impossible. But - it seems there is a knack. And once I had it sussed, it didn't take long to do all 24

Wound in the camshaft lifter block studs, job done! It's now wrapped up in plastic and sitting on the top shelf awaiting a freshly skimmed, cleaned and honed block. If that ever happens...

I'm off to Donington Park for an evening trackday in the car this week, then Blyton again on 17th of June. After that, the car is going to be retired for engine swap preparations.

The block I'd handed over for machining had excessive wear (0.07 mm - or 3 thou - taper in 5 bores) and water damage in the bores. The only way this block was going to work was with a +0.25 or +0.5 mm overbore. I didn't fancy dropping a grand on oversize pistons, so I sourced another block (thanks to mattxr2 on here) and dropped that off at the shop on Wednesday. I may still go the overbore route if sourcing a good block proves troublesome...but I get the impression from the shear number of people who seem to have done this build, that shouldn't be too hard? We'll see!

Anyway, I did get my freshly skimmed & tanked cylinder head back at least. So I got on with putting the valves back in that.

I started with some light lapping using a fine paste, checking valve guide clearance as I went. All seemed good and the lapping tidied up the exhaust valve pitting nicely. Didn't need a lot of it mind - and soon I seemed to have a good seal in all 6 chambers. Second photo is lapped vs. unlapped valve seat.

So out came all the valves again, keeping careful note of their original locations. Then I put the jetwash back onto the cylinder head to make sure it was completely clear of machine swarf and abrasives. Then I dried it in the conservatory. My garden is southwest facing and pretty open to the elements! So in this weekend's weather, the conservatory becomes a proverbial oven. Did the job nicely

So clean, engine-ruinous-matter free cylinder head was transferred back to the garage for new valve stem seals. Valves popped back into their correct locations. Oil non-return valve and valve spring bottom plates dropped back in. Then to faffing around with springs and collets.

I should add I'm using valve springs from the M54 throughout. The springs are the same part number as M52 valve springs, but after measuring them all up, it seems the M54 ones come in a few mm longer on average. Read - less compression, less wear?

I'd bought a cylinder head servicing toolset before taking the various engines to pieces - that used a lever arm compressor that has a frame that bolts to the head. It also came with a special little collet tool - a magnet for removal at one end (wonderful) and some kind of spring loaded gripper at the other (less so). Faffed around with this thing for a little while only to realise it wasn't going to work with the compressor in situ. So settled for fitting the collets by hand instead. I was worried after a few minutes that this would be impossible. But - it seems there is a knack. And once I had it sussed, it didn't take long to do all 24

Wound in the camshaft lifter block studs, job done! It's now wrapped up in plastic and sitting on the top shelf awaiting a freshly skimmed, cleaned and honed block. If that ever happens...

I'm off to Donington Park for an evening trackday in the car this week, then Blyton again on 17th of June. After that, the car is going to be retired for engine swap preparations.

Donington was great!

Now I'm not ashamed to admit I was pretty slow from the get go. I'd never been to Donington before and I know it can be a bit of a car wrecker so caution was in order. As the evening wore on though and I got a better feel for the lines and that the car wasn't going to bite, I got to go a bit quicker and in the last session, had a great time chasing down an Exige which then, ultimately, ended up holding me up. Surprised how little difference in acceleration there was, the E30 stayed with it well onto the straight out of the last corner.

I had Sf_Manta with me too - his first time out in the car since he helped with the engine swap a couple of years ago. He was on hand to provide guidance on tyre pressures (having been an ex race tyre engineer) and that made a difference without a doubt. He also took a couple of flybys for me:

Downsides? Well coming down from north of 115 mph twice per lap meant the OEM brake pads left deposits on the discs resulting in brake judder when hot. Not intolerable, just - well, it was noticeable! I guess some decent performance orientated pads will nip that in the bud. I have no on-board video footage because I arrived at Donny to find my GoPro battery was hosed and wouldn't hold charge. And what's this about the Cafe closing at 5.30? Nowhere to get a brew or even buy a bottle of water between sessions! Not for reference for future evening trackdays.

All in all though, great track - love that you can take loads of kerb, especially at the apex of the old hairpin. Car never missed a beat. I'll be back...

Now I'm not ashamed to admit I was pretty slow from the get go. I'd never been to Donington before and I know it can be a bit of a car wrecker so caution was in order. As the evening wore on though and I got a better feel for the lines and that the car wasn't going to bite, I got to go a bit quicker and in the last session, had a great time chasing down an Exige which then, ultimately, ended up holding me up. Surprised how little difference in acceleration there was, the E30 stayed with it well onto the straight out of the last corner.

I had Sf_Manta with me too - his first time out in the car since he helped with the engine swap a couple of years ago. He was on hand to provide guidance on tyre pressures (having been an ex race tyre engineer) and that made a difference without a doubt. He also took a couple of flybys for me:

Downsides? Well coming down from north of 115 mph twice per lap meant the OEM brake pads left deposits on the discs resulting in brake judder when hot. Not intolerable, just - well, it was noticeable! I guess some decent performance orientated pads will nip that in the bud. I have no on-board video footage because I arrived at Donny to find my GoPro battery was hosed and wouldn't hold charge. And what's this about the Cafe closing at 5.30? Nowhere to get a brew or even buy a bottle of water between sessions! Not for reference for future evening trackdays.

All in all though, great track - love that you can take loads of kerb, especially at the apex of the old hairpin. Car never missed a beat. I'll be back...

Well, that's it for now I guess! Did Blyton Park again on 16th June, now the car is parked up for what may be a number of months.

Another faultless showing from the car. Less so than me! I was slower than last time out and had a few 'moments', one of which got captured on camera. Unfortunately the big slide I just about managed to rescue missed being on video by about 30 seconds of battery life. Can only put it down to the car being so good, I started pushing my luck

So, obviously the engine swap has to go ahead. But while it's out, I thought I might as well go about sorting the wiring properly too. The engine wiring, being one of DanThe's looms, is fine, but a lot of the body loom is now redundant and can be removed. A few switches etc I'd like to relocate too and put in a USB power point - and finally get round to replacing bulbs on the instrument cluster. I may also have more focused suspension and trackday tyres too by the time it sees its next day out.

A few pictures from the day out

Another faultless showing from the car. Less so than me! I was slower than last time out and had a few 'moments', one of which got captured on camera. Unfortunately the big slide I just about managed to rescue missed being on video by about 30 seconds of battery life. Can only put it down to the car being so good, I started pushing my luck

So, obviously the engine swap has to go ahead. But while it's out, I thought I might as well go about sorting the wiring properly too. The engine wiring, being one of DanThe's looms, is fine, but a lot of the body loom is now redundant and can be removed. A few switches etc I'd like to relocate too and put in a USB power point - and finally get round to replacing bulbs on the instrument cluster. I may also have more focused suspension and trackday tyres too by the time it sees its next day out.

A few pictures from the day out

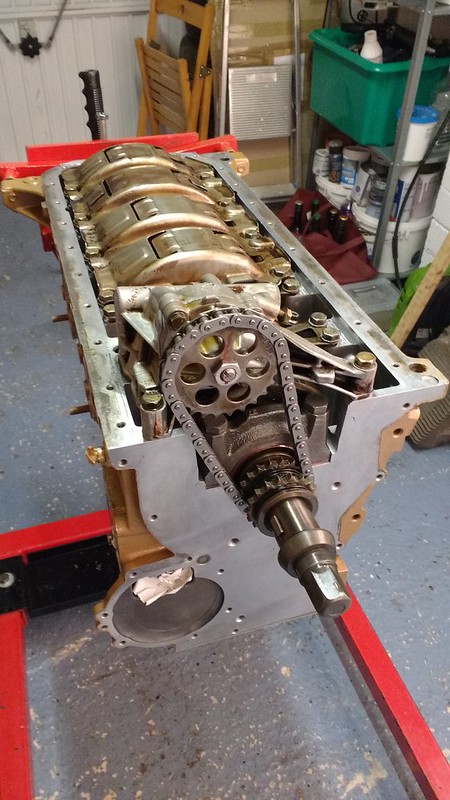

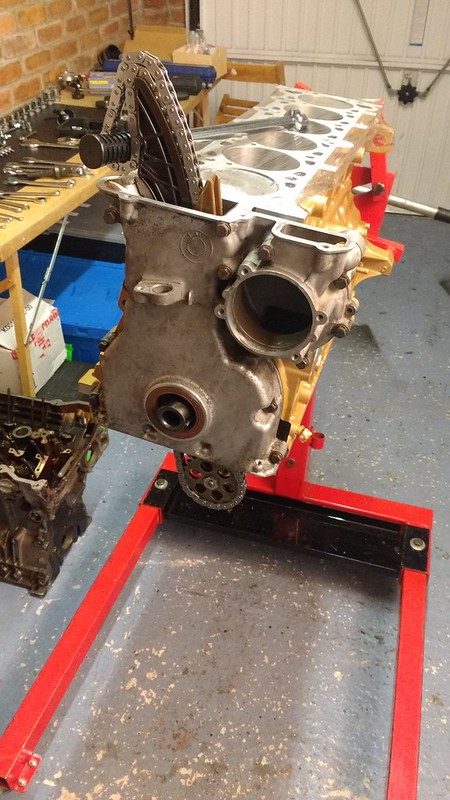

So over the past few weeks, everything has fallen in place for me to crack on with the engine build. After getting the block back from the machine shop, it got the pressure washer and superheated conservatory treatment too to get rid of any residual swarf. I'd already chased the head bolt threads with a tap before it went to the machine shop, so all good there. Then it was time for some paint. A coat of special metals primer followed by - well, I was thinking copper. A copper block with bare aluminium head and timing cover would've looked pretty steampunk I reckon. Shame Hammerite don't know the difference between copper and gold.

Ah well, I'm still pretty happy with the finish.

I then set about measuring all the main bearing clearances and installing the crank. The tolerances all came out great, but the install didn't quite go as planned. I'd order ARP main bearing studs - just as a 'while I'm there' sort of thing. Turns out the ARP studs arn't long enough to fully bottom out in the threaded holes in the block whilst still maintaining enough thread to torque the nuts down properly. ARP recommended winding the studs out sufficiently but I wasn't happy loosing 5 - 6 mm thread engagement in an aluminium block on something that's going to be torqued down to best part of

90 NM. Of course, ARP being American - US M52s had iron blocks - maybe less of a problem on those? Anyway I don't understand why the studs just couldn't be the correct length to begin with. The instructions issued with the studs do advise that they are bottomed out hand tight so it's all very strange.

Solution? OEM main bearing cap bolts. If I was to do this in the future, I'd measure up and just order 14 of the correct length ARP studs suited to the application rather than get the kit off the shelf.

Next issue was getting the crank turning smoothly. It seemed to have a tight spot that I tracked down to the thrust bearing. Upon inspection, the thrust bearing had an odd casting mark on one of the thrust surfaces (OEM Glyco Bearings).

The other side was flat and smooth. The area above the line sits about 0.2 mm proud of the remainder of the thrust surface. I did re-install and by using a pry to ensure the crank was fully seated against the thrust surface whilst torquing down, the crank turned smoothly and freely. Maybe it's meant to be this way so it wears in a certain manner? End float (measured using a dial indicator and measured again with feeler gauges at the thrust surface) came out fine. Nevertheless, I didn't trust it. So I ordered a set of King bearings for comparison. The King thrust bearing was flat on both thrust surfaces. Re-doing all the tolerances and the end-float, the King bearings made for a smooth crank install from the off.

Then it was full steam ahead really! Rings gapped up fine. Big end clearances were all good. No issues with ARP rod bolts. Got the short block assembled in short order.

Oil pump nut was torqued down dry with red loctite and I staked the threads for good measure to prevent it backing off.

Then came the bit I was most concerned about. Head gasket installation. I took every preventative measure I could think off to avert a thread pull. Chased with a tap, then cleaned with air before going to the machine shop. Cleaned with the pressure washer. Cleaned again with brake cleaner, then more pressurised air. Then I cleaned the NEW head bolts with carb cleaner and lint free cloth. I wound one of these bolts down all the threads to make sure it could be bottomed out hand-tight smoothly, on every one. Oiled the thread engagement length on every bolt and under every bolt head. Let the excess drain. Then went ahead.

No issues! Phew. Every one held the full 40 NM 2 x 90-degrees.

Like a few others have done, I'd had the M54 inlet cam VANOS gear machined down so it matched the M52 inlet cam, for a 'free' slightly more aggressive profile. So now I cracked on with the cam install.

And, finally, timing. It's worth knowing that an automatic flywheel is slim enough to fit between the rear crank oil seal housing and an engine stand. Makes locking the crank up a doddle!

Then, with everything locked up at TDC I commenced following the Haynes instructions to time it up. Double checking everything with the instructions from independent sources for good measure :p After testing for a couple of full rotations that everything returned properly to TDC, I was happy I'd got it right. Apart from setting the chain tension before torquing up the exhaust cam sprocket bolts (more on that later)!

Then finishing jobs...

Basically when it comes to torquing down the dummy tool to 1.3 NM before tightening the exhaust cam sprocket bolts to spec, well - I don't have a torque wrench that goes that low. Thinking I was clever, I worked out how much weight I had to hang from my spanner to give me 1.3 NM but like a retard, I used 10g/N rather than the 100g/N I should've used. So I have to go back and re-do that step but that shouldn't take too long

I still have to sort the ancillaries and electrics out and attach the oil filter housing, but these are small jobs. Also I've just fitted the E36 sump to seal it up for now, I'll be replacing that with the E34 sump along with the pickup pipe etc off the engine that's currently sat in the car when it comes out.

So all in all, hopefully a successful first time build. Time will tell in a few months when I drop it in.

Ah well, I'm still pretty happy with the finish.

I then set about measuring all the main bearing clearances and installing the crank. The tolerances all came out great, but the install didn't quite go as planned. I'd order ARP main bearing studs - just as a 'while I'm there' sort of thing. Turns out the ARP studs arn't long enough to fully bottom out in the threaded holes in the block whilst still maintaining enough thread to torque the nuts down properly. ARP recommended winding the studs out sufficiently but I wasn't happy loosing 5 - 6 mm thread engagement in an aluminium block on something that's going to be torqued down to best part of

90 NM. Of course, ARP being American - US M52s had iron blocks - maybe less of a problem on those? Anyway I don't understand why the studs just couldn't be the correct length to begin with. The instructions issued with the studs do advise that they are bottomed out hand tight so it's all very strange.

Solution? OEM main bearing cap bolts. If I was to do this in the future, I'd measure up and just order 14 of the correct length ARP studs suited to the application rather than get the kit off the shelf.

Next issue was getting the crank turning smoothly. It seemed to have a tight spot that I tracked down to the thrust bearing. Upon inspection, the thrust bearing had an odd casting mark on one of the thrust surfaces (OEM Glyco Bearings).

The other side was flat and smooth. The area above the line sits about 0.2 mm proud of the remainder of the thrust surface. I did re-install and by using a pry to ensure the crank was fully seated against the thrust surface whilst torquing down, the crank turned smoothly and freely. Maybe it's meant to be this way so it wears in a certain manner? End float (measured using a dial indicator and measured again with feeler gauges at the thrust surface) came out fine. Nevertheless, I didn't trust it. So I ordered a set of King bearings for comparison. The King thrust bearing was flat on both thrust surfaces. Re-doing all the tolerances and the end-float, the King bearings made for a smooth crank install from the off.

Then it was full steam ahead really! Rings gapped up fine. Big end clearances were all good. No issues with ARP rod bolts. Got the short block assembled in short order.

Oil pump nut was torqued down dry with red loctite and I staked the threads for good measure to prevent it backing off.

Then came the bit I was most concerned about. Head gasket installation. I took every preventative measure I could think off to avert a thread pull. Chased with a tap, then cleaned with air before going to the machine shop. Cleaned with the pressure washer. Cleaned again with brake cleaner, then more pressurised air. Then I cleaned the NEW head bolts with carb cleaner and lint free cloth. I wound one of these bolts down all the threads to make sure it could be bottomed out hand-tight smoothly, on every one. Oiled the thread engagement length on every bolt and under every bolt head. Let the excess drain. Then went ahead.

No issues! Phew. Every one held the full 40 NM 2 x 90-degrees.

Like a few others have done, I'd had the M54 inlet cam VANOS gear machined down so it matched the M52 inlet cam, for a 'free' slightly more aggressive profile. So now I cracked on with the cam install.

And, finally, timing. It's worth knowing that an automatic flywheel is slim enough to fit between the rear crank oil seal housing and an engine stand. Makes locking the crank up a doddle!

Then, with everything locked up at TDC I commenced following the Haynes instructions to time it up. Double checking everything with the instructions from independent sources for good measure :p After testing for a couple of full rotations that everything returned properly to TDC, I was happy I'd got it right. Apart from setting the chain tension before torquing up the exhaust cam sprocket bolts (more on that later)!

Then finishing jobs...

Basically when it comes to torquing down the dummy tool to 1.3 NM before tightening the exhaust cam sprocket bolts to spec, well - I don't have a torque wrench that goes that low. Thinking I was clever, I worked out how much weight I had to hang from my spanner to give me 1.3 NM but like a retard, I used 10g/N rather than the 100g/N I should've used. So I have to go back and re-do that step but that shouldn't take too long

I still have to sort the ancillaries and electrics out and attach the oil filter housing, but these are small jobs. Also I've just fitted the E36 sump to seal it up for now, I'll be replacing that with the E34 sump along with the pickup pipe etc off the engine that's currently sat in the car when it comes out.

So all in all, hopefully a successful first time build. Time will tell in a few months when I drop it in.

Once more, it’s been a long while since I updated this build thread. And once more, while I’ve not been updating, I have been getting on with things. Quite a lot of things in fact! So I’m warning you all now. This is a long post. Hopefully it’s not too snoozy, especially as it’s a little light on photos!

So I think last time I left this blog, I’d finished my engine build with the intension of doing the swap after Christmas. Er, yeah. Well, that hasn’t happened yet. I began, as you do, by stripping down the engine bay, a job that was much quicker than expected. I was also pleased at the cleanliness of the intake ports and valves on the old engine. Either the regular maintenance was paying dividends or it was overfuelling like a good ”˜un. The economy and smell didn’t indicate the latter, so I was happy.

After getting so far, I then made the decision to undertake a series of other updates that would be easier without all the engine stuff in the way ”“ ”awhile you’re there”a, as it were. And as usual, I got a little bit carried away. The big one being rewiring the whole car and moving the fusebox inside.

And why would I want to do that? Well I was still lugging around all the excess that comes with central locking, power mirrors, interior lighting, on board computer and all the other stuff a track car doesn’t need. It adds up ”“ it really does! But more so, removing it is free, all it takes is time.

Electric windows are one thing that are staying. The reason is that the door bars would get in the way of hand winders. I don’t fancy cooking myself in a car with plastic windows that don’t open. And as the car is still road legal and occasionally gets parked up, the lack of security and water tightness afforded by sliders didn’t appeal. Removing them if the car were ever converted to full race car would be a pretty trivial task.

Re-worked anti-chafe door looms for the windows:

And that’s kinda where I’m going with a lot of these mods. Standard E30s are fast rising in value. Race and rally cars are doing well too, but as always, half-assed trackday cars are worth f-all in comparison. Conclusion? Make it scrutineerable, or very very close to it. So as part of the rewiring project, there’s an FIA master switch going in with a push button start and the steering lock is going in the bin. A plumbed-in fire extinguisher system will be fitted too.

So once I’d got as far as reworking the electric window loom and unraveling it from all the central locking and electric mirror gubbins, I removed the dash and took it home to my workshop.

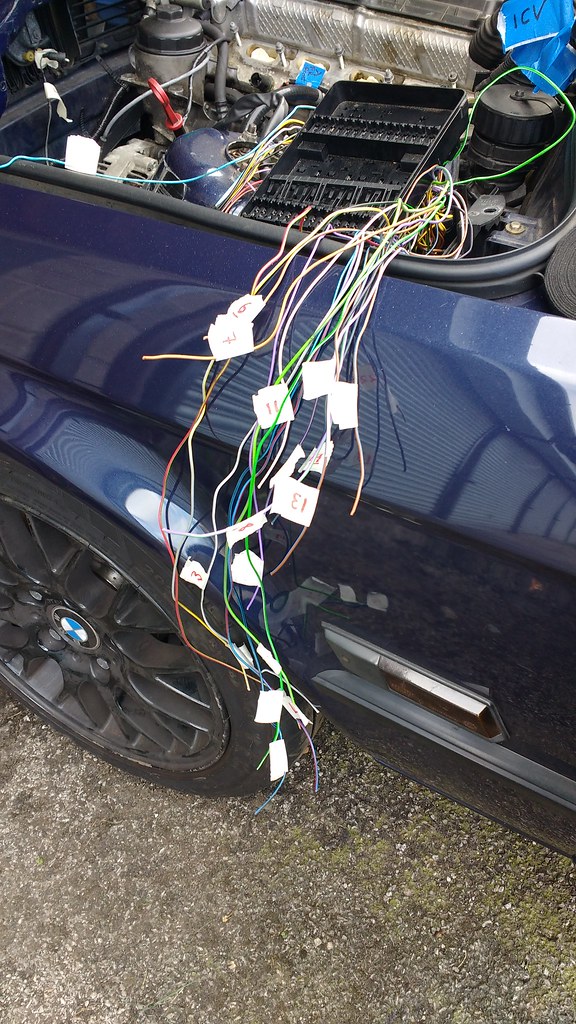

Incidentally, this is how much wiring makes up the central locking and power mirrors looms!

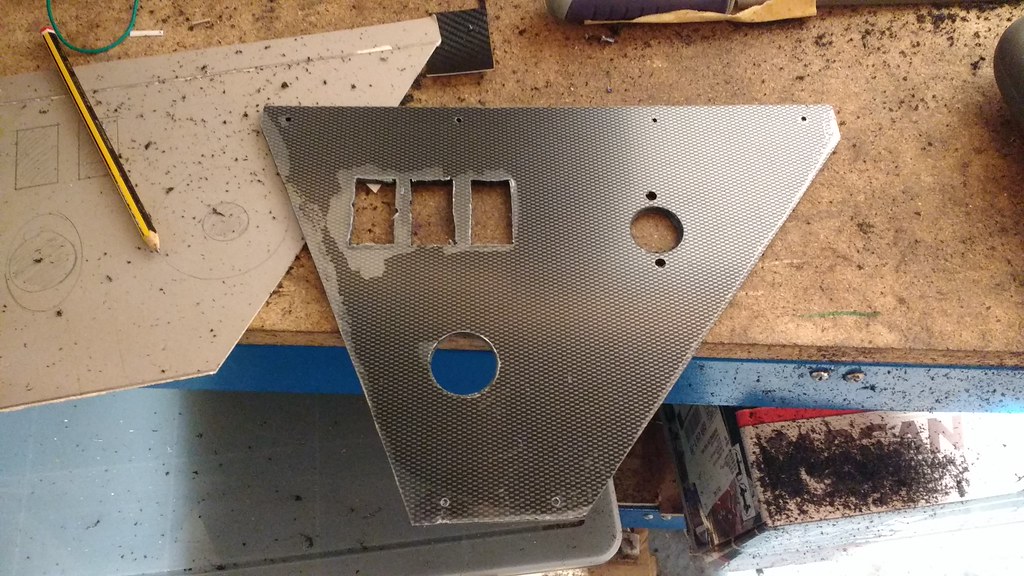

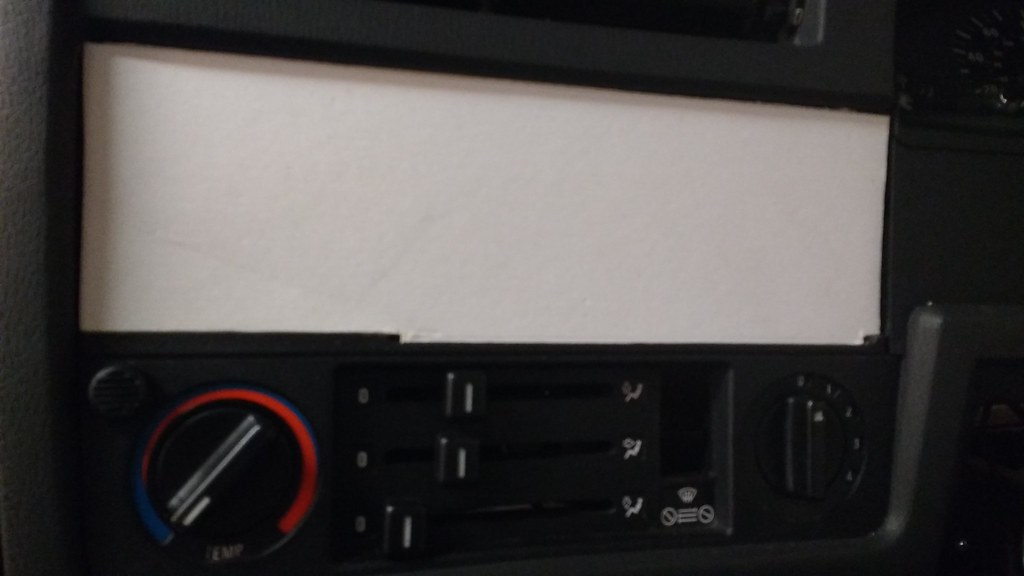

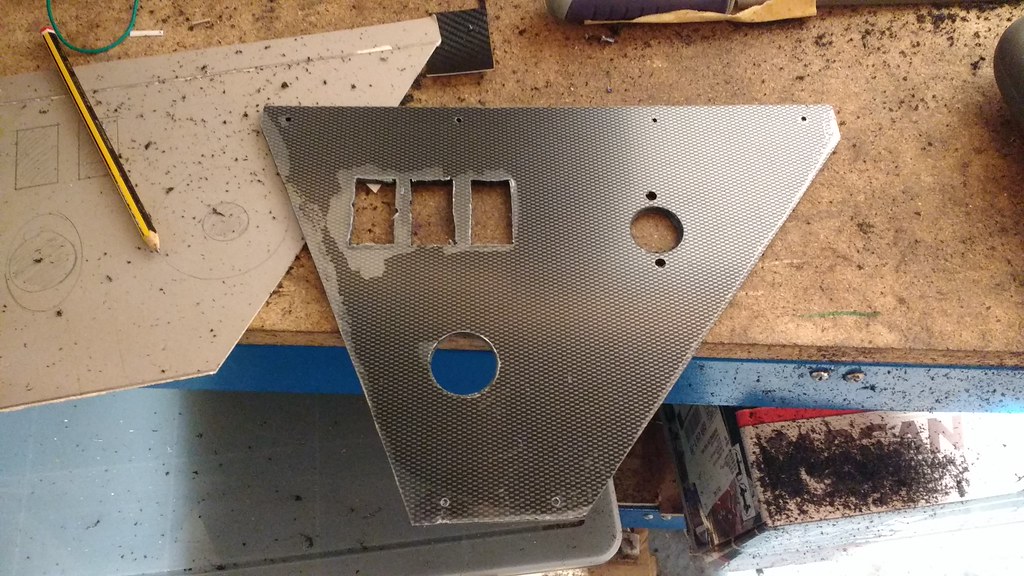

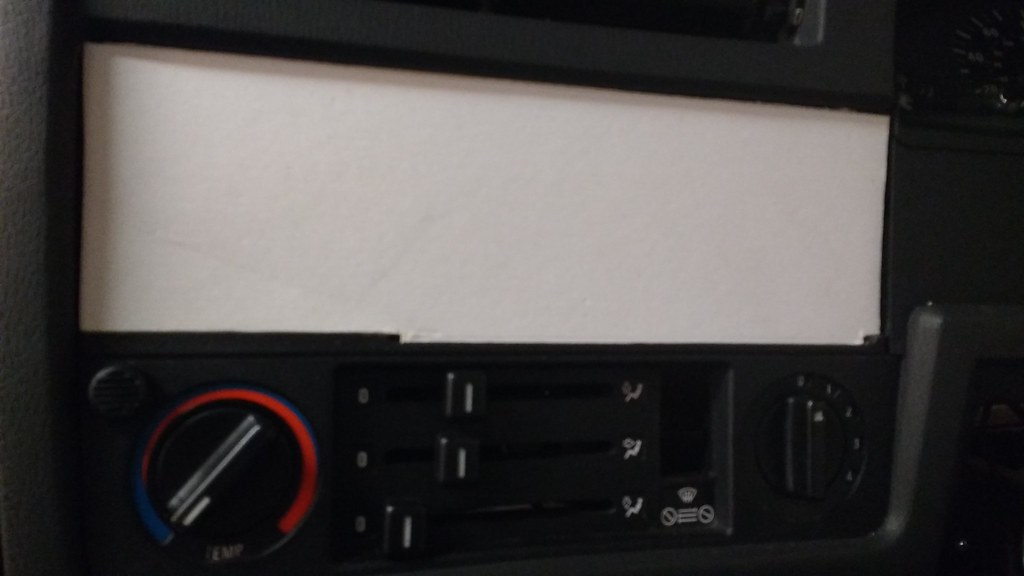

The dash loom was a nice thing to re-work in the warmth of a garage in winter. But while I was at it, I also filled in the side air vents with ABS plastic folded to fit. This also neatens up the sh*t looking aluminium bracket that my brake bias knob was previously attached to. The side vents were disconnected anyway, because of the cage. No loss there.

The centre vents stay, to blow cool or hot air in my face depending on how I feel. The centre fascia was also cut up to retain the standard heater controls but to allow a new panel in that will hold the ignition panel and a dual oil temperature/pressure gauge. This I sourced from SPA Designs. The option of the red backlight appealed as it will match all the standard BMW instruments. Feeling pretty handy with the ABS now, I made a panel to go between the dash and the transmission tunnel. This was to hold the electric window switches, hazard light switch, FIA master switch, a USB power point (more on that later) and the fire extinguisher cable pull. The loom needed extending for the relocation of the hazard light switch into this panel.

Reworked dash loom:

Dash modifications:

(and yes - the template for the new lower dash panel was made up whilst the dash was still in the car!)

A routine failure on E30s of this sort of age is the SI batteries in the instrument cluster failing. So I soldered in some new ones to save having to pull it apart again at some indeterminate point in the future and while I was there, fitted one of these shift light modules:

http://www.e30ig.com/#1thing

It’s quite a nice little thing. It replaces the LED board that illuminates the service indicator lights in the cluster, so that they can function as shift lights. At stage 1 ignition, it retains service indicator capability, but with the engine running, they perform the shift light function. They also have different thresholds for when the engine is cold and when it is hot. It’s all pretty easy to set up with the cluster on a bench, following the instructions. Perfect little gadget for tarts like me. Anyway, once all this had been done, the cluster was cleaned, reassembled and fitted to the dash.

Here's a video from setting up the shift lights:

And the completed cluster:

With the weather beginning to improve, I set about continuing with the fusebox relocation project. What’s the point you might ask? Well I figure race cars do it for some reason. The biggest benefit being to make the wiring loom modular, with all the connectors protected from heat/fluids/dirt etc in the engine bay. A minor weight distribution benefit will also be realised ”“ moving the fusebox inside the car means I can move the header tank from in front of the wheelarch to where the fusebox was. Like I’m gonna notice that! Still, every little helps.

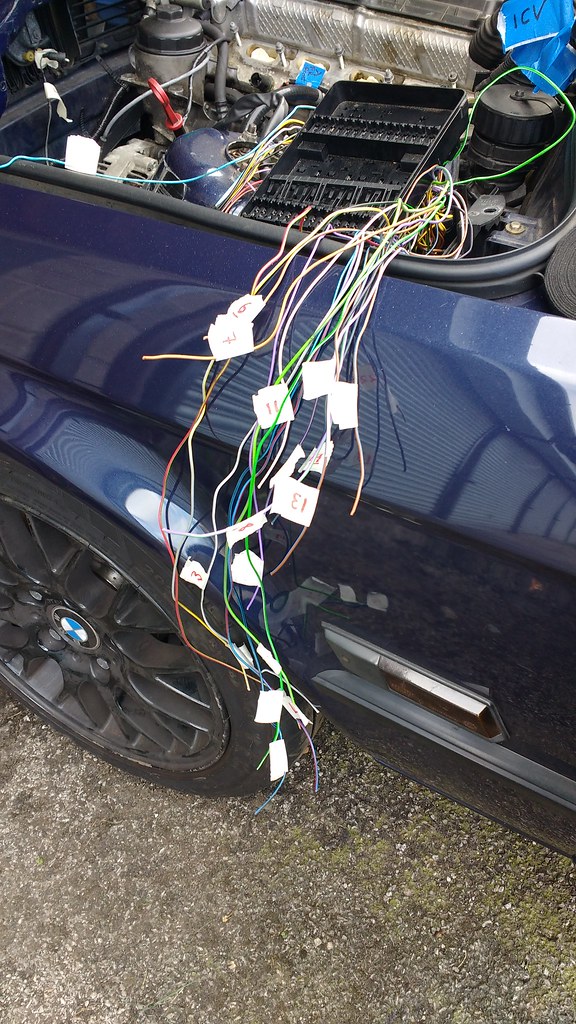

It’s no small job and not a job for anyone who lacks patience. It’s also a job that I’ve regretted undertaking on numerous occasions! But now I’m so far along, I can’t go back. The fusebox is out, all the wires have been labelled and fingers crossed it’ll all work right first time. Ha! Like that’s going to happen. I’ll find that out in a couple of weeks.

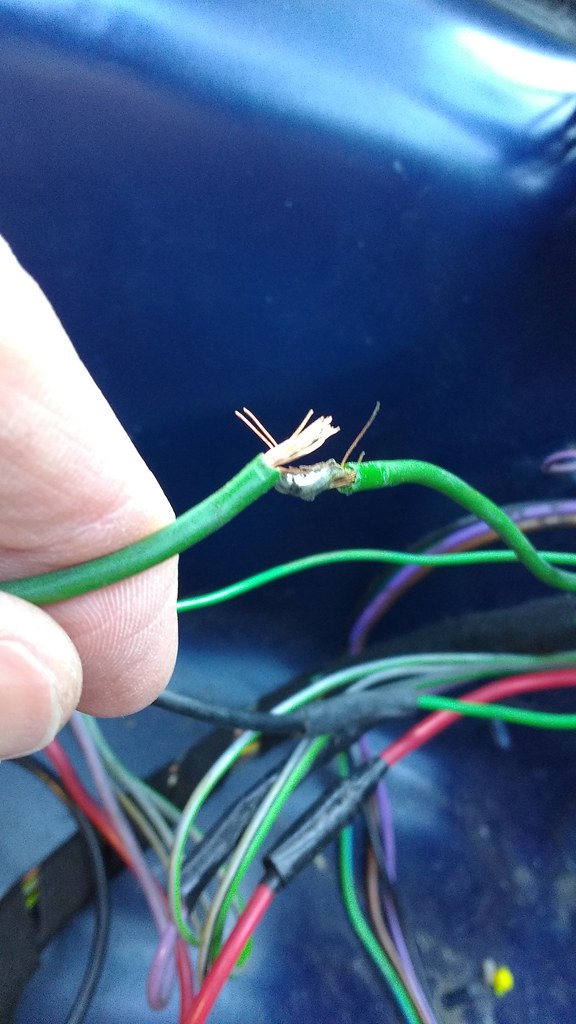

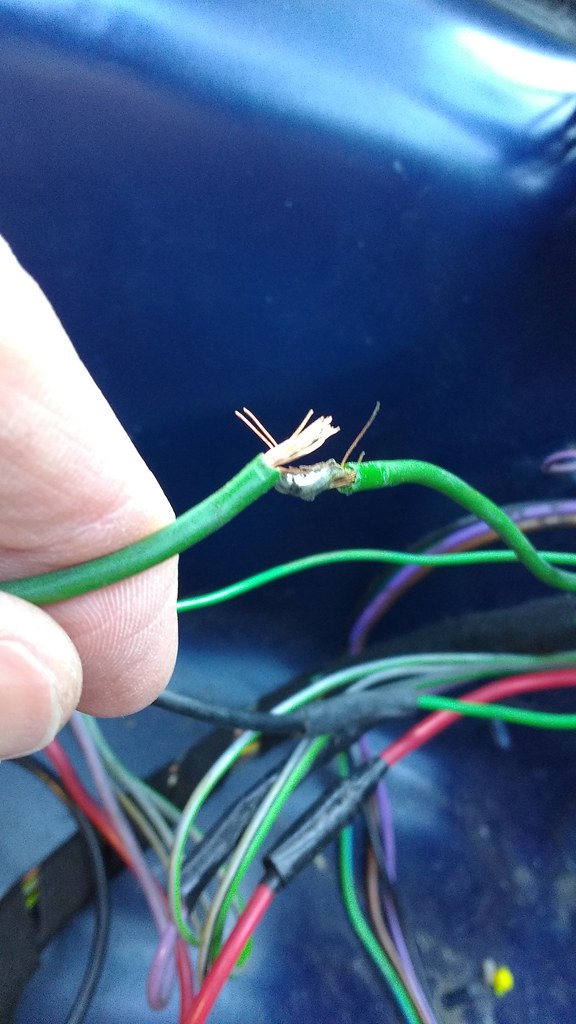

Just a small example of some of the dodgy soldering I've come across - work of previous alarm fitters:

And all of the stuff removed from the car permanently! Well, all of the stuff that fits in the box at least. It'll go on the scales when I'm done.

Back to the USB power point ”“ I’ve inherited my wife’s old Samsung Galaxy S3. As it was free, I plan to make use of that as a data logger. I’ve installed the full version of the Android app Race Chrono and have picked up a 10Hz Bluetooth GPS receiver. That should all work pretty well, though unfortunately my ECU isn’t fully OBD2 compliant (from a 1995 car). At least the likes of Torque and other generic OBD2 readers don’t seem to be able to read it. For diagnostics I have a specific BMW tool which works fine, so there must be some kind of difference in protocol. If anyone knows what’s going on with this and could help me out, that would be great. Being able to log throttle input and rpm would be a great addition.

So what else is on the cards? I’ve removed the massive lump of high density plastic inside the front bumper. That removes perhaps 7 or 8kg from way out in front of the front axle line. And I’ve been collecting bits. The engine is going to be opened up again as I have a set of Just Deutsch camshafts on order and bigger fuel injectors to go with them. Hopefully that will mean 250-260 bhp is on the cards once it’s been mapped. In my garage I have a DTM style gear shifter (desperately required!) and some adjustable fully rose-jointed front control arms to counter the caster issues created by the 5-stud swap. I have Carbon Lorraine RC5+ pads to go in the front calipers and EBC yellowstuff for the rears. And something to replace the Koni coilovers is in the wings. I think I’ve said before that I want to make use of the strut ARB pickup that the standard E36 compact coilovers don’t feature, and I find them a little soft for serious track use. I’m looking at getting a custom Bilstein B16 based set ordered, but I have to make the decision to stick with single adjustable or pay the extra for double. Having had a chat with Bilstein at Autosport, I didn’t realise they offer custom applications so readily and was well impressed with the product for the price.

Here's a couple of gratuitous photos of the adjustable arms with bump steer correction

And, that’s about it for now. It’s all taking much longer than I would like, but working on the car out of a single garage, 5 miles away from home means I only really get a day a week on it. 2 if I’m lucky. I’ve been trying to do as much stuff from home as possible, but there’s not much that can be done now the dash is finished. At least now it’s getting darker much later, I might get a few more hours a week in the evenings after work. A lot to do, not enough time so I’d best get cracking!

So I think last time I left this blog, I’d finished my engine build with the intension of doing the swap after Christmas. Er, yeah. Well, that hasn’t happened yet. I began, as you do, by stripping down the engine bay, a job that was much quicker than expected. I was also pleased at the cleanliness of the intake ports and valves on the old engine. Either the regular maintenance was paying dividends or it was overfuelling like a good ”˜un. The economy and smell didn’t indicate the latter, so I was happy.

After getting so far, I then made the decision to undertake a series of other updates that would be easier without all the engine stuff in the way ”“ ”awhile you’re there”a, as it were. And as usual, I got a little bit carried away. The big one being rewiring the whole car and moving the fusebox inside.

And why would I want to do that? Well I was still lugging around all the excess that comes with central locking, power mirrors, interior lighting, on board computer and all the other stuff a track car doesn’t need. It adds up ”“ it really does! But more so, removing it is free, all it takes is time.

Electric windows are one thing that are staying. The reason is that the door bars would get in the way of hand winders. I don’t fancy cooking myself in a car with plastic windows that don’t open. And as the car is still road legal and occasionally gets parked up, the lack of security and water tightness afforded by sliders didn’t appeal. Removing them if the car were ever converted to full race car would be a pretty trivial task.

Re-worked anti-chafe door looms for the windows:

And that’s kinda where I’m going with a lot of these mods. Standard E30s are fast rising in value. Race and rally cars are doing well too, but as always, half-assed trackday cars are worth f-all in comparison. Conclusion? Make it scrutineerable, or very very close to it. So as part of the rewiring project, there’s an FIA master switch going in with a push button start and the steering lock is going in the bin. A plumbed-in fire extinguisher system will be fitted too.

So once I’d got as far as reworking the electric window loom and unraveling it from all the central locking and electric mirror gubbins, I removed the dash and took it home to my workshop.

Incidentally, this is how much wiring makes up the central locking and power mirrors looms!

The dash loom was a nice thing to re-work in the warmth of a garage in winter. But while I was at it, I also filled in the side air vents with ABS plastic folded to fit. This also neatens up the sh*t looking aluminium bracket that my brake bias knob was previously attached to. The side vents were disconnected anyway, because of the cage. No loss there.

The centre vents stay, to blow cool or hot air in my face depending on how I feel. The centre fascia was also cut up to retain the standard heater controls but to allow a new panel in that will hold the ignition panel and a dual oil temperature/pressure gauge. This I sourced from SPA Designs. The option of the red backlight appealed as it will match all the standard BMW instruments. Feeling pretty handy with the ABS now, I made a panel to go between the dash and the transmission tunnel. This was to hold the electric window switches, hazard light switch, FIA master switch, a USB power point (more on that later) and the fire extinguisher cable pull. The loom needed extending for the relocation of the hazard light switch into this panel.

Reworked dash loom:

Dash modifications:

(and yes - the template for the new lower dash panel was made up whilst the dash was still in the car!)

A routine failure on E30s of this sort of age is the SI batteries in the instrument cluster failing. So I soldered in some new ones to save having to pull it apart again at some indeterminate point in the future and while I was there, fitted one of these shift light modules:

http://www.e30ig.com/#1thing

It’s quite a nice little thing. It replaces the LED board that illuminates the service indicator lights in the cluster, so that they can function as shift lights. At stage 1 ignition, it retains service indicator capability, but with the engine running, they perform the shift light function. They also have different thresholds for when the engine is cold and when it is hot. It’s all pretty easy to set up with the cluster on a bench, following the instructions. Perfect little gadget for tarts like me. Anyway, once all this had been done, the cluster was cleaned, reassembled and fitted to the dash.

Here's a video from setting up the shift lights:

And the completed cluster:

With the weather beginning to improve, I set about continuing with the fusebox relocation project. What’s the point you might ask? Well I figure race cars do it for some reason. The biggest benefit being to make the wiring loom modular, with all the connectors protected from heat/fluids/dirt etc in the engine bay. A minor weight distribution benefit will also be realised ”“ moving the fusebox inside the car means I can move the header tank from in front of the wheelarch to where the fusebox was. Like I’m gonna notice that! Still, every little helps.

It’s no small job and not a job for anyone who lacks patience. It’s also a job that I’ve regretted undertaking on numerous occasions! But now I’m so far along, I can’t go back. The fusebox is out, all the wires have been labelled and fingers crossed it’ll all work right first time. Ha! Like that’s going to happen. I’ll find that out in a couple of weeks.

Just a small example of some of the dodgy soldering I've come across - work of previous alarm fitters:

And all of the stuff removed from the car permanently! Well, all of the stuff that fits in the box at least. It'll go on the scales when I'm done.

Back to the USB power point ”“ I’ve inherited my wife’s old Samsung Galaxy S3. As it was free, I plan to make use of that as a data logger. I’ve installed the full version of the Android app Race Chrono and have picked up a 10Hz Bluetooth GPS receiver. That should all work pretty well, though unfortunately my ECU isn’t fully OBD2 compliant (from a 1995 car). At least the likes of Torque and other generic OBD2 readers don’t seem to be able to read it. For diagnostics I have a specific BMW tool which works fine, so there must be some kind of difference in protocol. If anyone knows what’s going on with this and could help me out, that would be great. Being able to log throttle input and rpm would be a great addition.

So what else is on the cards? I’ve removed the massive lump of high density plastic inside the front bumper. That removes perhaps 7 or 8kg from way out in front of the front axle line. And I’ve been collecting bits. The engine is going to be opened up again as I have a set of Just Deutsch camshafts on order and bigger fuel injectors to go with them. Hopefully that will mean 250-260 bhp is on the cards once it’s been mapped. In my garage I have a DTM style gear shifter (desperately required!) and some adjustable fully rose-jointed front control arms to counter the caster issues created by the 5-stud swap. I have Carbon Lorraine RC5+ pads to go in the front calipers and EBC yellowstuff for the rears. And something to replace the Koni coilovers is in the wings. I think I’ve said before that I want to make use of the strut ARB pickup that the standard E36 compact coilovers don’t feature, and I find them a little soft for serious track use. I’m looking at getting a custom Bilstein B16 based set ordered, but I have to make the decision to stick with single adjustable or pay the extra for double. Having had a chat with Bilstein at Autosport, I didn’t realise they offer custom applications so readily and was well impressed with the product for the price.

Here's a couple of gratuitous photos of the adjustable arms with bump steer correction

And, that’s about it for now. It’s all taking much longer than I would like, but working on the car out of a single garage, 5 miles away from home means I only really get a day a week on it. 2 if I’m lucky. I’ve been trying to do as much stuff from home as possible, but there’s not much that can be done now the dash is finished. At least now it’s getting darker much later, I might get a few more hours a week in the evenings after work. A lot to do, not enough time so I’d best get cracking!

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

You are brave taking on that loom  Those arms look tasty!

Those arms look tasty!

Good stuff!

Good stuff!

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos

!! LONG POST ALERT !!

This thread is long overdue an update. Between work, married life and trying to progress the car, I’ve not had a lot of time for updates. I’ve also been a bit distracted by driving around in this.

Anyway, now as the evenings draw in I have to find other ways of entertaining myself on the dark evenings. Time to update the build thread!

I also apologise for this being a bit text heavy. I’ve been so preoccupied with cracking on with the project that I haven’t taken many pictures ”“ and those pictures and videos I have taken aren’t the best!

Anyway. Let’s at least start with the best bit. The engine.

I figured as I’d put so much time and money into it ”“ and that I only really wanted to map it once ”“ I moved on the M54 inlet cam and opted for a pair of cams from Just Deutsch. These are M52 regrinds specifically developed for stroked engines. I won’t reveal lift & duration here, I’ll just say for now that they aren’t too far from the US S52 cams, but modified to yield more mid-range torque. These were accompanied by larger 24lb fuel injectors ”“ plug and play into the M52 fuel rail ”“ also supplied by Just Deutsch.

With a large bore throttle body and 6-paddle sprung clutch by Helix attached, it was time to lift out the old lump and drop in the new. Hopefully the new engine will be good for about 260 bhp and 250lbft of torque, but we’ll see. It needs to run first, right? We’ll return to that point later.

Onto electrics - I think the last thing I talked about before going AWOL was fusebox relocation. So how did that go? ”aNot swimmingly”a is the most apt phrase I think. Electrical work took me so much longer than planned. I lost days cutting, splicing, routing and taping and almost lost the will to live. But after weekends spent on my knees in the footwell (Ooh-er”¦), the time had come to test it.

The dashboard was in. The ignition panel and FIA master switch were wired up. All the modular loom connectors were attached to the fusebox which, for this purpose, was hastily laid on top of an old toolbox in the passenger footwell. The fire extinguisher was primed and ready. I connected the battery, turned the key to ”aaccessory”a and went through the list of tests.

It turns out three things didn’t work as they were supposed to.

1) The heater box didn’t work. At all.

2) The indicators were behaving strangely. Front/rear indicators on both sides worked fine off the stalk. But the side indicators didn’t work. Then with the hazard light switch on, ONLY the side indicators worked. Nothing from the front/rear indicators.

3) The handbrake light on the dash didn’t go out when the handbrake was released.

So it turned out that 1) and 2) were simple issues to deal with. The heater box only gets power in ”arun”a. Checked that ”“ it works, job done. The indicators ”“ The hazard light is wired into the dash loom and the indicator switch, the body loom. The right wires had to be spliced in the right places and I’d forgotten to do this. Once that was done, I had 6 working indicator lamps. Number 3) ”“ oh my.

First port of call was the switch on the handbrake. I quickly confirmed that this was working just fine, but the handbrake light still wouldn’t go out. I won’t go into the whole long, sorry saga here but I can say I spent about 20 hours trying to track down how the handbrake light on the dash was finding ground elsewhere. Before I realised that when the engine runs, the light goes out. And that is supposed to be the case. And that’s what the owner’s manual says. Did I say I’m not an auto electrician??

And you read that right. Yes! The engine runs! Apologies for the terrible video but I wasn’t expecting this (genuine first!) test fire to go quite so well.

So what else have I done?

In place of where the fusebox once was is a coolant bottle. This moves the weight of the full coolant bottle back to behind the front turrets. The E30 bottle won’t fit here, so I thought about various aftermarket bottles and couldn’t guarantee that any of those would fit either. Then I saw the Rover 75 bottle in my friend’s k-series engine’d MG Midget. That looked like the perfect size and shape.

They are cheap as chips and as an added bonus, it uses BMW expansion tank caps and has the same inlets/outlets as the E30 item. So that is now what resides in my engine bay. I’ve fitted the radiator and I’ve done almost all the plumbing so it’s not that far away from being filled with coolant.

While on the subject of my friend’s k-midget, he took that on its first track outing last month and after half a day of fun, it grenade its diff in quite spectacular fashion. Here are some photos from when we diagnosed the diff failure then pulled it to inspect the damage.

And the responsible component”¦

So, in addition to the aforementioned engine upgrades and again, to get the best out of it, I’ve sold on the standard M52 exhaust manifold and the E30 325i exhaust system that was on it. This has been replaced with a Fritz Bitz manifold and full system. The manifold is tubular with equal length headers and the system is twin 60 mm throughout with a resonator located just after the downpipes. Fitting the manifold was a saga and it needed the steering linkage splitting for clearance, but not it’s all back together there’s plenty room. I’ve fitted the system best I can for now (on my own, working with the car on stands) but it looks like it’s on the piss a little bit. So I’ll get the MOT man to sort that out when it goes for its test.

The oil cooler is fitted ahead of the front cross member using some DIY 4 mm thick aluminium brackets. I ordered PTFE lines with stainless steel braid along with the required JIC compression fittings from Torques UK and made them up at home.

The oil thermostat is a Mishimoto item and an aluminium bracket is all that’s required to mount that nicely to the side of the PAS pump. The M52 PAS pump did need some spacers to mount to the M50 oil filter housing to ensure that the auxiliary belt pulleys all stayed nicely in line but that wasn’t a big task. Here’s a pic of the thermostat fitting mocked up on a spare oil filter housing.

The oil cooler will remain un-plumbed until the engine is run in, then I’ll fit the sandwich plate take-off etc during the first oil change. But I did need to fit the oil cooler and thermostat lines before fitting the rad as it’s so tight up front. I’ve also got an SPA duel oil temperature/pressure gauge wired in, fused and located next to the ignition panel. I liked this as the backlighting colours are selectable ”“ the red backlight option is about as close to the E30 instrument cluster as I’ll get.

Other little jobs I’ve tackled include:

Ӣ Making some poly radiator mounts.

Ӣ Fitting the chassis-mounted DTM style shifter and isolating poly trans mounts to prevent transmission movement.

Ӣ Removing the crash structure from the front bumper (about 8kg) and making new bumper mounts

Ӣ Rebuilding the heater valve with a new o-ring, seeing as the old one was weeping slightly.

”¢ Taking out the old steel, threaded steering rack spacers and replacing with proper unthreaded aluminium spacers and new bolts/locking nuts. Believe me, doing this with the engine out was hard enough as the threaded spacers had seized onto the bolts and were near impossible to get a hold of. Glad I tackled it as I didn’t want to have to deal with them further down the line with the engine in situ, should I have to address any future steering rack issues.

So what’s left on the car?

I still need to permanently fit the fusebox (behind where the glovebox once was) and tidy up the wiring. There’s the plumbing to finish and coolant to fill. Doorcards and seats to fit. Extinguisher to plumb in, Aerocatch bonnet pins to fit and a few other little niggles to sort before it goes off for an MOT. But it isn’t that far away from being driveable.

Following an MOT, it’s time to break in the engine before dropping the oil, attaching the cooler and getting it mapped. Then there’s the suspension and brake upgrades to sort! I have a set of Z3M KW 2-way Clubsports to go on along with the adjustable lower control arms, tie rods and H&R anti-roll bars. I’ll outsource all of that and get it aligned and corner-weighted at the same time. Yokohama AD08Rs will be going on it for dual road/track duty (probably sticking with 205/45/16 for now) and I’m hoping to get a set of proper wheels for it too ”“ keeping the current ones as spares with some road rubber on them.

The brakes ”“ I have Carbon Lorraine RC5+ front pads to replace the OEM E36 M3 ones and some custom made backplates with brake cooling ducts. I’ll get EBC Bluestuff pads for the rear and be done with it, making sure I flush the old fluid through before the first trackday.

I’ll try to update again before that happens!

This thread is long overdue an update. Between work, married life and trying to progress the car, I’ve not had a lot of time for updates. I’ve also been a bit distracted by driving around in this.

Anyway, now as the evenings draw in I have to find other ways of entertaining myself on the dark evenings. Time to update the build thread!

I also apologise for this being a bit text heavy. I’ve been so preoccupied with cracking on with the project that I haven’t taken many pictures ”“ and those pictures and videos I have taken aren’t the best!

Anyway. Let’s at least start with the best bit. The engine.

I figured as I’d put so much time and money into it ”“ and that I only really wanted to map it once ”“ I moved on the M54 inlet cam and opted for a pair of cams from Just Deutsch. These are M52 regrinds specifically developed for stroked engines. I won’t reveal lift & duration here, I’ll just say for now that they aren’t too far from the US S52 cams, but modified to yield more mid-range torque. These were accompanied by larger 24lb fuel injectors ”“ plug and play into the M52 fuel rail ”“ also supplied by Just Deutsch.

With a large bore throttle body and 6-paddle sprung clutch by Helix attached, it was time to lift out the old lump and drop in the new. Hopefully the new engine will be good for about 260 bhp and 250lbft of torque, but we’ll see. It needs to run first, right? We’ll return to that point later.

Onto electrics - I think the last thing I talked about before going AWOL was fusebox relocation. So how did that go? ”aNot swimmingly”a is the most apt phrase I think. Electrical work took me so much longer than planned. I lost days cutting, splicing, routing and taping and almost lost the will to live. But after weekends spent on my knees in the footwell (Ooh-er”¦), the time had come to test it.

The dashboard was in. The ignition panel and FIA master switch were wired up. All the modular loom connectors were attached to the fusebox which, for this purpose, was hastily laid on top of an old toolbox in the passenger footwell. The fire extinguisher was primed and ready. I connected the battery, turned the key to ”aaccessory”a and went through the list of tests.

It turns out three things didn’t work as they were supposed to.

1) The heater box didn’t work. At all.

2) The indicators were behaving strangely. Front/rear indicators on both sides worked fine off the stalk. But the side indicators didn’t work. Then with the hazard light switch on, ONLY the side indicators worked. Nothing from the front/rear indicators.

3) The handbrake light on the dash didn’t go out when the handbrake was released.

So it turned out that 1) and 2) were simple issues to deal with. The heater box only gets power in ”arun”a. Checked that ”“ it works, job done. The indicators ”“ The hazard light is wired into the dash loom and the indicator switch, the body loom. The right wires had to be spliced in the right places and I’d forgotten to do this. Once that was done, I had 6 working indicator lamps. Number 3) ”“ oh my.

First port of call was the switch on the handbrake. I quickly confirmed that this was working just fine, but the handbrake light still wouldn’t go out. I won’t go into the whole long, sorry saga here but I can say I spent about 20 hours trying to track down how the handbrake light on the dash was finding ground elsewhere. Before I realised that when the engine runs, the light goes out. And that is supposed to be the case. And that’s what the owner’s manual says. Did I say I’m not an auto electrician??

And you read that right. Yes! The engine runs! Apologies for the terrible video but I wasn’t expecting this (genuine first!) test fire to go quite so well.

So what else have I done?

In place of where the fusebox once was is a coolant bottle. This moves the weight of the full coolant bottle back to behind the front turrets. The E30 bottle won’t fit here, so I thought about various aftermarket bottles and couldn’t guarantee that any of those would fit either. Then I saw the Rover 75 bottle in my friend’s k-series engine’d MG Midget. That looked like the perfect size and shape.

They are cheap as chips and as an added bonus, it uses BMW expansion tank caps and has the same inlets/outlets as the E30 item. So that is now what resides in my engine bay. I’ve fitted the radiator and I’ve done almost all the plumbing so it’s not that far away from being filled with coolant.

While on the subject of my friend’s k-midget, he took that on its first track outing last month and after half a day of fun, it grenade its diff in quite spectacular fashion. Here are some photos from when we diagnosed the diff failure then pulled it to inspect the damage.

And the responsible component”¦

So, in addition to the aforementioned engine upgrades and again, to get the best out of it, I’ve sold on the standard M52 exhaust manifold and the E30 325i exhaust system that was on it. This has been replaced with a Fritz Bitz manifold and full system. The manifold is tubular with equal length headers and the system is twin 60 mm throughout with a resonator located just after the downpipes. Fitting the manifold was a saga and it needed the steering linkage splitting for clearance, but not it’s all back together there’s plenty room. I’ve fitted the system best I can for now (on my own, working with the car on stands) but it looks like it’s on the piss a little bit. So I’ll get the MOT man to sort that out when it goes for its test.

The oil cooler is fitted ahead of the front cross member using some DIY 4 mm thick aluminium brackets. I ordered PTFE lines with stainless steel braid along with the required JIC compression fittings from Torques UK and made them up at home.

The oil thermostat is a Mishimoto item and an aluminium bracket is all that’s required to mount that nicely to the side of the PAS pump. The M52 PAS pump did need some spacers to mount to the M50 oil filter housing to ensure that the auxiliary belt pulleys all stayed nicely in line but that wasn’t a big task. Here’s a pic of the thermostat fitting mocked up on a spare oil filter housing.

The oil cooler will remain un-plumbed until the engine is run in, then I’ll fit the sandwich plate take-off etc during the first oil change. But I did need to fit the oil cooler and thermostat lines before fitting the rad as it’s so tight up front. I’ve also got an SPA duel oil temperature/pressure gauge wired in, fused and located next to the ignition panel. I liked this as the backlighting colours are selectable ”“ the red backlight option is about as close to the E30 instrument cluster as I’ll get.

Other little jobs I’ve tackled include:

Ӣ Making some poly radiator mounts.

Ӣ Fitting the chassis-mounted DTM style shifter and isolating poly trans mounts to prevent transmission movement.

Ӣ Removing the crash structure from the front bumper (about 8kg) and making new bumper mounts

Ӣ Rebuilding the heater valve with a new o-ring, seeing as the old one was weeping slightly.

”¢ Taking out the old steel, threaded steering rack spacers and replacing with proper unthreaded aluminium spacers and new bolts/locking nuts. Believe me, doing this with the engine out was hard enough as the threaded spacers had seized onto the bolts and were near impossible to get a hold of. Glad I tackled it as I didn’t want to have to deal with them further down the line with the engine in situ, should I have to address any future steering rack issues.

So what’s left on the car?

I still need to permanently fit the fusebox (behind where the glovebox once was) and tidy up the wiring. There’s the plumbing to finish and coolant to fill. Doorcards and seats to fit. Extinguisher to plumb in, Aerocatch bonnet pins to fit and a few other little niggles to sort before it goes off for an MOT. But it isn’t that far away from being driveable.

Following an MOT, it’s time to break in the engine before dropping the oil, attaching the cooler and getting it mapped. Then there’s the suspension and brake upgrades to sort! I have a set of Z3M KW 2-way Clubsports to go on along with the adjustable lower control arms, tie rods and H&R anti-roll bars. I’ll outsource all of that and get it aligned and corner-weighted at the same time. Yokohama AD08Rs will be going on it for dual road/track duty (probably sticking with 205/45/16 for now) and I’m hoping to get a set of proper wheels for it too ”“ keeping the current ones as spares with some road rubber on them.

The brakes ”“ I have Carbon Lorraine RC5+ front pads to replace the OEM E36 M3 ones and some custom made backplates with brake cooling ducts. I’ll get EBC Bluestuff pads for the rear and be done with it, making sure I flush the old fluid through before the first trackday.

I’ll try to update again before that happens!

Epic - love the perseverance! Will be good to see it out on the track

-

milescook

- E30 Zone Camper

- Posts: 1283

- Joined: Thu Jan 13, 2011 11:00 pm

- Location: The 'bran of Cwm

- Contact:

Track car prep porn  Great stuff mate, glad someone is still here!!

Great stuff mate, glad someone is still here!!

The story so far... http://www.cookracing.co.uk/

Also please help the race budget by watching some videos https://www.youtube.com/cookracinguk

https://www.youtube.com/cookracinguk

Also please help the race budget by watching some videos