My 320ise S62.

Moderator: martauto

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Yes Jonsku, my car hasn't been much higer than it is now since I've owned it! I'm worried it'll get dizzy when it goes up in the air for an MOT.

The pipe parts were measured on the car, cut and tacked together on the bench, fitted until it resembled an exhaust, then removed and finish welded on the bench.

I've not done much on the car over the last week or two, though there will be some photos to come quite soon.

Cheers! D.

The pipe parts were measured on the car, cut and tacked together on the bench, fitted until it resembled an exhaust, then removed and finish welded on the bench.

I've not done much on the car over the last week or two, though there will be some photos to come quite soon.

Cheers! D.

This is a great project Dave, Ive been following it for a while and it has kickstarted me into making a start at my own pS62 project,

http://www.e30zone.net/modules.php?name ... c&t=227245

I like your servo mount and will be doing similar myself.

Where did you get your engine mounts from,I need a mount about 50mm high with some offsetbut I cant seam to find anything.

Thanks

Dave[/url]

http://www.e30zone.net/modules.php?name ... c&t=227245

I like your servo mount and will be doing similar myself.

Where did you get your engine mounts from,I need a mount about 50mm high with some offsetbut I cant seam to find anything.

Thanks

Dave[/url]

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Thanks Dave, it's really good to hear that the old girl's given you some inspiration!  If you need any extra pictures (though there are around a million of them on here

If you need any extra pictures (though there are around a million of them on here  ) just give me a shout.

) just give me a shout.  I went a bit overboard on the bracing I'd say, but I'd rather that than a mile of flex/stuff breaking.

I went a bit overboard on the bracing I'd say, but I'd rather that than a mile of flex/stuff breaking.

I ordered my engine (and gearbox) mounts from these guys, which they made with the required height and offset:

http://www.e30zone.net/modules.php?name ... c&t=207349

They took a week or two to arrive IIRC.

I was thinking of building a few kits after my car's finished including a strengthened crossmember (with modded steering rack mounts), engine arms, and my own mounts. Maybe some fancy gearbox mounts too. It'll be a while away yet mind.

Cheers! Dave.

I ordered my engine (and gearbox) mounts from these guys, which they made with the required height and offset:

http://www.e30zone.net/modules.php?name ... c&t=207349

They took a week or two to arrive IIRC.

I was thinking of building a few kits after my car's finished including a strengthened crossmember (with modded steering rack mounts), engine arms, and my own mounts. Maybe some fancy gearbox mounts too. It'll be a while away yet mind.

Cheers! Dave.

Thanks Dave . That's excellent. I have a 60 mm high engine mount in at the minute and looks like I could get away with dropping the engine about 10 mm if the mounts are very stiff.

I saw you mentioned in another thread that you were thinking of using a different remote oil filter, haw did you get on with that.

Sorry for all the questions

Thanks

Dave

I saw you mentioned in another thread that you were thinking of using a different remote oil filter, haw did you get on with that.

Sorry for all the questions

Thanks

Dave

- GermanGorilla

- E30 Zone Regular

- Posts: 528

- Joined: Mon Feb 07, 2005 11:00 pm

Hi,

Your making good progress, and

its all coming together well.

I'll expect you will be glad to just

get in and drive the fooking thing

after all the effort and financial stress.

On the engine mounts 'UweM3' used

Hockey Pucks with very with good results.

You can also stack them for differeing

heights and even slice them etc.

Can even fit them in ''alloy cups'' if

desired.

A Straight brace on the RTA's as on the Z3M

Coupe arms would have saved you some

work, but its all looking good.

Regards,

The Gorilla.

Your making good progress, and

its all coming together well.

I'll expect you will be glad to just

get in and drive the fooking thing

after all the effort and financial stress.

On the engine mounts 'UweM3' used

Hockey Pucks with very with good results.

You can also stack them for differeing

heights and even slice them etc.

Can even fit them in ''alloy cups'' if

desired.

A Straight brace on the RTA's as on the Z3M

Coupe arms would have saved you some

work, but its all looking good.

Regards,

The Gorilla.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

No problem Dave.  I also modified the upper rack mounts for extra clearance. After recently removing the steering rack (PITA) to further modify one of the feed pipes (which was shaped for taller mounts and no longer fitted

I also modified the upper rack mounts for extra clearance. After recently removing the steering rack (PITA) to further modify one of the feed pipes (which was shaped for taller mounts and no longer fitted  ), I thought that it might be a good idea to make the lower rack mounts removable. Another idea for next time!

), I thought that it might be a good idea to make the lower rack mounts removable. Another idea for next time!  I ended up shortening my mounts a couple of times to get them the right height.

I ended up shortening my mounts a couple of times to get them the right height.

I'm using the standard oil filter housing for now.

There's perhaps the option of lengthening the feed and return pipes on the standard housing and dropping it through a hole in front of the near side inner wing depending on what you're doing with airboxes etc. I'd be more inclined to look at the filter mount on the drivers side though.

Cheers Gorilla. There speaks the voice of a man who's been there before I'd say

Yep, I did think of bracing the arms like the Z3M, but I wanted to add strength along the length of the arm where I removed some material for wheel clearance. I don't think they'll flex much now anyway!

I've got a few more bits and pieces ticked off the list.

The front arches now match the rears, and are a skim and a drop of paint away from being finished:

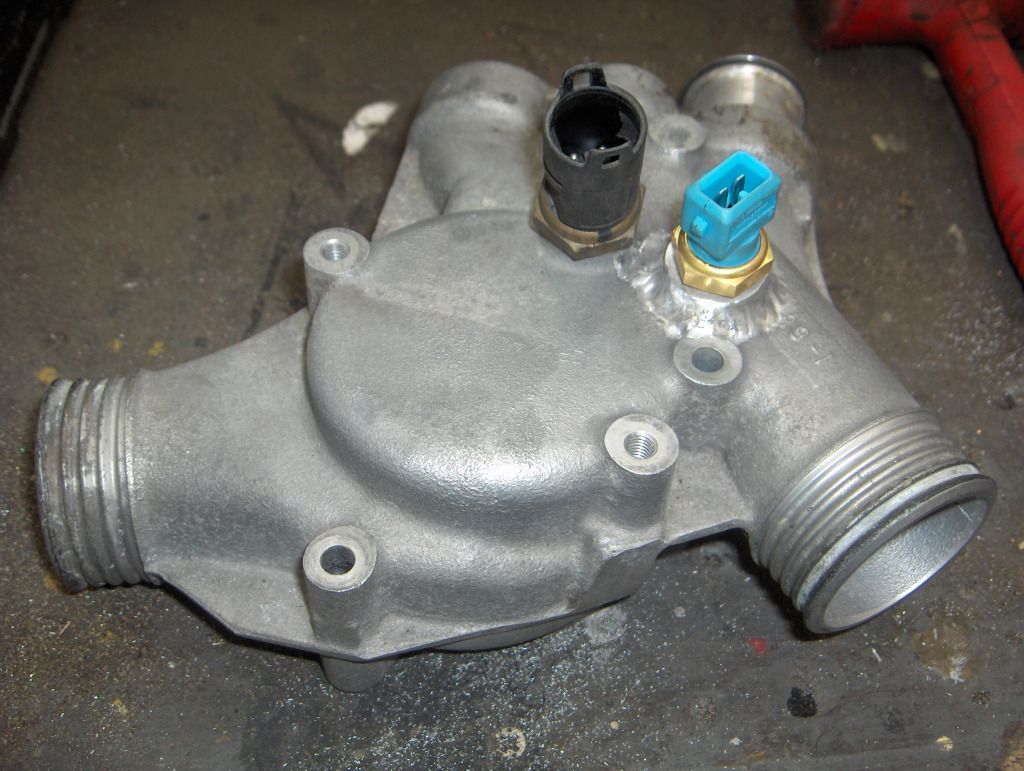

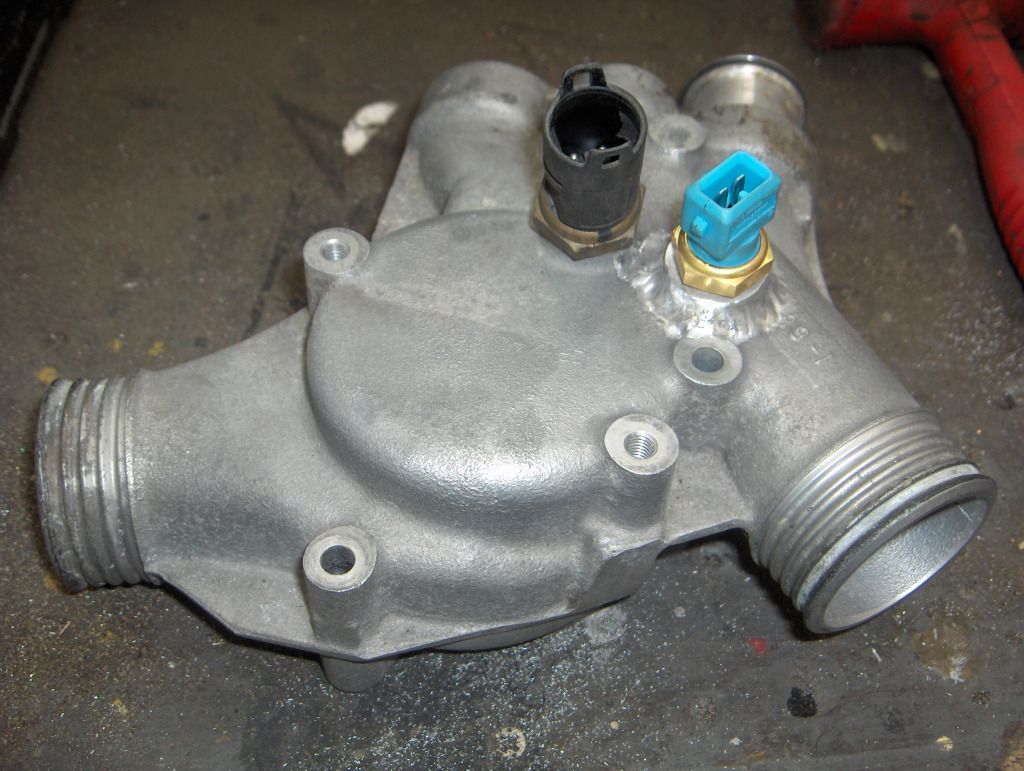

I made a boss, which James welded to the thermostat housing. The sensor will feed a Stack gauge.

The fan and rad look like they might be in to stay:

There's also been some more work on the exhausts. There's a mild step up just after the collectors for a bit of venturi effect:

There's a mild step up just after the collectors for a bit of venturi effect:

They go on like this:

and attach to this:

which goes here:

and stick out the back here:

Looks like I best get it running soon then eh!

Cheers. Dave.

I'm using the standard oil filter housing for now.

There's perhaps the option of lengthening the feed and return pipes on the standard housing and dropping it through a hole in front of the near side inner wing depending on what you're doing with airboxes etc. I'd be more inclined to look at the filter mount on the drivers side though.

Cheers Gorilla. There speaks the voice of a man who's been there before I'd say

Yep, I did think of bracing the arms like the Z3M, but I wanted to add strength along the length of the arm where I removed some material for wheel clearance. I don't think they'll flex much now anyway!

I've got a few more bits and pieces ticked off the list.

The front arches now match the rears, and are a skim and a drop of paint away from being finished:

I made a boss, which James welded to the thermostat housing. The sensor will feed a Stack gauge.

The fan and rad look like they might be in to stay:

There's also been some more work on the exhausts.

They go on like this:

and attach to this:

which goes here:

and stick out the back here:

Looks like I best get it running soon then eh!

Cheers. Dave.

- GermanGorilla

- E30 Zone Regular

- Posts: 528

- Joined: Mon Feb 07, 2005 11:00 pm

Hi,

'''Stepped Headers'' ala F1.

Never sure if the theory works as well

on Road Cars given the lengths involved,

but does not stop SuperSprint from selling

them at eyewatering prices.

May help exhaust scavenge a little.

Good quality work as always and executed

with some prior thought as opposed the

fix and then make it fit approach, adopted

by many.

Regards,

The Gorilla.

'''Stepped Headers'' ala F1.

Never sure if the theory works as well

on Road Cars given the lengths involved,

but does not stop SuperSprint from selling

them at eyewatering prices.

May help exhaust scavenge a little.

Good quality work as always and executed

with some prior thought as opposed the

fix and then make it fit approach, adopted

by many.

Regards,

The Gorilla.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

It would be nice to back to back test the exhausts with, and without the steps, but then again, it'd be nice to do a lot of things! The steps aren't huge. It would be a surprise if they lost power in any case.

Thanks for the compliments Duckmann and Gorilla. Much appreciated by both myself and James. (Duckman and Gorilla... Good band name!)

(Duckman and Gorilla... Good band name!)

There are a couple of things which should have paid a little more attention, on which clearance will be a little tighter than I'd have liked. I guess I'll have to put my hands up and admit all when the time comes!

I got my hands on a used lathe with a milling head on it a fair while ago. I finally had a bit of a go on it today. (Another thing which I've not messed around with before! )

)

So, I finally finished the steering U/J. The bolt heads are now recessed and the threads helicoiled for a little extra clearance:

While I was in the mood, I knocked up these. (Yes, I need to do some tool sharpening! ):

):

^Those, meant that I could fit my new discs with the correct spacing. The old (330 E46) discs:

The (back of the) new 345mm E46 CSL discs They have aluminium bells, which is nice :

They have aluminium bells, which is nice :

Here they are fitted. My iPhone is there for some kind of size referance. They're pretty big! :

:

I also popped a couple of gauges in a radio blank. I was going to put three gauges in there (which perhaps I still will), but the steering wheel could ideally do with a few inches of it being invisible for a clear view of the right hand one. There will probably be oil pressure and temp ones in there at some point:

There will probably be oil pressure and temp ones in there at some point:

That's about it for now. Cheers!

Cheers!

Thanks for the compliments Duckmann and Gorilla. Much appreciated by both myself and James.

There are a couple of things which should have paid a little more attention, on which clearance will be a little tighter than I'd have liked. I guess I'll have to put my hands up and admit all when the time comes!

I got my hands on a used lathe with a milling head on it a fair while ago. I finally had a bit of a go on it today. (Another thing which I've not messed around with before!

So, I finally finished the steering U/J. The bolt heads are now recessed and the threads helicoiled for a little extra clearance:

While I was in the mood, I knocked up these. (Yes, I need to do some tool sharpening!

^Those, meant that I could fit my new discs with the correct spacing. The old (330 E46) discs:

The (back of the) new 345mm E46 CSL discs

Here they are fitted. My iPhone is there for some kind of size referance. They're pretty big!

I also popped a couple of gauges in a radio blank. I was going to put three gauges in there (which perhaps I still will), but the steering wheel could ideally do with a few inches of it being invisible for a clear view of the right hand one.

That's about it for now.

- Mikey_Boy

- E30 Zone Regular

- Posts: 996

- Joined: Sun Mar 16, 2008 11:00 pm

- Location: Cheshire - trying to avoid the bling!

^^^ Excellent stuff!!

The F1 stepped exhaust probably won't work given its so far from the exhaust port but it won't hurt either - exhaust looks very interesting - great job!

I would definitely spend a bit of cash on an oil pressure gauge and bright light for the dash with a high pressure sender - it could save you an engine rebuild, plus you have a perfect space in your radio blank for it!!

The F1 stepped exhaust probably won't work given its so far from the exhaust port but it won't hurt either - exhaust looks very interesting - great job!

I would definitely spend a bit of cash on an oil pressure gauge and bright light for the dash with a high pressure sender - it could save you an engine rebuild, plus you have a perfect space in your radio blank for it!!

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers Jimbob.

There have been a few bits and bobs which I've looked at and asked myself what the hell's going on. It's cool when you figure that stuff out though.

It's cool when you figure that stuff out though.

I bought the blank from Fleabay. It's not a perfect colour match, but it'll do (and it was cheap! )

)

http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... 1170833261

As you say Mikey, the step won't hurt for sure. James seems alright at that stuff!

James seems alright at that stuff!  I'll definitely be having a pressure gauge in there. Funnily enough, I was looking at higher pressure warning light sensors and bright warning lights just last night.

I'll definitely be having a pressure gauge in there. Funnily enough, I was looking at higher pressure warning light sensors and bright warning lights just last night.  I might well find somewhere very much in view for the light.

I might well find somewhere very much in view for the light.

Cheers! D

There have been a few bits and bobs which I've looked at and asked myself what the hell's going on.

I bought the blank from Fleabay. It's not a perfect colour match, but it'll do (and it was cheap!

http://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... 1170833261

As you say Mikey, the step won't hurt for sure.

Cheers! D

- GermanGorilla

- E30 Zone Regular

- Posts: 528

- Joined: Mon Feb 07, 2005 11:00 pm

Hi,

CSL Discs are a very good option due

to the Alloy belles and the fact their

only 28mm wide.

Just be sure to take the time

and to bed them in correctly and

take them through at least one complete heat cycle

so they are just turning blue on the inner

and outer edges and with suitable pads, not

DS2500, they will do a very good job.

Pagid 19's or for more bite 29's, even Carbo Lor

work well with 6 pots and

CSL discs for 'spirited' road driving and the

odd Track appearance.

Can not remember if you fitted a rear Bias

valve to the rears ?

If not, you should fit one, as in the wet it will more

than pay for itself many times over.

Regards,

The Gorilla.

CSL Discs are a very good option due

to the Alloy belles and the fact their

only 28mm wide.

Just be sure to take the time

and to bed them in correctly and

take them through at least one complete heat cycle

so they are just turning blue on the inner

and outer edges and with suitable pads, not

DS2500, they will do a very good job.

Pagid 19's or for more bite 29's, even Carbo Lor

work well with 6 pots and

CSL discs for 'spirited' road driving and the

odd Track appearance.

Can not remember if you fitted a rear Bias

valve to the rears ?

If not, you should fit one, as in the wet it will more

than pay for itself many times over.

Regards,

The Gorilla.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

I got a little more done today.

As we know, the best place for an oil temperature sender is in the sump. Luckily, the sender which I'd bought has an M12 x 1.5 thread. Not so luckily, the sump thread is M14 x 1.5. A bit more luckily, this here Timecert thread repair insert has an outer thread of M14 x 1.5, and an inner thread of M12 x 1.5:

It now lives here:

There's also a big red battery lead which goes from the starter motor, through an isolated fitting through the transmission tunnel, then into the boot. I took more photos, but my camera has decided to eat them. Here's where it comes through to the interior:

Here's where it comes through to the interior:

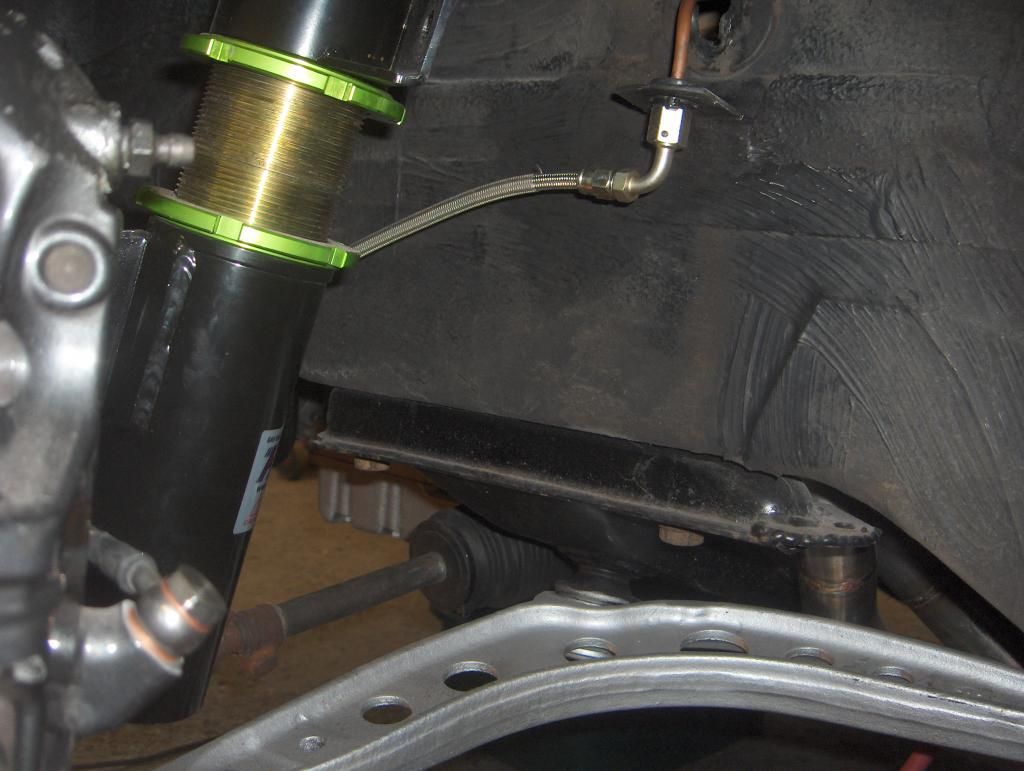

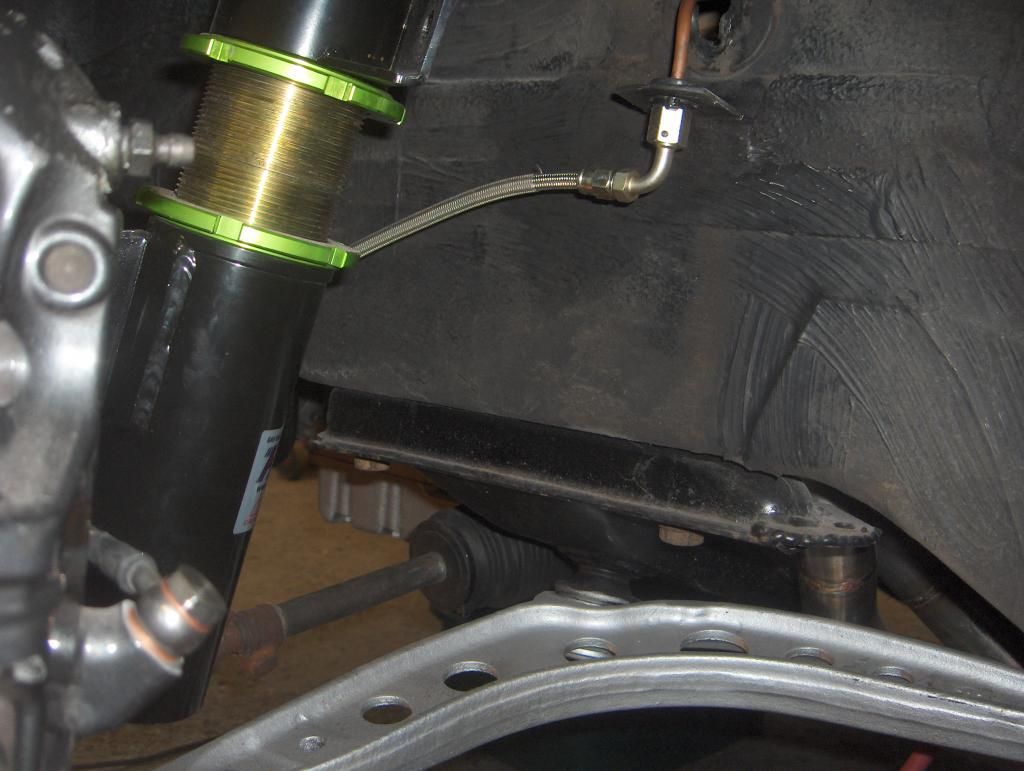

I ordered a few hose ends, which meant I could make some brake hoses out of some braided motocycle hoses which I had lying around. :

:

Cheers!

As we know, the best place for an oil temperature sender is in the sump. Luckily, the sender which I'd bought has an M12 x 1.5 thread. Not so luckily, the sump thread is M14 x 1.5. A bit more luckily, this here Timecert thread repair insert has an outer thread of M14 x 1.5, and an inner thread of M12 x 1.5:

It now lives here:

There's also a big red battery lead which goes from the starter motor, through an isolated fitting through the transmission tunnel, then into the boot. I took more photos, but my camera has decided to eat them.

I ordered a few hose ends, which meant I could make some brake hoses out of some braided motocycle hoses which I had lying around.

Cheers!

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

I've managed to slow any recent progress by having a dumb workshop accident.

I don't know how many wheels I've taken off cars, trucks, motorcycles, JCB's, pushbikes etc etc in the past. It really isn't something that I've ever thought might be risky! However...

I thought a fit up of the rear calipers was in order last Friday. The rear wheels were fitted, and the car on stands at a reasonable height. Like I said, I've taken wheels off a million times before, so it's kind of one of those auto-pilot jobs.

Anyway, after removing the wheel bolts, I put my hand between the wheel spokes under the top inside part of the rim. As we all know, there's usually enough support where the wheel centre fits over the hub to stop the wheel moving unexpectedly. Unfortunately, being on auto-pilot and thinking about my calipers, I forgot to take into account that my hubs are fitted with 5mm spacers. My hand touching the rim was enough to make the wheel drop onto the brake disc. Luckily for the paint on the wheel, my middle finger cushioned the blow. The result of this cushioning effect is that I detached most of my finger nail, pushing it a few mm out of the end of my finger, lacerated the nail bed, gashed the side of the finger open and crushed the bone in the tip. I won't lie. It hurt a bit.

The result of this cushioning effect is that I detached most of my finger nail, pushing it a few mm out of the end of my finger, lacerated the nail bed, gashed the side of the finger open and crushed the bone in the tip. I won't lie. It hurt a bit.

I've since been to the hospital, where they removed the nail, removed some bone fragments (through the nail bed), stitched up the lacerations in the nail bed and side of the finger, and popped the nail back on as a splint (which will fall off again).

Bugger.

Anyway, while I'm here....

while I'm here....

I'm going to knock up an oil distribution block so I can run a low pressure warning light and pressure sensor off of the filter housing. It would be convienient to use -3 braided hose from the housing to feed the block remotely (as I have some hose and fittings), but I'm a little concerned that the bore size might be a touch too small.

What do you reckon guys?

TIA! Dave.

I don't know how many wheels I've taken off cars, trucks, motorcycles, JCB's, pushbikes etc etc in the past. It really isn't something that I've ever thought might be risky! However...

I thought a fit up of the rear calipers was in order last Friday. The rear wheels were fitted, and the car on stands at a reasonable height. Like I said, I've taken wheels off a million times before, so it's kind of one of those auto-pilot jobs.

Anyway, after removing the wheel bolts, I put my hand between the wheel spokes under the top inside part of the rim. As we all know, there's usually enough support where the wheel centre fits over the hub to stop the wheel moving unexpectedly. Unfortunately, being on auto-pilot and thinking about my calipers, I forgot to take into account that my hubs are fitted with 5mm spacers. My hand touching the rim was enough to make the wheel drop onto the brake disc. Luckily for the paint on the wheel, my middle finger cushioned the blow.

I've since been to the hospital, where they removed the nail, removed some bone fragments (through the nail bed), stitched up the lacerations in the nail bed and side of the finger, and popped the nail back on as a splint (which will fall off again).

Bugger.

Anyway,

I'm going to knock up an oil distribution block so I can run a low pressure warning light and pressure sensor off of the filter housing. It would be convienient to use -3 braided hose from the housing to feed the block remotely (as I have some hose and fittings), but I'm a little concerned that the bore size might be a touch too small.

What do you reckon guys?

TIA! Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers Mikey.

Well, seeing as the S62 transplants on here have gone a bit quiet of late, I thought it was time for a couple of small updates.

So, I made this:

Bolted these into it:

Then mounted it here. It's fed from the stock pressure switch position via a braided hose (which I didn't get a picture of!:

It'll more than likely end up with a higher pressure sender for the low pressure warning light.

In the workshop, weirdly, the ride height looked ok (ish), but rolled outside, it had a little monster truck about it.

The HSD's have adjustable spring platforms, which were bottomed out (not in the position they are here obviarsely):

So, I removed the collars and made a sleeve to stop the spring rattling around:

I then had a go at TIG welding. This is the first weld, done by James:

My welds weren't quite like that!

While I was at the back end, I knocked up some rear hoses:

After opening the mounting hole on the back plate, they fitted like this:

If/when the springs settle a touch, I reckon the ride height will be somewhere close to where I want it. If it isn't, I'll be getting some slightly shorter rear springs.

Hopefully I'll get a bit more done in the near future (like get the bugger running! ) but I've the feeling that Christmas, work, and drinking are going to interfere a touch. I've had the engine turning over (after rebuilding the starter motor), but not firing. It's (hopefully) just a couple of bits and bobs away from making a bit of noise!

) but I've the feeling that Christmas, work, and drinking are going to interfere a touch. I've had the engine turning over (after rebuilding the starter motor), but not firing. It's (hopefully) just a couple of bits and bobs away from making a bit of noise!

Cheers! Dave.

Well, seeing as the S62 transplants on here have gone a bit quiet of late, I thought it was time for a couple of small updates.

So, I made this:

Bolted these into it:

Then mounted it here. It's fed from the stock pressure switch position via a braided hose (which I didn't get a picture of!:

It'll more than likely end up with a higher pressure sender for the low pressure warning light.

In the workshop, weirdly, the ride height looked ok (ish), but rolled outside, it had a little monster truck about it.

The HSD's have adjustable spring platforms, which were bottomed out (not in the position they are here obviarsely):

So, I removed the collars and made a sleeve to stop the spring rattling around:

I then had a go at TIG welding. This is the first weld, done by James:

My welds weren't quite like that!

While I was at the back end, I knocked up some rear hoses:

After opening the mounting hole on the back plate, they fitted like this:

If/when the springs settle a touch, I reckon the ride height will be somewhere close to where I want it. If it isn't, I'll be getting some slightly shorter rear springs.

Hopefully I'll get a bit more done in the near future (like get the bugger running!

Cheers! Dave.

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

I got a bit more done today. Happy Christmas to me!

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers!  It's hard to get a proper idea with it in the workshop, but it seems RATHER LOUD!

It's hard to get a proper idea with it in the workshop, but it seems RATHER LOUD!  I'll get it outside soon and see what it's really like. You might notice that the iPhone I took the video with moves when I rev the engine!

I'll get it outside soon and see what it's really like. You might notice that the iPhone I took the video with moves when I rev the engine!

-

davethegoat

- E30 Zone Regular

- Posts: 455

- Joined: Fri Oct 28, 2011 11:00 pm

Cheers guys! Believe me, I'm a very smiley goat tonight!

(About bloody time too!

(About bloody time too!  )

)

Here y' go Dan. I should have got one of the nurses to get a pic while the nail was been peeled off really. Just waiting for the (black) nail to fall off now... This was taken a few hours after I did it after a quick clean up.

Just waiting for the (black) nail to fall off now... This was taken a few hours after I did it after a quick clean up.

Cheers!

Here y' go Dan. I should have got one of the nurses to get a pic while the nail was been peeled off really.

Cheers!

-

e30topless

- E30 Zone Team Member

- Posts: 13598

- Joined: Wed Aug 23, 2006 11:00 pm

- Location: surrounded by scrap

try this Glen, That sounds Awesome ! well doneglenn wrote:whats wrong with my youtube?

the link opens up, but the video just doesn't start

[youtube][/youtube]

Last edited by e30topless on Sun Dec 23, 2012 7:47 pm, edited 1 time in total.