M42 Rotrex (for sale!) + track build

Moderator: martauto

Buy a rotrex charger rich easy peasy to mount youve done half the work. Sell your charger use the money you save on a manifold and a new turbo youd be there.....ish

Run it slower than mine an you wont have to change comp till you want more boost then just change the pulley! Also less heat to get rid of.

Run it slower than mine an you wont have to change comp till you want more boost then just change the pulley! Also less heat to get rid of.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

The beaufitul simplicty of the Rotrex does make me want to burst into tears but they're alot of money

Where did you get yours from and any idea on which model I should be looking at? One with a gargantuan pulley something like the C-15?

something like the C-15?

£1,633

£1,633

Where did you get yours from and any idea on which model I should be looking at? One with a gargantuan pulley

Rich, centrifugal pumps are very different beasts to roots pumps. Both have their advantages and disadvantages. A constant volume (roots) pump, despite its poor effciency (and thus high heat output and significant load upon the engine) has a significant torque advantage over a centrifugal pump. If I were you I would stick with the roots pump until you have exhausted its potential. Also, if you ever plan to drop your compression ratio and add a turbo you'd best keep your roots pump as a centrifugal pump does not fill in the gap left by the turbo at low rpm as well as a roots pump will.

Just a suggestion. Sorry, don't mean to interfere.

Seems our two values are in agreement. About 12psi it is then.

Seems our two values are in agreement. About 12psi it is then.

Just a suggestion. Sorry, don't mean to interfere.

Coolrix313 wrote:Now obviously my first caculation for desired engine power did not take into account the huge amount of power required to run the charger which Geoff pointed out so to even further back up on what's already been said:

Desired BHP

Current BHP

235

135

= 1.74

Boost = 0.74 x 14.6 (atmospheric pressure)

= 11.39psi (2dp)

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

As it's a track car then the low down roots torque will obviously be a bonus but the sheer simplicty of fitting the Rotrex makes it ever so tempting. With the roots there's what will inevitably be a fairly complicated mounting system coupled with yet again an inevitably poorly flowing system for mounting the throttle body up stream of the charger, then having a valve in vacuum to keep the engine running when the throttle is shut.

Something about a simple bracket and 'pop it on' seems ever so sweet.

Just I could save up, enjoy the car then have a nice time putting it all together.

Something about a simple bracket and 'pop it on' seems ever so sweet.

Just I could save up, enjoy the car then have a nice time putting it all together.

I understand. Then I think the Rotrex C30-84 (same as Appletree) would be your best option. But keep in mind that you will need to lower your compression ratio if you ever plan to seriously take advantage of a centrifugal pump. A centrifugal pump is, after all, little else than a belt driven turbocharger. If you adjust the pulley ratio to accommodate your higher compression ratio engine, you won't be making much boost at low RPM.

Bare in mind that (in the absence of leakage around the rotors) a roots pump attempts (ideally) to keep your boost pressure constant (assuming temperature is constant) at all engine rpm. In other words it tries to function as a "constant boost" pump, regardless of engine speed.

A centrifugal pump, on the other hand, progressively increases boost as your engine RPM increase. If your engine is limited to 10psi boost (say) then you'll have to choose your pulley ratios so as not to exceed 10psi boost at peak RPM with the Rotrex. At all rpm below that the Rotrex will produce less boost than this.

With a roots pump, however, you can have (more or less) your full 10psi of boost across all rpm. Can you see the fundamental difference Rich? So long as you plan to keep your current compression ratio I'd suggest you stick with the Eaton.

What am I missing here? Why do you have to place your throttle before your roots pump?

Bare in mind that (in the absence of leakage around the rotors) a roots pump attempts (ideally) to keep your boost pressure constant (assuming temperature is constant) at all engine rpm. In other words it tries to function as a "constant boost" pump, regardless of engine speed.

A centrifugal pump, on the other hand, progressively increases boost as your engine RPM increase. If your engine is limited to 10psi boost (say) then you'll have to choose your pulley ratios so as not to exceed 10psi boost at peak RPM with the Rotrex. At all rpm below that the Rotrex will produce less boost than this.

With a roots pump, however, you can have (more or less) your full 10psi of boost across all rpm. Can you see the fundamental difference Rich? So long as you plan to keep your current compression ratio I'd suggest you stick with the Eaton.

What am I missing here? Why do you have to place your throttle before your roots pump?

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

I paid £1500 inc Vat de;ivered for the charger including the oil, oil res, filter and pipework+fittings. from Richard at TTS performance.

http://www.tts-performance.co.uk/tts.shtml.

It is alarge enitial out lay but its modern technology and ive used the same pully as you again, youve already got the alternator moved and the intercooler mounted.

Ive got braket drawings infront of me now and can copy them for you, just let me know before you want them so i can get my act togeather and finaly get them to you

http://www.tts-performance.co.uk/tts.shtml.

It is alarge enitial out lay but its modern technology and ive used the same pully as you again, youve already got the alternator moved and the intercooler mounted.

Ive got braket drawings infront of me now and can copy them for you, just let me know before you want them so i can get my act togeather and finaly get them to you

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Not much Geoff, hoshey put his after the eaton and struggled to find valves that would flow enough air at low-mid RPM at part throttle/cruising which ment the charger was always loaded up and ended up using a 50mm race blow off valve iirc, it also made it a bit on/off on the throttle response. it was a good set up and abit of development work would have got it great but he turned to the dark side and bought a *cough e36 M3 cough*.GeoffBob wrote:What am I missing here? Why do you have to place your throttle before your roots pump?

there was alarge thread about it somewere, but in the end i think we all decided BMW (mini), jag and Aston all put the throttle infront for a reason

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

I think my oil pipe work would get in the way of you're backet Matt but easily altered.

I spoke to Paul @ TTS. He was mega helpful also and did say he'd throw in and oil cooler for that price too but it's still alot.

I spoke to Paul @ TTS. He was mega helpful also and did say he'd throw in and oil cooler for that price too but it's still alot.

Last edited by rix313 on Sat Dec 10, 2011 3:01 pm, edited 1 time in total.

The oil coolers they supply are good, you'd be supprised how much clearence there would be around there as ive got clearence between oil filter housing which you no longer have.

One thing that is a basturd is the dip stick tube!

You can also play around with belt length and use spacers between the block and the bracket to give you more space. if you do decide to go the rotrex route, if you send me some meausrements i can check them against my charger to make sure the bracket would fit the same.

if it fits then if you send me some steel i can make it for you at work, and it'll be the Mk 2 version of mine with the lessons learned

One thing that is a basturd is the dip stick tube!

You can also play around with belt length and use spacers between the block and the bracket to give you more space. if you do decide to go the rotrex route, if you send me some meausrements i can check them against my charger to make sure the bracket would fit the same.

if it fits then if you send me some steel i can make it for you at work, and it'll be the Mk 2 version of mine with the lessons learned

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Sounds like a Rotrex is the way to go then. BTW, Graham Bell has good things to say about centrifugal pumps. Due to the lower boost at low rpm they will help save your clutch, diff, tyres etc which a roots pump can rip right through at low rpm if you are not careful. Bell also goes on to comment that the lower boost at low rpm is not an issue in most competition classes where engine speed is generally maintained fairly high. He does however warn that if a centrifugal pump is geared to provided high boost at low rpm (to function similar to a roots pump) then the boost will be excessive at high rpm.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

With out going into adjusting too much in the engine which C30 then. I'd be happy with one of the smaller two (64 or 74) if it would give me my 200bhp, can always upgrade later with pulleys etc.

If it's going to be a T'rex I need to save, big time.

Matt any way you can send me drawings so I cna look at them?

If it's going to be a T'rex I need to save, big time.

Matt any way you can send me drawings so I cna look at them?

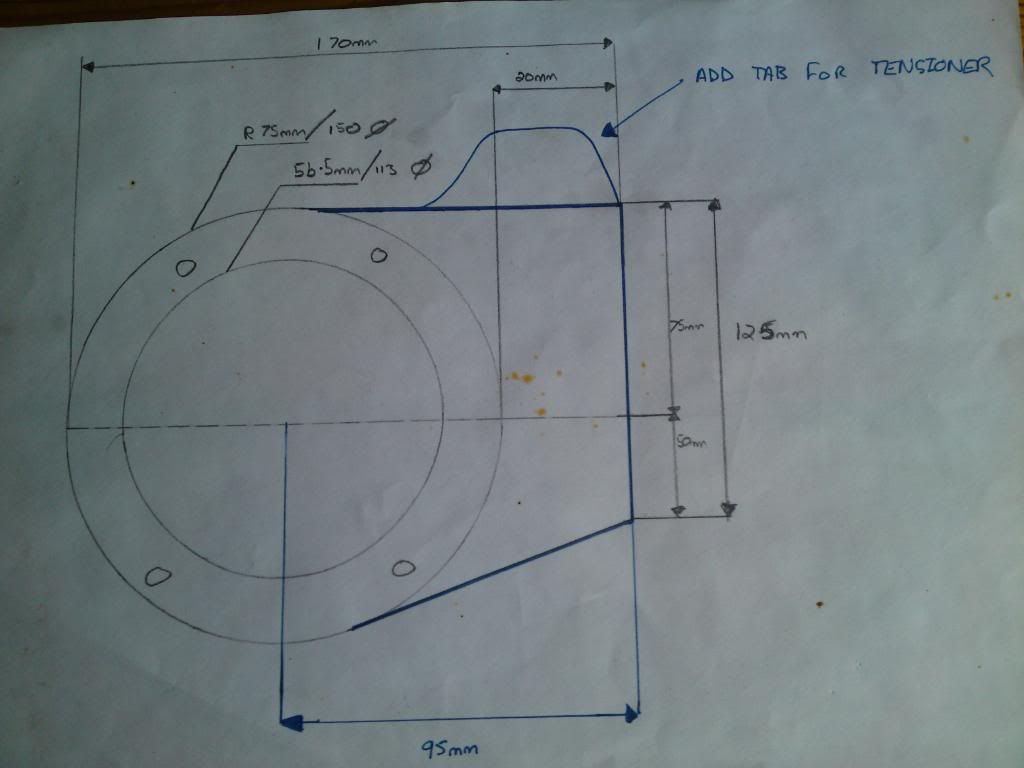

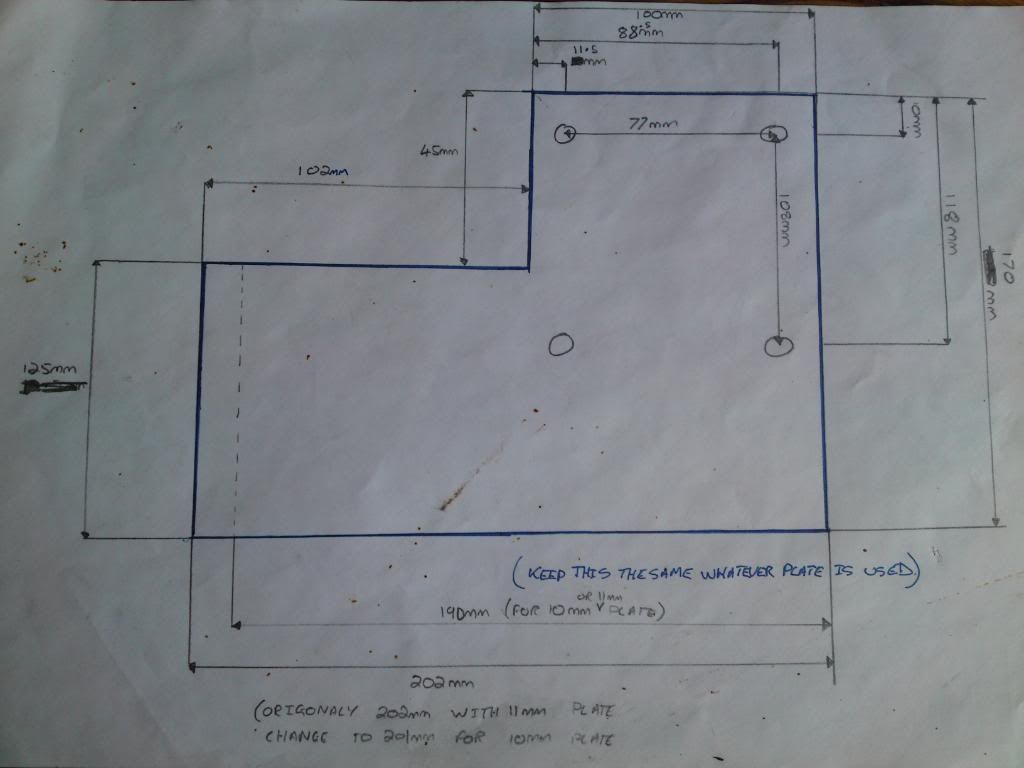

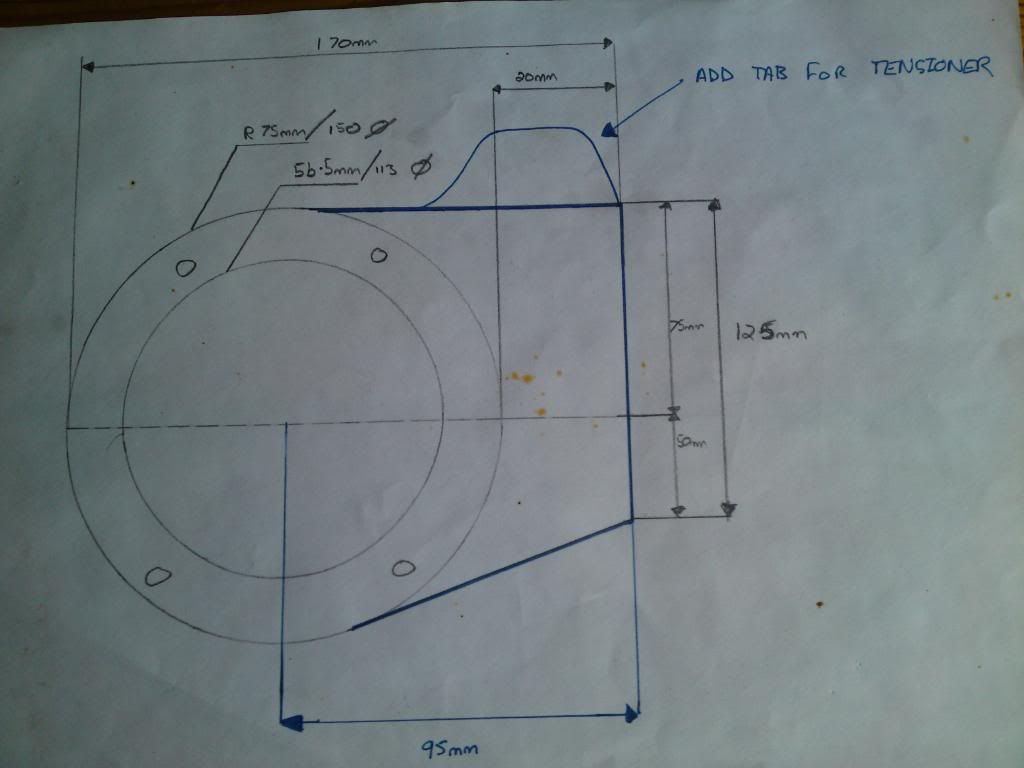

Could probly doit it tomorrow, draw them out take a pic the PM you them with the big images. Hardest bit is boring the hole for the charger to locate on.

They would'nt be the mk2 design either although ive got a good idea which bit needs more material to add a excentric tensioner and save the hassel with the PAS belts.

They would'nt be the mk2 design either although ive got a good idea which bit needs more material to add a excentric tensioner and save the hassel with the PAS belts.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

Cool cheers Matt.

So which one should I look at getting? The one I can get for £600 is an 84 but I'd need to get the other bits for it as it's off of a car which now has a bigger one fitted.

I'll only be looking for the 7-8psi (seeing as my spec sheet says the charger is 96% efficient I shouldn't neeed much more?) to get the car to 200bhp I don't need a massive one. TTS recon the C30-64 and I've done some sums lyke:

Charger redline

engine redline

12600

6500 = 1.93

Crank pulley

1.93

140mm

1.93 = 72.5

I recon the 75 pulley or the 80 to be really safe.

So which one should I look at getting? The one I can get for £600 is an 84 but I'd need to get the other bits for it as it's off of a car which now has a bigger one fitted.

I'll only be looking for the 7-8psi (seeing as my spec sheet says the charger is 96% efficient I shouldn't neeed much more?) to get the car to 200bhp I don't need a massive one. TTS recon the C30-64 and I've done some sums lyke:

Charger redline

engine redline

12600

6500 = 1.93

Crank pulley

1.93

140mm

1.93 = 72.5

I recon the 75 pulley or the 80 to be really safe.

The C30-84 is the one that i now have fitted wether with a largenough pully it would be ok low down i don know * await geoff to update* i think that the largest pully you can get is 110mm but i may be wrong.

at current with this charger mines making 188bhp 5200rpm at 8-10psi (still havent checked with the new charger as the cars SORN at the moment) so if you run it slower you should be able to get that 10psi to be peak at the red line and have a charger that you can afford to get and that as geoff has calculated if you do decided to drop the comp should get or be very close to 300bhp

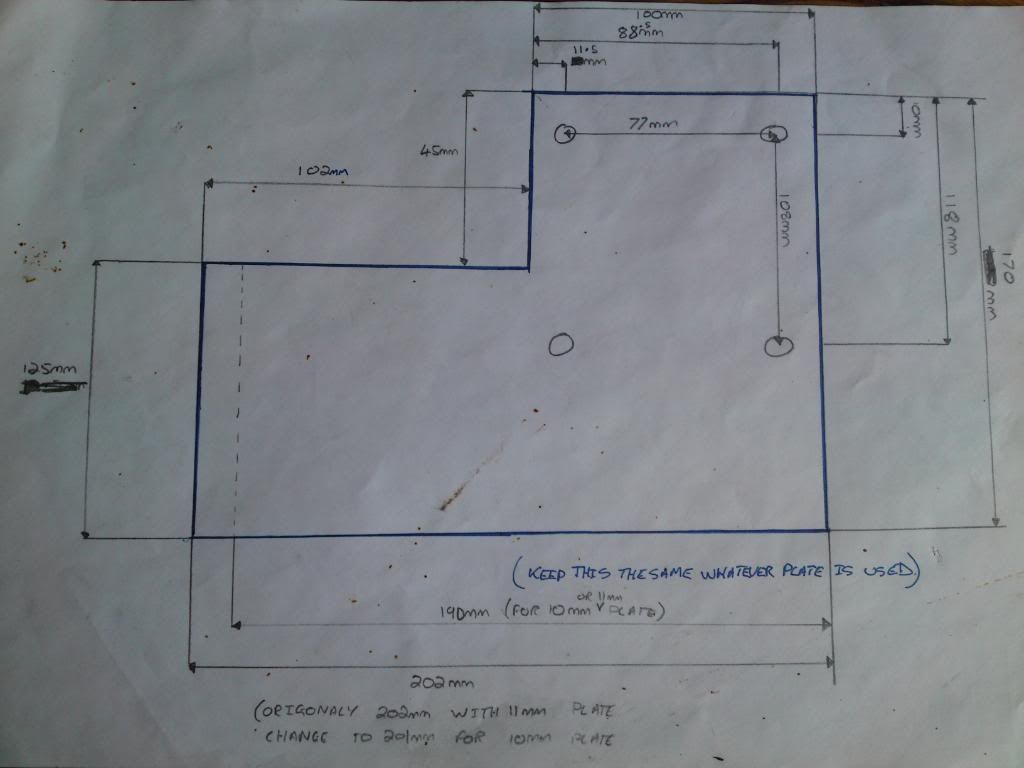

i'll load the Pics here large and let the zone resize them then anyone can save them who wants them buy clicking and viewing the larger images. mods if thats not ok fee free to adjust/remove.

The bit a the bottom about 202mm or 201mm was because i had some 11mm plate laying around i was going to use but then decided to use 10mm for ease so the dimsions should be 190mm on the inside and 201mm on the ouside.

Miss placed the drawing with the connecting block.

ive left the PCD of the rotrex bolts off as i'm not sure there the same on all sizes but there all on the rotrex website. if you do go with the C30-84 i 'll do another drawing with the possitons for the holes on i did most of the work in my head as i went along and didnt realy wright much down..oops so there may be an odd dimesion missing so if you spot one let me know and i'll get it off mine.

You can use any rubber here doesnt have to be a stadler one

Just a note i designed this to leave one "V" of the 8V pully spare on either side of the pully so that i could fit the thicker plate in and not recess it on the charger side (lots of work) but also keeps the over hand/leverage on the front charger bearing from the belt pulling to a minimum

Edit looking at this now theres afew little mods to add, so i'll do another drawing over the weekend and post it up on monday when i get back form working in irland theres nothing major just afew little bits.

theres nothing major just afew little bits.

at current with this charger mines making 188bhp 5200rpm at 8-10psi (still havent checked with the new charger as the cars SORN at the moment) so if you run it slower you should be able to get that 10psi to be peak at the red line and have a charger that you can afford to get and that as geoff has calculated if you do decided to drop the comp should get or be very close to 300bhp

i'll load the Pics here large and let the zone resize them then anyone can save them who wants them buy clicking and viewing the larger images. mods if thats not ok fee free to adjust/remove.

The bit a the bottom about 202mm or 201mm was because i had some 11mm plate laying around i was going to use but then decided to use 10mm for ease so the dimsions should be 190mm on the inside and 201mm on the ouside.

Miss placed the drawing with the connecting block.

ive left the PCD of the rotrex bolts off as i'm not sure there the same on all sizes but there all on the rotrex website. if you do go with the C30-84 i 'll do another drawing with the possitons for the holes on i did most of the work in my head as i went along and didnt realy wright much down..oops so there may be an odd dimesion missing so if you spot one let me know and i'll get it off mine.

You can use any rubber here doesnt have to be a stadler one

Just a note i designed this to leave one "V" of the 8V pully spare on either side of the pully so that i could fit the thicker plate in and not recess it on the charger side (lots of work) but also keeps the over hand/leverage on the front charger bearing from the belt pulling to a minimum

Edit looking at this now theres afew little mods to add, so i'll do another drawing over the weekend and post it up on monday when i get back form working in irland

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

Using a -64 with a 75mm pulley doesn't leave much scope for easy future power increases does it so wondering about the -74 on a larger pulley so I could always drop a pulley size for more puff? I don't want to spent £600 + the ££ for the other bits and find that I've got one thats just too big and I can't use with out an engine rebuild, then have to buy a new one any way or rebuild the engine.

If I can get a new one at a good price then game on.

Ya probly best Rich and its all new and you know no ones ragged the tats off it with out running it correctly an so on....

Theres next to nothing in the difference between the -74 and -84 IIRC as Geoff pointed out theve got the same or nearly the same graph on the rotrex website, when i asked them why they said that the difference was mainly the inlet and out let dimesions.

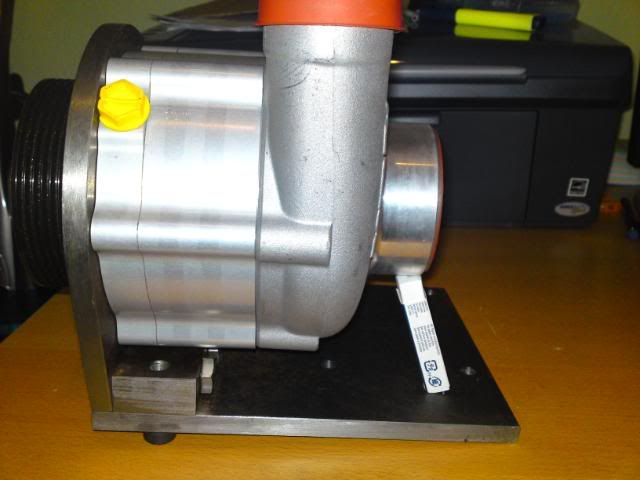

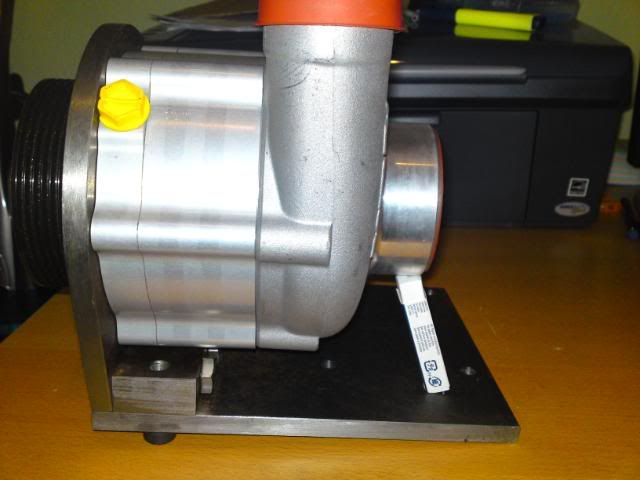

If you get the -84 youve got alot of skope the only thing looking at the bracket is that the pully in the pic is the 100mm on that the -94 i bought first came with so i dont know if you would get a much bigger pully on there before you hit the bracket.

You'd have to do some calculations and see what a -84 with a 100mm pully would do. you can also use restriction sleeves like this to "cap" the peak boost.

Stormdevelopments do the sleeves to hush hush

Theres next to nothing in the difference between the -74 and -84 IIRC as Geoff pointed out theve got the same or nearly the same graph on the rotrex website, when i asked them why they said that the difference was mainly the inlet and out let dimesions.

If you get the -84 youve got alot of skope the only thing looking at the bracket is that the pully in the pic is the 100mm on that the -94 i bought first came with so i dont know if you would get a much bigger pully on there before you hit the bracket.

You'd have to do some calculations and see what a -84 with a 100mm pully would do. you can also use restriction sleeves like this to "cap" the peak boost.

Stormdevelopments do the sleeves to hush hush

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

We used to cringe after building a new car and then watching the owner of the company, redline it all the way down the roadappletree wrote:Ya probly best Rich and its all new and you know no ones ragged the tats off it with out running it correctly an so on....

I've emailed Rotrex see what I can get from them.

I've got all the numbers it's just arranging them all.

Rich, first decide if you plan to lower your engines compression ratio as this will decide the amount of boost that you can run. Then choose your pulley ratio accordingly so as not to produce more boost than your engine can handle.

Remember, the Rotrex is very different in the way it pumps air to an Eaton, and a Rotrex will never match the torque of an Eaton. An Eaton attempts to maintain a constant boost across your full range of rpm while a Rotrex produces progressively more boost as your rpm increase. This may sound a bit like a turbocharger, but even a turbocharger has a wastegate at the turbine which works to keep the boost constant above a certain airflow (rpm and throttle dependent). A Rotrex will thus produce maximum boost at maximum rpm, and at any rpm below maximum it will produce less boost. So, if your maximum boost (at maximum engine rpm) is limited by your compression ratio, it will be even less below maximum rpm.

I know this is not what you want to hear Rich, but unless you plan to lower your compression ratio don't expect phenomenal results from a Rotrex as you will be surprised at how little boost you will be making at low rpm simply in order to limit your boost at maximum rpm.

Remember, the Rotrex is very different in the way it pumps air to an Eaton, and a Rotrex will never match the torque of an Eaton. An Eaton attempts to maintain a constant boost across your full range of rpm while a Rotrex produces progressively more boost as your rpm increase. This may sound a bit like a turbocharger, but even a turbocharger has a wastegate at the turbine which works to keep the boost constant above a certain airflow (rpm and throttle dependent). A Rotrex will thus produce maximum boost at maximum rpm, and at any rpm below maximum it will produce less boost. So, if your maximum boost (at maximum engine rpm) is limited by your compression ratio, it will be even less below maximum rpm.

I know this is not what you want to hear Rich, but unless you plan to lower your compression ratio don't expect phenomenal results from a Rotrex as you will be surprised at how little boost you will be making at low rpm simply in order to limit your boost at maximum rpm.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

Then you may very well be better off with a C30-64 with the pulleys selected to give you no more than 10psi boost at 6500rpm engine speed. I'll run some numbers and see what happens, but please don't expect miracles. In the mean time you might want to consider if it's not possible to solve your engineering probems with your Eaton, at least then you'd have 10psi more or less across your rev range, rather than 10psi only at 6500rpm.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

So long as you keep you compression ratio standard your pressure ratio (P2/P1) over the pump will be limited to around 1.7. That is to say 0.7bar of boost a 1bar atmospheric pressure. Thus, from nothing else other then a brief look at the Rotrex data sheets I can tell you that you are restricted to either a C30-64, -74 or -84 in order to flow the 0.16kg/sec of air that you will need in order to make 200hp. I must still determine, however, whether your engine will flow 0.16kg/s of air at 0.7bar boost at 6500rpm. If not, you will not make 200hp. And that's 200hp of net work output, we still have to take pumping and friction losses into account.

More to follow..

More to follow..

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

Have you both watched the mazda video i posted and the way the sleave helped to cap the boost and level it out. I know you wont be able to work out a flow graph but might be worth a email to them or a call to storm as they have had some good results from experience and trying different sleaves.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Seems a 100mm diameter pulley on a C30-84 will work well. I've done the calculations and so long as I haven't overestimated the VE of your M42 you should be able to flow just over 0.16kg/sec of air at a pressure ratio of 1.7 into an M42 spinning at 6200rpm. That means that with a 140mm crank pulley the Rotrex will be spinning at roughly 82000rpm. This is absolutely nowhere near the 120000rpm limit of the Rotrex, so there is plenty of scope to reduce the diameter of the Rotrex pulley later on if you ever get around to reducing your engines compression ratio. Also, the engines loadline passes almost directly through the zone of maximum efficiency in this setup (although it will soon move to the left of as you start reducing the pulley size)

Whatever you do, don't go reducing the pulley size until you have a firm plan for reducing your compression ratio, otherwise you will either set an artificial redline on your engine that you will have to adhere to or risk damaging it as a result of detonation.

Whatever you do, don't go reducing the pulley size until you have a firm plan for reducing your compression ratio, otherwise you will either set an artificial redline on your engine that you will have to adhere to or risk damaging it as a result of detonation.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

-

rix313

- E30 Zone Team Member

- Posts: 4957

- Joined: Fri Oct 31, 2008 11:00 pm

- Location: Silverstone

- Contact:

What sort of power would it produce for the time being? So as long as the -84 has a 100mm pulley and redline of 6200rpm it wont cause any problems?

What I'm thinking now is I have my old engine which needs a rebuild any way due to failing HG and leaking oil seals so I could very well make that the next 'project' for more power?

Rich

What I'm thinking now is I have my old engine which needs a rebuild any way due to failing HG and leaking oil seals so I could very well make that the next 'project' for more power?

Rich

Gee, there's gratitude for you. Isn't it enough to know that it will work, now you want to know how much power it will make too.

Just kidding Rich, busy working on exactly that at the moment. Will post when I have some numbers.

Your spare engine idea should work well. Build a lower compression model while you have the stock engine running in the car. You won't have any problems with the 140:100 pulley ratio on the stock engine so long as your intercooler is at least 85% efficient. As soon as you start pumping hot air into your engine you'll know all about it.

Just kidding Rich, busy working on exactly that at the moment. Will post when I have some numbers.

Your spare engine idea should work well. Build a lower compression model while you have the stock engine running in the car. You won't have any problems with the 140:100 pulley ratio on the stock engine so long as your intercooler is at least 85% efficient. As soon as you start pumping hot air into your engine you'll know all about it.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

I'm pleased for you, glad to be of help.

Right, from the above graph, at an engine speed of 6500 rpm (Rotrex speed of 86000 rpm) you'll be flowing roughly 0.165kg/sec of air. This should equate to a net engine power of roughly 152kW or 204hp. That should leave you with roughly 190hp at the flywheel at a cost of 14hp to your Rotrex (running 75% efficient) and friction. At this power (at a pressure ratio of just over 1.8 ) the air coming out of your Rotrex will be 60'C hotter than ambient, so be sure to make sure your intercooler works properly (as Appletree did with his tests) else you could land up with detonation even at low boost.

Spend some of that money you are saving on that exhaust design I recommended to you earlier. That way you can get the VE of your engine up so that you won't need more boost in order to make more power!

Right, from the above graph, at an engine speed of 6500 rpm (Rotrex speed of 86000 rpm) you'll be flowing roughly 0.165kg/sec of air. This should equate to a net engine power of roughly 152kW or 204hp. That should leave you with roughly 190hp at the flywheel at a cost of 14hp to your Rotrex (running 75% efficient) and friction. At this power (at a pressure ratio of just over 1.8 ) the air coming out of your Rotrex will be 60'C hotter than ambient, so be sure to make sure your intercooler works properly (as Appletree did with his tests) else you could land up with detonation even at low boost.

Spend some of that money you are saving on that exhaust design I recommended to you earlier. That way you can get the VE of your engine up so that you won't need more boost in order to make more power!

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

Geoff if/when you next visit the uk me n rich owe you some drinks... You wont buy your own all night! Lol.

At least you know that you can go down to an 80mm pulley like mine, get 300ish bhp an be safe.

At least you know that you can go down to an 80mm pulley like mine, get 300ish bhp an be safe.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

Ta very much gents. Will definitely try and take you up on that offer.

Matt, I couldn't get enough bandwidth to watch that video of the Miato. Service provider acting up again I think, but I'm still interested to hear what these "sleeves" are all about? Believe it or not, the problem of continously rising boost on a centrifugal pump was first solved in about 1923 by fitting a 3-speed auto gearbox to the compressor wheel. The pump literally used to change gears in order to keep its own revs, and thus boost, down. I don't think it was an idea that ever caught on though - probably not very practical. This was followed by a design that used two conical shaped pulleys in an infinitely variable drive arrangement. This was a lot smoother than the 3-speed arrangement (boost could be kept at a constant value) but it still wasn't very practical. I dare say though that someone out there still owns the rights to that idea and is still trying to perfect it, even to this day.

Matt, I couldn't get enough bandwidth to watch that video of the Miato. Service provider acting up again I think, but I'm still interested to hear what these "sleeves" are all about? Believe it or not, the problem of continously rising boost on a centrifugal pump was first solved in about 1923 by fitting a 3-speed auto gearbox to the compressor wheel. The pump literally used to change gears in order to keep its own revs, and thus boost, down. I don't think it was an idea that ever caught on though - probably not very practical. This was followed by a design that used two conical shaped pulleys in an infinitely variable drive arrangement. This was a lot smoother than the 3-speed arrangement (boost could be kept at a constant value) but it still wasn't very practical. I dare say though that someone out there still owns the rights to that idea and is still trying to perfect it, even to this day.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti

Its cought on geoff theres a company who makes a 2 or 3 speed box but its twice as long as a standard charger and very dear.

The sleaves fit in the inlet and restrict the amount of air the charger can suck in and limit boost but what it ment in the dyno test in the vid is that boost gets to 8psi then seams to 'hold' that boost with a more liniar rise.

Could you use realplayer to download the vid then watch it? I normaly get the 'download this video' flash up if you got to the top right corner of video window.

There was someone running a c30.94 at 10psi on a 1.6ltr saxo using a large reduction sleeve.

The sleaves fit in the inlet and restrict the amount of air the charger can suck in and limit boost but what it ment in the dyno test in the vid is that boost gets to 8psi then seams to 'hold' that boost with a more liniar rise.

Could you use realplayer to download the vid then watch it? I normaly get the 'download this video' flash up if you got to the top right corner of video window.

There was someone running a c30.94 at 10psi on a 1.6ltr saxo using a large reduction sleeve.

You should never underestimate the predictability of stupidity

M42 Supercharged 285bhp + M3 6speed box

I follow. Sounds like the same principle as the DPV (dispositif pre-rotation variable) device that Jean-Pierre Boudy put on the inlet to the compressor on the 1985 Renault F1 cars, as well as some of the R5Turbos. It worked by controlling the flow of air through the compressor. The advantage of the DPV device is that it is adjustable (they typically operated it off the throttle linkage). Not quite the same as the sleeve that you described, but I believe it has the same effect. It works by redirecting the flow of air over the turbine wheel in order to reduce the pressure drop over the compressor at a given value of mass-air-flow through the compressor (It essentially fouls the aeodynamic effciency of the compressor wheel). I see no reason why a DPV could not be fitted to a Rotrex in order to maintain near constant boost despite increasing compressor speed at higher engine speed.appletree wrote:The sleaves fit in the inlet and restrict the amount of air the charger can suck in and limit boost but what it ment in the dyno test in the vid is that boost gets to 8psi then seams to 'hold' that boost with a more liniar rise.

"It is amazing how many drivers, even at the Formula-1 level, think that brakes are for slowing the car down." - Mario Andretti