E30 M3 minor rust repair (few finished pic's)

Moderator: martauto

- ChemicalAl

- E30 Zone Regular

- Posts: 565

- Joined: Mon Sep 22, 2008 11:00 pm

- Location: Sydney

I too have been stuck in Holyhead for more than 6 hours........Self harm wasn't a million miles away!

Alpine White (but then i'm biased)!

Amazing work.......can't wait for the next update!

Alpine White (but then i'm biased)!

Amazing work.......can't wait for the next update!

1987 E28 528i Diamond Black 74k

1986 E28 525e Saturn Blau 72k

1988 E28 525i 56k

1987 E28 525e 51k

1991 E32 730i SE Granite Silber 75k

1988 E30 316 Black 81k

1992 E30 318i Touring Diamond Black 43k

1990 E30 325i Touring Alpine White 2 65k

1986 E30

1986 E28 525e Saturn Blau 72k

1988 E28 525i 56k

1987 E28 525e 51k

1991 E32 730i SE Granite Silber 75k

1988 E30 316 Black 81k

1992 E30 318i Touring Diamond Black 43k

1990 E30 325i Touring Alpine White 2 65k

1986 E30

- Returnof318i

- E30 Zone Regular

- Posts: 277

- Joined: Sun Jan 23, 2005 11:00 pm

This thread is fantastic,

"fabricate.... (like that word?, sounds real fancy for beating the shit out

of a piece of steel till it roughly resembles the bit you hacked off) "

PMSL

Only thing i will say is, You have too much money.

"fabricate.... (like that word?, sounds real fancy for beating the shit out

of a piece of steel till it roughly resembles the bit you hacked off) "

PMSL

Only thing i will say is, You have too much money.

-

iDreamBeemer

- E30 Zone Camper

- Posts: 1177

- Joined: Mon Feb 14, 2005 11:00 pm

- Location: Camberley

No such thing as too much money!! Only people that don't know how to spend it properly!Only thing i will say is, You have too much money.

Regarding "damage" when dipping. I've heard that's relatively common. Not wonderful when the dipping is several hundred pounds.

Obviously you're doing this as and when time allows. How much do you estimate something like this would cost a customer? Curious mainly, not about to send you a shell.

Obviously you're doing this as and when time allows. How much do you estimate something like this would cost a customer? Curious mainly, not about to send you a shell.

- Returnof318i

- E30 Zone Regular

- Posts: 277

- Joined: Sun Jan 23, 2005 11:00 pm

Dont get me wrong, if i had enough money and the equipment he has, an rb26 powered capri, a jag v8 supercharged capri, and a 325 built especially for drifting would be well and truly mine!

Thanks one and all for your kind words.

Jon_Bmw

Can the dents be pushed out as you must have reasonable access.

Theres only 2 real dents as such, the one you see in the

pic and another on the sill, the other 3 are more dings than dents.

Yep, they should push out ok, but they will leave a mark in the metal

work requiring more effort to totally repair them. Not the end of the world

but is just a little frustrating after grafting the new roof on without putting

a dent in it. To dwell on it would raise one's stress, of which I need no more of.

One thing I have always been keen to find out, is how do you chop the metal so neatly, especially curved sections? Also what thickness is the metal you are replacing?

To hack bits off the shell we use...

and

and for cutting the sheet steel to go back on, a left hand curved, a right

hand curved and a straight cut, metal snips.

The sheet of steel used for repairs is 0.8 mm and is identical to the thickness of the oem metal coming out, except for the shock towers metal

photo'ed earlier on, that was closer to 2mm thick.

Morat

Wow, how much does it cost to have a shell dipped?

£930 for acid dipping and £1050 for primer dipping is what

Visa say I need to find.

Theo325

Why do you only want to paint it a sport evo colour?

No complicated reason, just like them two.

Returnof 318i

Only thing i will say is, You have too much money.

and my bank manager says I have too much debt, bless him.

Rich_W

Regarding "damage" when dipping. I've heard that's relatively common. Not wonderful when the dipping is several hundred pounds.

I had read that too, so wasn't shocked.

How much do you estimate something like this would cost a customer?

To be honest I haven't been counting the hours on this and I haven't

a clue what the bill would add up to. What I can say is I'm almost sure I

wouldn't take on to do this much work on a shell for someone else, money

would be nice but the time spent on it can't be repayed.

Jon_Bmw

Can the dents be pushed out as you must have reasonable access.

Theres only 2 real dents as such, the one you see in the

pic and another on the sill, the other 3 are more dings than dents.

Yep, they should push out ok, but they will leave a mark in the metal

work requiring more effort to totally repair them. Not the end of the world

but is just a little frustrating after grafting the new roof on without putting

a dent in it. To dwell on it would raise one's stress, of which I need no more of.

One thing I have always been keen to find out, is how do you chop the metal so neatly, especially curved sections? Also what thickness is the metal you are replacing?

To hack bits off the shell we use...

and

and for cutting the sheet steel to go back on, a left hand curved, a right

hand curved and a straight cut, metal snips.

The sheet of steel used for repairs is 0.8 mm and is identical to the thickness of the oem metal coming out, except for the shock towers metal

photo'ed earlier on, that was closer to 2mm thick.

Morat

Wow, how much does it cost to have a shell dipped?

£930 for acid dipping and £1050 for primer dipping is what

Visa say I need to find.

Theo325

Why do you only want to paint it a sport evo colour?

No complicated reason, just like them two.

Returnof 318i

Only thing i will say is, You have too much money.

and my bank manager says I have too much debt, bless him.

Rich_W

Regarding "damage" when dipping. I've heard that's relatively common. Not wonderful when the dipping is several hundred pounds.

I had read that too, so wasn't shocked.

How much do you estimate something like this would cost a customer?

To be honest I haven't been counting the hours on this and I haven't

a clue what the bill would add up to. What I can say is I'm almost sure I

wouldn't take on to do this much work on a shell for someone else, money

would be nice but the time spent on it can't be repayed.

Last edited by x-works on Mon Jan 26, 2009 10:00 pm, edited 1 time in total.

- stevesingo

- E30 Zone Newbie

- Posts: 77

- Joined: Mon May 15, 2006 11:00 pm

- Location: Cumbria

I can't believe they damaged your shell. After our conversation I'm sure you spoke to them regarding damage, and still they can't prevent it.

You are a hero, though. Is the race on for finished cars?

When do you expect to be finished?

Best of luck

Steve

You are a hero, though. Is the race on for finished cars?

When do you expect to be finished?

Best of luck

Steve

Howya Steve,

Yeah I got the complementary dents too , still it's not like my panels

, still it's not like my panels

were mirrior finish to start with, a few more hours on the paint prep end should

have them sorted though.

As for the race for the finish I'm fairly certain you got me on that one,

I'm up to final demand notices on the credit cards now, it'll not take

them much longer to find me I'd like to have it finished for the

I'd like to have it finished for the

summer, we'll see what happens.

Hopefully you'll stay ahead so I can see how it should be done.

(For anyone that doesn't know Steve, he's also doing a full

restoration on an M3 at the moment, only better. The first 2 pictures

in the shell dipping sequence above are of his car.)

Yeah I got the complementary dents too

were mirrior finish to start with, a few more hours on the paint prep end should

have them sorted though.

As for the race for the finish I'm fairly certain you got me on that one,

I'm up to final demand notices on the credit cards now, it'll not take

them much longer to find me

summer, we'll see what happens.

Hopefully you'll stay ahead so I can see how it should be done.

(For anyone that doesn't know Steve, he's also doing a full

restoration on an M3 at the moment, only better. The first 2 pictures

in the shell dipping sequence above are of his car.)

Last edited by x-works on Mon Jan 26, 2009 9:55 pm, edited 1 time in total.

Thanks for the reply, I'm suprised snips actually cut 0.8mm of metal, impressed actually. Just don't get your fingers caught!

Steve, you best be getting some photos of yours up then! Or at least a link to some.

Steve, you best be getting some photos of yours up then! Or at least a link to some.

- stevesingo

- E30 Zone Newbie

- Posts: 77

- Joined: Mon May 15, 2006 11:00 pm

- Location: Cumbria

To save me the hassle of posting it all up again, here is the link to the thread on s14power.com...

http://board.s14power.com/showthread.php?t=2508

Registration is required unfortunately.

Steve

http://board.s14power.com/showthread.php?t=2508

Registration is required unfortunately.

Steve

By far the best thread I've read on here yet!! Was mega impressed with the roof work, then the fabrication of all those small bits..... Then seeing it back from being dipped?? OMG that's ace. U must have the patience of a saint! Amazin stuff.

-

scottidog

- E30 Zone Regular

- Posts: 575

- Joined: Thu Jun 26, 2008 11:00 pm

- Location: bradford, west yorkshire

i know its been said twice already! but i just cant beleive they handed that car back over to you with them dents in the shell. The F*£CKING cheek of it. They surely have some sort of resposibility for handing a shell back to the customer the same shape as it was presented. Afterall they do specialise in this sh1t. OMG

Evening all,

Sorry for the delay in updates but unfortunately we had a tough decision

to make. With the current recession and global economic

downturn we had to do some long hard thinking and in the end both

came to the same regrettable decision...

It's too f**kin cold to be working out in the garage during december.

Alas by mid January the temperature was picking up and the snow had melted away.

Before I go any further I'd like to explain that it wasn't to cold for us in the garage,

we were concerned that the low temperatures would play havoc with the paints and

sealers going on the car next and afraid that the metalwork underneath might be

damp and the underbody shultz going on might trap dampness in to the shell.

Thats our story and we're sticking with it.

So back to the work, first things first, heat...

and then back to where we left off last time, the underneath of

the shell was sanded and ready for a good coat of primer.

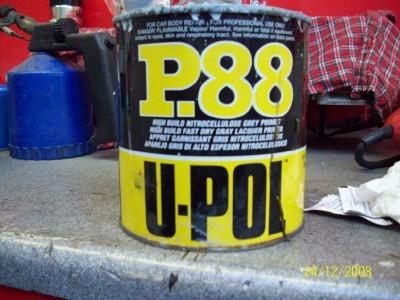

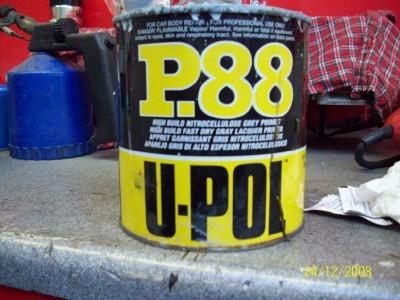

We have used this primer in the past and have found it good. Its

Upol P88 and can either be hand painted or thinned out and sprayed.

For under the car we went with a good heavy hand painted coat....

after this it was time for seam sealer. We used two types of sealer for this,

I had 3 quarters of a can of Upol sealer left over from another job which

was still good to go and also bought another 2 cans of 3m to finish the job off....

in the second picture above you can see the special brush that seam sealer

comes with to reproduce factory finish effect. I don't like using that brush

so instead you can see in the 1st pic the brush I prefer to use. It's a normal

half inch brush with about 1cm cut off the end of the bristles.

On the application itself basically you apply the sealer to any panel gap on the

underside of the car where water can creep in

to where you don't want it....

as well as any brackets on the underside of the car, although water

getting in to the car isn't a concern here what does happen

is water seeps in between the bracket and the floorpan of the car and stays there

slowly but surely rotting the surrounding metalwork....

with the underneath done it was time to move on and do the inside,

the boot and the engine bay.....

on the whole the seam sealer was fairly straight forward to put on,

if a little time consuming, there was however one b**tard of

an area to get to, the compartment underneath the front scuttle panel....

I'm pretty sure I got more on me than in there.

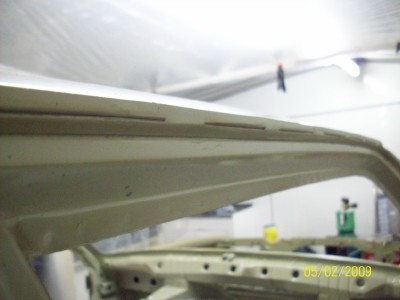

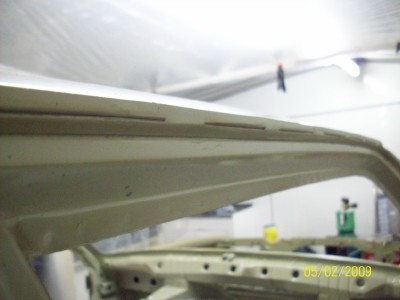

The next area that needed sealing was along the roof gutters and

rear windscreen clip. This will be visible under the final spray job

so it needs to be a little neater...

so we use this stuff, same principle, it's a seam sealer but instead of brush on

it's in a tube and can be squirted a little neater....

it can be put on using a normal silicone gun but with the temperatures

still a little low the stuff is fairly stubborn in the tube so we used an air gun to apply it.....

next job after that was to rebond the roof. When the shell was dipped

all sealer and bonder was disolved so it didn't make much sense to bond

the roof before dipping, so we done it now....

With all that done we could move on to Shultzing the underneath of the shell.

Before this started we "masked" off the section off the garage the car was in.

This was not so much to stop the Shultz getting on everything, it's a reasonably

tidy application, but instead to stop the dust from the sanding which was

coming next from getting everywhere. The car itself was masked of for

shultzing....

and as you may have noticed from some of the earlier pic's all

the little threaded nuts and brackets where you don't want the

stone gaurd to get were masked up.

For the underseal itself we decided to go with the 3m gear

thanks to some advice from a member on here RJB6 (thanks Roy).

The stuff comes in foil packets and cost 18euro a pack....

The other thing needed was the special gun used to apply the stuff, it cost 60 euro....

the gun is a little on the expensive side compared to other products guns

but the one upside, unlike others, is that the sealer doesn't run through

this style of gun so you don't have to clean it out after or worry about it clogging up.

The air pressure comes out of the gun and siphons the gue

up out of the packet and splatters it on to the shell....

Having not used this stuff before I made some "complicated calculations" on how much

exactly I would need to do the whole underside and came to the conclusion

that 6 packs would be sufficient.....

and the result....

yeah, 6 packs covered one third of the underneath, f**kin egit

so back to the motorfactors again.

12 packs later....

the finish is sweet, looks more or less identical to the factory stuff....

Thats about it for tonight. Have a load more pics online and hope

to get them up here tomorrow evening. Heads melted from

typing all this crap now, so, till tomorrow.....

Sorry for the delay in updates but unfortunately we had a tough decision

to make. With the current recession and global economic

downturn we had to do some long hard thinking and in the end both

came to the same regrettable decision...

It's too f**kin cold to be working out in the garage during december.

Alas by mid January the temperature was picking up and the snow had melted away.

Before I go any further I'd like to explain that it wasn't to cold for us in the garage,

we were concerned that the low temperatures would play havoc with the paints and

sealers going on the car next and afraid that the metalwork underneath might be

damp and the underbody shultz going on might trap dampness in to the shell.

Thats our story and we're sticking with it.

So back to the work, first things first, heat...

and then back to where we left off last time, the underneath of

the shell was sanded and ready for a good coat of primer.

We have used this primer in the past and have found it good. Its

Upol P88 and can either be hand painted or thinned out and sprayed.

For under the car we went with a good heavy hand painted coat....

after this it was time for seam sealer. We used two types of sealer for this,

I had 3 quarters of a can of Upol sealer left over from another job which

was still good to go and also bought another 2 cans of 3m to finish the job off....

in the second picture above you can see the special brush that seam sealer

comes with to reproduce factory finish effect. I don't like using that brush

so instead you can see in the 1st pic the brush I prefer to use. It's a normal

half inch brush with about 1cm cut off the end of the bristles.

On the application itself basically you apply the sealer to any panel gap on the

underside of the car where water can creep in

to where you don't want it....

as well as any brackets on the underside of the car, although water

getting in to the car isn't a concern here what does happen

is water seeps in between the bracket and the floorpan of the car and stays there

slowly but surely rotting the surrounding metalwork....

with the underneath done it was time to move on and do the inside,

the boot and the engine bay.....

on the whole the seam sealer was fairly straight forward to put on,

if a little time consuming, there was however one b**tard of

an area to get to, the compartment underneath the front scuttle panel....

I'm pretty sure I got more on me than in there.

The next area that needed sealing was along the roof gutters and

rear windscreen clip. This will be visible under the final spray job

so it needs to be a little neater...

so we use this stuff, same principle, it's a seam sealer but instead of brush on

it's in a tube and can be squirted a little neater....

it can be put on using a normal silicone gun but with the temperatures

still a little low the stuff is fairly stubborn in the tube so we used an air gun to apply it.....

next job after that was to rebond the roof. When the shell was dipped

all sealer and bonder was disolved so it didn't make much sense to bond

the roof before dipping, so we done it now....

With all that done we could move on to Shultzing the underneath of the shell.

Before this started we "masked" off the section off the garage the car was in.

This was not so much to stop the Shultz getting on everything, it's a reasonably

tidy application, but instead to stop the dust from the sanding which was

coming next from getting everywhere. The car itself was masked of for

shultzing....

and as you may have noticed from some of the earlier pic's all

the little threaded nuts and brackets where you don't want the

stone gaurd to get were masked up.

For the underseal itself we decided to go with the 3m gear

thanks to some advice from a member on here RJB6 (thanks Roy).

The stuff comes in foil packets and cost 18euro a pack....

The other thing needed was the special gun used to apply the stuff, it cost 60 euro....

the gun is a little on the expensive side compared to other products guns

but the one upside, unlike others, is that the sealer doesn't run through

this style of gun so you don't have to clean it out after or worry about it clogging up.

The air pressure comes out of the gun and siphons the gue

up out of the packet and splatters it on to the shell....

Having not used this stuff before I made some "complicated calculations" on how much

exactly I would need to do the whole underside and came to the conclusion

that 6 packs would be sufficient.....

and the result....

yeah, 6 packs covered one third of the underneath, f**kin egit

so back to the motorfactors again.

12 packs later....

the finish is sweet, looks more or less identical to the factory stuff....

Thats about it for tonight. Have a load more pics online and hope

to get them up here tomorrow evening. Heads melted from

typing all this crap now, so, till tomorrow.....

Last edited by x-works on Fri Mar 04, 2016 10:38 pm, edited 1 time in total.

I've said it before in this thread but i'll say it again: Your attention to detail is superb. The precision, skill and patience involved in this rebuild is staggering.

Plus it makes excellent reading!

Have you set any kind of timescale for completion, or is it more of a case of 'it's done when it's done'?

Plus it makes excellent reading!

Have you set any kind of timescale for completion, or is it more of a case of 'it's done when it's done'?

-

beardymat

- E30 Zone Squatter

- Posts: 1979

- Joined: Tue Jun 14, 2005 11:00 pm

- Location: sheffield, city of steel, and rust apparently

aaahhh! good old sh!t in a bag... havnt seen that in a while mostly due to the cost and the fact it doesnt go far but its good stuff and as hard as a b@st@rd.

i cant tell you how much i want to pull my car apart and get it dipped, proper blank canvas stuff and just about the only way to end up with a rust free shell.

i cant tell you how much i want to pull my car apart and get it dipped, proper blank canvas stuff and just about the only way to end up with a rust free shell.

No longer self employed but still available for welding duties.

-

Simon13

- The longest resto in the world !

- Posts: 22697

- Joined: Mon Jan 10, 2005 11:00 pm

- Location: Camberley, Surrey don't u know

Heroic! you've covered more areas underneath with seam sealer and underseal than the factory. Alot of the brackets on the rear and along the transmission tunnel are not protected like you guys have done

Thats a better job than factory! but i expect cost for them was an issue

Thats a better job than factory! but i expect cost for them was an issue

-

bmwe30mtech

- Engaged to the E30 Zone

- Posts: 5288

- Joined: Thu Feb 03, 2005 11:00 pm

Amazing work! Im glad to see this car being done properly, I havent seen anybody else use that proper factory look underseal yet. It looks brand new, well done.

Do you find that when your using grey stripe it starts to dry on the brush after about 10 minutes of working with it? I find it also partly dissolves the primer and mixes in with it a bit, perhaps its meant to.

I would love to do this sort of resto one day to an M3 or M3 cab.

Once again, great work

Do you find that when your using grey stripe it starts to dry on the brush after about 10 minutes of working with it? I find it also partly dissolves the primer and mixes in with it a bit, perhaps its meant to.

I would love to do this sort of resto one day to an M3 or M3 cab.

Once again, great work

1988 M3 EvoII, Macau Blue/EvoII trim

1989 325i Sport M Tech II, Diamond Black/Black leather

1989 325i Sport M Tech II, Diamond Black/Black leather

-

Simon13

- The longest resto in the world !

- Posts: 22697

- Joined: Mon Jan 10, 2005 11:00 pm

- Location: Camberley, Surrey don't u know

My 2 door has this in the repaired sections of the car!bmwe30mtech wrote:Amazing work! Im glad to see this car being done properly, I havent seen anybody else use that proper factory look underseal yet. It looks brand new, well done.

Do you find that when your using grey stripe it starts to dry on the brush after about 10 minutes of working with it? I find it also partly dissolves the primer and mixes in with it a bit, perhaps its meant to.

I would love to do this sort of resto one day to an M3 or M3 cab.

Once again, great work

-

bmwe30mtech

- Engaged to the E30 Zone

- Posts: 5288

- Joined: Thu Feb 03, 2005 11:00 pm

Oh right I didnt realise, to be honest mine had similar stuff used also (I think, Matt will know!)

Talking of your 2 door...any progress? Pm me rather than spam this.

Talking of your 2 door...any progress? Pm me rather than spam this.

1988 M3 EvoII, Macau Blue/EvoII trim

1989 325i Sport M Tech II, Diamond Black/Black leather

1989 325i Sport M Tech II, Diamond Black/Black leather