Motronic 1.0

Motronic 1.0 was a short-lived engine management system for the early M20 engines. It replaced the neolithic Jetronic system, but was quickly replaced by Motronic 1.1.

For the lucky few who own one of these clunky installations, here's a low-down on how to get the most out of Motronic 1.0.

Contents

Overview

Motronic 1.0 has some key differences to its far more popular Motronic 1.3 variant. For instance:

- Motronic 1.0 doesn’t have an O2 sensor / lambda control

- Motronic 1.0 uses a 2-row 35-pin connector on the ECU instead of the three-row 55 pin one.

- Motronic 1.0 has an additional idle air bypass screw on the throttle body

There’s also quite some information on the early US 325(e)s, which is in general more comparable, but again there are differences:

- No separate idle control module (ICM), function integrated in the ECU.

- No cold-start injector

- No thermo-time switch

As long as you’re aware of these differences, much of the information on both these systems is fully applicable (including sensor resistance values, voltages, etc.), but you have to be a little creative.

ECU Connector Pin-Out

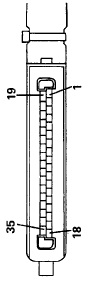

The Motronic 1.0 ECU employs a 35-pin plug to connect to all the engine bay components.

| Pin | Function | Pin | Function | Image |

|---|---|---|---|---|

| 1 | Ignition coil output | 19 | Ground |

|

| 2 | Idle switch | 20 | Main relay | |

| 3 | WOT switch | 21 | Tachometer | |

| 4 | Cranking signal | 22 | AFM Temp sensor | |

| 5 | Ground/Crank PosS Gnd | 23 | Inlet Air Temp/Crank SpS Gnd | |

| 6 | AFM ground | 24 | O2 sensor signal * | |

| 7 | AFM signal | 25 | Crank position sensor 1 | |

| 8 | Crank speed sensor 1 | 26 | Crank position sensor 2 | |

| 9 | AFM supply | 27 | Crank speed sensor 2 | |

| 10 | Auto only special | 28 | Water Pressure switch | |

| 11 | Fuel consumption gauge | 29 | A/C switch (if installed) | |

| 12 | 30 | +Inlet Air Temp | ||

| 13 | Water Temp | 31 | ||

| 14 | Injector output cyl 3&4 | 32 | ||

| 15 | Injector output cyl 1&2 | 33 | ICV pulse | |

| 16 | Ground | 34 | ICV pulse | |

| 17 | Ground | 35 | Injector ground | |

| 18 |

Components

Connectors and wiring

As the whole wiring loom in most of our cars is now over 25 years old, wires and connectors tend to be pretty oxidized by now. When you check any of the following components, inspect and clean (with electric contact cleaner and a toothbrush) their connectors carefully.

One connector that you won’t find by following the guide below is the large round connector mounted on the firewall, next to the fusebox. Known as the C101 plug, this connector mates the various wiring looms in the car together and can corrode pretty badly over time, causing all kinds of intermittent and unexplainable failures. You can easily unclip it from the firewall and it screws open by turning the two halves a quarter clockwise.

Coolant Temperature Sensor

Motronic 1.0 suffers from all the same coolant sensor issues that affect later Motronic versions.This Coolant Temperature Sensor to determine if the engine is cold or at operating temperature and adjusts the fuel supply accordingly. If it fails, it usually thinks the engine is cold, causing a rich mixture all the time.

The temp sensor is a blue sensor in the thermostat on top of the front of the engine. Don’t confuse it with the brown sensor which is only used for the gauge in the dashboard.

The resistance between the two pins should read:

- around 3KOhm when cold

- around 200 Ohm when hot

If it’s faulty, it needs to be replaced which implies you’ll need to drain some coolant. As a bodge you could connect both terminals with a 200 Ohm resistor so it’ll at least idle correctly when hot.

Idle Control Valve (ICV)

The ICV is used to allow extra air to bypass the throttle when the engine is cold.The ICV is the black tube thing on top of the engine, sticking in the large rubber intake boot and the throttle body.

First check if the valve is still ‘electrically’ okay by unplugging the connector and measuring resistance with a multimeter:

- resistance between outer terminals: around 40 Ohm

- resistance between each outer and the inner terminal: around 20 Ohm

If anything is wrong with these values, one or both of the coils is burnt and you’ll need a new one. Price is about 130 Euros at the stealer. As an additional test you could apply 9V to the inner pin and - to one of the outer pins, the valve should open or close with a audible ’snap’.

If the valve seems to be okay, turn on the ignition measure the current from the ECU to the valve at the connector:

- between the inner pin and ground there should be battery voltage

- between any outer pin and the inner pin there should be around 10V

If these values are off, something is wrong with the ECU, or something is wrong with a signal to the ECU. The signal to the outer pins comes from ECU pins 33 and 34, the inner pin is fed from somewhere else (sorry, haven’t trace this wire).

Now, take the valve off the car and see if it moves freely by quickly rotating the housing. If it doesn’t (or just looks icky), clean it out toroughly with carb and/or electric contact cleaner. Using WD-40 over here is said to attract to much dirt over time, but trust your own instincts on this.

Throttle Position Switch (TPS)

The TPS is mounted on the underside of the Throttle Body (TB) and tells the computer if the throttle is closed, partially open, or wide open (WOT). As the switch is mounted on the bottom of the TB, oil, fuel and other crud tends to find it’s way into it, causing it to fail eventually. When it fails, it results in erratic idle, higher fuel consumption or lack of power on WOT.First check if you hear an audible click when you fully close or open the throttle. If you don’t hear this, the switch is really shot, misaligned or somebody messed with the throttle stop.

If you hear it clicking, check if it actually works by disconnecting it’s connector and measuring continuity across it’s pins.

- With the throttle closed there should be continuity between the inner and one of the outer pins

- With the throttle partially open there should be no continuity between any of the pins

- With the throttle fully open (about 7 degrees from it’s end) there should be continuity between the inner and the other of the outer pins

As a quick check if at least the idle switch is working you could disconnect the connector with the car idling. The idle speed should rise when you do this.

Air Flow Meter (AFM)

The AFM measures (unsurprisingly) the amount of incoming air. Basically it’s just a spring-loaded flap in the intake connected to a potentiometer. As the engine sucks in more air, the flap gets pushed open wider and so the resistance of the potentiometer changes. By measuring this resistance, the ECU knows how much air is entering the engine, and thus how much fuel is needed.There’s a number of things that can go wrong with the AFM:

- The idle mixture bypass screw can be out of adjustment, causing a wrong idle mixture.

- The spring tension for the flap can be out of whack, causing a wrong idle and part-open throttle mixture.

- The flap can stick due to carbon buildup or because it’s out of alignment (because of a backfire for example), causing all kinds of freaky stuff.

- The carbon track can wear out, causing all kinds of freaky stuff, usually cutting out.

Fuel Injectors

While they can get quite noisy (according to some people, you should only be worried when they stop making noise), the fuel injectors on these cars rarely break, but you can check them to be sure.They can get clogged up though. You could try running some injection cleaner trough the fuel (doing this once in a while, just before an oil change might be good preventive maintenance anyway), or try a “hot soak” procedure (do a google search), but if they’re really clogged, it’s probably best to remove them from the car and bring them to a specialized shop (in Europe, the Bosch Car Service Centres do this and are present in most areas, cost about 12 Euro per injector). As a bonus, they’ll replace the O-rings, the tiny filter in the injector and measure the spray pattern and flow rate. I had them cleaned on my car and noticed a slight different in the idle, but a definate difference in power in 4th and 5th gear.

Adjusting the base idle speed and mixture

First, make sure everything else is up to spec (check sensors, ignition, air leaks, throttle, TPS, etc.) before messing with these settings. The factory settings should be pretty much spot on, perhaps a little lean if everything is working fine.If that’s okay, warm the car completely, and unplug the TPS connector and short all three pins together. This instructs the ECU not to “mess” with the idle speed and sets the the ICV in a nominal position.

Start the engine and adjust the idle with the bypass screw on top of the TB. Try to set it to around 800rpm. Rev it in-between adjustments, as sometimes the adjustments don’t have an immediate effect. If you can’t get the idle up high enough, your mixture is too lean, so you need to dial in some with the bypass screw on the AFM.

Adjust the mixture in small steps (wait about 30seconds each half turn for the computer to ‘catch up’) to obtain the so-called “best high idle”, which means that you stop enrichening the mixture as soon as the RPMs stop rising when you do so. Now, lean it out 1/4th of a turn again, this should provide an “about right” mixture. Next, rev it up to about 3000rpm and quickly close the throttle. If the RPMs drop briefly under the set idle RPM and then come back up the mixture is too rich and you need to lean it out a little more.

If you can’t turn the screw anymore (usually inwards/richer) and still haven’t reached a correct mixture, the AFM spring probably needs adjustment. Turn the screw to approximately half way, open the AFM and adjust the spring one or two notches either way (clockwise is leaner, ccw is richer, exactly the opposite of the CO screw), until it runs better, then make final adjustments with the screw.

If you think you’ve got it right, plug back in the TPS and take it for a spin, and make minute adjustments to your likings.

It’s probably wise to check with an exhaust gas analyzer (drive by your garage or a service shop) afterwards if the CO is within spec (0.5-1.5), but following the above you should be able to set the idle pretty much to spec without.

If you can’t get it to idle correctly this way, you have another problem. Most likely your valve clearances are set too tight.