Where do you jack car to put on axle stands?

Moderator: martauto

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

i personally find the E30 is a pain to jack up! (mine is lowered too so that doesn't help!

personally, i don't use the 'jacking points' on the car unless i can help it as mine have been mangled enough already by idiots in the past and i still want them good enough to safely use the factory jack if i need to change a wheel.

at the front, i use the front of the chassis rails under the footwells for the jack and axle stand IF i'm only doing one front corner, then swap over to do the other side. if the front has to go the whole way up, i use the centre of the cross member, under the sump to jack from and the chassis rails for the axle stands. this is probably technically wrong but i'd rather damage the crtossmember (bolt on) than anything else if it goes wrong! jack positioning has to be very good as its a small curved area and a trolley jack will pull the car forwards while lifting. (neutral gear and handbrake off forthis part is a must, as is level ground!)

at the rear, i use the stud in the centre of the rear subframe mounting (in front of the rear wheel) to jack from and then axle stands on the rear jacking points. having two trolley jacks helps a lot.

the rear diff 'looks' very tempting to jack from but i suspect this will at best screw the diff mounting bushes, or worse!

to jack the whole car (4 wheels) takes a long time and is hairy! doing it in several stages helps keep everything level.

hope that helps...

the one thing that will make lief easier is a good large (garage size) trolley jack as the extra length makes the lift a lot more vertical over the range you'll use most.

i'm open to any better advise myself too!

personally, i don't use the 'jacking points' on the car unless i can help it as mine have been mangled enough already by idiots in the past and i still want them good enough to safely use the factory jack if i need to change a wheel.

at the front, i use the front of the chassis rails under the footwells for the jack and axle stand IF i'm only doing one front corner, then swap over to do the other side. if the front has to go the whole way up, i use the centre of the cross member, under the sump to jack from and the chassis rails for the axle stands. this is probably technically wrong but i'd rather damage the crtossmember (bolt on) than anything else if it goes wrong! jack positioning has to be very good as its a small curved area and a trolley jack will pull the car forwards while lifting. (neutral gear and handbrake off forthis part is a must, as is level ground!)

at the rear, i use the stud in the centre of the rear subframe mounting (in front of the rear wheel) to jack from and then axle stands on the rear jacking points. having two trolley jacks helps a lot.

the rear diff 'looks' very tempting to jack from but i suspect this will at best screw the diff mounting bushes, or worse!

to jack the whole car (4 wheels) takes a long time and is hairy! doing it in several stages helps keep everything level.

hope that helps...

the one thing that will make lief easier is a good large (garage size) trolley jack as the extra length makes the lift a lot more vertical over the range you'll use most.

i'm open to any better advise myself too!

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

oh yeah, forgot about the centre of the rear subframe... i can just get my jack under there but then can't move the handle!

is jacking off the difff really a good idea? i'ts on void bushes...

is jacking off the difff really a good idea? i'ts on void bushes...

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

-

Simon13

- The longest resto in the world !

- Posts: 22697

- Joined: Mon Jan 10, 2005 11:00 pm

- Location: Camberley, Surrey don't u know

nothing wrong with jacking the car on the diff done it loads of times and its been fine, after all it's bolted to the rear beam. And the diff is some big heavy tough but if kit.

Go for it nothing to worry about there. Just use front chassis legs and NEVER factory jacking points as it's a rust trap and most are really rusty and frail here now. Eg jack through the floor pan, not a fun thought to imagine the top of the jack touching your glovebox

Go for it nothing to worry about there. Just use front chassis legs and NEVER factory jacking points as it's a rust trap and most are really rusty and frail here now. Eg jack through the floor pan, not a fun thought to imagine the top of the jack touching your glovebox

-

Dan318-is

- Married to the E30 Zone

- Posts: 8006

- Joined: Wed Jul 06, 2005 11:00 pm

- Location: Surrey/London

i remember iansport saying that factory jacking points are what they say they are - jacking points for the robots to carry the e30s round the factory

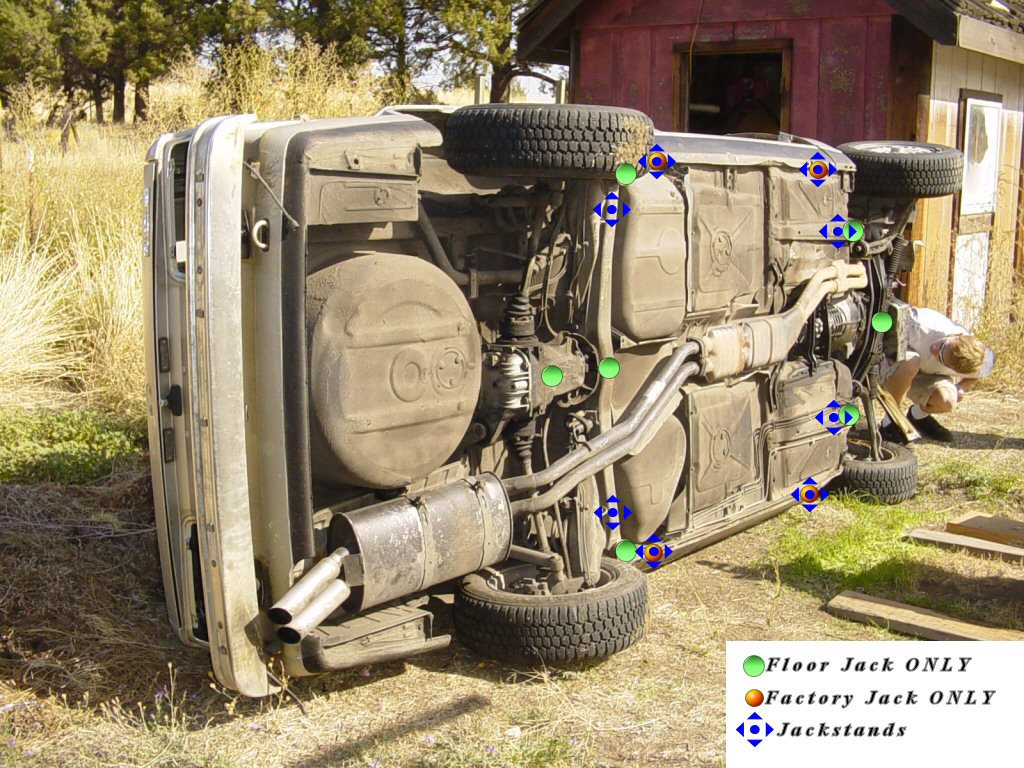

i jack mine from the diff usually an chuck sum stands under there, and on the front as shown in that funny picture up there^

hope its a 316!

i jack mine from the diff usually an chuck sum stands under there, and on the front as shown in that funny picture up there^

hope its a 316!

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

i still wouldn't use the diff!

the touring is a 50/50 weight split and weighs about 1200kg. that's 600kg to jack the rear. on those (old) rubber void bushes? no thanks!

the touring is a 50/50 weight split and weighs about 1200kg. that's 600kg to jack the rear. on those (old) rubber void bushes? no thanks!

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

-

Simon

- E30 Zone Team Member

- Posts: 14936

- Joined: Sun Jan 09, 2005 11:00 pm

- Location: South Wales

- Contact:

No, Ian meant the square things behind the front wheel, you can see the, just behind the front wheel in the above pic, they are commonly and wrongly reffered to as a jacking point, and a lot of people use them as a jacking point too.318-is wrote:i remember iansport saying that factory jacking points are what they say they are - jacking points for the robots to carry the e30s round the factory!

In the above pic, you can quite clearly see the factory jacking points, indicated by the orange circle, these are OK to use, but can only be used with the factory jack, which in all honesty is dangerous.

And as Simon13 says, these jacking points quickly turn rusty, so should be avoided.

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

Jhonno wrote:its not 600kgs tho, you lift the car with the front wheels as a pivot. The bush is designed to take quite a bit of force i should imagine

how do you figure that then! i'm not here to argue with everyone but 50% of 1200kg is 600kg.

assuming your theory is right and it's less than 600kg, then if you jack up the front inline with the axle and that's also less than 600kg..... where is the extra weight acting?

the 1200kg is distributed 50/50 between front and rear axles, if you lift the rear axle at its centreline (diff) the weight is transferred onto the jack. 600kg.

the bush is not designed to take any vertical load, it's only designed for location of the diff and to sustain the torque loading and reaction forces imparted by the prop torque and the driving torque to the rear wheels. if you look underneath, you'll see it's a set of void bushes! if these don't fail immediately, it'll significantly reduce the lifespan.

if you choose to use the jack on the diff, it's up to you but in my opinion as a professional engineer, its a very bad idea. at the end of the day, i'm only offering advice in good faith, ignore it if you want. i'm sure it will help others.

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

Jack the car a few times on the diff and those 15 year old rubber bushes won't put up with it. They'll most likely begin to tear, or if perished will just split and crumble away, leaving your diff flapping around!!!!

Then you'll be asking what that funny thump/knock noise is every time you pull away hard or lift-off-then-plant-the-throttle-again......

I've experienced people jacking on the sills and then them giving way due to rust....... not a pretty sight!!

Jacking on floorpans, sparewheel wells, sumps and fuel tanks are obvious NO-NO's but so called 'Mechanics' in tyre and exhaust garages do just this on a daily basis!! Then get arsey when you point out the correct jacking points on your vehicle and ask them to re-position their jacks, because you're 'telling them how to do their job', but they don't even know how to use a torque wrench properly!!!!!

IMO chassis rails and subframes etc are the best and stronges places to jack and support any vehicle. Wouldn't try anywhere else, just in case!!!!

Then you'll be asking what that funny thump/knock noise is every time you pull away hard or lift-off-then-plant-the-throttle-again......

I've experienced people jacking on the sills and then them giving way due to rust....... not a pretty sight!!

Jacking on floorpans, sparewheel wells, sumps and fuel tanks are obvious NO-NO's but so called 'Mechanics' in tyre and exhaust garages do just this on a daily basis!! Then get arsey when you point out the correct jacking points on your vehicle and ask them to re-position their jacks, because you're 'telling them how to do their job', but they don't even know how to use a torque wrench properly!!!!!

IMO chassis rails and subframes etc are the best and stronges places to jack and support any vehicle. Wouldn't try anywhere else, just in case!!!!

When it's upside down and burning, you've gone too FAST!!!

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

I would never put an axle stand on the factory jacking points! they will just bend into nothing!

Gareth the E30 suspension at the back is triangulated and thus that Diff bush is designed to take vertical loads, but maybe not 600kg!

Andrew

Gareth the E30 suspension at the back is triangulated and thus that Diff bush is designed to take vertical loads, but maybe not 600kg!

Andrew

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

i suspect it's more likely to be a safer bet on a lighter saloon (base model 4 pot maybe?) but the arse end of a tourer is deginately heavy, you can feel it when jacking. still more of a pain to risk changing bushes than just using the proper jacking points!

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

Well lets just say i would not jack my car up from the diff!

Andrew

Andrew

Yes there is 600kg at the back BUT the point was that the front wheels act as a pivot when they are still on the ground so it isn't as hard as lifting the full 600kg. It works in a similar way to a wheelbarrow or whatever you call them over there, you can load it up with heaps of stuff that you couldn't lift by yourself but you have no trouble lifting the back of it because the front wheel is a pivot and you don't lift it straight up but on a slight angle.gareth wrote:Jhonno wrote:its not 600kgs tho, you lift the car with the front wheels as a pivot. The bush is designed to take quite a bit of force i should imagine

how do you figure that then! i'm not here to argue with everyone but 50% of 1200kg is 600kg.

assuming your theory is right and it's less than 600kg, then if you jack up the front inline with the axle and that's also less than 600kg..... where is the extra weight acting?

the 1200kg is distributed 50/50 between front and rear axles, if you lift the rear axle at its centreline (diff) the weight is transferred onto the jack. 600kg.

Aston

BMW E30 323i with some stuff

1:05.17 @ Queensland Raceway Sprint track

1:10.09 @ Queensland Raceway Clubman track

1:21.67 @ Morgan Park Raceway

1:05.17 @ Queensland Raceway Sprint track

1:10.09 @ Queensland Raceway Clubman track

1:21.67 @ Morgan Park Raceway

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

ok... the E30 wheelbarrow weighs 1200kg. lift it from the rear wheels and you're sharing the 1200kg between the lifting point and the front wheels. that's 600kg.

a wheelbarrow uses this principle but the long handles reduce the resultant moment at the lifting point.

therefore, if you jacked the E30 up on a bar 2 feet behind the rear bumper (replicating the wheelbarrow design principle) then you would see a reduced load at the (new) jacking point as the centre of gravity is biased more towards the front axle with respect to the (new) jacking point.

like i said, i'm not here to argue. the facts i stated are correct. i design F1 cornerweight and suspension force measurement systems for a living and the maths involved here are gcse level!

weight on the rear wheels should be assumed to be 50% of the cars total curb weight as this is the worst case. in any case, it'll be between 500 - 600kg on almost any E30 and the bushes are simply not designed for this.

all i can say is that i would rather shove wasps up my arse than jack a E30 from the diff!

a wheelbarrow uses this principle but the long handles reduce the resultant moment at the lifting point.

therefore, if you jacked the E30 up on a bar 2 feet behind the rear bumper (replicating the wheelbarrow design principle) then you would see a reduced load at the (new) jacking point as the centre of gravity is biased more towards the front axle with respect to the (new) jacking point.

like i said, i'm not here to argue. the facts i stated are correct. i design F1 cornerweight and suspension force measurement systems for a living and the maths involved here are gcse level!

weight on the rear wheels should be assumed to be 50% of the cars total curb weight as this is the worst case. in any case, it'll be between 500 - 600kg on almost any E30 and the bushes are simply not designed for this.

all i can say is that i would rather shove wasps up my arse than jack a E30 from the diff!

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

the suspension is triangulated, but the diff is rubber mounted and should not be considered a load bearing member. it's just common sense at the end of the day.Demlotcrew wrote:Gareth the E30 suspension at the back is triangulated and thus that Diff bush is designed to take vertical loads, but maybe not 600kg!

would anyone here try and jack their car up from the engine?

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

Dude the whole rear end is rubber mounted!gareth wrote:the suspension is triangulated, but the diff is rubber mounted and should not be considered a load bearing member. it's just common sense at the end of the day.Demlotcrew wrote:Gareth the E30 suspension at the back is triangulated and thus that Diff bush is designed to take vertical loads, but maybe not 600kg!

would anyone here try and jack their car up from the engine?

Have you seen this diff cover?

So you still think its not designed to take vertical loads?

The diff is only mounted at the back with the mount, most of the forces are put into the subframe which holds the Diff on the car with four large bolts.

Can you also share these GCSE maths with us? Im not convinced you are a F1 suspension designer!

Andrew

Ok I should say I wasn't agreeing or disagreeing with the original poster I was just trying to make clear what they were saying. BUT this has got me interested now so I just went outside and tried it and even if I lift the wheel barrow not by the handle but by the back of the wheel barrow itself I can still lift it with more weight sitting on the back of the wheel barrow than I could if I lifted it without the wheel barrow.gareth wrote:ok... the E30 wheelbarrow weighs 1200kg. lift it from the rear wheels and you're sharing the 1200kg between the lifting point and the front wheels. that's 600kg.

a wheelbarrow uses this principle but the long handles reduce the resultant moment at the lifting point.

therefore, if you jacked the E30 up on a bar 2 feet behind the rear bumper (replicating the wheelbarrow design principle) then you would see a reduced load at the (new) jacking point as the centre of gravity is biased more towards the front axle with respect to the (new) jacking point.

like i said, i'm not here to argue. the facts i stated are correct. i design F1 cornerweight and suspension force measurement systems for a living and the maths involved here are gcse level!

weight on the rear wheels should be assumed to be 50% of the cars total curb weight as this is the worst case. in any case, it'll be between 500 - 600kg on almost any E30 and the bushes are simply not designed for this.

all i can say is that i would rather shove wasps up my arse than jack a E30 from the diff!

Anyway I can't definately say for the E30 but I know of a few cars that can use the differential as a jacking point including the Mitsubishi Evo which says so in the factory workshop manual and that also has about 600kg at the rear. Maybe it's differential is mounted differently.

Aston

BMW E30 323i with some stuff

1:05.17 @ Queensland Raceway Sprint track

1:10.09 @ Queensland Raceway Clubman track

1:21.67 @ Morgan Park Raceway

1:05.17 @ Queensland Raceway Sprint track

1:10.09 @ Queensland Raceway Clubman track

1:21.67 @ Morgan Park Raceway

stop winging at each other and work it out. (I'm frantically googling trying to myself but I failed gcse maths  )

)

It's second class lever and the weight (for arguments sake) is distributed equally over the length of the lever.

Somebody must know how to figure this out ?

Don't forget to take in to account the condition of the bush itself, when it's new it will be a lot stronger than the decayed piece of crap that's due for replacement on my car.

In empirical terms I've jacked up our old 325 by the diff and it was fine... but I wouldn't of got myself under there, that's just common sense!

When this thread has run its course I think it should be cleaned up and made sticky. The original photo is pretty useful

It's second class lever and the weight (for arguments sake) is distributed equally over the length of the lever.

Somebody must know how to figure this out ?

Don't forget to take in to account the condition of the bush itself, when it's new it will be a lot stronger than the decayed piece of crap that's due for replacement on my car.

In empirical terms I've jacked up our old 325 by the diff and it was fine... but I wouldn't of got myself under there, that's just common sense!

When this thread has run its course I think it should be cleaned up and made sticky. The original photo is pretty useful

E46 M3 CSL but dreaming of another E30.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

The diff will lift the car no problem, but then it's just a big lump of metal stuck on top of the jack

You all keep going on about bush in the diff back plate but what you seem to be missing is that when raised the weight of the car is transfered through the steel plates the that hold the bush to the bodywork and are only designed to hold the weight of the rear axle.

Personaly i don't jack the car from any part of the rear axle as it is a "floating" axle and can't be done without damaging one bush or another.

I've got my car in bit's at the minuet so i'll try to get some pic's to show what i'm on about.

You all keep going on about bush in the diff back plate but what you seem to be missing is that when raised the weight of the car is transfered through the steel plates the that hold the bush to the bodywork and are only designed to hold the weight of the rear axle.

Personaly i don't jack the car from any part of the rear axle as it is a "floating" axle and can't be done without damaging one bush or another.

I've got my car in bit's at the minuet so i'll try to get some pic's to show what i'm on about.

There is NO nucleus.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

Simon, no one said it can't be done. But you won't catch me doing it like that.

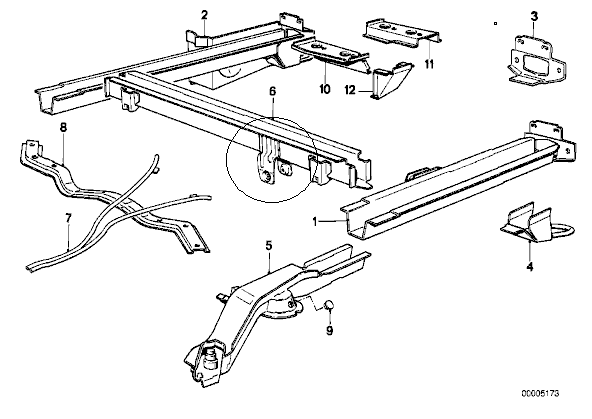

This is why i don't lift it from the axle.

The first pic is how the rear beam sits when the suspension is unloaded, the second shows how the bush is stretched when you jack it up by the beam.

When the weight is on the wheels the beam should sit about halfway between the two so you can see if the bushes are gone just by trying to get your fingers in the gap.

The third pic is of the rear diff mount.

So if you lift it by positioning the jack under the diff all the weight is transfered to that piece of sheet metal.

(each to there own )

)

As for the original post subject Gareth has the front covered and likewise when it cames to lifting the rear i don't use the sill's, the best way i've found is to lift it from under the trailing arm if just changing a wheel or by the beam mount (1st pic) and then stuff a chopped up cargo pallet under the wheel if i need to get under the car once the jack is removed.

But like today i've removed the trailing arm so used the rear chassie frame (1st post) for the axle stand, the other side will not be as easy because the exhaust is in the way. so i'll chance working with it on the jack.

so i'll chance working with it on the jack.

This is why i don't lift it from the axle.

The first pic is how the rear beam sits when the suspension is unloaded, the second shows how the bush is stretched when you jack it up by the beam.

When the weight is on the wheels the beam should sit about halfway between the two so you can see if the bushes are gone just by trying to get your fingers in the gap.

The third pic is of the rear diff mount.

So if you lift it by positioning the jack under the diff all the weight is transfered to that piece of sheet metal.

(each to there own

As for the original post subject Gareth has the front covered and likewise when it cames to lifting the rear i don't use the sill's, the best way i've found is to lift it from under the trailing arm if just changing a wheel or by the beam mount (1st pic) and then stuff a chopped up cargo pallet under the wheel if i need to get under the car once the jack is removed.

But like today i've removed the trailing arm so used the rear chassie frame (1st post) for the axle stand, the other side will not be as easy because the exhaust is in the way.

There is NO nucleus.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

Your car mate do what you like with it

There is NO nucleus.

-

gareth

- E30 Zone Team Member

- Posts: 11009

- Joined: Tue Jan 11, 2005 11:00 pm

- Location: hastings, east sussex

calm down children!

Demlotcrew, read the post. i never said i design F1 suspension but "i design F1 cornerweight and suspension force measurement systems". this relates mainly to cornerweight and axle weight for chassis balancing purposes. what reason do i have to lie? i'm simply trying to help those who aren't ignorant of the facts!

the photos hosted above show the bush mounting very well. it's a void bush, designed for a soft vertical movement, to reduce noise transission into the car. imagine it's fairly hard and perished, it's very likely to 'peel' the sides of the rubber from the outer housing. if it doesn't, this is due to luck more than anything. several of my previous E30s have obvious signs of this happening. in fact , the one on the left has started to crack already!

the method of attachment of the diff to the subframe allows a large bending moment to be applied to a member that is simply not designed for it. the photos above also show what happens to the main subframe bushes! try and tell me this is good?!!!

the maths... this is the first link i could find online to explain bending moments... http://physics.uwstout.edu/StatStr/stat ... beam41.htm fairly simple stuff. each axle being a simple support. it's hardly interesting! i can't find any closer examples to our situation anywhere without spending a whole evening on it!

the wheelbarrow comment... give me strength! hang on, i feel an uncontrollable urge to re-write the laws of physics! they have just been proven wrong!

anyway, i'll leave it to everyone to make their own minds up. at the end of the day, i really don't care if anyone wants to keep jacking wherever they want, it's not my car!

Demlotcrew, read the post. i never said i design F1 suspension but "i design F1 cornerweight and suspension force measurement systems". this relates mainly to cornerweight and axle weight for chassis balancing purposes. what reason do i have to lie? i'm simply trying to help those who aren't ignorant of the facts!

the photos hosted above show the bush mounting very well. it's a void bush, designed for a soft vertical movement, to reduce noise transission into the car. imagine it's fairly hard and perished, it's very likely to 'peel' the sides of the rubber from the outer housing. if it doesn't, this is due to luck more than anything. several of my previous E30s have obvious signs of this happening. in fact , the one on the left has started to crack already!

the method of attachment of the diff to the subframe allows a large bending moment to be applied to a member that is simply not designed for it. the photos above also show what happens to the main subframe bushes! try and tell me this is good?!!!

the maths... this is the first link i could find online to explain bending moments... http://physics.uwstout.edu/StatStr/stat ... beam41.htm fairly simple stuff. each axle being a simple support. it's hardly interesting! i can't find any closer examples to our situation anywhere without spending a whole evening on it!

the wheelbarrow comment... give me strength! hang on, i feel an uncontrollable urge to re-write the laws of physics! they have just been proven wrong!

anyway, i'll leave it to everyone to make their own minds up. at the end of the day, i really don't care if anyone wants to keep jacking wherever they want, it's not my car!

Sole founder of Fe2O3-12V it's a lifestyle

LSD rebuilding / modification services provided, PM for details

LSD rebuilding / modification services provided, PM for details

gareth wrote:the wheelbarrow comment... give me strength! hang on, i feel an uncontrollable urge to re-write the laws of physics! they have just been proven wrong!

I have no idea what gsce maths is and I know I am not qualified to talk about these things, the highest level maths I have done is only at university and before that just high school Maths B and C whatever that equates to over there (levels were A, B and C with A being easiest and C hardest). I am not going to pretend that I can also design F1 suspension or whatever, I am well aware I can't.

Aston

BMW E30 323i with some stuff

1:05.17 @ Queensland Raceway Sprint track

1:10.09 @ Queensland Raceway Clubman track

1:21.67 @ Morgan Park Raceway

1:05.17 @ Queensland Raceway Sprint track

1:10.09 @ Queensland Raceway Clubman track

1:21.67 @ Morgan Park Raceway