Was hopeing to keep the finish as it is, maybe even a polish if the machine is working, should be easy enough to do any finish, that crackle paint looks good too, I'll just wait to see how many scratches I have too polish out! Too many and I'm joining you.

Rotrex M42 Build - 285bhp little update

Moderator: martauto

Most of the companies I do work for are off till next week, so kinda twiddling thumbs today, will take some work in with me tomorrow

Was hopeing to keep the finish as it is, maybe even a polish if the machine is working, should be easy enough to do any finish, that crackle paint looks good too, I'll just wait to see how many scratches I have too polish out! Too many and I'm joining you.

Was hopeing to keep the finish as it is, maybe even a polish if the machine is working, should be easy enough to do any finish, that crackle paint looks good too, I'll just wait to see how many scratches I have too polish out! Too many and I'm joining you.

More progress today on the plenum, got a big hole saw and cut two 55mm holes in the base plate.

The little bit i left at the side of the holes is for a M8 bolt to thread in to the back of the plate of the plenum from the back.

Then joind them up with the slitting disc in the grinder.

the view with the plate cut out, the bolts on the inside will be bolted on first before the plenum bolts over the job lot and lock tighted in place, i might even use longer bolts and even up some nylocks on the bits that poke out.

Next clamped all the way round with mole grips ready to drill the holes and keep everything aligned

Holes drilled and a slight downward pointing bend welded on to the plenum, not that neat as when i weled the two joining halfs of the plenum togeather and must have slightly miss judged how big a half was as its ended up at just over 3".

All trimmed on the edge of the stainless and ally sheet, just need to make a gasket.

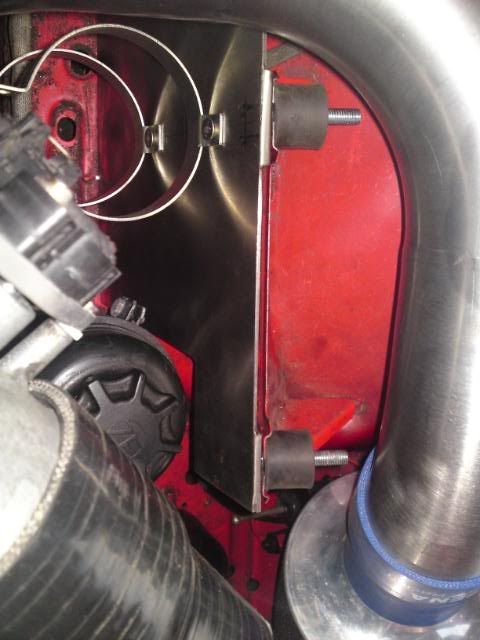

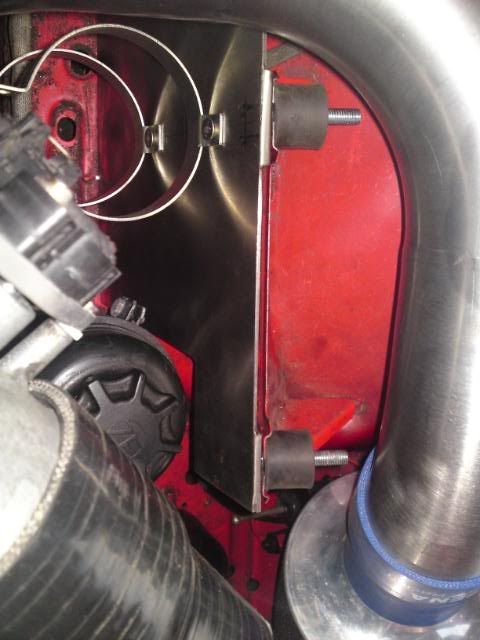

Bolted it on to the car which ment i could weld up a boost pipe for the IC to TB leg of the pipework just need to work out were i want to put the dump valve.

need to make up the plate that the TB will bolt to next, got a peice of 10mm stainless flat bar which i will be able to cut out and then grind/polish it to match it to the plenum and the TB as there very slightly different sizes probly 3" and 2 3/4" or maybe even less

The little bit i left at the side of the holes is for a M8 bolt to thread in to the back of the plate of the plenum from the back.

Then joind them up with the slitting disc in the grinder.

the view with the plate cut out, the bolts on the inside will be bolted on first before the plenum bolts over the job lot and lock tighted in place, i might even use longer bolts and even up some nylocks on the bits that poke out.

Next clamped all the way round with mole grips ready to drill the holes and keep everything aligned

Holes drilled and a slight downward pointing bend welded on to the plenum, not that neat as when i weled the two joining halfs of the plenum togeather and must have slightly miss judged how big a half was as its ended up at just over 3".

All trimmed on the edge of the stainless and ally sheet, just need to make a gasket.

Bolted it on to the car which ment i could weld up a boost pipe for the IC to TB leg of the pipework just need to work out were i want to put the dump valve.

need to make up the plate that the TB will bolt to next, got a peice of 10mm stainless flat bar which i will be able to cut out and then grind/polish it to match it to the plenum and the TB as there very slightly different sizes probly 3" and 2 3/4" or maybe even less

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

not sure i'll be saying that when its up and running

Last edited by appletree on Tue Dec 30, 2008 8:09 pm, edited 1 time in total.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

papercutout

- E30 Zone Regular

- Posts: 404

- Joined: Fri Oct 12, 2007 11:00 pm

- Location: Near Oxford, UK.

Looks fantastic, I'm still watching this project in anticipation of the finished product! Its going to be even better than before, and it was great then!

-

Turbo-Brown

- Boost Junkie

- Posts: 4705

- Joined: Tue Feb 15, 2005 11:00 pm

- Location: Aldershot, Hants

- Contact:

He heeee, that really does look fantastic!

Actually I though your last kit looked fookin' awesome too!

Oh dear, I fear I might have to go back and re-make some stuff just to keep up!

Actually I though your last kit looked fookin' awesome too!

Oh dear, I fear I might have to go back and re-make some stuff just to keep up!

- DieselMeister

- E30 Zone Regular

- Posts: 388

- Joined: Sat Nov 12, 2005 11:00 pm

Simply awesome

"Pass me the wheel before you hurt yourself, mate."

Think it would mount ok as it uses the same mounts but i dont know if it would hold the pressure or hold enough water??? Spose the issue is really the surface area available to disipate the heat.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

turned this up this morning, ready to be welded on to the boost pipe to mount the dump valve.

As i bought the dump valve with the 38mm fitting kit i made a new stub out of 1 1/2" dairy pipe and machined a grove for the grub screws to lock in to

Filed the bottom to make it but up to the boost pipe

Hole sawd the middle out and then welded the pipe on.

Polished up with the dump valve ftted

Next machiuned out the stainless plate to weld to the manifold for the throttle to mount on to, as the throttle was just alittle bit smaller than the 3" bore of the manifold, hopefully it will make it flow well

Welded the plate on along with a small plate to work as a mount for the throttle cable to pull against just need to round off the plate and polish it up

Also welded this plate on to work as the pressure/vacume take off for all the various sensors.

Dump valve

FPR

IVC

MAP sensor

Temp sensor

Boost gauge

an some more i forgot....

Here it is all bolted up and polished, still think i'm going to crackle black it.

As i bought the dump valve with the 38mm fitting kit i made a new stub out of 1 1/2" dairy pipe and machined a grove for the grub screws to lock in to

Filed the bottom to make it but up to the boost pipe

Hole sawd the middle out and then welded the pipe on.

Polished up with the dump valve ftted

Next machiuned out the stainless plate to weld to the manifold for the throttle to mount on to, as the throttle was just alittle bit smaller than the 3" bore of the manifold, hopefully it will make it flow well

Welded the plate on along with a small plate to work as a mount for the throttle cable to pull against just need to round off the plate and polish it up

Also welded this plate on to work as the pressure/vacume take off for all the various sensors.

Dump valve

FPR

IVC

MAP sensor

Temp sensor

Boost gauge

an some more i forgot....

Here it is all bolted up and polished, still think i'm going to crackle black it.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

shalmaneser

- E30 Zone Newbie

- Posts: 23

- Joined: Mon Jul 24, 2006 11:00 pm

Woah! Awesome fabrication there!

Bet she'll go like the proverbial, nice smooth bends, you've clearly given a lot of thought to airflow, great to see such attention to detail!

Good luck - hope she goes as good as she looks!

Bet she'll go like the proverbial, nice smooth bends, you've clearly given a lot of thought to airflow, great to see such attention to detail!

Good luck - hope she goes as good as she looks!

-

cliffybabe

- Powered by Nelly

- Posts: 10020

- Joined: Sun Dec 18, 2005 11:00 pm

- Location: Croydon

looks wicked dude

Considering Selling the Cabby, looks like its gonna go

-

GrindCulture

- E30 Zone Addict

- Posts: 2955

- Joined: Mon Mar 03, 2008 11:00 pm

- Location: Exeter

Not in E30s any more

Thanks grindculture is it you with the same name on the m42 club? id guess it is

Dont under stand rix, this is the origonal engine that the car has always had. i bought a spare one to mock it up on last time and that is now getting built up for this one lower comp and forged.

What do you need? ive got 4 heads and 3 blocks ( 3 complete engines + the one in the car)

Dont under stand rix, this is the origonal engine that the car has always had. i bought a spare one to mock it up on last time and that is now getting built up for this one lower comp and forged.

What do you need? ive got 4 heads and 3 blocks ( 3 complete engines + the one in the car)

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

GrindCulture

- E30 Zone Addict

- Posts: 2955

- Joined: Mon Mar 03, 2008 11:00 pm

- Location: Exeter

Yeah I'm on there every now and again getting my fix and pretending I know what I'm on aboutappletree wrote:Thanks grindculture is it you with the same name on the m42 club? id guess it is

Not in E30s any more

thats going to look the dogs bollox when its done, its quite long isnt it guess its going to get to just past your old dump valve take off judging by the pic in your sig.

And its got to flow better than the 90 bend in the current set up, cant wiat to see it finished

And its got to flow better than the 90 bend in the current set up, cant wiat to see it finished

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Bit more progress over the last two weeks or so firstly i finished off making the tesioner, ive used an E36 m43 idler pully which also donated its crank pully to make the charger pully so its should be rated at the same sort of rpm/power.

Trail fitted the inlet manifold today and worked out were the FPR will fit, fingers crossed it wont be need after its mapped and it will run fine on the 3bar reg but it gives me the option to play about if needed.

Made this plate to bolt up to old air box mounts so that i can mount the supercharger oil resivour of it, it right next to the charger so the pipe length to the supercharger oil pump is kept to a minimum which is good.

Made a plate to mount on the old throttle pot bolt holes with the large plug and now fitted the newer smaller throttle pot with the now normal plug on it.

Nothing realy major but i decided to paint the charger bracket silver just to stop it going rusty and looking crap. need to sort out the wiring for the oil temp and pressure sensors to now i can get there.

Somthing that i was never realy happy was the old oil resivour i fitted from the suzuki swift, it did a job but mountd off the strut brace it looked naff and the pipes were in the way.

Found my old origonal one cleaned it and refitted it and replaced the low fluid level switch, always nice to know youve got brakes

Mark, that inlet looks great in the other pics you sent, keep emailing you back but 3 days later i get a Email not sent warning! god knows why. Any more news on it by the way?

Would a 540 throttle be any good to you? its around 82mm, fits over a 3" pipe anyway with alittle to spare.

Trail fitted the inlet manifold today and worked out were the FPR will fit, fingers crossed it wont be need after its mapped and it will run fine on the 3bar reg but it gives me the option to play about if needed.

Made this plate to bolt up to old air box mounts so that i can mount the supercharger oil resivour of it, it right next to the charger so the pipe length to the supercharger oil pump is kept to a minimum which is good.

Made a plate to mount on the old throttle pot bolt holes with the large plug and now fitted the newer smaller throttle pot with the now normal plug on it.

Nothing realy major but i decided to paint the charger bracket silver just to stop it going rusty and looking crap. need to sort out the wiring for the oil temp and pressure sensors to now i can get there.

Somthing that i was never realy happy was the old oil resivour i fitted from the suzuki swift, it did a job but mountd off the strut brace it looked naff and the pipes were in the way.

Found my old origonal one cleaned it and refitted it and replaced the low fluid level switch, always nice to know youve got brakes

Mark, that inlet looks great in the other pics you sent, keep emailing you back but 3 days later i get a Email not sent warning! god knows why. Any more news on it by the way?

Would a 540 throttle be any good to you? its around 82mm, fits over a 3" pipe anyway with alittle to spare.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

rix313

- E30 Zone Team Member

- Posts: 4948

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

I was wondering when the next installment would be looks awsome. Got any of the whole engine bay with it how it is atm?

I've hit my brick wall atm rattled on how the S/C is going to go.

You should recieve the slab of ali tomorrow mate

I've hit my brick wall atm rattled on how the S/C is going to go.

You should recieve the slab of ali tomorrow mate

Cheers, might get chance to do it tomorrow as ive got the afternoon off, or at least get some of it done.

i'll get a bay shot next time its altogeather although its in bits at the moment as i'm siliconing all up with my new gaskets.

just got the dip stick and the oil cooler to get in place then its near enough ready for a test run, engine only though as the lights and stuff need doing before it can go on the road.

i'll get a bay shot next time its altogeather although its in bits at the moment as i'm siliconing all up with my new gaskets.

just got the dip stick and the oil cooler to get in place then its near enough ready for a test run, engine only though as the lights and stuff need doing before it can go on the road.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Just done a little more, got my injectors back from being cleaned at Emerald and fitted them to the inlet manifold.

They were £30 and are from a rover 620i but they are also fitted to other rover trubos like the 220.

Cleaning From emerald with new lilters, tips and o-rings was £15 each

For any one intrested there 440cc at 3bar or 460 at 4bar fuel pressure.

Part numbers on the injectors are

MJY100460

D3184GB

0646

They were £30 and are from a rover 620i but they are also fitted to other rover trubos like the 220.

Cleaning From emerald with new lilters, tips and o-rings was £15 each

For any one intrested there 440cc at 3bar or 460 at 4bar fuel pressure.

Part numbers on the injectors are

MJY100460

D3184GB

0646

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Looking good!

Inlets stuck in progress, have been advised I must have a radius on the inlets in the manifold, so I've looked into flaring the runners, no go, so spoke to a machinest who quoted me 50 for 6 mild steel radius tops that will slide over the runners a give me what I need. My only other option is to start again with ali tube and a 20mm thick plate and have the runners radius edge milled in but I find ali is quite aweful to work with, I need more tools!

That TB sounds ideal, 540 you say?

Inlets stuck in progress, have been advised I must have a radius on the inlets in the manifold, so I've looked into flaring the runners, no go, so spoke to a machinest who quoted me 50 for 6 mild steel radius tops that will slide over the runners a give me what I need. My only other option is to start again with ali tube and a 20mm thick plate and have the runners radius edge milled in but I find ali is quite aweful to work with, I need more tools!

That TB sounds ideal, 540 you say?

Few bay shots for you Rich.

Little more progress, got the bracket for the resivour mounted on the plate i made, used some rubber mounts to holed the plate to the airbox mounts so that i can pick up on the other stud to make a flexible mount for the inlet pipe so it can rock with the engine.

Also got these hose tails fitted today, the inlet is now fitted all sealed up and ready to go!

TB pics for you, it mahooosive! think the palte bit could be machined down easy to make it more managable. its actualy two Tb's one normaly open and one normaly closed, is one the traction control? you dont need both for it to work, its a 540 one ya E39

what size trumpets do you need?

Little more progress, got the bracket for the resivour mounted on the plate i made, used some rubber mounts to holed the plate to the airbox mounts so that i can pick up on the other stud to make a flexible mount for the inlet pipe so it can rock with the engine.

Also got these hose tails fitted today, the inlet is now fitted all sealed up and ready to go!

TB pics for you, it mahooosive! think the palte bit could be machined down easy to make it more managable. its actualy two Tb's one normaly open and one normaly closed, is one the traction control? you dont need both for it to work, its a 540 one ya E39

what size trumpets do you need?

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Mark i can get these from work, there very nearly a trumpet shape and would weld streight on to stainless pipe, they come in 1/2" sizes but you could just open them up abit if your runners are a different.

Might be worth a punt.

Might be worth a punt.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

I'd say that was pretty big too, that bend will be awkward to make work, the other looks nice and small, will need to see where the outlet sits in the engine bay before making a decision.

I need trumpets for the 50mm pipe you sent me, was told it wouldn't flare very well.

I need trumpets for the 50mm pipe you sent me, was told it wouldn't flare very well.

Last edited by e30_Turbo on Wed Feb 04, 2009 9:53 pm, edited 1 time in total.