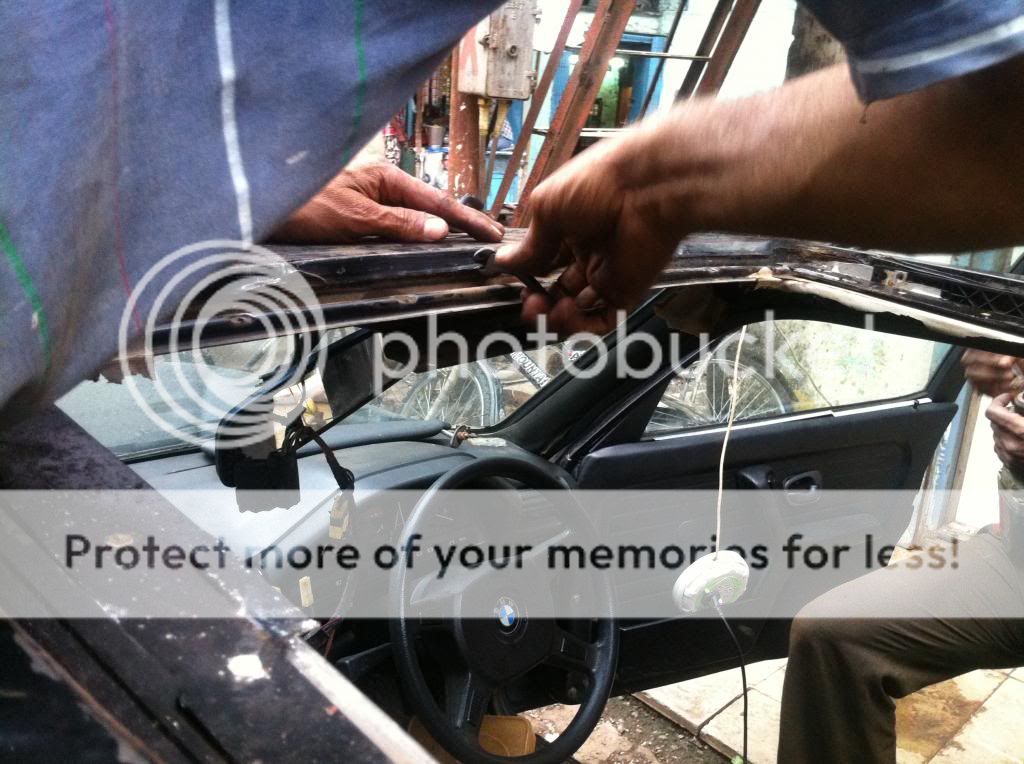

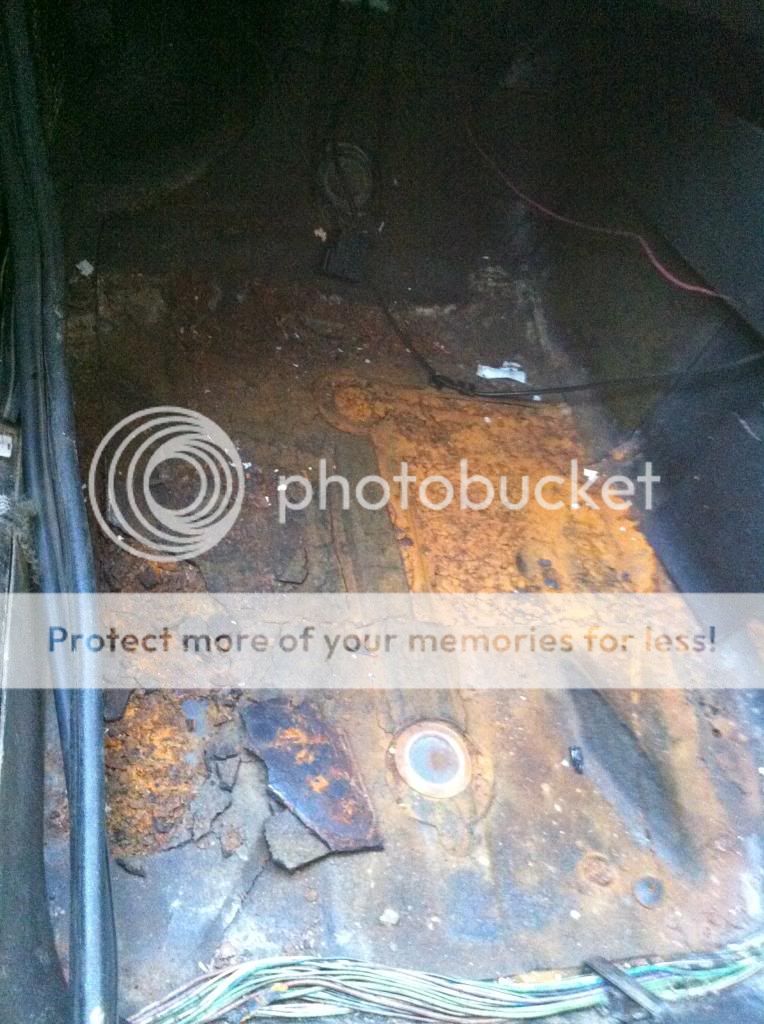

We have made slow progress. It's been close to 4 months since I said the floor rust would get tackled in a couple of weeks. Famous last words.

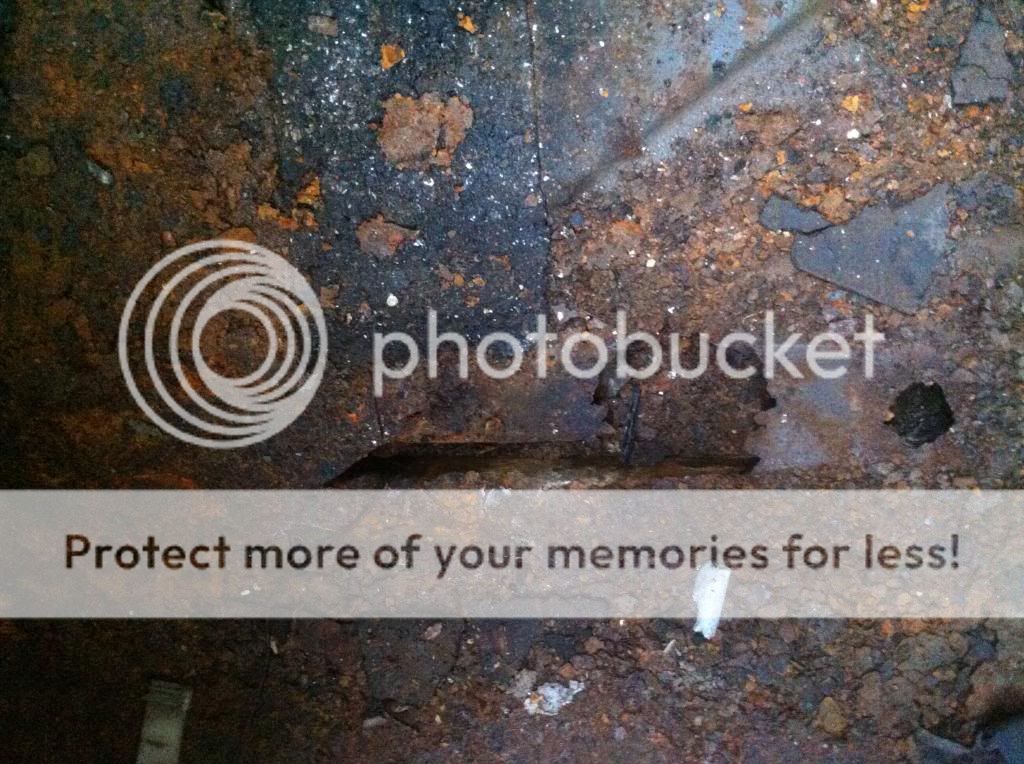

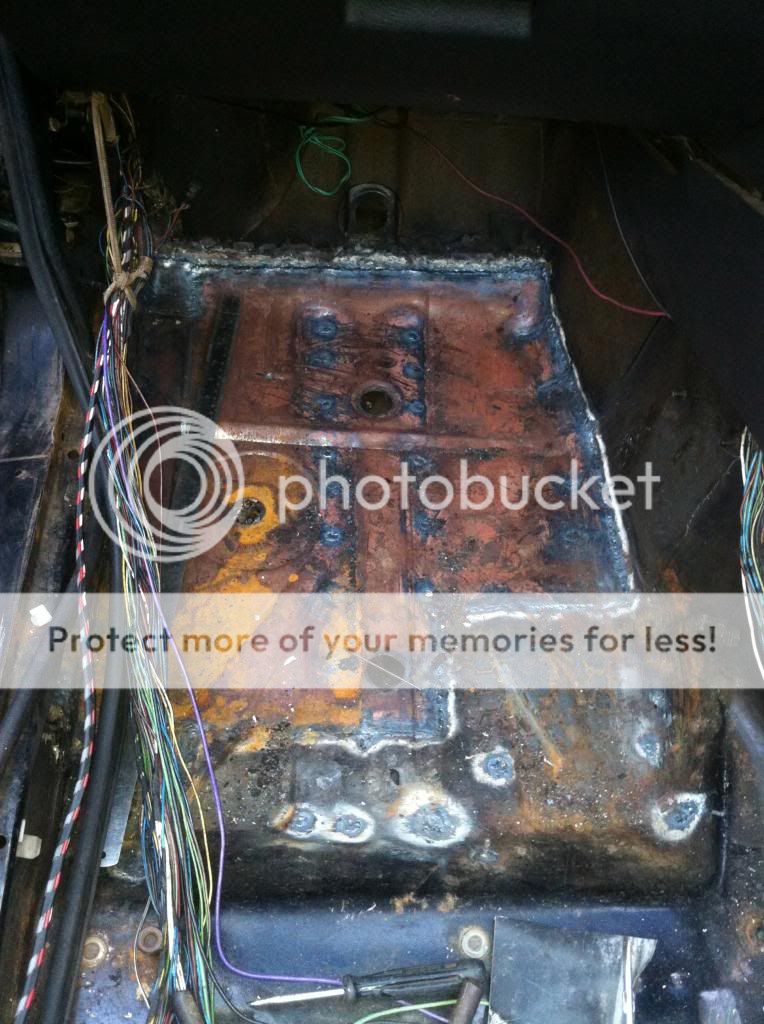

The welder found a sheet that had been welded on to existing rust

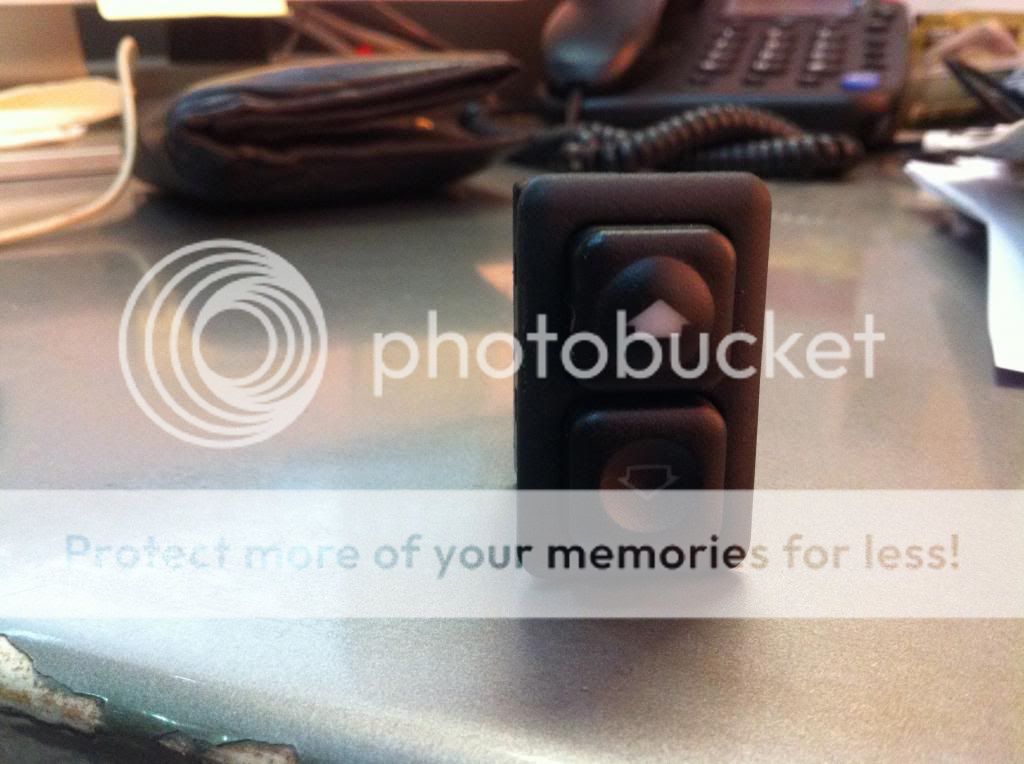

Chucked in the back. And you can see Hyundai Santro door opener, with a metal piece added to fit it.

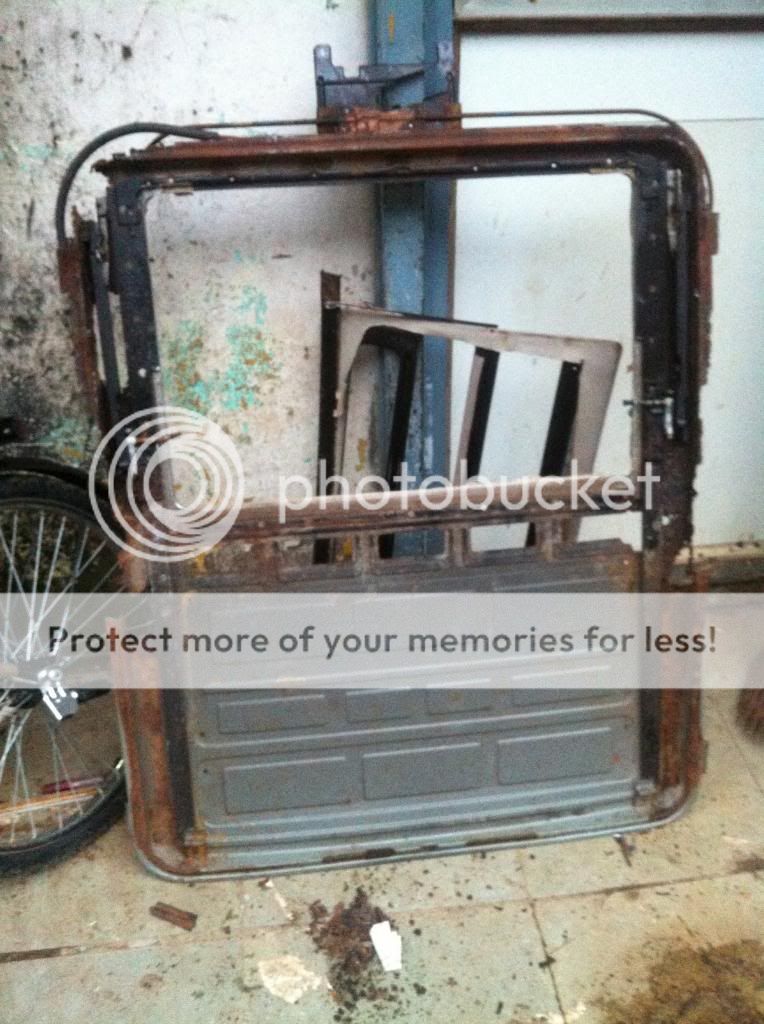

Soon the twin layers of rusted metal were hacked off.

The welder claims the chassis underneath is fine

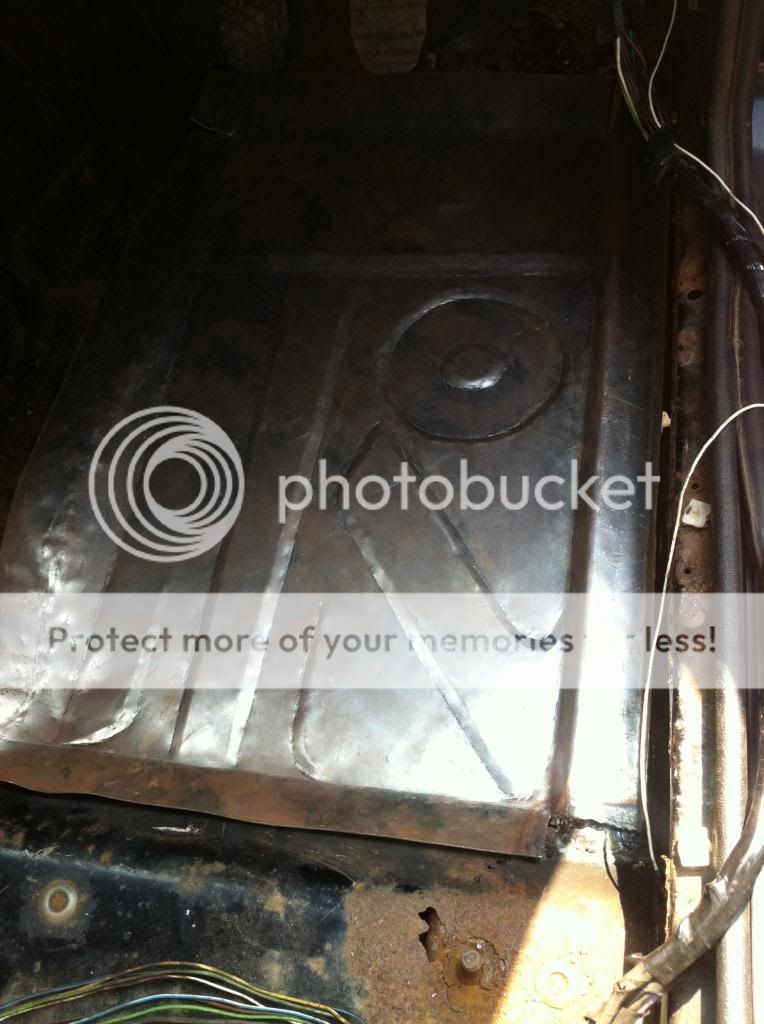

Anyway, he sorted that out, before making a pattern from the pics that I supplied from your collated pictures from various threads.

After much head scratching on how he got stuck with this job, he and his mate got down to it. It was Diwali time in 1st week of November by the time welding and chopping started in earnest.

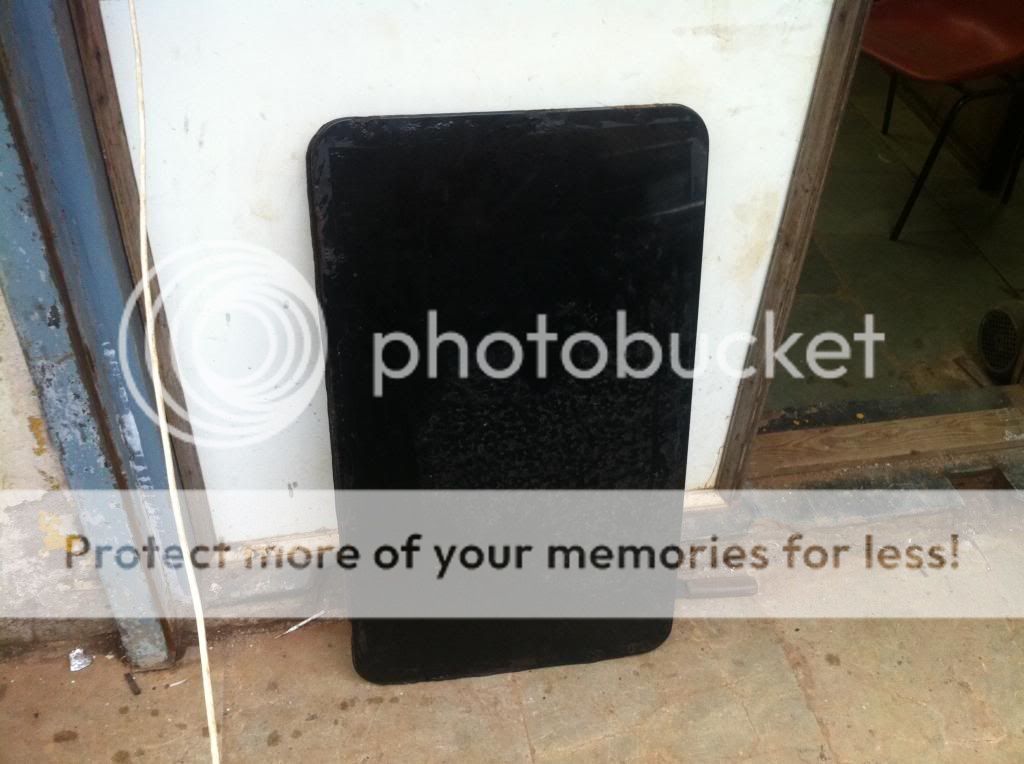

Placed to see if it fits in the yawning gap.

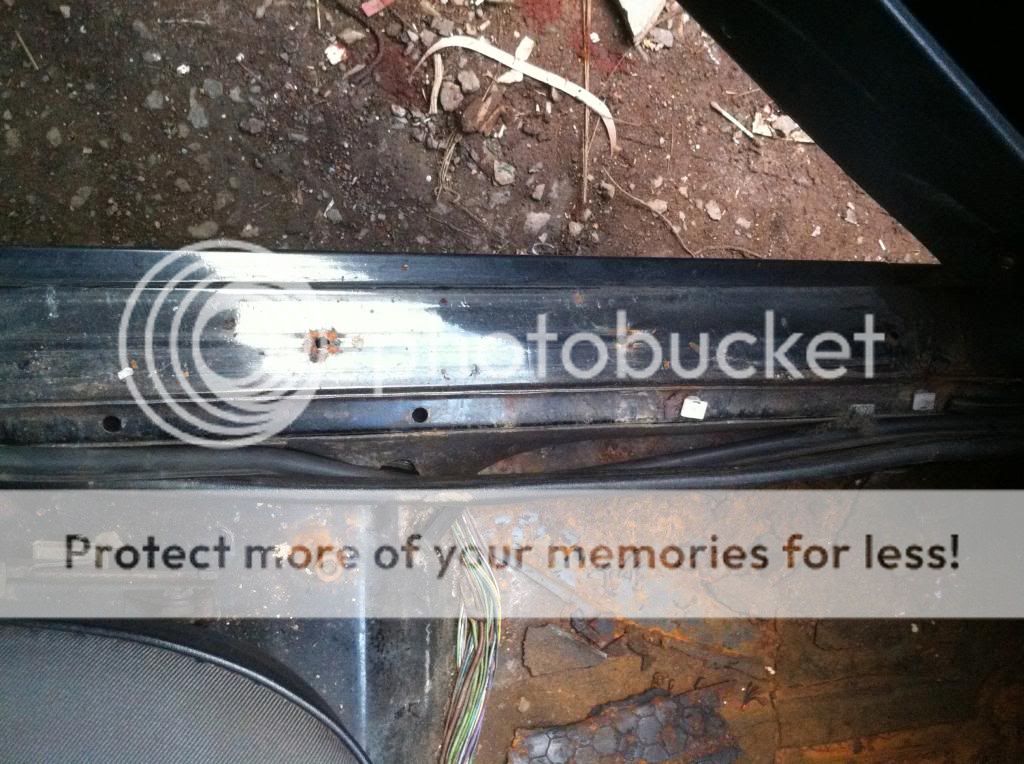

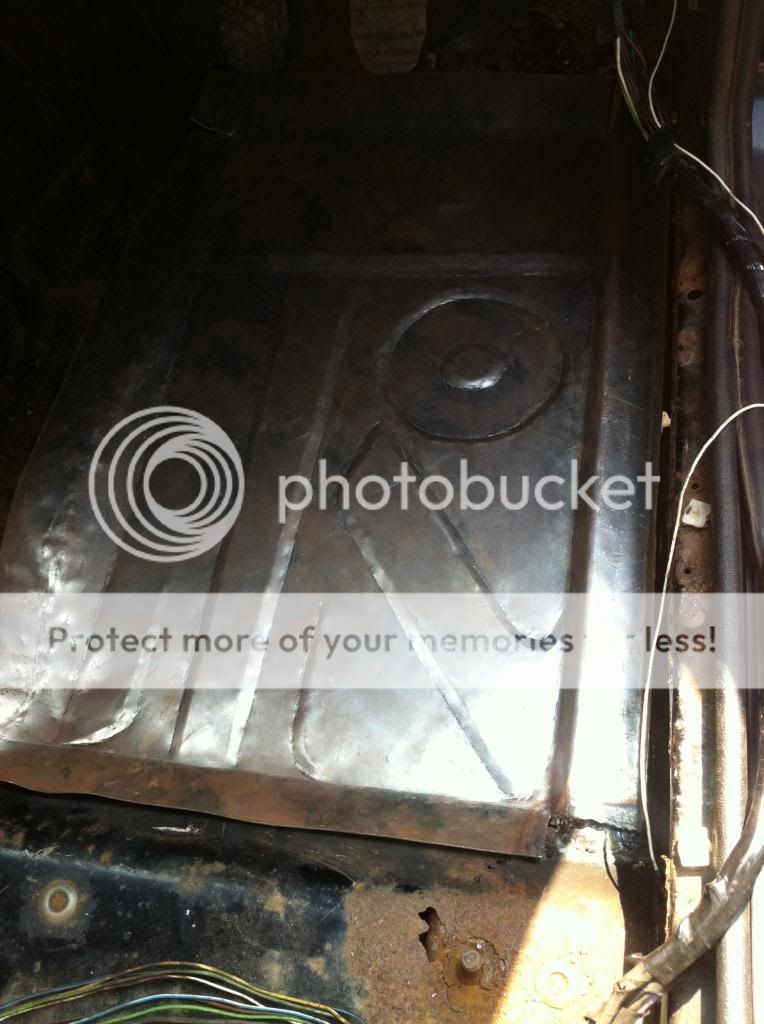

And finally, welded in. The running board had also got the blight. so that was tackled on both sides of the floor.

Left passenger side.

He made paper dies for the accelerator pedal holder. Quite the craftsman.

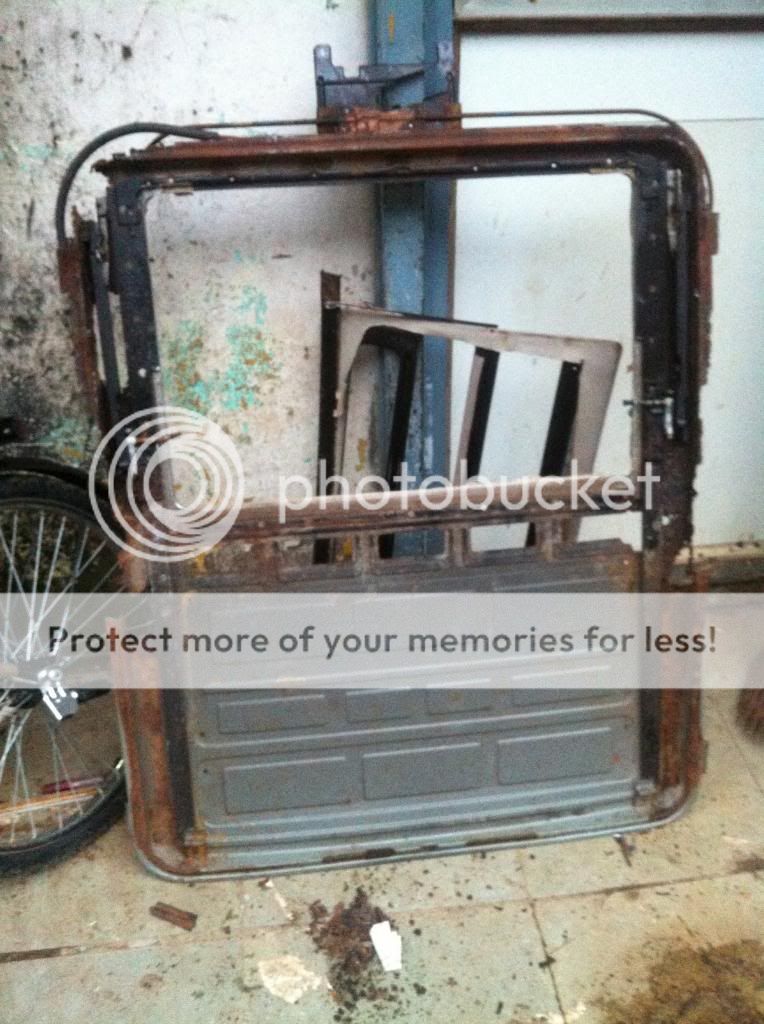

The Hyundai-ness was reduced a bit, by removing the metal piece and re-welding pieces that would help original locks fit.

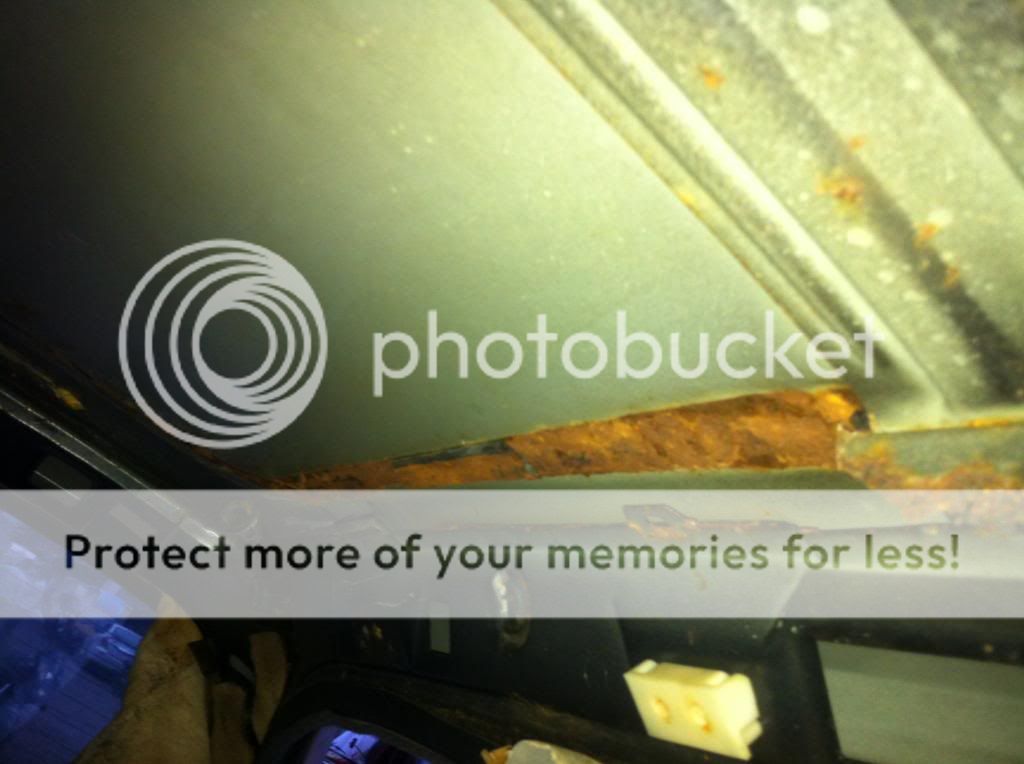

When the sunroof area was sanded down and a bit of the blow torch shown to the metal, the paint cover peeled away to reveal the lattice work.

Another section of the roof, with the new pieces welded in.

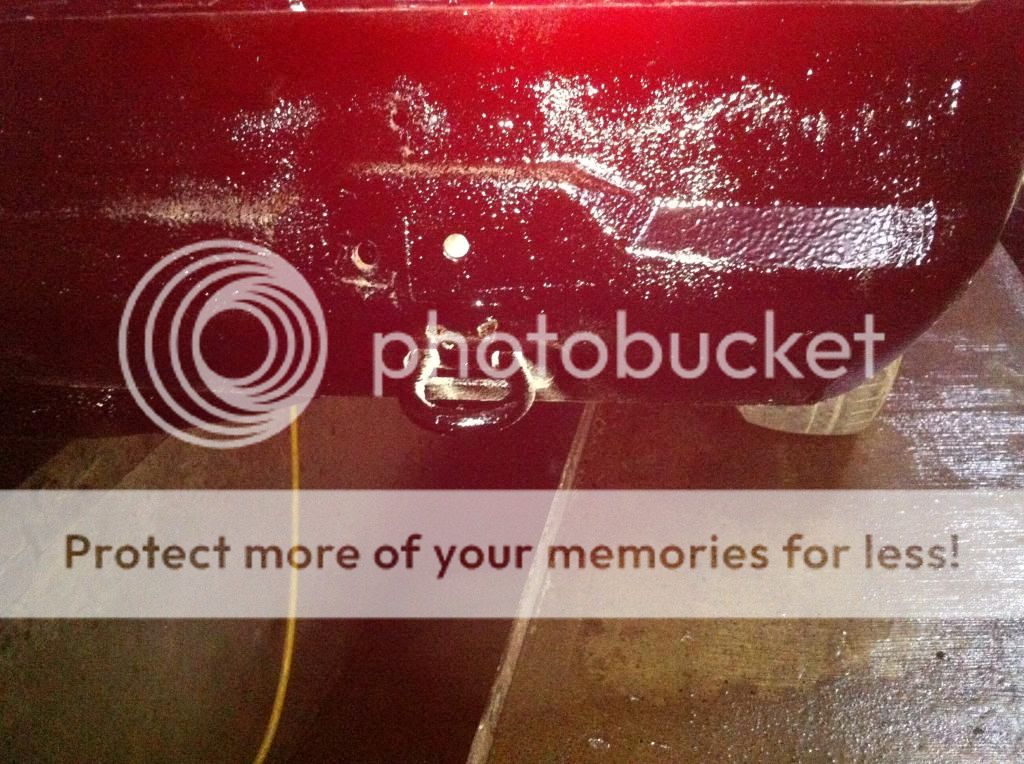

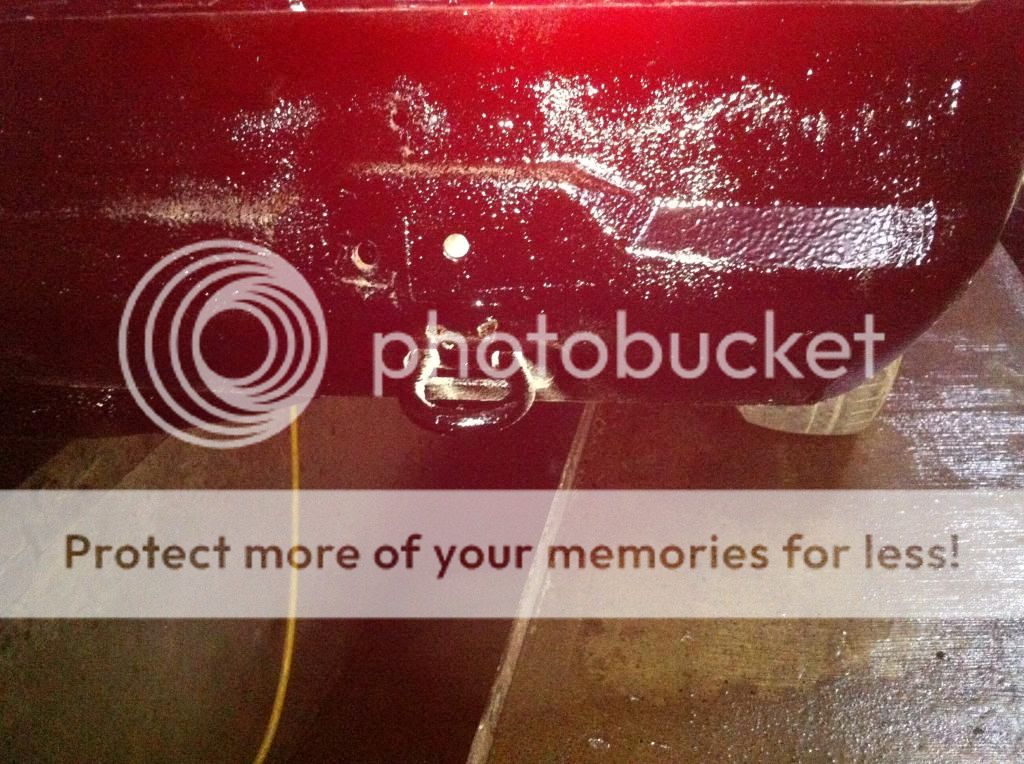

The boot had a couple of spots, one of the bigger coin sized one was under the rubber spoiler.

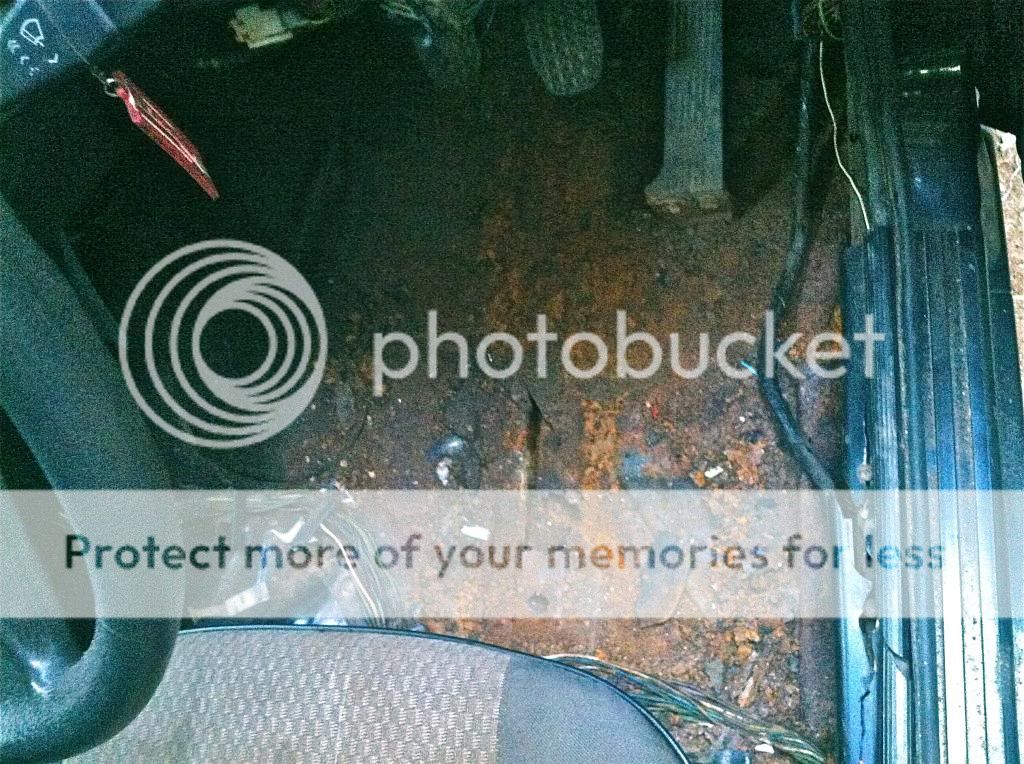

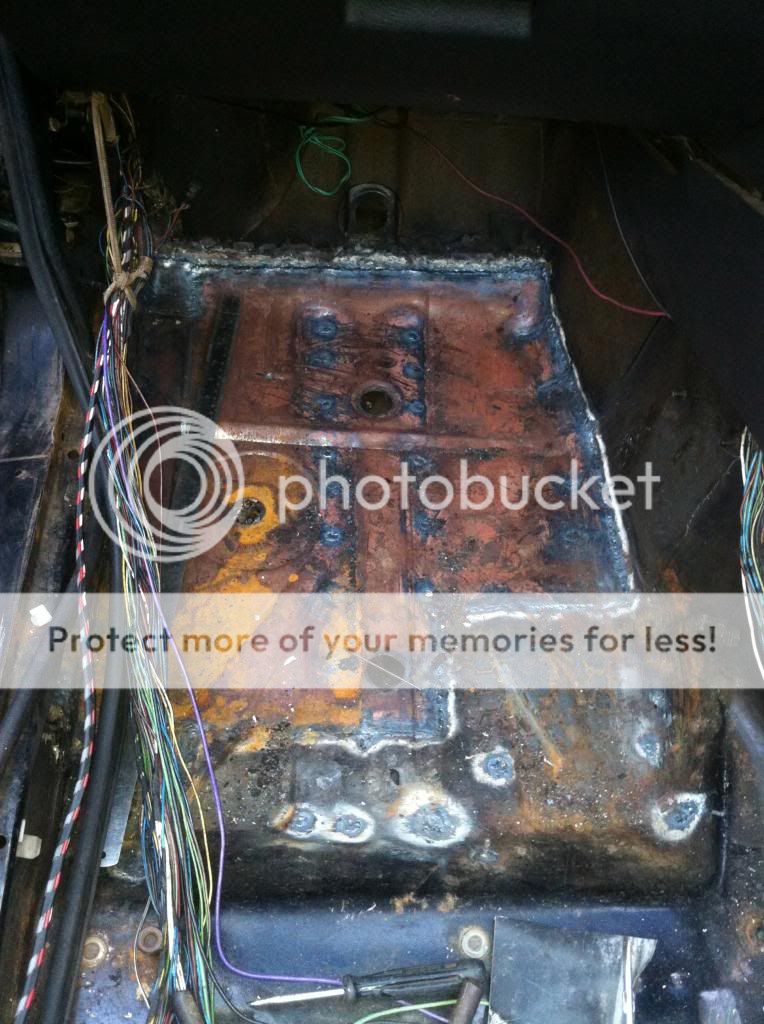

We finally prevailed upon him to check the firewall. I guess he was tired and wanted to run away.

The extra fresh air and moisture that these holes were allowing in were sorted out.

A couple of spots near the steering column, where the piping for the AC system comes into the cabin.

After a couple of weeks of sanding down the weld spots, it was Red Oxide time! Don't know the equivalent stuff that you all use.

The bracket to keep the accelerator pedal from pushing down too much was also recreated and fitted.

The sunroof tray was gone. But these guys saved me ton of money, by doubling the effort to rescue it.

After a long exile at the welders' the tired old thing was back in the garage.

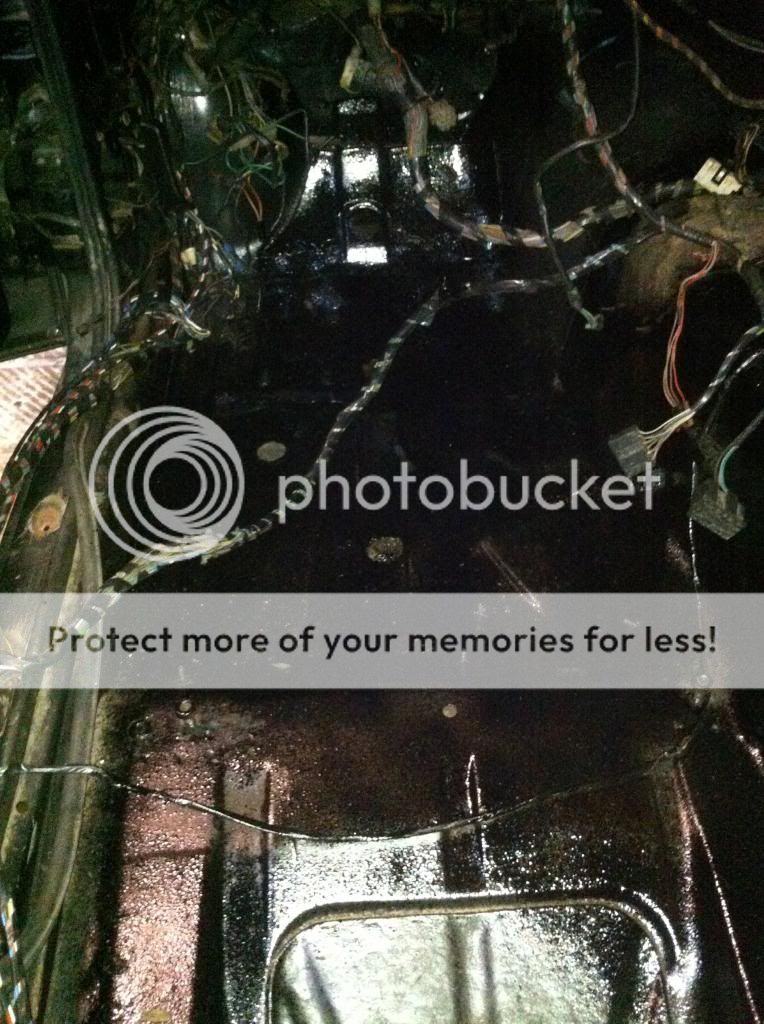

After a bath, got the Waxoyl chaps to liberally spray boot, interior, underbody, doors, running boards and bonnet with the Black liquid, and the clear stuff inside the cavities.

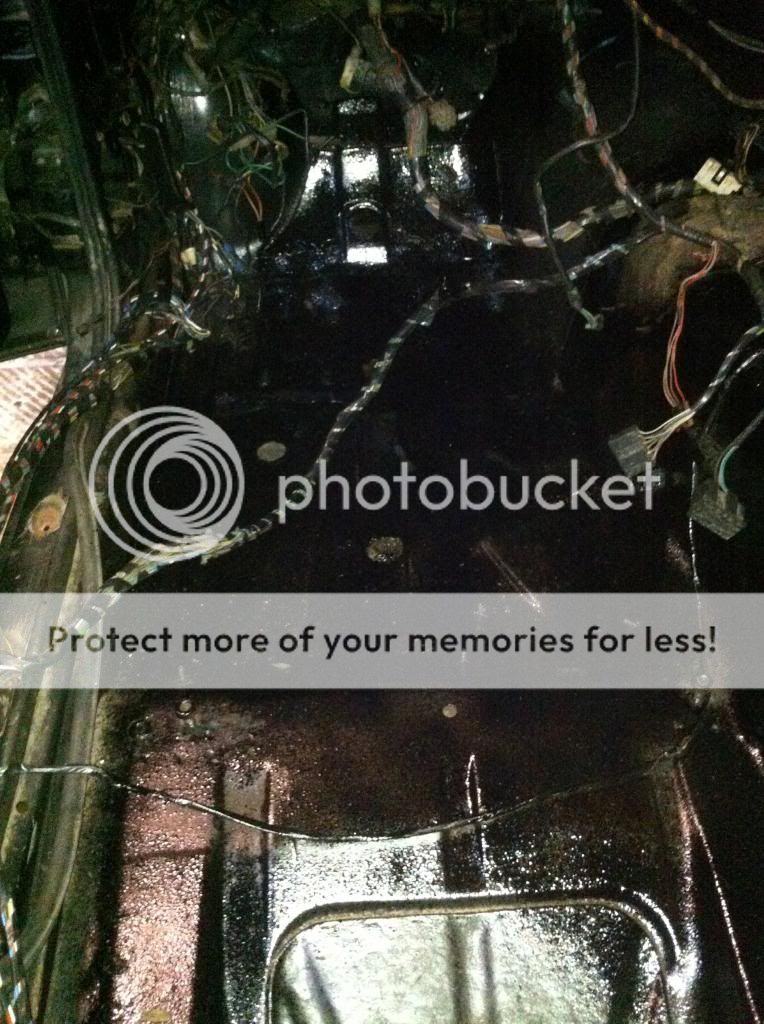

Dried and less shiny inside.

The AC Blower was refurbished and fitted in a couple of days back. Getting a new condensor, lines, receiver/dryer, and compressor fitted. One of the few parts that I'm ok to put non-OEM, BMW branded. As long as it cools in the Mumbai weather.

After I discovered that the electrician had chopped the loom when the welding work was going on, since he didn't pull out the entire loom out, we sourced some connectors and got them fitted under the main fuse box. So now fuse box is plug in and plug out.

That's where we are today. The sunroof tray has gone to the sunroof guy to fit in the slider mechanism I ordered.