M40 hydraulic lifter movement

Moderator: martauto

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

The one on the right looks ok, once its in the oil pressure acts as a shock absorber and stiffens it.

The left one is probably full of stale oil so has no movement and will eventualy knacker your cam lobes, crush it in a vice to get a bit of life back into it. There's no way to clean them internaly because the oil only goes in and doesn't come out (unlike Fords )

)

The left one is probably full of stale oil so has no movement and will eventualy knacker your cam lobes, crush it in a vice to get a bit of life back into it. There's no way to clean them internaly because the oil only goes in and doesn't come out (unlike Fords

There is NO nucleus.

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

how are ford ones designed compared to BMW ?

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

Fords have a tiny hole in the top that is closed when the follower pushes down on it and as it releases the oil pressure sqiurts out the top so it gradualy flows through the lifter.

With the BM ones it just has a hole in the side where the oil enters and stays in so eventualy turns to crap

With the BM ones it just has a hole in the side where the oil enters and stays in so eventualy turns to crap

There is NO nucleus.

-

Demlotcrew

- E30 Zone Team Member

- Posts: 13329

- Joined: Mon Dec 20, 2004 11:00 pm

- Location: East Anglia

This is only true on the M40!

They should not be easy to compress by hand if at all!

They should not be easy to compress by hand if at all!

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

Does anyone know how or if BMW rectified the problem with the E46 M43 engine ?

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

Would drilling a second hole in the base allow the oil to circulate?

or would it render them useless? (I have a spare head and lifters to test it on so won't be breaking my engine)

I noticed that the Head has a second oil channel at the base which goes directly to the head.

and the oilway for the lifters is blocked off with a plug at the back of the head.

or would it render them useless? (I have a spare head and lifters to test it on so won't be breaking my engine)

I noticed that the Head has a second oil channel at the base which goes directly to the head.

and the oilway for the lifters is blocked off with a plug at the back of the head.

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

After a bit of browsing the net...

So could i just line up the holes and drill them bigger?3rd Generation Hydraulic Lifters.

99 spec hydraulic lifters, have a large 3mm hole, rather than the small 1mm hole that the old lifters had.

This will increase the oil flow around the cylinder heads.

The 3rd gen lifters will stop the lifter tick, that is so common on the M40 engine.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

I think if you drill into thre bottom it will cause it to loose all the pressure, it will depend on how it looks internaly.

Rip the top off one and have a look.

The bung at the back of the head may just be where the oil way changes direction and the drill hole is then sealed off, again, pull it apart and have a look.

I suspect making the hole 2mm bigger will just let the pressure escape easier and then it will just force its way up around the tappet.

On the other hand fitting a new oil pump

Rip the top off one and have a look.

The bung at the back of the head may just be where the oil way changes direction and the drill hole is then sealed off, again, pull it apart and have a look.

I suspect making the hole 2mm bigger will just let the pressure escape easier and then it will just force its way up around the tappet.

On the other hand fitting a new oil pump

There is NO nucleus.

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

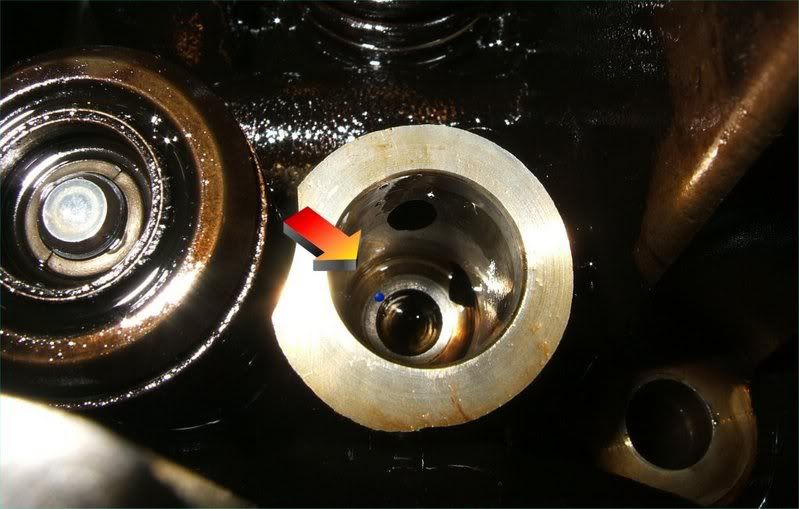

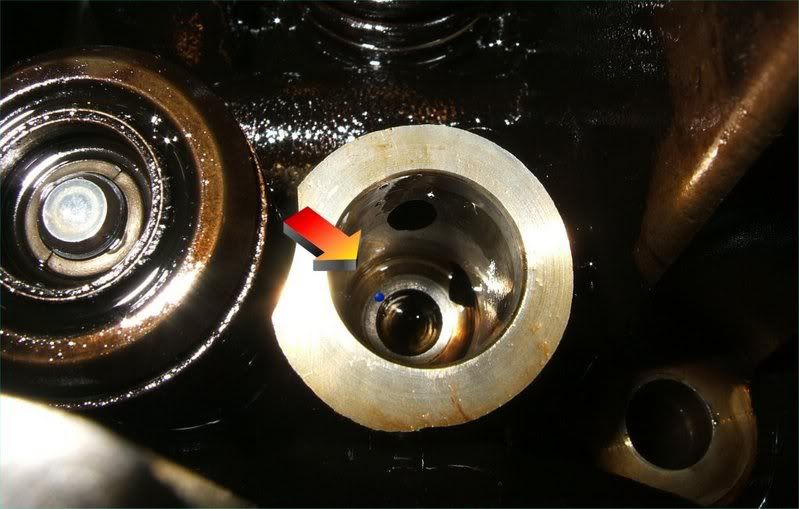

I opened up one of the fauty ones. Nothing special inside as you can see.

Drilling a hole in the bottom would render it useless. drilling a bigger hole wouldnt work either.

Drilling a hole in the bottom would render it useless. drilling a bigger hole wouldnt work either.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

Where does the ball bearing go ?

There is NO nucleus.

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

It fits inside the cup shaped part 3rd from the left which clips inside the cylinder 6th from left.

The small spring forces the ball bearing into a small hole which acts as a one way valve.

The small spring forces the ball bearing into a small hole which acts as a one way valve.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

So is the large spring at the bottom where all the gunk builds up ?

There is NO nucleus.

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

Yes. and because the ball is held in position not allowing any new oil into the area, after a while the lifter locks up.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

If you drilled a hole in the base of the lifter but off centre so it matches the blue dot it may work as it would/should be closed when its compressed.

I wouldn't want to be the one to test it though, cam out job to change them

I wouldn't want to be the one to test it though, cam out job to change them

There is NO nucleus.

go to www.rovertech.net and ask about solid lifters on k-series and t-series engine

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

I think the problem is that there is no "new" oil getting into the chamber below the plunger.

I have compare them to other hydrauilc lifters and all of the others seem to have a hole on the very top of the plunger. (some are 1mm while others are 3mm)

I have 7 left to practice on anyway.

I have compare them to other hydrauilc lifters and all of the others seem to have a hole on the very top of the plunger. (some are 1mm while others are 3mm)

I have 7 left to practice on anyway.

-

Martinaston

- E30 Zone Addict

- Posts: 3749

- Joined: Mon Mar 14, 2005 11:00 pm

- Location: London

If you drill at the bottom it may drain all the oil out when the engine is off and then sound like a bag of spanners until it fills up again. In the pic of the head, is the bottom hole a second oil feed channel or a drain hole back to the sump ?

You could try drilling down through the top of the lifter but would it get the oil flowing at the bottom where the spring is ?

You could try drilling down through the top of the lifter but would it get the oil flowing at the bottom where the spring is ?

There is NO nucleus.

-

smithy318i

- Engaged to the E30 Zone

- Posts: 5797

- Joined: Thu Apr 28, 2005 11:00 pm

- Location: Tyne & Wear

I cant just drill a hole in the top as this would simply squirt the oil out of the lifter when its compressed. The section below the plunger relies on oil pressure in the chamber above to work properly.Martinaston wrote:You could try drilling down through the top of the lifter but would it get the oil flowing at the bottom where the spring is ?

The lifters with a hole at the top also have a "oil metering disc" at the appeture of the upper oil passage.

Looks like im no further forward

-

daimlerman

- **BANNED**

- Posts: 15968

- Joined: Mon Feb 27, 2006 11:00 pm

- Location: Grumpy Old Man

Looks like solid lifters are the way forward.But how would you arrange for tappet clearance and ajustment? I have just put new lifters/rockers in the 316i and the layout seems odd to me with the rocker under the cam and in constant contact with each other.Little wonder that they wear!!

Youth is wasted on the young.

Sorry to hi-jack this thread slightly, but I'm new on here and looking for info on the 1993 E30 318i Touring (M40) I'm doing a bit of a re-build on at the moment. I'm replacing the knackered cam, rockers and the lash-caps on the tops of the valves, now I'm concerned that I might have to put new lifters in too at £85 on top of all the other bits - I can't see the pictures as my work firewall has blocked them, what should I check to see if they're OK - the engine is fairly quiet at idle but rattles horribly over about 1500 RPM.

Also where are the cam/timing belt marks on the pullies/engine, I've got the engine as close to TDC as I can by looking at the cam/checking the piston is at the top and have marked everything with paint but if someone's fitted the belt a tooth out before I'll make the same mistake..?

Also where are the cam/timing belt marks on the pullies/engine, I've got the engine as close to TDC as I can by looking at the cam/checking the piston is at the top and have marked everything with paint but if someone's fitted the belt a tooth out before I'll make the same mistake..?

Not really struggling as such, pretty good with mechanics in general but this is the first BMW I've owned and I only have a 6-cylinder haynes book at the moment. I've found some useful bits of info on here so far but want to somehow check my lifters otherwise I'll end up taking the bloody thing apart again if it still rattles.m-dtech wrote:i have a new set of tappets of your struggling.

pm me if interested.

mike

I have a friend who has had 320 -325's, we've done the rear subframe bushes, brake lines/flexi's/handbrake cables etc but he's never worked on the M40 engine either.

Any checks I can do would be very helpful!