Question about piston skirts and 2.8 m20's

Moderator: martauto

-

ross_jsy

- Married to the E30 Zone

- Posts: 7307

- Joined: Sun Jul 12, 2009 11:00 pm

- Location: Jersey, C.I.

So I started mocking up a 2.8 build last night and found the pistons I have are the longer skirt type and need machining down. I popped into an engine builder who I know to talk about where to get it machined and he is worried about how much has to come off the bottom and how it is going to effect piston stability in the bore, especially with the increased leverage ratio on the con rod from a shorter rod and longer throw.

So to anyone who has built 2.8's, is this an issue? Do you get piston slap or noticed any increased or unusual wear?

It seems to me, the idea of a cheap 2.8 build isn't a great route to take. Apart from the increased wear, I foresee a fair amount of power robbing friction from sidewall pressure. A longer rod/custom piston with higher pin height would probably see a decent boost in power/torque. Be interested to get peoples views on this.

Thanks

Ross

So to anyone who has built 2.8's, is this an issue? Do you get piston slap or noticed any increased or unusual wear?

It seems to me, the idea of a cheap 2.8 build isn't a great route to take. Apart from the increased wear, I foresee a fair amount of power robbing friction from sidewall pressure. A longer rod/custom piston with higher pin height would probably see a decent boost in power/torque. Be interested to get peoples views on this.

Thanks

Ross

-

HairyScreech

- Engaged to the E30 Zone

- Posts: 6265

- Joined: Sun Jan 21, 2007 11:00 pm

It's not significant, the friction is about 1-3% increase and the skirts are huge for the stroke of the engine.

4" bore x4.4" stroke v8s get away with smaller skirts than a shortened B25 piston.

If wear is a big concern, don't build a tuned engine.

4" bore x4.4" stroke v8s get away with smaller skirts than a shortened B25 piston.

If wear is a big concern, don't build a tuned engine.

2.8 development thread http://www.e30zone.net/modules.php?name ... c&t=170822

m3.3.1 m20 thread - now running, chip needed - any volunteers?

http://www.e30zone.net/modules.php?name ... =viewtopic&

m3.3.1 m20 thread - now running, chip needed - any volunteers?

http://www.e30zone.net/modules.php?name ... =viewtopic&

-

ross_jsy

- Married to the E30 Zone

- Posts: 7307

- Joined: Sun Jul 12, 2009 11:00 pm

- Location: Jersey, C.I.

That's a lot less than I thought it would have been. Looking at previous m20's I have stripped, they seem to have marks the entire length of the skirt, hence my concern. I suppose rod to stroke ratios are acceptable using 130mm rods so I shouldn't be too worried.

Wear is not the concern, excessive wear from poorly matched components is.

Cheers Willnz, I'll be doing all that when I rebuild it. Are Goetze rings of decent quality?

Dropped the pistons off at a machine shop earlier. Old boy is doing it for free, result. Will buy him a bottle of something nice.

Wear is not the concern, excessive wear from poorly matched components is.

Cheers Willnz, I'll be doing all that when I rebuild it. Are Goetze rings of decent quality?

Dropped the pistons off at a machine shop earlier. Old boy is doing it for free, result. Will buy him a bottle of something nice.

she'll be right mate, you wont notice any power with a longer rod, the change in angularity and piston motion is minuscule. Ant said hes build many 2.7 with 130 and 135mm rods and they are the same within a couple bhp. I'm sure a longer rod will have better longevity but its still going to be good for many many years.

get the clearances correct and balance it all and good to go.

get the clearances correct and balance it all and good to go.

E30 325is with M20B31

272 schrick or 284/272. IMO steer clear of catcams on streetmotor you lose way too much oomph below 3500rpm which defeats the purpose of a stroker, they do make decent topend so if it sees the track its an ok compromise...

enem Z45 (280) would be what id use for higher comp one

id get a cam vernier to, make sure you check clearances and you get the block skimmed to maintain the about 1mm squishband

enem Z45 (280) would be what id use for higher comp one

id get a cam vernier to, make sure you check clearances and you get the block skimmed to maintain the about 1mm squishband

Last edited by reggid on Wed Nov 25, 2015 2:13 am, edited 1 time in total.

E30 325is with M20B31

another punchy cam is the dbilas 276, a fellow guy from oz had one in a 2.8L m20 and was torquey as hell. it plotted out slighty smaller than 276 but had big lift on it. I think he made 180odd hp at wheels so a great street engine

E30 325is with M20B31

- motormanmick

- E30 Zone Regular

- Posts: 259

- Joined: Sun Nov 02, 2014 11:00 pm

- Location: Coffs Hbr, Aust

G'day ross_jsy, as reggid saysreggid wrote:272 schrick or 284/272. IMO steer clear of catcams on streetmotor you lose way too much oomph below 3500rpm which defeats the purpose of a stroker, they do make decent topend so if it sees the track its an ok compromise...

enem Z45 (280) would be what id use for higher comp one

id get a cam vernier to, make sure you check clearances and you get the block skimmed to maintain the about 1mm squishband

something that may benefit you is an adjustable cam sprocket on your new cam, as one of their comments says (quoted) on the link below

https://store.vacmotorsports.com/vac--- ... -p964.aspx

In general, advancing the cam timing increases low RPM torque and improves part-throttle engine response. Retarding the camshaft timing will generally shift the powerband upward in the RPM, increasing top end power. This gear will allow you to adjust for peak performance and exact power range you desire, or to help spool up a turbo on the m20

-

HairyScreech

- Engaged to the E30 Zone

- Posts: 6265

- Joined: Sun Jan 21, 2007 11:00 pm

If torque is king it might be worth just getting +1mm valves put in, a light tickle of the head and keeping the stock cam.

If you want torque then aim for less valve overlap and less intake valve opening after BDC.

If you want torque then aim for less valve overlap and less intake valve opening after BDC.

2.8 development thread http://www.e30zone.net/modules.php?name ... c&t=170822

m3.3.1 m20 thread - now running, chip needed - any volunteers?

http://www.e30zone.net/modules.php?name ... =viewtopic&

m3.3.1 m20 thread - now running, chip needed - any volunteers?

http://www.e30zone.net/modules.php?name ... =viewtopic&

For a vernier pulley have a word with DanThe, he had some custom made when he was building my M20B28.

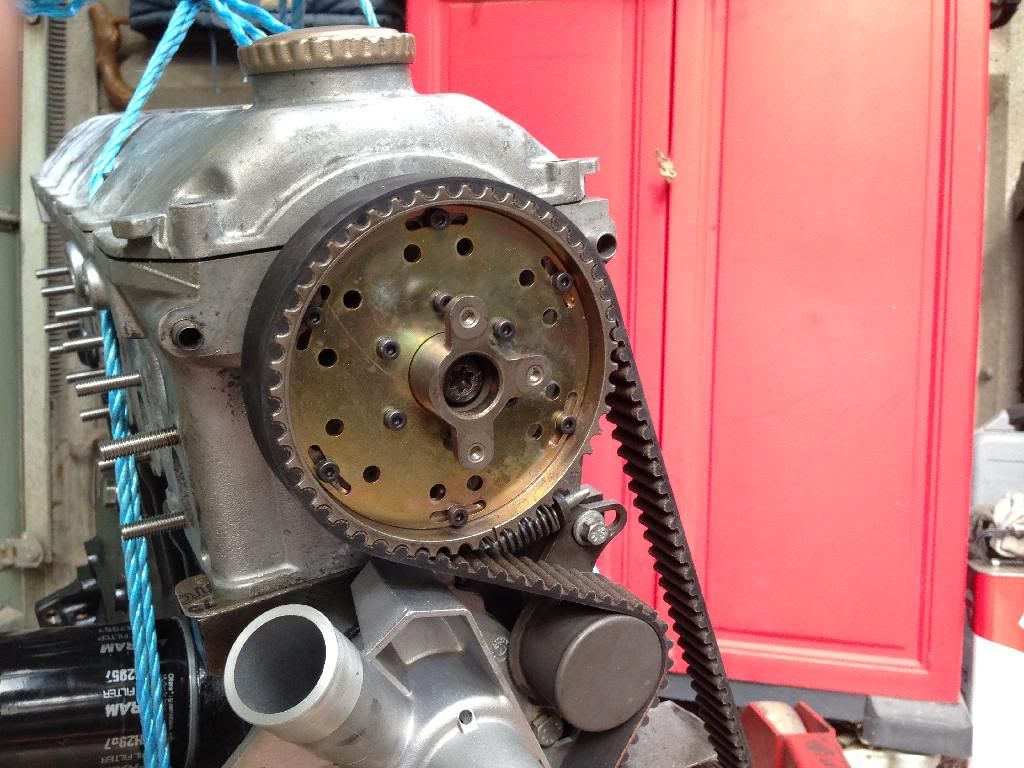

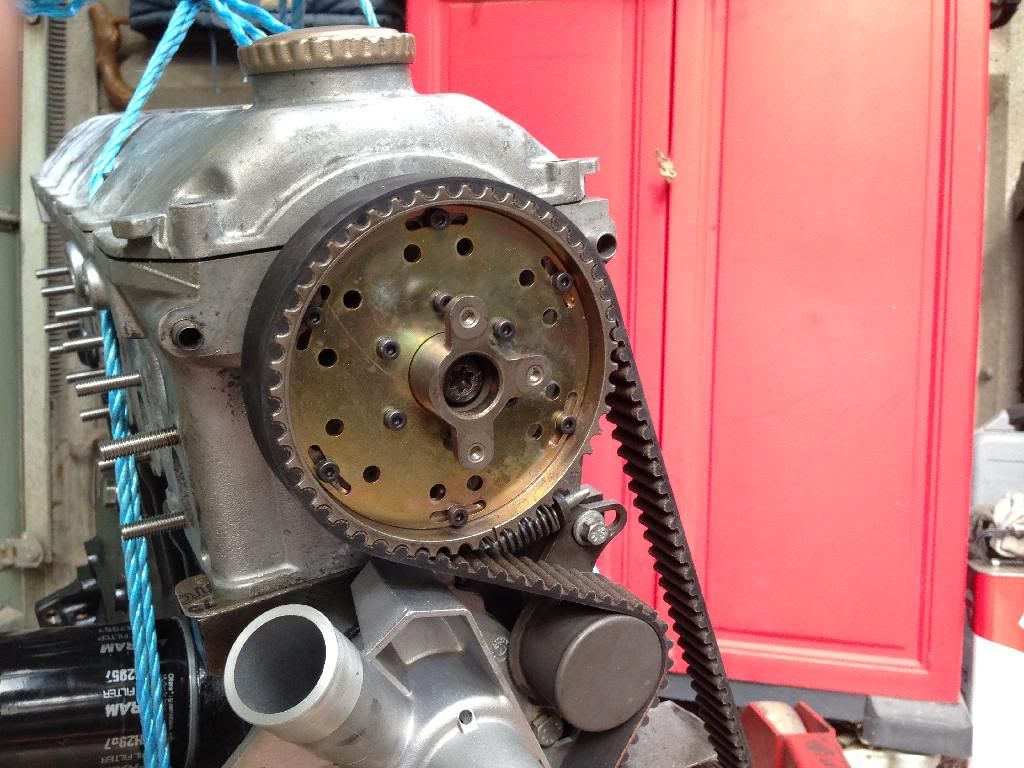

For the record, my M20B28 is running a Schrick 272 cam, early small webbed M52B28 crank, early M20B25 pistons which had to have the skirt trimmed and valve relief's deepened, but then Dan was chasing high CR.

For the record, my M20B28 is running a Schrick 272 cam, early small webbed M52B28 crank, early M20B25 pistons which had to have the skirt trimmed and valve relief's deepened, but then Dan was chasing high CR.

That's kind of what Alpina did, a lightly ported head and retaining a smallish cam . An Alpina style cam seems to be a great allround cam. When you see it plottted out against the b25 cam they basically retained the same inlet valve closing point and exhaust valve opening point so the added 10* or so duration just created more overlap. its not huge overlap (ame as 272 roughly) but gives good allround power with a sorted exhaust system. a stock cam might give more bottom end on an Alpina than their own cam but id guess it would only be below 2000rpmHairyScreech wrote:If torque is king it might be worth just getting +1mm valves put in, a light tickle of the head and keeping the stock cam.

If you want torque then aim for less valve overlap and less intake valve opening after BDC.

too much overlap hurts right at the very bottom end but helps at midrange. when you add duration without adding more overlap area it tends to hurt torque as well as you can bleed off too much compression. a cam vernier can bandaid it sometimes

E30 325is with M20B31

how far above the deck were the pistons? what gasket did you use (1.75 or 2.05mm)? did you measure piston to head squish clearance? any rolling road numbers/graphs?Kedge wrote:For a vernier pulley have a word with DanThe, he had some custom made when he was building my M20B28.

For the record, my M20B28 is running a Schrick 272 cam, early small webbed M52B28 crank, early M20B25 pistons which had to have the skirt trimmed and valve relief's deepened, but then Dan was chasing high CR.

Last edited by reggid on Wed Nov 25, 2015 9:34 pm, edited 1 time in total.

E30 325is with M20B31

this combination will nominally sit 0.5mm down from how BMW did it.mr2peak wrote:How much did you take off the block? Shouldn't those pistons be sitting at .5mm below the deck?

75mm-->84mm stroke is 4.5mm throw inrease, with a 5mm shorter rod you are 0.5 mm down further from nominal.

But BMW had the pistons above the block face to start with

throw 37.5 mm + rod 135 mm + piston compression height 34.2 mm = 206.7 mm.

the two b25 blocks ive measured (no obvious signs of block being machined) were 206.2 mm so this means by design the pistons sit 0.5 mm (206.7-206.2) above block face.

combine this with 1.75 mm gasket and you have about 1.25 mm clearance head to piston crown which a little higher than ideal of 1.0 mm or perhaps slightly less.

when you have head with material removed and block with material removed you need to use actual measurements and adjust to suit

E30 325is with M20B31

-

HairyScreech

- Engaged to the E30 Zone

- Posts: 6265

- Joined: Sun Jan 21, 2007 11:00 pm

I just wrote a big long post about this and measuring the PTV and squish clearance but it didn't post. FML.

I will try and rewrite it later tonight if I remember.

I will try and rewrite it later tonight if I remember.

2.8 development thread http://www.e30zone.net/modules.php?name ... c&t=170822

m3.3.1 m20 thread - now running, chip needed - any volunteers?

http://www.e30zone.net/modules.php?name ... =viewtopic&

m3.3.1 m20 thread - now running, chip needed - any volunteers?

http://www.e30zone.net/modules.php?name ... =viewtopic&

-

DanThe

- E30 Zone Team Member

- Posts: 28641

- Joined: Sat Sep 10, 2005 11:00 pm

- Location: Staffs

- Contact:

Kedges engine uses a standard 1.75 gasket, the piston to head clearance is just under 1mm and the pistons had to have the valve reliefs cut out to give clearance, I can't remember the details exactly, I've been to bed since and messed with other engines plus I don't write anything down, but the cr is around 11:1

I have a couple of vernier pulleys available btw

I have a couple of vernier pulleys available btw

- Brianmoooore

- E30 Zone Team Member

- Posts: 49358

- Joined: Mon Jan 10, 2005 11:00 pm

Nice to hear I'm not the only one that writes out a 500 word essay and then forgets to click on the 'submit' button!HairyScreech wrote:I just wrote a big long post about this and measuring the PTV and squish clearance but it didn't post. FML.

206.7 is the stack height not the block deck heightmr2peak wrote:Well that clears that up.

However, I keep turning up 2 different deck heights, 206.7 and 206.2

Guess I'll have to measure the block I get and go from there.

stack height is

=crank throw+rod length+piston height

deck height is distance between deck face and crank C/L

ive measured b25 and b27 blocks never seen one 206.7mm but the stack height is 206.7 when you use the mahle piston data.

there probabl;y is some variation in block in part due to things being pulled apart and M/c over the last 20-25years

E30 325is with M20B31

good to see its been screwed together correctly and that important details haven't been thrown out the window like 99% of other builds seem to.DanThe wrote:Kedges engine uses a standard 1.75 gasket, the piston to head clearance is just under 1mm and the pistons had to have the valve reliefs cut out to give clearance, I can't remember the details exactly, I've been to bed since and messed with other engines plus I don't write anything down, but the cr is around 11:1

I have a couple of vernier pulleys available btw

Kedge needs to pull his finger out and get it tuned and running its best

E30 325is with M20B31