318is m42 project update

Moderator: martauto

- 328touring

- E30 Zone Newbie

- Posts: 45

- Joined: Mon Dec 05, 2005 11:00 pm

- Location: Plymouth

If you want foam and resin there's a couple of routes to take. Either Polyurethane foam with polyester resin or high density expanded polystyrene with epoxy resin. Epoxy is way way stronger and lighter than polyester and is usually used for laminating carbon/kevlar also. You should be able to get the foam easily enough from somewhere close as it is readily used from packaging to insulation and is easy to shape. If you can't find it thick enough its easy enough to bond together to get the thickness you need with an epoxy based glue like araldite.

Hope thats of some use!

Hope thats of some use!

thanks 328touring, very helpful. just bought a load of stuff from cfsnet this morning unfortunately though, typical huh! thought i'd have a crack and make something up, even if its just a mk1 effort and will be redone. i've made a cardboard template with curvy edges that i think should be up to the job - its internally braced to be a bit stronger, well i'll find out soon enough anyway. I bought the following:

5kg pack General Purpose Resin 1

Ԛ£16.13 Ԛ£16.13

2kg Roll CSM 300gm 1

Ԛ£6.78 Ԛ£6.78

Catalyst 500gm pack 1

Ԛ£3.69 Ԛ£3.69

Black Pigment 500gm 1

Ԛ£4.66 Ԛ£4.66

1 Square Metre Roll Surface Tissue 30gm 1

Ԛ£1.12 Ԛ£1.12

Moldex 2405 Valved Respirator mask each 2

Ԛ£1.94 Ԛ£3.88

Low Cost Resin Brush 12mm (0.5") Box of 12 1

Ԛ£2.58 Ԛ£2.58

Paddle Roller 70mm x 21mm 1

Ԛ£3.03 Ԛ£3.03

seem like a sensible starting point? I thought i'd put some black pigment in so it doesn't look too terrible, if epoxy resin is that much stronger though, it might be a better option as i don't really want to sacrifice strength. what i may do is add an overlay of carbon fabric over this once finished if i'm happy, as i won't be finishing this at this stage - think thats jumping the gun a bit given my experience etc. any hints/info on finishing, especially if I'd like a carbon finish? I have very little idea, trust me you won't be insulting my intelligence on this one!

is my general plan of action for this about right?

1) sort out some way of releasing the fibreglass. i forgot about this when ordering stuff

2) cover in resin

3) add a layer of mat and saturate with resin

4) cut in half and remove from template

5) add trumpets and fibreglass in place

6) add several layers of fibreglass

then the finishing is anyone's guess really.

5kg pack General Purpose Resin 1

Ԛ£16.13 Ԛ£16.13

2kg Roll CSM 300gm 1

Ԛ£6.78 Ԛ£6.78

Catalyst 500gm pack 1

Ԛ£3.69 Ԛ£3.69

Black Pigment 500gm 1

Ԛ£4.66 Ԛ£4.66

1 Square Metre Roll Surface Tissue 30gm 1

Ԛ£1.12 Ԛ£1.12

Moldex 2405 Valved Respirator mask each 2

Ԛ£1.94 Ԛ£3.88

Low Cost Resin Brush 12mm (0.5") Box of 12 1

Ԛ£2.58 Ԛ£2.58

Paddle Roller 70mm x 21mm 1

Ԛ£3.03 Ԛ£3.03

seem like a sensible starting point? I thought i'd put some black pigment in so it doesn't look too terrible, if epoxy resin is that much stronger though, it might be a better option as i don't really want to sacrifice strength. what i may do is add an overlay of carbon fabric over this once finished if i'm happy, as i won't be finishing this at this stage - think thats jumping the gun a bit given my experience etc. any hints/info on finishing, especially if I'd like a carbon finish? I have very little idea, trust me you won't be insulting my intelligence on this one!

is my general plan of action for this about right?

1) sort out some way of releasing the fibreglass. i forgot about this when ordering stuff

2) cover in resin

3) add a layer of mat and saturate with resin

4) cut in half and remove from template

5) add trumpets and fibreglass in place

6) add several layers of fibreglass

then the finishing is anyone's guess really.

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

I could try and get you some different grades Micromesh so you can sand back the final layer and polish it up nicely?!!

(Micromesh is what we use in the aviation industry for polishing out scratches in ploycarbonate windows and canopies. As well as blending out damage on jet engine compressor blades........ Damn Good Stuff!!!!!)

(Micromesh is what we use in the aviation industry for polishing out scratches in ploycarbonate windows and canopies. As well as blending out damage on jet engine compressor blades........ Damn Good Stuff!!!!!)

When it's upside down and burning, you've gone too FAST!!!

if you could, that sounds like a really good idea, esp if I add a final layer of carbon fibre. cheers! I'll have a look at whether I can get some off the web too. hopefully should be getting the supplies today and have a little time later on so will start to have a go at making it. can see its gonna be a complete mess, but its a learning experience! Will post up pics if its not a complete disaster!

I'm becoming impatient to get this finished now, i really want to hear those throttle bodies!

I'm becoming impatient to get this finished now, i really want to hear those throttle bodies!

-

jaistanley

- E30 Zone Addict

- Posts: 2517

- Joined: Tue Jan 18, 2005 11:00 pm

- Location: Coventry and Essex

How're you going about the making of the plenum?

I think the best bet is to make the foam the shape you want the external surface of the finished product to be: Surface finish and all. This means you should make the foam the right shape, apply layers of fibreglass and resin, then resin and fibreglass 'tissue' (very very fine fibre glass mat) with a final coat of car body filler. Sand and smoothe it all to a lovely almost shiny finish.

You now have a 'mock up' of your finished plenum.

The next step is to make the mould: For this you will need to paint the outside of your blank with a releasing agent (so the new fibreglass doesn't stick) and first apply a layer of gel coat then layers and layers of thick and strong fibreglass. The thicker and stronger, the longer your mould will last. When set, remove the mould and you're half way (more like 75%) there.

Now to make plenum: Use releasing agent in your mold, then gelcoat, then as many layers of composite as you think is neccassary for the strength required. You can fit metal 'rings' or faces at this stage

The hard part is making the mold. Do it right though and you can make as many plenums as you see fit! You have to consider how the plenum will split: You can bond T nuts in and make a seam in the mould for instance, or a single backing plate that bolts onto throttle bodies with trumpets, and forms the back part of the plenum.

Sorry I haven't gone into much detail: You should look up fibregalss mold making on google and see if you can find pictures of fibreglass plenums to get ideas from.

On the mes front: Oh yes it's messy. Collect as many jam jars, old paint brushes and buy a load of latex gloves (you'll CURSE if you dont - resin takes months to come off hands/fingernails). I made a mixer out of a bent coat hanger in a cordless drill. Means you spend less time mixing and more time layering.

Good luck mate and contact me for any other useless suggestions I can come up with!

The only thing that concerns me is that you seem to think you're goint to make a solid plenum and not a mold: This would work if you could dissolve the foam from the inside of the finished product but it seems unlikely.. I think layering fibreglass onto cardboard will work but might dissapoint you a bit..

I suppose when the blank is made (step 1) you could easily cut it in 2 where you wish the seam to be: fit both halves to a board of wood and layer releasing agent then layers of fibreglass on each. This way it'd be easy to make the seam and fit T nuts etc..

I'll draw some diagrams and scan them in when I get home.. Found a project for the evening!! Picture is worth a thousand words and all that.

Jai

I think the best bet is to make the foam the shape you want the external surface of the finished product to be: Surface finish and all. This means you should make the foam the right shape, apply layers of fibreglass and resin, then resin and fibreglass 'tissue' (very very fine fibre glass mat) with a final coat of car body filler. Sand and smoothe it all to a lovely almost shiny finish.

You now have a 'mock up' of your finished plenum.

The next step is to make the mould: For this you will need to paint the outside of your blank with a releasing agent (so the new fibreglass doesn't stick) and first apply a layer of gel coat then layers and layers of thick and strong fibreglass. The thicker and stronger, the longer your mould will last. When set, remove the mould and you're half way (more like 75%) there.

Now to make plenum: Use releasing agent in your mold, then gelcoat, then as many layers of composite as you think is neccassary for the strength required. You can fit metal 'rings' or faces at this stage

The hard part is making the mold. Do it right though and you can make as many plenums as you see fit! You have to consider how the plenum will split: You can bond T nuts in and make a seam in the mould for instance, or a single backing plate that bolts onto throttle bodies with trumpets, and forms the back part of the plenum.

Sorry I haven't gone into much detail: You should look up fibregalss mold making on google and see if you can find pictures of fibreglass plenums to get ideas from.

On the mes front: Oh yes it's messy. Collect as many jam jars, old paint brushes and buy a load of latex gloves (you'll CURSE if you dont - resin takes months to come off hands/fingernails). I made a mixer out of a bent coat hanger in a cordless drill. Means you spend less time mixing and more time layering.

Good luck mate and contact me for any other useless suggestions I can come up with!

The only thing that concerns me is that you seem to think you're goint to make a solid plenum and not a mold: This would work if you could dissolve the foam from the inside of the finished product but it seems unlikely.. I think layering fibreglass onto cardboard will work but might dissapoint you a bit..

I suppose when the blank is made (step 1) you could easily cut it in 2 where you wish the seam to be: fit both halves to a board of wood and layer releasing agent then layers of fibreglass on each. This way it'd be easy to make the seam and fit T nuts etc..

I'll draw some diagrams and scan them in when I get home.. Found a project for the evening!! Picture is worth a thousand words and all that.

Jai

Hi

I am owrin on the same thingbut for a e21, I am try the lost foam route, I will make the mould in expand polystrene, the coat and smooth it in in PVC to fill the gaps, then a coat of epoxy resin (not poly) the wet lay some cf, when it sets you wash it out with pertrol to dissovle the polystrene.

Jason

I am owrin on the same thingbut for a e21, I am try the lost foam route, I will make the mould in expand polystrene, the coat and smooth it in in PVC to fill the gaps, then a coat of epoxy resin (not poly) the wet lay some cf, when it sets you wash it out with pertrol to dissovle the polystrene.

Jason

jai, a pic would be excellent but dont stress over it! Well, in light of the info and today's play i think the plan is to finish off my current lfibreglass over the cardboard effort i have, smooth off with surface tissue and a load of sanding etc and anything else to get it looking ok and bung it on the car for testing. i think you're totally right about the cardboard/fibreglass etc Jai, i just want to have a play to get a feel for things. then i'll be able to see how well it works, which trumpets are best, if there are any unforeseen problems etc. It will also give me chance to get familiar with some of the techniques etc. then i'll have a go with polystyrene foam to make a more appealing shape, make an external fibreglass mould and try some CF as per your instructions Jai!

i think your method sounds spot on, took me a while to get my head around what you meant, but makes a lot of sense!

is it really necessary to fibreglass and resin the mockup? could i not just use the foam + go straight to p38?

i like the idea of making the two moulds on a wooden base so it would be easy to get the seams on.

i can't find expandable polystyrene on cfsnet, where would i be able to get some from?

and as for the carbon itself, how many layers of this

http://www.cfsnet.co.uk/acatalog/CFS_Ca ... ic_35.html

200gm stuff wouldyou reckon i should use? Would this stuff be appropriate too?

Can you explain what the gelcoat's in aid of too, and what would be the best way to finish the carbon?

cheers very much for your reply, and yours jason, am beginning to get an idea of whats involved now

i think your method sounds spot on, took me a while to get my head around what you meant, but makes a lot of sense!

is it really necessary to fibreglass and resin the mockup? could i not just use the foam + go straight to p38?

i like the idea of making the two moulds on a wooden base so it would be easy to get the seams on.

i can't find expandable polystyrene on cfsnet, where would i be able to get some from?

and as for the carbon itself, how many layers of this

http://www.cfsnet.co.uk/acatalog/CFS_Ca ... ic_35.html

200gm stuff wouldyou reckon i should use? Would this stuff be appropriate too?

Can you explain what the gelcoat's in aid of too, and what would be the best way to finish the carbon?

cheers very much for your reply, and yours jason, am beginning to get an idea of whats involved now

- WARLOCKM42

- E30 Zone Newbie

- Posts: 47

- Joined: Fri Feb 10, 2006 11:00 pm

- Location: Athens,Greece

- Contact:

Maybe u can make a skeleton out off steel wire. u can bend and solder pieces together in order to make the 3D shape u want. After this use this fabric the use to make this really tight girly t shirts to coat ur construction whith. Strech the fabric all over the wire skeleton till it fits like flesh on bones.When the fabric is streched over the wire skelleton it will have the actual shape of ur plenum.Use polyester on the fabric as if it was fiberglass.Polyester will make fabric stable like plastic.U can use fiber glass or carbon fibre over this to make it more hard. Remember to build in bushins everywhere u want to use bolts nuts etc because polyester cracs even if u use fiberglass or carbon.I used this technique when i made my door panels it works!  sorry for my english im only greek

sorry for my english im only greek

-

jaistanley

- E30 Zone Addict

- Posts: 2517

- Joined: Tue Jan 18, 2005 11:00 pm

- Location: Coventry and Essex

If the mock up is smoothe enough it'll be fine. This should be where the surface finish originates. The better the mock up, the easier it'll be to get a good finish.

Made better if you use a layer of gel-coat before layering glass fibre mat into the mould... Can add pigments to the gel coat too..

Go for: Gel coat, then a layer or two of tissue then hardcore glass fibre matting. The smoother shiny gel coat will be on the outside. Gel coat stays tacky in air but in the mold it'll harden fine (to harden gel coat in air you need to add a wax additive but is possible)

Jai

Made better if you use a layer of gel-coat before layering glass fibre mat into the mould... Can add pigments to the gel coat too..

Go for: Gel coat, then a layer or two of tissue then hardcore glass fibre matting. The smoother shiny gel coat will be on the outside. Gel coat stays tacky in air but in the mold it'll harden fine (to harden gel coat in air you need to add a wax additive but is possible)

Jai

- WARLOCKM42

- E30 Zone Newbie

- Posts: 47

- Joined: Fri Feb 10, 2006 11:00 pm

- Location: Athens,Greece

- Contact:

U can use spray filler to do the finish its easy to aplly and can be worked with sand paper to get a really smooth finish. Use virious numbers of sand paper starting at No200 and finish whith No1000. The best would be to get ur hands on a No6000 they use this to polish canopys on combat aircraft.Its a lot of rubbing involved so i whish u good luck and may the force be with u....  Dont forget to use sandpaper which can be used with water they make a lot o better and easyer job!!!!

Dont forget to use sandpaper which can be used with water they make a lot o better and easyer job!!!!

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

6000 is only half way!!!!

Then you go 8000 and use 12000 to finish off (well, using micromesh you do).

Tim, PM me you address and i'll post some to you (if we have any in stores). You'll have to be quick though, i'm going abroad for 5weeks on Tuesday!!! Damn last minute changes.........

Then you go 8000 and use 12000 to finish off (well, using micromesh you do).

Tim, PM me you address and i'll post some to you (if we have any in stores). You'll have to be quick though, i'm going abroad for 5weeks on Tuesday!!! Damn last minute changes.........

When it's upside down and burning, you've gone too FAST!!!

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

Sunny Bahrain!!!! Be nice to get away from all this horrible coldness and rain for a while!!

Just not too happy about being away for 5weeks on the trot. Went last year in may/june and it can get very boring towards the end........

And we're moving to Cyprus when the GP is on so we can't go and see that

But i'm going with different people this time so it could be completely different and a top laugh.........you just never know!!!

Just not too happy about being away for 5weeks on the trot. Went last year in may/june and it can get very boring towards the end........

And we're moving to Cyprus when the GP is on so we can't go and see that

But i'm going with different people this time so it could be completely different and a top laugh.........you just never know!!!

When it's upside down and burning, you've gone too FAST!!!

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

Well, i go in 7hours!! Didn't have a chance to get you some Micromesh Tim, but i'll have a look when i get back (although you'll probably have a plenum made by then and be telling everyone how good it is and how much quicker the car goes with TB's on it!!!!!!

).

).

If i can get internet access while i'm out there i'll have a look on here to see how you're getting on Tim!!

Catch you Later.........

If i can get internet access while i'm out there i'll have a look on here to see how you're getting on Tim!!

Catch you Later.........

When it's upside down and burning, you've gone too FAST!!!

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

How the plenum going tim?? Made much progress???

Managed to get on the 'net' out here (even if it's only for 1/2hour at a time, when i'm in work.... )

)

Managed to get on the 'net' out here (even if it's only for 1/2hour at a time, when i'm in work....

When it's upside down and burning, you've gone too FAST!!!

woah, hey there tommy! hows it going? wasn't expecting to hear from you!

the plenum is pretty good for a first try, i'm well chuffed. did have dome drama earlier in the wkend as my mk1 effort didn't fit - it hit the MC tank. but i've chopped it up and fibreglassed it back together. i've decided to paint it black and have a BMW M Power transfer along the top, with a BMW E36 M3 GT 'BMW motorsport international - limited edition' plaque on the side. didn;t want to fork out for topcoat and lots of labour and experimentation so went for paint. here's the latest pics:

Things kinda worked themselves out really. thought i'd build a fibreglass mockup as a starting point to see how it went, which definitely turned out for the best cos of the orig mockup being too big to fit. The finished item is pretty good so i'm going to run with it for a little while, if not permanently. It's also pretty tough having had a good few layers of fibreglass, and doesn't resonate much due to being so thick and having dynamat resined to the inside. this is in keeping with what i want as cos its a daily i dont want it to be too loud. the trumpets also fit pretty nicely with this setup, and are a decent length, about 5" to the throttle body and 6" to the butterfly.

the afm-plenum bellow has been ordered from bmw, as has the throttle linkage clip, they wouldn't do me the GT plaque without a chassis number, so i had to order from germany. now its just sorting out the breather hoses and an air filter to use (must be something cheap and temporary as it'll probably be discarded when i go to the final MAF setup). also want to put an IAT sensor in the plenum for potential MS use.

the plenum is pretty good for a first try, i'm well chuffed. did have dome drama earlier in the wkend as my mk1 effort didn't fit - it hit the MC tank. but i've chopped it up and fibreglassed it back together. i've decided to paint it black and have a BMW M Power transfer along the top, with a BMW E36 M3 GT 'BMW motorsport international - limited edition' plaque on the side. didn;t want to fork out for topcoat and lots of labour and experimentation so went for paint. here's the latest pics:

Things kinda worked themselves out really. thought i'd build a fibreglass mockup as a starting point to see how it went, which definitely turned out for the best cos of the orig mockup being too big to fit. The finished item is pretty good so i'm going to run with it for a little while, if not permanently. It's also pretty tough having had a good few layers of fibreglass, and doesn't resonate much due to being so thick and having dynamat resined to the inside. this is in keeping with what i want as cos its a daily i dont want it to be too loud. the trumpets also fit pretty nicely with this setup, and are a decent length, about 5" to the throttle body and 6" to the butterfly.

the afm-plenum bellow has been ordered from bmw, as has the throttle linkage clip, they wouldn't do me the GT plaque without a chassis number, so i had to order from germany. now its just sorting out the breather hoses and an air filter to use (must be something cheap and temporary as it'll probably be discarded when i go to the final MAF setup). also want to put an IAT sensor in the plenum for potential MS use.

-

Andy335Touring

- Married to the E30 Zone

- Posts: 7144

- Joined: Sun Jan 09, 2005 11:00 pm

- Location: Long Eaton,Nottingham

- Contact:

Looking good

How about using some wrinkle paint on it ? Might save a lot of effort to get it smooth enough to paint with normal paint ?

This is the wrinkle paint

How about using some wrinkle paint on it ? Might save a lot of effort to get it smooth enough to paint with normal paint ?

This is the wrinkle paint

good idea! i reckon wrinkle paint would look pretty good, but due to wanting to stick a BMW M power logo onto the top surface and the plaque on the side, reckon i'll labour to try to get a decent smooth finish. With all the time and effort i've put into it so far, it would be a shame to stop here! if i get annoyed with trying to get a good finish, i'll give up and wrinkle paint it. thanks for the suggestion!

-

jaistanley

- E30 Zone Addict

- Posts: 2517

- Joined: Tue Jan 18, 2005 11:00 pm

- Location: Coventry and Essex

I second the vote for crinkle paint...

Good progress mate!

Jai

Good progress mate!

Jai

- TommyC

- E30 Zone Newbie

- Posts: 157

- Joined: Fri Nov 11, 2005 11:00 pm

- Location: Brize Norton (and Hastings)

That's lookin' damn good mate!!!!!!!!! I'll deffo try and get you some micromesh for your smooth finish cos the badges etc, will make it look like a BMW made one off!!!!!!!!!!

Unless you could work out a way of very preciely masking off the badges once they're on there and then crinkle paint it........i'm sure that would give the factory look too??!!!

Unless you could work out a way of very preciely masking off the badges once they're on there and then crinkle paint it........i'm sure that would give the factory look too??!!!

When it's upside down and burning, you've gone too FAST!!!

cheers guys!

am mightily pissed off today though, as went to have a look at the plenum to do some work on getting it smooth and found lumps in it! take a look:

this has happened in a few places. admittedly this is mainly on the side nearest to the heat where i've been drying it out, but is definitely not the filler or paint, feels like the fibreglass! its thick enough that its not really a prob, but i dont want this to happen when its in the engine bay!!! any ideas?

am mightily pissed off today though, as went to have a look at the plenum to do some work on getting it smooth and found lumps in it! take a look:

this has happened in a few places. admittedly this is mainly on the side nearest to the heat where i've been drying it out, but is definitely not the filler or paint, feels like the fibreglass! its thick enough that its not really a prob, but i dont want this to happen when its in the engine bay!!! any ideas?

nearly there now. have given up trying to paint it, am going to pay someone to do it as air bubbles and things have really pissed me off. if anyone in the bristol area can help or has any ideas on that would be grateful else its going into a bodyshop in the wk. Here's the setup nearly ready to go though:

still got a few things to iron out. got to put on the acc cable clip, going to need a new MAF/AFM (m30) or intake pipe, as the inlet i have is too big for the m42 afm, have to sort out the fuel lines, the breathers and a t piece for the brake servo take off as the ICV needs to go in too, also a little filing to one of the linkages on the tbs as its knocking against the idle rail at max throttle. otherwise its pretty much done now. need to get the megasquirt in too.

still got a few things to iron out. got to put on the acc cable clip, going to need a new MAF/AFM (m30) or intake pipe, as the inlet i have is too big for the m42 afm, have to sort out the fuel lines, the breathers and a t piece for the brake servo take off as the ICV needs to go in too, also a little filing to one of the linkages on the tbs as its knocking against the idle rail at max throttle. otherwise its pretty much done now. need to get the megasquirt in too.

tell me about it! don't believe what a bastard its being! i've spent a week and over Ԛ£20 of paint/filler on it and its still bubbling and looks shit. never had paint bubble like this before. i don't even think its air under the fibreglass, the fibreglass is solid and pretty sorted, im not quite sure whats happening. have got dust everywhere, am tired and pissed off with it, so thought rather than waste any more money on it, i'l just pay someone to paint it properly.

-

StreetSpec

- E30 Zone Newbie

- Posts: 40

- Joined: Mon Jan 17, 2005 11:00 pm

- Location: Adelaide, AUS

hot tim, hot. watching closely.

hey, i forget tho, did these mate up, or did you end up using a sandwich plate?

hey, i forget tho, did these mate up, or did you end up using a sandwich plate?

-

jaistanley

- E30 Zone Addict

- Posts: 2517

- Joined: Tue Jan 18, 2005 11:00 pm

- Location: Coventry and Essex

Sounds like the paint you're using is reacting with the resin in the GRP you've made..

If it's really driving you nuts, wait til its in the engine bay, hot and dirty. It'll all bubble off like crazy.

You could strip it all back and first paint with an inhibitor.

Looks fantastic though mate.. Ideal bit of home bodgery! You've gone down the exact route I was gonna go down before wimping out and buying the 3.2

Jai

If it's really driving you nuts, wait til its in the engine bay, hot and dirty. It'll all bubble off like crazy.

You could strip it all back and first paint with an inhibitor.

Looks fantastic though mate.. Ideal bit of home bodgery! You've gone down the exact route I was gonna go down before wimping out and buying the 3.2

Jai

yeah think you might right jai. was standard polyester resin though. have taken it in to be painted by the guy i normally use for bodywork, he wants Ԛ£30 to do it. he reckons its the filler reacting with too much thinners in the aerosol, which could also make sense and would explain why its happening around where i've dug out the top layer of fibreglass and filled it. think i shouldn't have dug out the fibreglass in these areas. sods law though, they're going to have a go and make sure its ok under heat etc. so in short not my problem, which is a relief as it was really pissing me off. at least it will look sweet now as will no doubt look better painted by him than by me. was driving me nuts.

hey guys, another update.

have been to visit the engine at the machinists this morning. the rebuild's costing an absolute fortune (will be Ԛ£700 once complete), but it is about as sexual as an engine block can be. looks brand new, and the bore spacing, which was a bit of a worry going for such large pistons, looks absolutely fine. the reground and modded crank is also a work of art.

only had my phone on me but here are some pics of the crank, tried some of the gorgeous newly modded rods and rebored block (soon to be decked so it will look completely brand new!) but they didn't come out well, the light was terrible in their workshop:

god i'm happy with their work. sadly I'm pretty skint at the mo and am worried that i might have to sell her on. if i got the right offer i'd accept. have had loads of bills come at once this month. i hope it doesn't come to that, i've spent nearly Ԛ£1500 on this block, but just looking at the work and knowing that its one of the very few 2.1l m42s in existence (and imo done more cleverly and to a higher standard than the much more expensive hartge conversions) makes me glad i've gone down this route. i'm sure its going to make huge power! actually with that crank and the CR etc its going to be an absolute torque monster.

next week once i've paid up and its assembled i'll take some more pics, it really does look absolutely stunning.

have been to visit the engine at the machinists this morning. the rebuild's costing an absolute fortune (will be Ԛ£700 once complete), but it is about as sexual as an engine block can be. looks brand new, and the bore spacing, which was a bit of a worry going for such large pistons, looks absolutely fine. the reground and modded crank is also a work of art.

only had my phone on me but here are some pics of the crank, tried some of the gorgeous newly modded rods and rebored block (soon to be decked so it will look completely brand new!) but they didn't come out well, the light was terrible in their workshop:

god i'm happy with their work. sadly I'm pretty skint at the mo and am worried that i might have to sell her on. if i got the right offer i'd accept. have had loads of bills come at once this month. i hope it doesn't come to that, i've spent nearly Ԛ£1500 on this block, but just looking at the work and knowing that its one of the very few 2.1l m42s in existence (and imo done more cleverly and to a higher standard than the much more expensive hartge conversions) makes me glad i've gone down this route. i'm sure its going to make huge power! actually with that crank and the CR etc its going to be an absolute torque monster.

next week once i've paid up and its assembled i'll take some more pics, it really does look absolutely stunning.

only a few odds and sods really.

plenum:

that's after being sprayed by the bodyshop. unfortunately after a night it bubbled up again just like when I sprayed it, so its back with them again! in a weird way feel a bit vindicated that they had the same problem - at least it wasn't my painting skills! bit worried about whether they're gonna be able to sort it.

the bottom end is ready now, got nailed big time on new rings for the pistons from BMW but trying not to think about that too much.

much more exciting is the megasquirt, and i owe a lot of thanks to ant for answering my emails! what a gent!

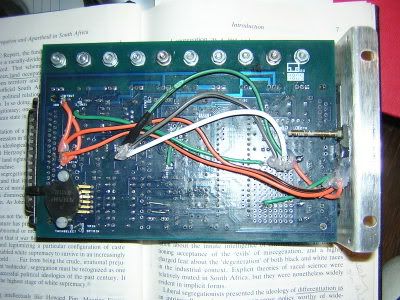

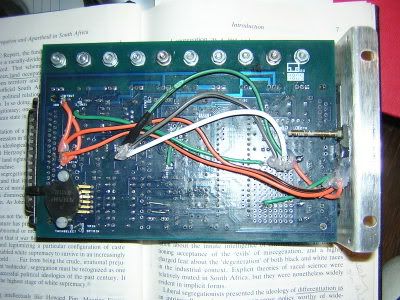

so now the car will now start on megasquirt! not many pics, but you can see the mods I've had to do to the MS to tailor it to our configuration:

and a wiring mess photo

so far I've managed to wire it all in, sharing all the sensors with the motronic. I've made it so that to swap to MS requires simply uplugging two molex connectors from the motronic and into the Megasquirt, takes like 10 secs. means i can still drive the car around on motronic for now, and test just fuel or just sparks on the MS. It works pretty well using MS for fuel and motronic for spark at the mo, that's about it though. this is an interesting proposition really. sparks and idle on MS are still a bit dodgy. I'm struggling to get MS to control our idle, but only started on that today and got dragged away to the pub with omi for most of the daytime (well thats my excuse anyway). at the mo it surges between 500ish/stalling and 1000rpm, mb not quite so drastic but still pretty shit. i'm pretty much at a loss as to why its doing that, need to do some research and annoy ant some more. i hope i don't have to revert to using the throttle stop to control idle.

other than that, have an 02 bung being welded on on monday, and that's about it really at the mo. its pretty damn close, but i want to be patient and do everything right, and i don't want the new engine in until the megasquirt and throttle bodies are on as i don't want to stress the engine when its running in at all.

plenum:

that's after being sprayed by the bodyshop. unfortunately after a night it bubbled up again just like when I sprayed it, so its back with them again! in a weird way feel a bit vindicated that they had the same problem - at least it wasn't my painting skills! bit worried about whether they're gonna be able to sort it.

the bottom end is ready now, got nailed big time on new rings for the pistons from BMW but trying not to think about that too much.

much more exciting is the megasquirt, and i owe a lot of thanks to ant for answering my emails! what a gent!

so now the car will now start on megasquirt! not many pics, but you can see the mods I've had to do to the MS to tailor it to our configuration:

and a wiring mess photo

so far I've managed to wire it all in, sharing all the sensors with the motronic. I've made it so that to swap to MS requires simply uplugging two molex connectors from the motronic and into the Megasquirt, takes like 10 secs. means i can still drive the car around on motronic for now, and test just fuel or just sparks on the MS. It works pretty well using MS for fuel and motronic for spark at the mo, that's about it though. this is an interesting proposition really. sparks and idle on MS are still a bit dodgy. I'm struggling to get MS to control our idle, but only started on that today and got dragged away to the pub with omi for most of the daytime (well thats my excuse anyway). at the mo it surges between 500ish/stalling and 1000rpm, mb not quite so drastic but still pretty shit. i'm pretty much at a loss as to why its doing that, need to do some research and annoy ant some more. i hope i don't have to revert to using the throttle stop to control idle.

other than that, have an 02 bung being welded on on monday, and that's about it really at the mo. its pretty damn close, but i want to be patient and do everything right, and i don't want the new engine in until the megasquirt and throttle bodies are on as i don't want to stress the engine when its running in at all.