Supercharged M20, forged pistons chipped/cracked!!

Posted: Sun Nov 01, 2015 8:32 pm

Hello all.

I'm new on this forum so hello from me.

I'm a heating engineer/plumber from Bristol and I love cars.

I have just got an old flame back in my life... the e30.

I bought my car a few months ago from an enthusiast with a supercharged m20 in it.

I have been experiencing some engine issues and would like to share my experience in the hope of getting some sound advice/direction.

History:

The engine is an m20 from an E30 325. It was put together last year by the previous owner from a bottom end and top end built by a chap called Byron in Wales.

The spec is confirmed with receipts and as follows:

Ireland Engineering 135mm H-Beam rods - M20 spec - include ARP bolts

Ireland Engineering MLS Head Gasket - M20

Ireland Engineering Oil Pan Windage Tray - M20

Ireland Engineering/Ross Racing Custom Forged Pistons - M20 (885 head, 85mm bore, 8.5:1 comp for 135mm rods, 84mm stroke)

ARP head bolts

Lightened flywheel

I believe this is somewhere near a 2.9 stroker.

The head is apparently re-worked but I cant confirm or get confirmation on exactly what has been worked.

Rotrex C30 94 Supercharger kit

Stage 3 DriveTorque clutch

S80 Pro ECU and DTA wiring harness

2.5l swirl pot

Red Top lift pump

Bosch 044 pump and twin filters

VR6 coil packs

Magnecore HT leads

Custom CAT Cam 264 Degree- full specs available

Nice 6 branch exhaust manifold

Bosch 42lb / 440cc injectors

436BHP, 360ft/lbs at the flywheel - (data taken from rolling road during my ownership)

Here is the story:

I bought the car knowing that there was going to be a little work to do to get it ready for some track use. The engine had covered 4000 miles running on a ”˜safe’ map that was done when this engine was originally put together. It was long overdue a proper map and had clearly not been given a proper run for its money. I was also told that there was a rev limiter on it, set to 5k which was done at the time of the original map. The original map was clearly quite rich.

I loved the look of the car, I really liked the guy I bought the car from so I had some faith that it should be ok. The car is quite well known and has appeared in a few magazines and has won numerous trophies at custom car shows.

Once I got the car home I had covered 30/40 miles and it was clear I needed to make sure the engine (being the most expensive bit) needed to be tuned properly before driving it again. I have had other issues with the car that I am dealing with (wiring & brakes to name a few) but the issue I want to get to the bottom of most is the engine issue I have recently discovered.

Firstly it may be worth mentioning that the previous owner is not what I would consider a driver, he is a custom car guy but doubt he will ever have driven the car like I drive mine. He makes a car look great, is a brilliant fabricator but my attention to detail performance wise isn’t his priority. This is by no means a diss on him, I’m mearly pointing out that I don’t believe he would have necessarily cared about the little issues I found which have lead me to my discovery, enough to have found them himself for some time, if at all. I like the way a car looks, I love a clean car and i’m very particular but through the years I have seen enough engine trouble to know that a catastrophic failure on track is a terrible experience (engine blew up on the Nurburgring a few years ago to name one) and before a car goes anywhere near a track, the engine needs to be in tip top condition. I probably didn’t look hard enough at it when buying the car in the first place TBH. I say all this so as not to hold him personally responsible in this report, if he should read this - I am not making a public attack. However if he should read this and want to offer some advice or help in some way, he is very welcome”¦ I’m sure he will at least regret verbally guaranteeing the engine once he has read to the bottom.

I arrived home from purchasing it.

I noticed the engine oil level was on the minimum. I called the previous owner and he apologised for not checking and confirmed he was using 5w 30, fully synth.

Personally I think 5w 30 is too thin for this particular spec but the oil debate is too much for now - needless to say, running the engine oil this low isn’t ideal. I topped it up.

I planned an oil change with 10w 50 as its not my daily, when installing an oil cooler as it doesn’t have one.

I also planned on fitting an oil temp sensor/gauge as it doesn’t have one of these either.

I noticed the engine (which has no idle control valve) was very lumpy at idle and missed a little when cruising and the engine cut out when floored.

I thought the rev limiter was the cut out issue, although it was hard to determine exactly if it cut out at the same rpm or not.

I also noticed that the coolant temperature gauge was only running at 60 ish.

I booked the car in for a rolling road tune at Circuit Motors (next to castle Combe) as they knew the car from the previous owner and had set up the original map it was running on when I got it. I’ve never used them before, they were very difficult to get an appointment with but they said they knew the engine builder Byron and that they would regroup with him to check on all specs ready for the final tune. I thought this sounded the best option rather than finding a different tuner, however even 6 weeks later this hadn’t happened so I was beginning to loose faith. I finally managed to get it booked in albeit without the consult from Byron.

Before the tuning date around a month ago I carried out a few checks. I charged the battery, started the car, checked the usual stuff. It was wierdly only firing on 5 cylinders. I checked the plugs - all an even colour. On further inspection one of the porcelain ends was loose! It was from the cylinder closest the front (cylinder 1, I believe)

I did some research on the plugs that were used. They were Bosch Super Plus WR7DC. The gaps were 0.029 to 0.031”a These are ok for a well tuned car but maybe not perfect for a 400 odd hp car with a supercharger.

I put in some NGK BPR8ES plugs gapped to 0.025”a

The engine took a while to fire but was fine once going, still lumpy on idle but not as bad as before.

On the drive over to Circuit Motors, another 20/30 miles, the rev limiter had miraculously gone. I think the spark plugs were not quite as cold as they need to be and the gaps were too big? It was like chalk and cheese. No missing a beast either.

The car was strapped down on the rollers and Layton at Circuit Motors went about his work. As we couldn’t get hold of Byron to find out if the springs were uprated in the head or even exactly what work was done to the head and the previous owner couldn’t remember - rev limit unsure and so was set to 7k after running it for an hour or so.

All seemed well. The result was 436BHP, 360ft/lbs at the flywheel with 19psi boost at 6700rpm. This is quite a bit less than the previous owner thought it would do but I thought this was a sensible good result. The C30 Rotrex supercharger is only rated to circa 440bhp anyway.

The car was unstrapped and Layton went out for his final check drive and was gone for quite a while.

20 minutes later he limped into the forecourt with an overheating car.

The coolant temperature on the laptop from the DTA ECU sensor showed 105 degrees and this was assuming of course that there was water surrounding the sensor. The coolant gauge was still only at 75 so it was clear that this was completely wrong although Layton had been reading his own temperatures from the laptop.

We checked the water level which was low, put water in, bled it etc the temps all dropped and the car seemed to start and run fine. There were no signs of anything else wrong so we assumed that the level had been too low or an air lock or ”¦.. anyway, it was fine now”¦..so test it”¦.

So off he went again for his test.

He limped in pretty quickly and it was clear there was a water leak, the clutch had been slipping and water was gushing through the bell housing and out the bottom from somewhere up high but below the head. It took us ages to find where it was coming from, we had it on the ramps, it was very difficult to see. As soon as the engine was turned off and the steam cleared, the least couldn’t be seen.

Long story short, the car was run far too long without the correct amount of coolant in my opinion but we eventually found the problem as being a cracked freeze plug which only seemed to open up when the engine was running and up to a temperature.

I was gutted and concerned about the whole experience.

The car was trailered home.

Once it was home I was obviously going to worried about the head/head gasket etc.

I set about replacing the freeze plug, which I did in situ and it was the one furthest into the bulkhead!

I checked the spark plugs to find number 5 to be much darker than the rest. I decided to get another set of new plugs, re gapped them then put all the bits back together, put a new coolant sensor in (to match the gauges) bled properly etc and got it running. All seemed good.

The oil had no signs of water and the water had no signs of oil. Also it seemed to pass a hydrocarbon test.

There was some blow by but I had read that this can be normal on forced induction engines.

Road test.

Wow. The car ran like a dream on high output although a touch lumpy down below. Really fast. Nice.

I did notice however that at full chat high revs (I didn’t hit the limiter though) it ran really well but there was a slight pinging or rattling noise.

On my return to home after 15 miles I looked into the engine bay to find oil all around the bottom of the block near the bitch tube. It looked as though the oil was leaking from the top and the bottom of this tube. I thought maybe the rattling noise was down to the spring on this tube being moved erratically as the blow by (which hasn’t been managed properly yet) pushes its way out a bit.

I checked cylinder number 5 and it was dark again.

Research led me to the breathing set ups on forced induction cars where some people just vent to atmosphere and some through other means but it was clear from the open to atmosphere set up that I have that the blow by really needed to be managed as clearly crankcase pressure was high.

I took the inlet manifold off to get the bitch tube out to sort the issue of the leak whilst thinking about the dark plug. I have planned an electric crankcase evac pump to suck the crankcase pressure out. More later.

The inlet manifold gasket had oil between the gasket and the head and it was clear some of the leaking was from here! The manifold didn’t come with its rocker cover bracket which i ordered up. Maybe it was too loose without the brace?

To be honest, oil seemed to be a little everywhere, something I should maybe expect with lots of forced induction and no proper crankcase evac/ventilation. Some will say there shouldn’t be any blow by anyway”¦ maybe they are right..

Compression tests all came out good, 170-180 for all.

As the manifold was out, I sent all the injectors off to get tested and cleaned to see if one was running rich, maybe explaining the dark plug. The results were inconclusive as they were all fairly similar.

I plan to somehow test the VR6 coil pack but haven’t as yet properly researched this..

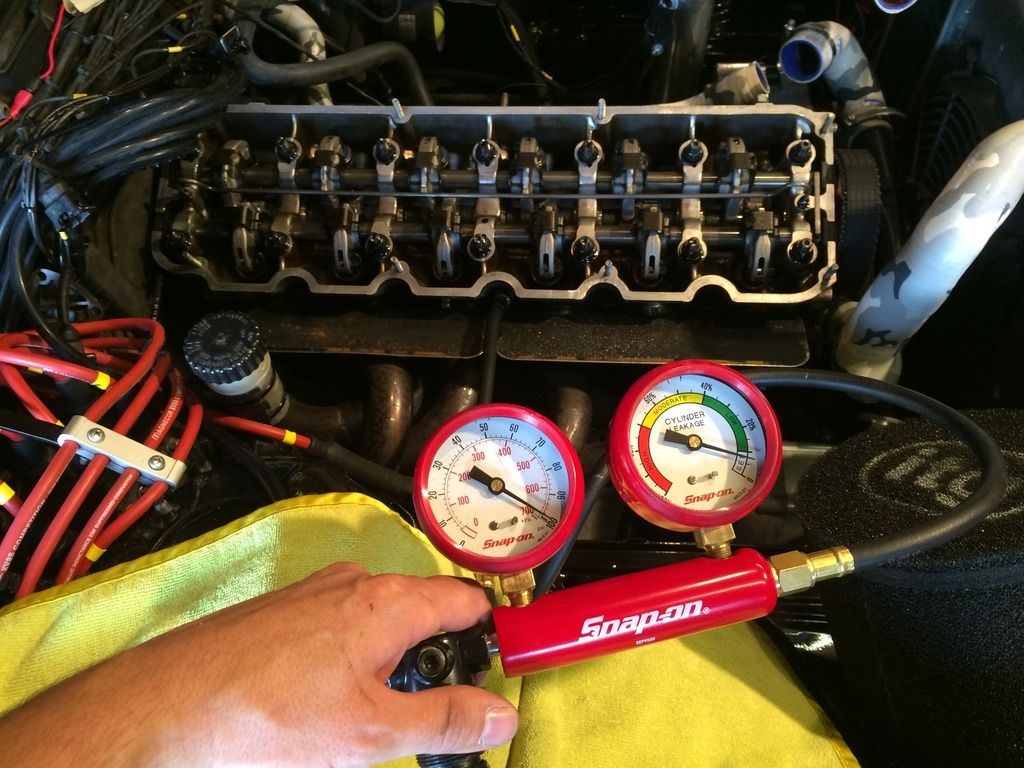

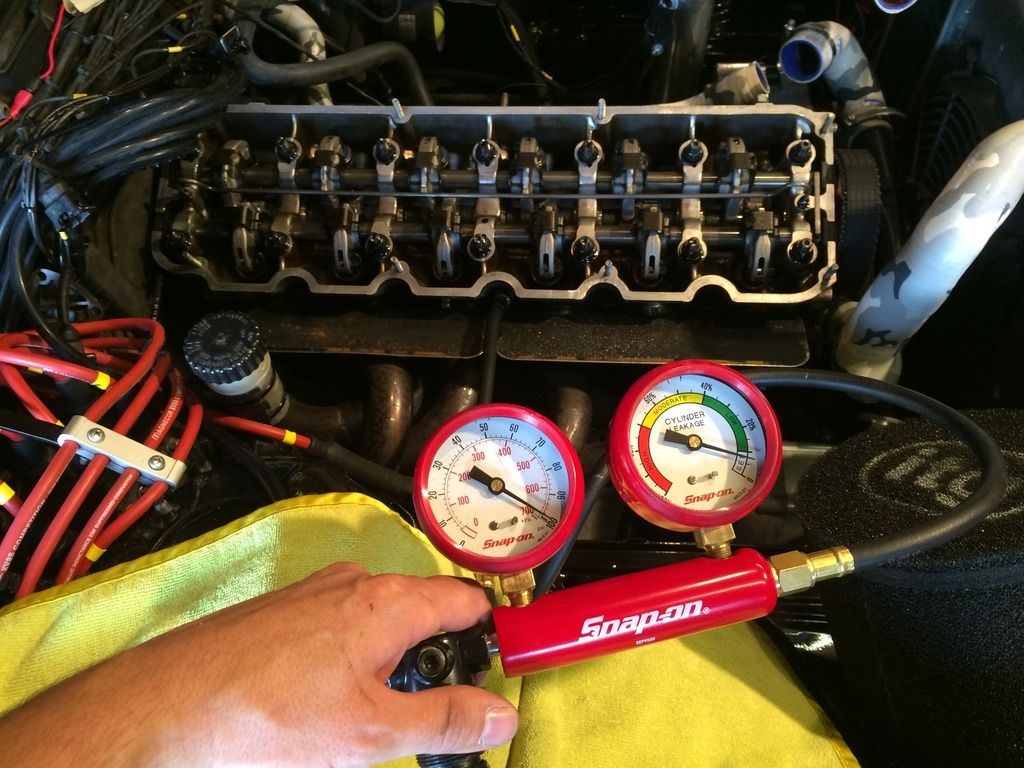

I also carried out a leak down test and found there was 20% more blow by on cylinder 4, 15% cylinder 5 and 10% cylinder 6. All the others where spot on. The air seemed to be passing the rings rather than the valves etc but I’m not an expert. However this was all enough for me to justify pulling the head which I did.

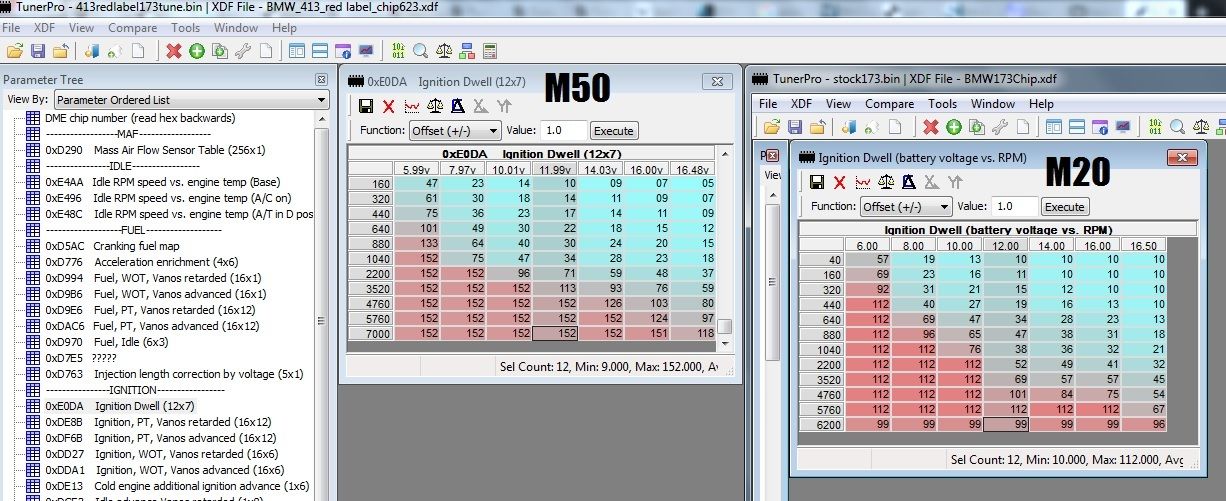

Good pistons leak down reading:

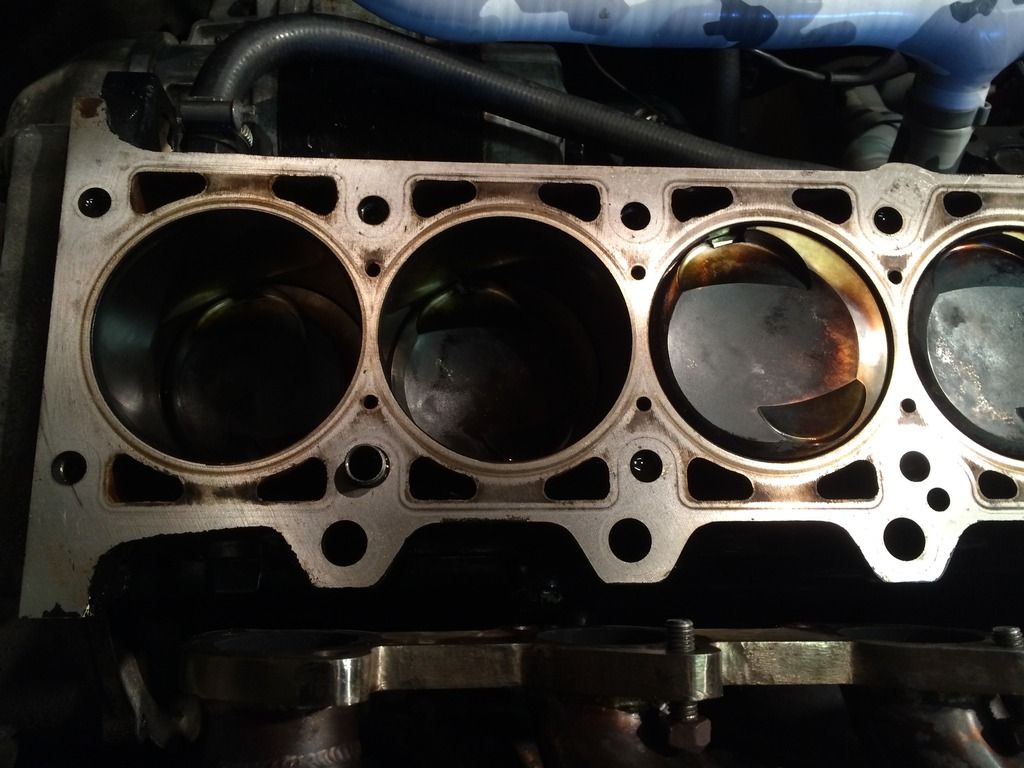

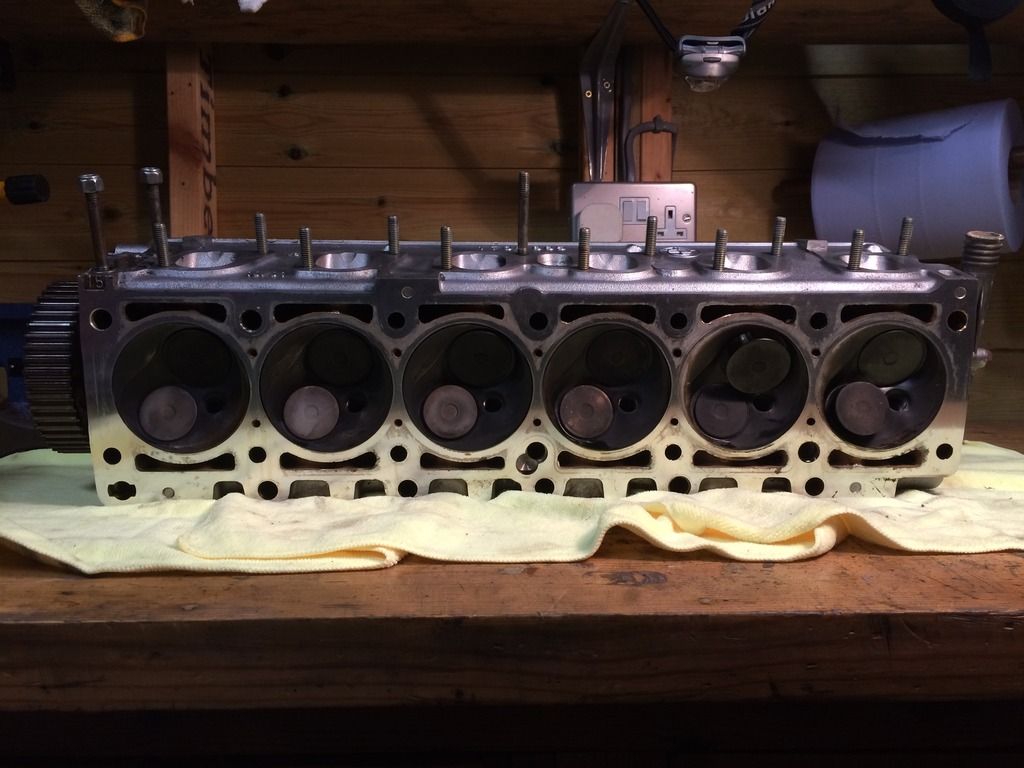

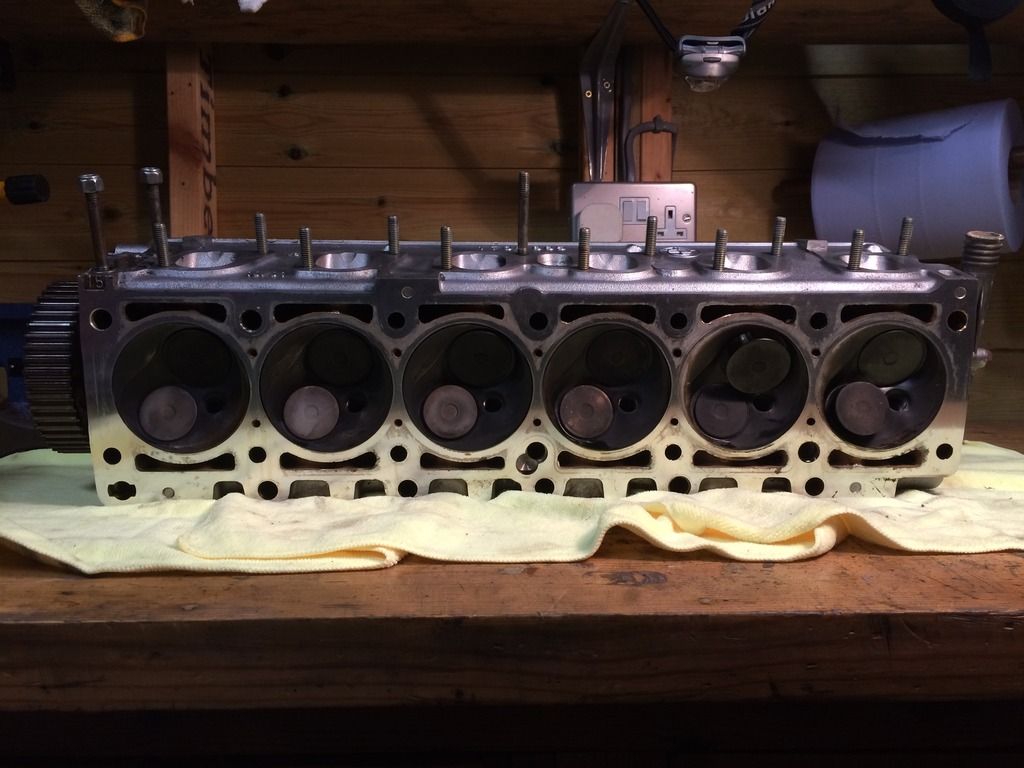

This is what I found:

Piston no.6

Piston no.5

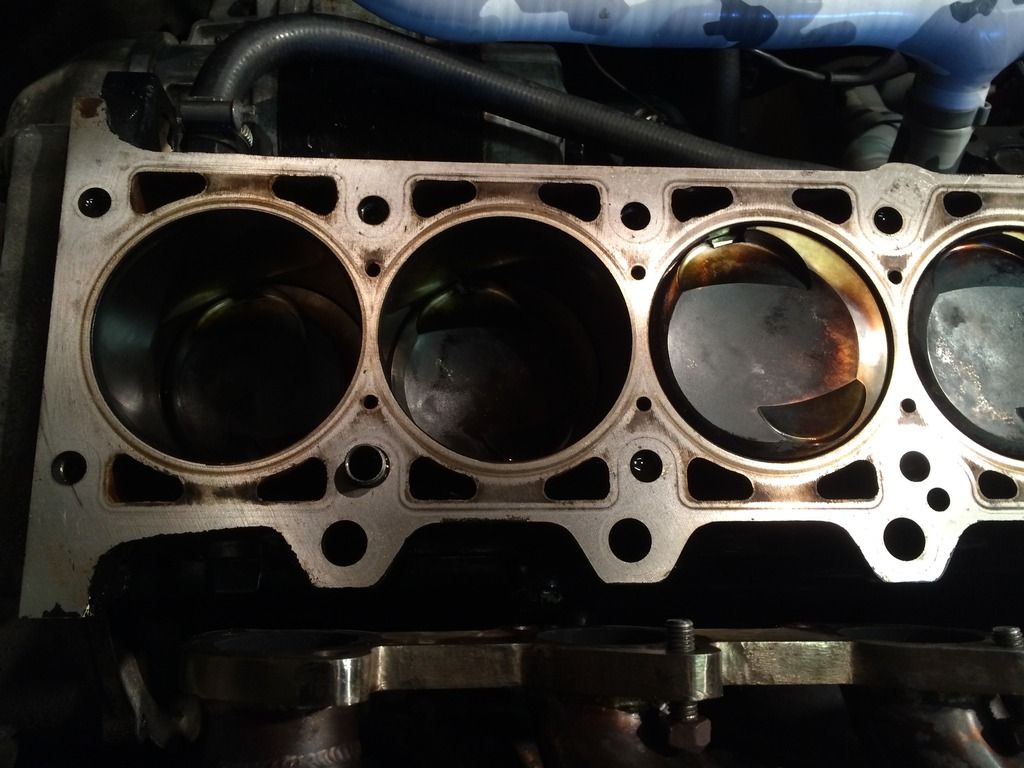

Piston no.4

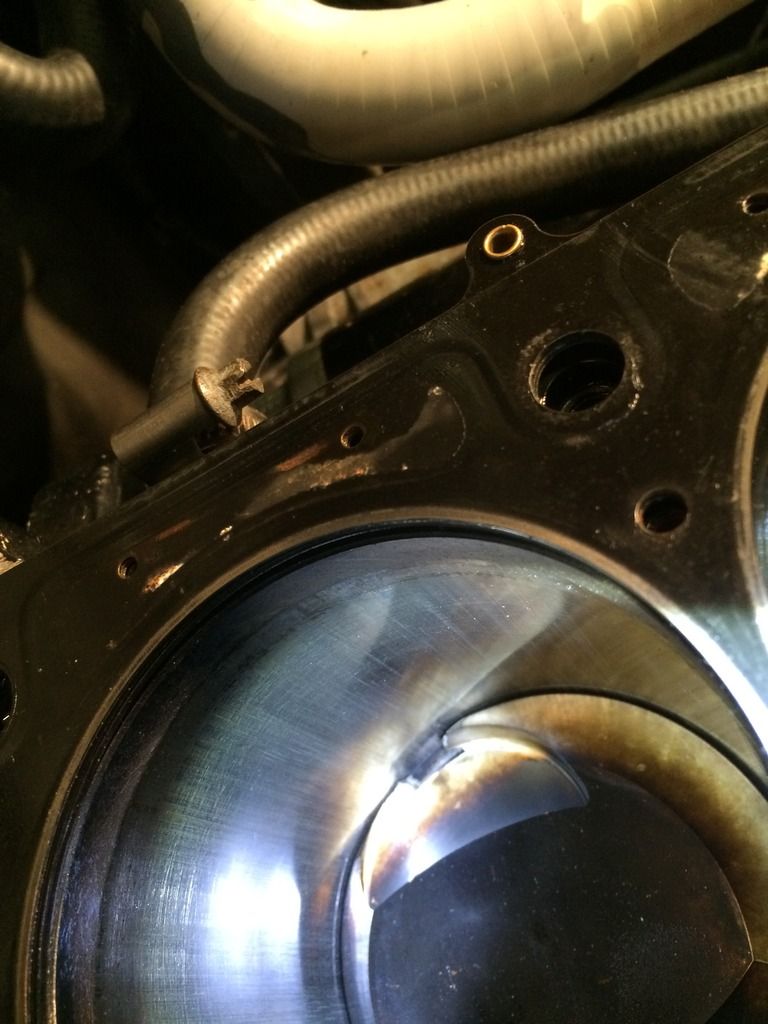

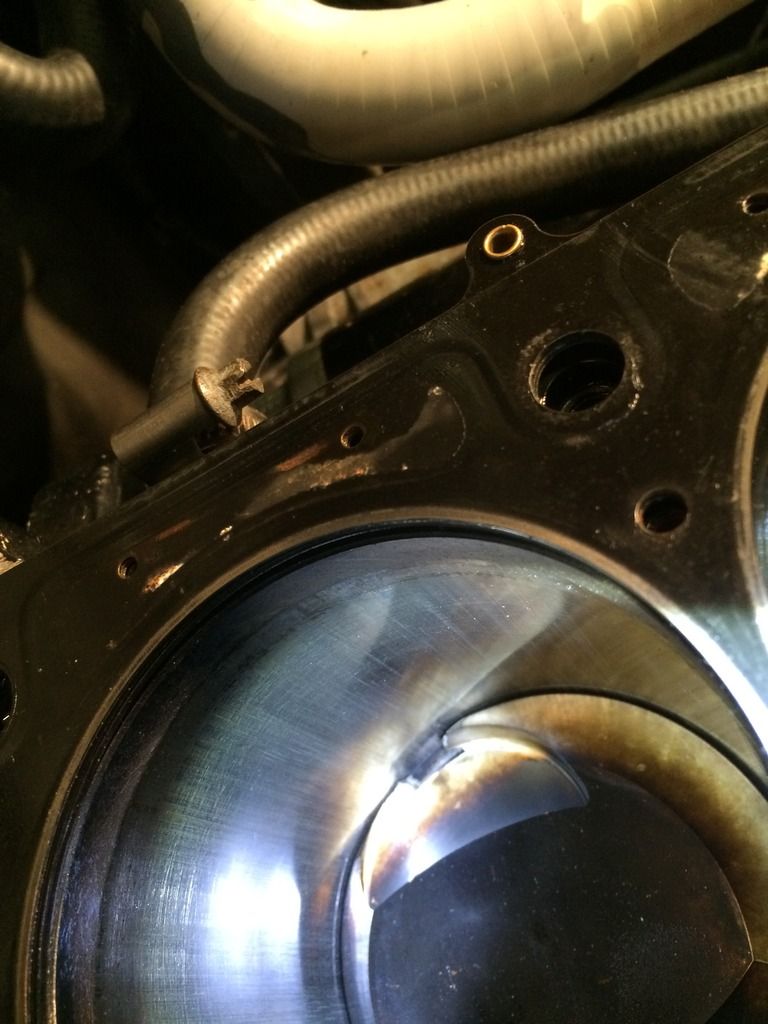

There are chunks missing from the 3 pistons nearest the bulkhead. One of the chunks looks as though it has been pulled up which shows it happened on down stroke or from the piston ring moving up or ??

I’ve noticed there really isn’t much meat on the bone between the ring and the cut out for the valve. A design flaw?

The bores on the 3 good pistons look like they have never been used. The bores on the damaged pistons look as shown in the pictures - there are visible vertical markings although I can’t physically feel them.

There are no marks on the valves from hitting the pistons:

I’ve managed to put a very small scratch on the head between a dowel and the cylinder position so I may need to get this sorted but apart from that the head, to me, looks fine. Clearly given the circumstances, it will have to be checked properly.

Should forged pistons do this?

What on earth has happened here?

I am now properly gutted as one can imagine.

I guess I need to do the following:

Take out the block (I assume honing is needed and replacing pistons may be tricky with he block still in the car)

Have it re-honed if its ok enough for that

Get some new pistons and rings of a better quality and get them installed - which pistons?

Plop the extra baffle I have ready into the sump whilst I’m at it

Get the head checked over, pray it doesn’t need machining so the compression ratio stays the same to avoid loads of extra tuning and make sure it has strong springs.

Order up new gaskets and seals - MLS gasket again? Maybe from another source, preferably one with some sealant for a sure fit?

Either get the person checking the head and block to put them together with my ARP bolts and I will drop the engine in and finish off or do it myself

Sort out the crankcase evacuation

Install oil cooler

Put new oil and filter in

Flush coolant passage ways and use nice antifreeze -maybe a drop of water wetter.

Get an accurate coolant gauge and re-position the sensor”¦

Have it all checked over by a reputable tuner ready for me to drive on track.

Another option is do it all myself but I work 70-80 hours a week so learning how to do a head and hone/build a block may be out of the question right now?

Can anyone shed some light on what may have happened here and give me some feedback the events, also maybe recommend someone near Bristol for help.

Thank you for reading.

Dave

I'm new on this forum so hello from me.

I'm a heating engineer/plumber from Bristol and I love cars.

I have just got an old flame back in my life... the e30.

I bought my car a few months ago from an enthusiast with a supercharged m20 in it.

I have been experiencing some engine issues and would like to share my experience in the hope of getting some sound advice/direction.

History:

The engine is an m20 from an E30 325. It was put together last year by the previous owner from a bottom end and top end built by a chap called Byron in Wales.

The spec is confirmed with receipts and as follows:

Ireland Engineering 135mm H-Beam rods - M20 spec - include ARP bolts

Ireland Engineering MLS Head Gasket - M20

Ireland Engineering Oil Pan Windage Tray - M20

Ireland Engineering/Ross Racing Custom Forged Pistons - M20 (885 head, 85mm bore, 8.5:1 comp for 135mm rods, 84mm stroke)

ARP head bolts

Lightened flywheel

I believe this is somewhere near a 2.9 stroker.

The head is apparently re-worked but I cant confirm or get confirmation on exactly what has been worked.

Rotrex C30 94 Supercharger kit

Stage 3 DriveTorque clutch

S80 Pro ECU and DTA wiring harness

2.5l swirl pot

Red Top lift pump

Bosch 044 pump and twin filters

VR6 coil packs

Magnecore HT leads

Custom CAT Cam 264 Degree- full specs available

Nice 6 branch exhaust manifold

Bosch 42lb / 440cc injectors

436BHP, 360ft/lbs at the flywheel - (data taken from rolling road during my ownership)

Here is the story:

I bought the car knowing that there was going to be a little work to do to get it ready for some track use. The engine had covered 4000 miles running on a ”˜safe’ map that was done when this engine was originally put together. It was long overdue a proper map and had clearly not been given a proper run for its money. I was also told that there was a rev limiter on it, set to 5k which was done at the time of the original map. The original map was clearly quite rich.

I loved the look of the car, I really liked the guy I bought the car from so I had some faith that it should be ok. The car is quite well known and has appeared in a few magazines and has won numerous trophies at custom car shows.

Once I got the car home I had covered 30/40 miles and it was clear I needed to make sure the engine (being the most expensive bit) needed to be tuned properly before driving it again. I have had other issues with the car that I am dealing with (wiring & brakes to name a few) but the issue I want to get to the bottom of most is the engine issue I have recently discovered.

Firstly it may be worth mentioning that the previous owner is not what I would consider a driver, he is a custom car guy but doubt he will ever have driven the car like I drive mine. He makes a car look great, is a brilliant fabricator but my attention to detail performance wise isn’t his priority. This is by no means a diss on him, I’m mearly pointing out that I don’t believe he would have necessarily cared about the little issues I found which have lead me to my discovery, enough to have found them himself for some time, if at all. I like the way a car looks, I love a clean car and i’m very particular but through the years I have seen enough engine trouble to know that a catastrophic failure on track is a terrible experience (engine blew up on the Nurburgring a few years ago to name one) and before a car goes anywhere near a track, the engine needs to be in tip top condition. I probably didn’t look hard enough at it when buying the car in the first place TBH. I say all this so as not to hold him personally responsible in this report, if he should read this - I am not making a public attack. However if he should read this and want to offer some advice or help in some way, he is very welcome”¦ I’m sure he will at least regret verbally guaranteeing the engine once he has read to the bottom.

I arrived home from purchasing it.

I noticed the engine oil level was on the minimum. I called the previous owner and he apologised for not checking and confirmed he was using 5w 30, fully synth.

Personally I think 5w 30 is too thin for this particular spec but the oil debate is too much for now - needless to say, running the engine oil this low isn’t ideal. I topped it up.

I planned an oil change with 10w 50 as its not my daily, when installing an oil cooler as it doesn’t have one.

I also planned on fitting an oil temp sensor/gauge as it doesn’t have one of these either.

I noticed the engine (which has no idle control valve) was very lumpy at idle and missed a little when cruising and the engine cut out when floored.

I thought the rev limiter was the cut out issue, although it was hard to determine exactly if it cut out at the same rpm or not.

I also noticed that the coolant temperature gauge was only running at 60 ish.

I booked the car in for a rolling road tune at Circuit Motors (next to castle Combe) as they knew the car from the previous owner and had set up the original map it was running on when I got it. I’ve never used them before, they were very difficult to get an appointment with but they said they knew the engine builder Byron and that they would regroup with him to check on all specs ready for the final tune. I thought this sounded the best option rather than finding a different tuner, however even 6 weeks later this hadn’t happened so I was beginning to loose faith. I finally managed to get it booked in albeit without the consult from Byron.

Before the tuning date around a month ago I carried out a few checks. I charged the battery, started the car, checked the usual stuff. It was wierdly only firing on 5 cylinders. I checked the plugs - all an even colour. On further inspection one of the porcelain ends was loose! It was from the cylinder closest the front (cylinder 1, I believe)

I did some research on the plugs that were used. They were Bosch Super Plus WR7DC. The gaps were 0.029 to 0.031”a These are ok for a well tuned car but maybe not perfect for a 400 odd hp car with a supercharger.

I put in some NGK BPR8ES plugs gapped to 0.025”a

The engine took a while to fire but was fine once going, still lumpy on idle but not as bad as before.

On the drive over to Circuit Motors, another 20/30 miles, the rev limiter had miraculously gone. I think the spark plugs were not quite as cold as they need to be and the gaps were too big? It was like chalk and cheese. No missing a beast either.

The car was strapped down on the rollers and Layton at Circuit Motors went about his work. As we couldn’t get hold of Byron to find out if the springs were uprated in the head or even exactly what work was done to the head and the previous owner couldn’t remember - rev limit unsure and so was set to 7k after running it for an hour or so.

All seemed well. The result was 436BHP, 360ft/lbs at the flywheel with 19psi boost at 6700rpm. This is quite a bit less than the previous owner thought it would do but I thought this was a sensible good result. The C30 Rotrex supercharger is only rated to circa 440bhp anyway.

The car was unstrapped and Layton went out for his final check drive and was gone for quite a while.

20 minutes later he limped into the forecourt with an overheating car.

The coolant temperature on the laptop from the DTA ECU sensor showed 105 degrees and this was assuming of course that there was water surrounding the sensor. The coolant gauge was still only at 75 so it was clear that this was completely wrong although Layton had been reading his own temperatures from the laptop.

We checked the water level which was low, put water in, bled it etc the temps all dropped and the car seemed to start and run fine. There were no signs of anything else wrong so we assumed that the level had been too low or an air lock or ”¦.. anyway, it was fine now”¦..so test it”¦.

So off he went again for his test.

He limped in pretty quickly and it was clear there was a water leak, the clutch had been slipping and water was gushing through the bell housing and out the bottom from somewhere up high but below the head. It took us ages to find where it was coming from, we had it on the ramps, it was very difficult to see. As soon as the engine was turned off and the steam cleared, the least couldn’t be seen.

Long story short, the car was run far too long without the correct amount of coolant in my opinion but we eventually found the problem as being a cracked freeze plug which only seemed to open up when the engine was running and up to a temperature.

I was gutted and concerned about the whole experience.

The car was trailered home.

Once it was home I was obviously going to worried about the head/head gasket etc.

I set about replacing the freeze plug, which I did in situ and it was the one furthest into the bulkhead!

I checked the spark plugs to find number 5 to be much darker than the rest. I decided to get another set of new plugs, re gapped them then put all the bits back together, put a new coolant sensor in (to match the gauges) bled properly etc and got it running. All seemed good.

The oil had no signs of water and the water had no signs of oil. Also it seemed to pass a hydrocarbon test.

There was some blow by but I had read that this can be normal on forced induction engines.

Road test.

Wow. The car ran like a dream on high output although a touch lumpy down below. Really fast. Nice.

I did notice however that at full chat high revs (I didn’t hit the limiter though) it ran really well but there was a slight pinging or rattling noise.

On my return to home after 15 miles I looked into the engine bay to find oil all around the bottom of the block near the bitch tube. It looked as though the oil was leaking from the top and the bottom of this tube. I thought maybe the rattling noise was down to the spring on this tube being moved erratically as the blow by (which hasn’t been managed properly yet) pushes its way out a bit.

I checked cylinder number 5 and it was dark again.

Research led me to the breathing set ups on forced induction cars where some people just vent to atmosphere and some through other means but it was clear from the open to atmosphere set up that I have that the blow by really needed to be managed as clearly crankcase pressure was high.

I took the inlet manifold off to get the bitch tube out to sort the issue of the leak whilst thinking about the dark plug. I have planned an electric crankcase evac pump to suck the crankcase pressure out. More later.

The inlet manifold gasket had oil between the gasket and the head and it was clear some of the leaking was from here! The manifold didn’t come with its rocker cover bracket which i ordered up. Maybe it was too loose without the brace?

To be honest, oil seemed to be a little everywhere, something I should maybe expect with lots of forced induction and no proper crankcase evac/ventilation. Some will say there shouldn’t be any blow by anyway”¦ maybe they are right..

Compression tests all came out good, 170-180 for all.

As the manifold was out, I sent all the injectors off to get tested and cleaned to see if one was running rich, maybe explaining the dark plug. The results were inconclusive as they were all fairly similar.

I plan to somehow test the VR6 coil pack but haven’t as yet properly researched this..

I also carried out a leak down test and found there was 20% more blow by on cylinder 4, 15% cylinder 5 and 10% cylinder 6. All the others where spot on. The air seemed to be passing the rings rather than the valves etc but I’m not an expert. However this was all enough for me to justify pulling the head which I did.

Good pistons leak down reading:

This is what I found:

Piston no.6

Piston no.5

Piston no.4

There are chunks missing from the 3 pistons nearest the bulkhead. One of the chunks looks as though it has been pulled up which shows it happened on down stroke or from the piston ring moving up or ??

I’ve noticed there really isn’t much meat on the bone between the ring and the cut out for the valve. A design flaw?

The bores on the 3 good pistons look like they have never been used. The bores on the damaged pistons look as shown in the pictures - there are visible vertical markings although I can’t physically feel them.

There are no marks on the valves from hitting the pistons:

I’ve managed to put a very small scratch on the head between a dowel and the cylinder position so I may need to get this sorted but apart from that the head, to me, looks fine. Clearly given the circumstances, it will have to be checked properly.

Should forged pistons do this?

What on earth has happened here?

I am now properly gutted as one can imagine.

I guess I need to do the following:

Take out the block (I assume honing is needed and replacing pistons may be tricky with he block still in the car)

Have it re-honed if its ok enough for that

Get some new pistons and rings of a better quality and get them installed - which pistons?

Plop the extra baffle I have ready into the sump whilst I’m at it

Get the head checked over, pray it doesn’t need machining so the compression ratio stays the same to avoid loads of extra tuning and make sure it has strong springs.

Order up new gaskets and seals - MLS gasket again? Maybe from another source, preferably one with some sealant for a sure fit?

Either get the person checking the head and block to put them together with my ARP bolts and I will drop the engine in and finish off or do it myself

Sort out the crankcase evacuation

Install oil cooler

Put new oil and filter in

Flush coolant passage ways and use nice antifreeze -maybe a drop of water wetter.

Get an accurate coolant gauge and re-position the sensor”¦

Have it all checked over by a reputable tuner ready for me to drive on track.

Another option is do it all myself but I work 70-80 hours a week so learning how to do a head and hone/build a block may be out of the question right now?

Can anyone shed some light on what may have happened here and give me some feedback the events, also maybe recommend someone near Bristol for help.

Thank you for reading.

Dave