update

Moderator: martauto

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Looks pretty good to me! The M20 is miles out if you turn the manifold upside-down.

Think I'm gonna turn up a 10mm thick shim and see what that gets me. Had a quick peek under the mounts on the subframe and they're already as far left as they can be

On the plus side, I've finally come up with some workable connections for the oil to the turbos so that's a weight off! Also, just went out to fit the new exhaust which bolted straight on this time, plus the down pipes fitted first time!

Just recovering from the shock of something going right at the moment!

Think I'm gonna turn up a 10mm thick shim and see what that gets me. Had a quick peek under the mounts on the subframe and they're already as far left as they can be

On the plus side, I've finally come up with some workable connections for the oil to the turbos so that's a weight off! Also, just went out to fit the new exhaust which bolted straight on this time, plus the down pipes fitted first time!

Just recovering from the shock of something going right at the moment!

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Some of today's efforts:

A collector for one of the downpipes:

And the (hopefully standard looking) new exhaust:

A collector for one of the downpipes:

And the (hopefully standard looking) new exhaust:

alex have you considered the 316 style engine mount dampers they might take some of the movement out?

cheers for the sugestions guys the cluch switch sounds like a good idea. perhaps if i use that aswell as the throttle switch to make sure its not on at idle.

the cluch switch sounds like a good idea. perhaps if i use that aswell as the throttle switch to make sure its not on at idle.

A sprung preload pulley on the return side of the belt might help take out the slack when theres no load. as the new pulley is so much bigger that when the charger turns on the extra grip on the belt is pulling the charger down giving slack on the oposite side where the waterpump pulley runs if the slack hits that it may push it forwards.

anyway new belt new day try again!

cheers for the sugestions guys

A sprung preload pulley on the return side of the belt might help take out the slack when theres no load. as the new pulley is so much bigger that when the charger turns on the extra grip on the belt is pulling the charger down giving slack on the oposite side where the waterpump pulley runs if the slack hits that it may push it forwards.

anyway new belt new day try again!

Some serious progression guys. Toby can you not port the bolt holes so that the actual ports line up better, it may be easier than opening up the actual exhaust ports??

Also toby thank your lucky socks that the m30 downpipe/front pipe(not sure which) is a single exit. On the m20 i had to go from 2.5 inch downpipe to the standard twin pipe.

Took the turbo to an airfield day, but check the motorsport section for more details, but i can tell you it drove home fine.

Also toby thank your lucky socks that the m30 downpipe/front pipe(not sure which) is a single exit. On the m20 i had to go from 2.5 inch downpipe to the standard twin pipe.

Took the turbo to an airfield day, but check the motorsport section for more details, but i can tell you it drove home fine.

good to hear yours is running good jon

Think ive found the problem!

After spending most of lastnight trying to line everything up again

went for a testdrive the belt stayed on but it still screached between gears on closer inspection

on closer inspection

my water pump pulley looked a bit too clean!

So marked it with a dry board marker and had another test sure enough it was clean!

Looks like the slack on the return side of the s/c pulley is rubbing the waterpump pulley.

So i need some kind of spring loaded active tensioner on the back of the belt to remove the slack when the charger turns off

I will have a look later see what i can dream up

Think ive found the problem!

After spending most of lastnight trying to line everything up again

went for a testdrive the belt stayed on but it still screached between gears

my water pump pulley looked a bit too clean!

So marked it with a dry board marker and had another test sure enough it was clean!

Looks like the slack on the return side of the s/c pulley is rubbing the waterpump pulley.

So i need some kind of spring loaded active tensioner on the back of the belt to remove the slack when the charger turns off

I will have a look later see what i can dream up

Ok got some bearings! made up a pulley and bracket that worked great until one of the bearings seized locking the pulley burning the belt

But it did stay on so another belt ordered try again!

But it did stay on so another belt ordered try again!

Too many!

Think im up to 5 pos 6 this time!

The only reason this one went was the seized bearing tho

Think im up to 5 pos 6 this time!

The only reason this one went was the seized bearing tho

-

kam-325i

- E30 Zone Team Member

- Posts: 4851

- Joined: Tue Sep 27, 2005 11:00 pm

- Location: TELFORD !!!! (Shropshire) Stevetigger Land !!!

- Contact:

Anyway of making a bar tensioner, that's spring loaded to tension both the feed and return side.

Pete don't care about colour, He would shag a rainbow if he could find the end of it....

Hi Lentec,

Am also thinking of adding a supercharger to a 2.7 conversion I've recently completed for a m8. Had been thinking of driving with a toothed belt (similar to a cam belt but wider) a number of companies supply these together with a wide range of pulleys. Obviously the pulleys would need some machining but was wondering if you had thought of this route?

Am also thinking of adding a supercharger to a 2.7 conversion I've recently completed for a m8. Had been thinking of driving with a toothed belt (similar to a cam belt but wider) a number of companies supply these together with a wide range of pulleys. Obviously the pulleys would need some machining but was wondering if you had thought of this route?

Apal i did consider that route in the begining

As the s/c came with a 6-v pulley i decided to stay with that.

Besides i cant make a toothed pulley!

Latest: the belt is on for how long is anyones guess!

for how long is anyones guess!

The design of my tensioner pulley is a bit naff but seems to be working

Alltho it was getting hot! perhaps stainless was not such a good idea on a pulley!

Will try to use an oem one later

As the s/c came with a 6-v pulley i decided to stay with that.

Besides i cant make a toothed pulley!

Latest: the belt is on

The design of my tensioner pulley is a bit naff but seems to be working

Alltho it was getting hot! perhaps stainless was not such a good idea on a pulley!

Will try to use an oem one later

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

He he, how much are the belts Len?

Wouldn't have thought that the stainless would have generated more heat than other metals with the same surface finish TBH.

Might the heat be being caused by any rubbing that'd be caused if the axis of the pulley wasn't exactly parallel to that of the belt?

Just out of interest, what grade of ball bearings did you use? I'm always a bit paranoid about sealed BBs for some reason, like the can't possible get enough lube in them when they're made...can they?

Wouldn't have thought that the stainless would have generated more heat than other metals with the same surface finish TBH.

Might the heat be being caused by any rubbing that'd be caused if the axis of the pulley wasn't exactly parallel to that of the belt?

Just out of interest, what grade of ball bearings did you use? I'm always a bit paranoid about sealed BBs for some reason, like the can't possible get enough lube in them when they're made...can they?

i'd say the possibility of getting any grit or dust into an open bearing is much more worrying! once there's a little grinding paste to work with it won't last long! by contrast i don't think a ballrace should need much lube at all if working properly?

looking forward to ten pages of raging arguments about which ballbearings are the best

looking forward to ten pages of raging arguments about which ballbearings are the best

Alex not funny mate at Ԛ£11 - Ԛ£16 a pop it getting expensive

The bearings ive used are skf sealed ballberings

As far as i know sealed bearings are non friction type ie: no parts rub against each other as the balls/rollers are rolling and so dont need much lube!

The bearings ive used are skf sealed ballberings

As far as i know sealed bearings are non friction type ie: no parts rub against each other as the balls/rollers are rolling and so dont need much lube!

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Alas even a whif of axial load will cause rubbing in a ball bearing (not that it's anything to worry about mind  )

)

Guess a big killer of bearings is shite getting in to damage the surfaces so they'll last foreeeever!

How's the latest belt lasting?

I've had an evening of selective assembly going on to make the throttle links all exactly the same length. I had a bit of a problem when I fitted the TBs to the car in that they all closed at the same point, but all opened at wildly different rates. However, should hopefully be able to eliminate the problem tomorrow evening by resetting the butterflies.....fingers crossed!

Depending on how that goes, might even get around to machining up a metal replacement for the rubber flexy disc in the steering so that it can't melt!

I'm actually hesitantly confident that it might get started by the end of the weekend, although I won't be able to MOT it for another week even if I do

Guess a big killer of bearings is shite getting in to damage the surfaces so they'll last foreeeever!

How's the latest belt lasting?

I've had an evening of selective assembly going on to make the throttle links all exactly the same length. I had a bit of a problem when I fitted the TBs to the car in that they all closed at the same point, but all opened at wildly different rates. However, should hopefully be able to eliminate the problem tomorrow evening by resetting the butterflies.....fingers crossed!

Depending on how that goes, might even get around to machining up a metal replacement for the rubber flexy disc in the steering so that it can't melt!

I'm actually hesitantly confident that it might get started by the end of the weekend, although I won't be able to MOT it for another week even if I do

-

Andy335Touring

- Married to the E30 Zone

- Posts: 7144

- Joined: Sun Jan 09, 2005 11:00 pm

- Location: Long Eaton,Nottingham

- Contact:

Alex, do you want to borrow this gizmo for setting up your TB's ?

Trouble is i guess you'd have to have your car running N/A to use it ?

Are you going to be using a wide band O2 sensor with your Emerald to tune it up ?

Trouble is i guess you'd have to have your car running N/A to use it ?

Are you going to be using a wide band O2 sensor with your Emerald to tune it up ?

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Andy that'd be awesome if I could!

I reckon if I just make sure they all shut at the same point and open on the idle screw by the same amount it should get me running well enough for the MOT, but if I could borrow that do-hickey it'd make things miles easier

Access shouldn't be a problem as the air-box comes right off leaving just the TB entrances.

Not made provision for O2 bosses yet, will have a quick search on saturday. Anyone know what thread they are? Seem to recall they're M18 or something?

Cheers!

Alex.

I reckon if I just make sure they all shut at the same point and open on the idle screw by the same amount it should get me running well enough for the MOT, but if I could borrow that do-hickey it'd make things miles easier

Access shouldn't be a problem as the air-box comes right off leaving just the TB entrances.

Not made provision for O2 bosses yet, will have a quick search on saturday. Anyone know what thread they are? Seem to recall they're M18 or something?

Cheers!

Alex.

Its still on!!

Alltho only on 4 ribs now!

The problem with the bearings was that i had locked them up too tight!

As the pulley was seized if you like, it burned the back of the belt.

New bearings and a washer it seems to be ok now!

The o2 boss thread is a m18 x 1.5 any local exhaust company ie:speedflow will have them in stock.

Alltho only on 4 ribs now!

The problem with the bearings was that i had locked them up too tight!

As the pulley was seized if you like, it burned the back of the belt.

New bearings and a washer it seems to be ok now!

The o2 boss thread is a m18 x 1.5 any local exhaust company ie:speedflow will have them in stock.

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Got them from some lumps of metal, a lathe, a pillar drill, some Bastard files and a Dremmel.

Cheers for the boss thread info len, will have a search now

If anyone's really interested in TBs, I'll be looking into knocking a few sets up (casting them rather than fabricating them though) at some point in the new year.

-

Andy335Touring

- Married to the E30 Zone

- Posts: 7144

- Joined: Sun Jan 09, 2005 11:00 pm

- Location: Long Eaton,Nottingham

- Contact:

No probs mate, just drop me a PM with your ady and i will post it for youTurbo-Brown wrote:Andy that'd be awesome if I could!

I reckon if I just make sure they all shut at the same point and open on the idle screw by the same amount it should get me running well enough for the MOT, but if I could borrow that do-hickey it'd make things miles easier

Access shouldn't be a problem as the air-box comes right off leaving just the TB entrances.

Not made provision for O2 bosses yet, will have a quick search on saturday. Anyone know what thread they are? Seem to recall they're M18 or something?

Cheers!

Alex.

I'm going to attempt to tweak my Emerald with a WBO2 i've just ordered as i'm fairly sure mine is over fueling.

http://www.innovatemotorsports.com/xcar ... hp?cat=253

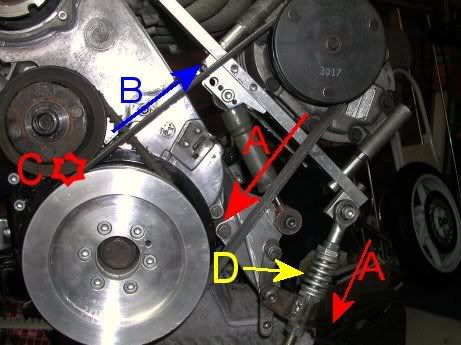

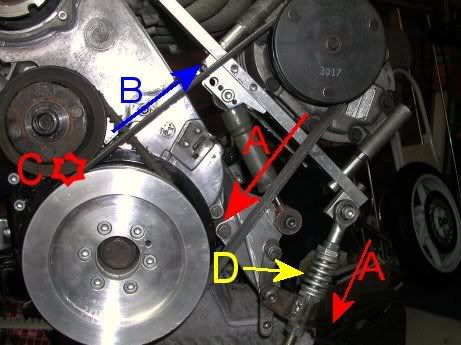

Ive worked out the belt probs

I forgot how i intended the front bracket to work!

Think a pic might help explain!

As the forces in direction (A) are a lot greater with a larger pulley this causes

the spring (D) to compress pulling the whole charger down

Creating slack in direction (B) and making the belt ride up the inside edge of the s/c pulley and possibly contact at (c)!

So if i make a spacer to sit under the spring (D) to preload it

Any sugestions?

I forgot how i intended the front bracket to work!

Think a pic might help explain!

As the forces in direction (A) are a lot greater with a larger pulley this causes

the spring (D) to compress pulling the whole charger down

Creating slack in direction (B) and making the belt ride up the inside edge of the s/c pulley and possibly contact at (c)!

So if i make a spacer to sit under the spring (D) to preload it

Any sugestions?

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Think if it were me I'd lose the spring and put an M12 turnbuckle in there

Cheers alex

Do you mean somyhing like this?

http://cgi.ebay.co.uk/12MM-316-GRADE-ST ... dZViewItem

Think thats what it needed in the first place! just didnt know what they where called!

Do you mean somyhing like this?

http://cgi.ebay.co.uk/12MM-316-GRADE-ST ... dZViewItem

Think thats what it needed in the first place! just didnt know what they where called!

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Yeah should do the job I'd have thought

Nice an meaty, and looks nice too! Should be no compressing that bad boy

Nice an meaty, and looks nice too! Should be no compressing that bad boy

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Yay!

Throttle bodies are on properly.

Metal steering donut is made and on.

Air box is all together with air temp sensor.

Got some vacuum hose for the servo and water hose for the turbo coolant.

Got Oil proof hose for the turbo oil drains.

Need to make clearance for the front blower and then they can go on together with the downpipes.

SO close!

Throttle bodies are on properly.

Metal steering donut is made and on.

Air box is all together with air temp sensor.

Got some vacuum hose for the servo and water hose for the turbo coolant.

Got Oil proof hose for the turbo oil drains.

Need to make clearance for the front blower and then they can go on together with the downpipes.

SO close!

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Boo, despite my bestest efforts, didn't get to try starting her up this weekend

Got the IC scoops on and all the boost plumbing in, but now the front valance won't go on which it did used to. Does look mean though

Got the IC scoops on and all the boost plumbing in, but now the front valance won't go on which it did used to. Does look mean though

Use a bigger hammerTurbo-Brown wrote: but now the front valance won't go on which it did used to.

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

Holy crap!

It went back on (with a bit of fettling to the boost pipes)

Here's the mostly completed engine bay

The exhaust system snaking it's way along the car

And the completed engine bay with heat shielding all over the place!

It went back on (with a bit of fettling to the boost pipes)

Here's the mostly completed engine bay

The exhaust system snaking it's way along the car

And the completed engine bay with heat shielding all over the place!

Mate that looks

Good to see all your hard work coming together

Good luck on the ticket!

-

Andy335Touring

- Married to the E30 Zone

- Posts: 7144

- Joined: Sun Jan 09, 2005 11:00 pm

- Location: Long Eaton,Nottingham

- Contact:

Nice work mate !

Theres a lot of plumbing involved with two turbos, it must have been a PITA to get every thing right !

Theres a lot of plumbing involved with two turbos, it must have been a PITA to get every thing right !