Difference between revisions of "Stripping and Rebuilding an M20 Cylinder Head"

| Line 25: | Line 25: | ||

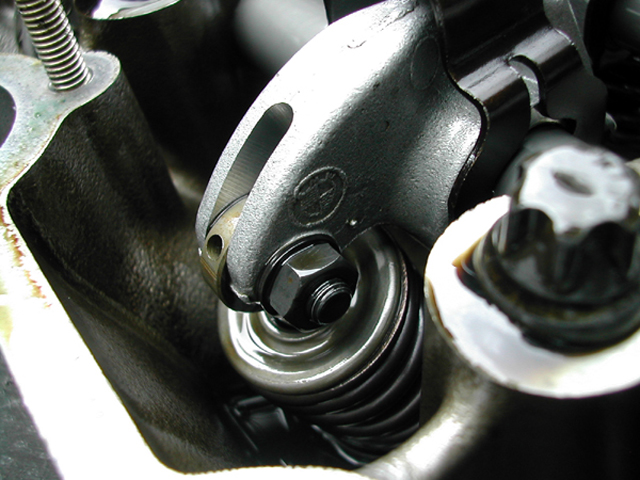

The first thing to do is slacken off all the valve eccentrics. Use a 10mm spanner and loosen the nut on each rocker pictured below. | The first thing to do is slacken off all the valve eccentrics. Use a 10mm spanner and loosen the nut on each rocker pictured below. | ||

| − | [ | + | [[Image:m20head-1.jpg]] |

Once you've slackened off the eccentrics, we need to remove the top pulley so that we can remove the rocker shafts. This is done by securing the pulley with an old timing belt and a pair of lockable pliers, you will now be able to remove the torx bolt holding the pulley in place. | Once you've slackened off the eccentrics, we need to remove the top pulley so that we can remove the rocker shafts. This is done by securing the pulley with an old timing belt and a pair of lockable pliers, you will now be able to remove the torx bolt holding the pulley in place. | ||

| − | [ | + | [[Image:m20head-2.jpg]] |

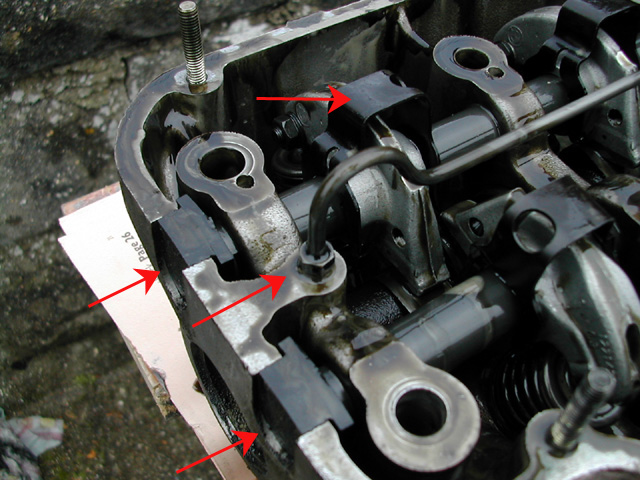

Once the front pulley has been removed, unclip all 12 rocker retaining clips. These can be eased off with a screw driver of pulled off by hand. Also remove the rocker shaft end seals (4) and the oil spray bar which is attached with 2 x 8mm nuts. All parts to be removed are arrowed on the image below. | Once the front pulley has been removed, unclip all 12 rocker retaining clips. These can be eased off with a screw driver of pulled off by hand. Also remove the rocker shaft end seals (4) and the oil spray bar which is attached with 2 x 8mm nuts. All parts to be removed are arrowed on the image below. | ||

| − | [ | + | [[Image:m20head-3.jpg]] |

The next part of the procedure is to remove the rockers and shafts. I usually work with the pulley end of the head to my right. Concentrate on removing one rocker shaft at a time. We will be removing the exhaust side rocker shaft to begin with. Place the pulley bolt back into the end of the camshaft so that you turn the camshaft. Keep turning the bolt until it fully tightens. | The next part of the procedure is to remove the rockers and shafts. I usually work with the pulley end of the head to my right. Concentrate on removing one rocker shaft at a time. We will be removing the exhaust side rocker shaft to begin with. Place the pulley bolt back into the end of the camshaft so that you turn the camshaft. Keep turning the bolt until it fully tightens. | ||

| Line 43: | Line 43: | ||

Next remove the rocker shaft retaining plate, this should come free with some gentle persuasion using a flat bladed screw driver. | Next remove the rocker shaft retaining plate, this should come free with some gentle persuasion using a flat bladed screw driver. | ||

| − | [ | + | [[Image:m20head-4.jpg]] |

Take a suitable drift, I found that a 1/2" drive extension bar was the perfect size. Use a hammer to knock the exhaust rocker shaft out from the right hand side of the cylinder head. You only need to knock it a short distance, just enough so that you can slide the number 1 exhaust rocker from it's shaft. | Take a suitable drift, I found that a 1/2" drive extension bar was the perfect size. Use a hammer to knock the exhaust rocker shaft out from the right hand side of the cylinder head. You only need to knock it a short distance, just enough so that you can slide the number 1 exhaust rocker from it's shaft. | ||

| − | [ | + | [[Image:m20head-5.jpg]] |

Once the first rocker is removed, you will need to turn the camshaft so that the exhaust lobe for rocker number 1 is in the same position as before. It will not be pushing on a rocker as before because you have removed this rocker. Before turning the camshaft, ensure that the rockers are all centred over their respective camshaft lobes because they can easily be moved when you drift the rocker shaft out. When the camshaft for exhaust rocker number 1 is at full lift, you will find that the remaining rockers on the exhaust side will be under no tension. You should now be able to pull the rocker shaft out using your hands. Remember to keep the rockers in the correct order in which they were removed. It's a good idea to mark them with a permanent pen. | Once the first rocker is removed, you will need to turn the camshaft so that the exhaust lobe for rocker number 1 is in the same position as before. It will not be pushing on a rocker as before because you have removed this rocker. Before turning the camshaft, ensure that the rockers are all centred over their respective camshaft lobes because they can easily be moved when you drift the rocker shaft out. When the camshaft for exhaust rocker number 1 is at full lift, you will find that the remaining rockers on the exhaust side will be under no tension. You should now be able to pull the rocker shaft out using your hands. Remember to keep the rockers in the correct order in which they were removed. It's a good idea to mark them with a permanent pen. | ||

| Line 57: | Line 57: | ||

Now that the rockers and shafts have been removed, we can take the camshaft out. Remove the 2 x 10mm bolts holding the end plate in place then carefully prise the plate free with a flat bladed screw driver. Once the plate has been removed, the camshaft will slide out. | Now that the rockers and shafts have been removed, we can take the camshaft out. Remove the 2 x 10mm bolts holding the end plate in place then carefully prise the plate free with a flat bladed screw driver. Once the plate has been removed, the camshaft will slide out. | ||

| − | [ | + | [[Image:m20head-6.jpg]] |

The final thing to do is to remove the valves. These are held in place with a spring assembly which needs to be compressed using a Valve Spring Compressor in order for them to be removed. Turn the cylinder head on it's side and then compress the valve spring with the compressor. When you have compressed the valve spring you will be able to use a magnetic screw driver to remove the valve retaining collets from the end of the valve stem. | The final thing to do is to remove the valves. These are held in place with a spring assembly which needs to be compressed using a Valve Spring Compressor in order for them to be removed. Turn the cylinder head on it's side and then compress the valve spring with the compressor. When you have compressed the valve spring you will be able to use a magnetic screw driver to remove the valve retaining collets from the end of the valve stem. | ||

| − | [ | + | [[Image:m20head-7.jpg]] |

| − | [ | + | [[Image:m20head-8.jpg]] |

You can see from the below picture how the collets clasp around the end of the valve stem. | You can see from the below picture how the collets clasp around the end of the valve stem. | ||

| − | [ | + | [[Image:m20head-9.jpg]] |

Once you have removed the collets, slacken off the valve spring compressor and remove the springs. The valve should now slide out from the underside of the head. | Once you have removed the collets, slacken off the valve spring compressor and remove the springs. The valve should now slide out from the underside of the head. | ||

| − | [ | + | [[Image:m20head-10.jpg]] |

Once again, it's important to mark the valves and keep the springs in order so that they can be replaced in the same order in which they were removed. Repeat this procedure for each valve in turn and then keep all springs and components in a box or a safe place. | Once again, it's important to mark the valves and keep the springs in order so that they can be replaced in the same order in which they were removed. Repeat this procedure for each valve in turn and then keep all springs and components in a box or a safe place. | ||

| − | [ | + | [[Image:m20head-11.jpg]] |

The final part of stripping the cylinder head is to remove the old valve stem oil seals. These are the red coloured seals in the picture below and can be easily removed with a pair of long-nosed pliers. Once these are removed you will be left with a bare cylinder head casting. | The final part of stripping the cylinder head is to remove the old valve stem oil seals. These are the red coloured seals in the picture below and can be easily removed with a pair of long-nosed pliers. Once these are removed you will be left with a bare cylinder head casting. | ||

| − | [ | + | [[Image:m20head-12.jpg]] |

| − | [ | + | [[Image:m20head-13.jpg]] |

==Rebuilding== | ==Rebuilding== | ||

Revision as of 18:58, 8 July 2008

<<Work in progress>>

In this guide, we will show you the correct procedure for stripping and rebuilding an M20 Cylinder Head. This includes 2.0, 2.3, 2.5 litre engines. For the benefit of the guide, we will be using an M20 2.5 head.

- Required Tools

- Female Torx Socket

- Old Timing Belt

- Lockable Grips

- 8mm Spanner

- 10mm Spanner

- 3mm Allen Key

- 11mm Deep 1/4" Drive Socket

- Short 1/4" Drive Extension Bar

- Feeler Gauges

- Valve Spring Compressor

- Valve Grinding Stick & Paste

- Suitable drift (1/2" Drive Extension)

- Hammer

- Magnetic Ended Screw Driver

- Spark Plug Wrench

Stripping the Cylinder Head Before doing anything else, it's preferable to place the head on a workmate or similar work bench with a gap in the middle because as you turn the valve train over, the valves will hit if you have it on a flat surface. Now remove the spark plugs with a suitable plug wrench.

The first thing to do is slacken off all the valve eccentrics. Use a 10mm spanner and loosen the nut on each rocker pictured below.

Once you've slackened off the eccentrics, we need to remove the top pulley so that we can remove the rocker shafts. This is done by securing the pulley with an old timing belt and a pair of lockable pliers, you will now be able to remove the torx bolt holding the pulley in place.

Once the front pulley has been removed, unclip all 12 rocker retaining clips. These can be eased off with a screw driver of pulled off by hand. Also remove the rocker shaft end seals (4) and the oil spray bar which is attached with 2 x 8mm nuts. All parts to be removed are arrowed on the image below.

The next part of the procedure is to remove the rockers and shafts. I usually work with the pulley end of the head to my right. Concentrate on removing one rocker shaft at a time. We will be removing the exhaust side rocker shaft to begin with. Place the pulley bolt back into the end of the camshaft so that you turn the camshaft. Keep turning the bolt until it fully tightens.

IMPORTANT NOTE: Remember that you will only be able to turn the camshaft in a clockwise direction from now on. Attempts to turn in a counter clockwise direction will just remove the torx bolt.

Rotate the camshaft until exhaust rocker number 6 is under full load. You can tell this because the camshaft lobe will be pointing upwards and you will be able to feel the other rockers will not be under tension because they will move back and forth slightly. Please see the diagram which shows a cross section view of how exhaust rocker number 6 should look at this time. For reference, cylinder number 1 is the cylinder nearest the top pulley end of the head and number 6 is the opposite end.

Next remove the rocker shaft retaining plate, this should come free with some gentle persuasion using a flat bladed screw driver.

Take a suitable drift, I found that a 1/2" drive extension bar was the perfect size. Use a hammer to knock the exhaust rocker shaft out from the right hand side of the cylinder head. You only need to knock it a short distance, just enough so that you can slide the number 1 exhaust rocker from it's shaft.

Once the first rocker is removed, you will need to turn the camshaft so that the exhaust lobe for rocker number 1 is in the same position as before. It will not be pushing on a rocker as before because you have removed this rocker. Before turning the camshaft, ensure that the rockers are all centred over their respective camshaft lobes because they can easily be moved when you drift the rocker shaft out. When the camshaft for exhaust rocker number 1 is at full lift, you will find that the remaining rockers on the exhaust side will be under no tension. You should now be able to pull the rocker shaft out using your hands. Remember to keep the rockers in the correct order in which they were removed. It's a good idea to mark them with a permanent pen.

Repeat the above procedure for the inlet rocker shaft and remove this also, you should now be left with the camshaft and valves left in place for removal.

NOTE: You can now place the cylinder head on a flat surface if you wish because all valves will now be closed.

Now that the rockers and shafts have been removed, we can take the camshaft out. Remove the 2 x 10mm bolts holding the end plate in place then carefully prise the plate free with a flat bladed screw driver. Once the plate has been removed, the camshaft will slide out.

The final thing to do is to remove the valves. These are held in place with a spring assembly which needs to be compressed using a Valve Spring Compressor in order for them to be removed. Turn the cylinder head on it's side and then compress the valve spring with the compressor. When you have compressed the valve spring you will be able to use a magnetic screw driver to remove the valve retaining collets from the end of the valve stem.

File:M20head-7.jpg File:M20head-8.jpg

You can see from the below picture how the collets clasp around the end of the valve stem.

Once you have removed the collets, slacken off the valve spring compressor and remove the springs. The valve should now slide out from the underside of the head.

Once again, it's important to mark the valves and keep the springs in order so that they can be replaced in the same order in which they were removed. Repeat this procedure for each valve in turn and then keep all springs and components in a box or a safe place.

The final part of stripping the cylinder head is to remove the old valve stem oil seals. These are the red coloured seals in the picture below and can be easily removed with a pair of long-nosed pliers. Once these are removed you will be left with a bare cylinder head casting.

File:M20head-12.jpg File:M20head-13.jpg